Escolar Documentos

Profissional Documentos

Cultura Documentos

Grind2Energy CaseStudy Blackwell Inn

Enviado por

ahowar22Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Grind2Energy CaseStudy Blackwell Inn

Enviado por

ahowar22Direitos autorais:

Formatos disponíveis

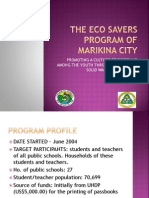

Issue #19 Summer 2012

News and information about better

food waste management

Opportunity

To help create an eco-friendly environment, The Ohio State University (OSU) continually focuses on

executing ground-breaking programs to reduce, reuse and recycle. In an effort to reduce landfill waste, OSUs

Facilities Operations and Development

AT-A-GLANCE

LOCATION:

Department collaborated with the

Energy Services and Sustainability office to set up a pilot program for composting organic materials from the Blackwell Inn and Conference Center on campus. required an This initial pilot of

College of Business campus of The Ohio State University

PRODUCT INSTALLED:

The Blackwell Inn, located on the Fisher

Grind2Energy

investment

BY THE NUMBERS:

approximately $1,600 to purchase the necessary bins and toters, which led the OSU team to pursue a more cost-effective solution.

Processed 4.5 tons of organic material per month Reduced hauling costs by

requiring only one pick up per week at a cost of $120

Eliminated hauling of the toters to the compost facility saving roughly $669 per month in labor and

equipment costs

InSinkErator Pilot Program

In an effort to reduce hauling costs and contamination in the organic material, OSU entered into a pilot program with InSinkErator and Kurtz Bros. In this program, the Blackwell Inn collected its organic waste and then used a specially designed resource recovery system from InSinkErator called Grind2Energy to grind the food waste and then transfer it to a holding tank. A vacuum truck was used to vacuum the ground food slurry out of the holding tank once per week and deliver the materials to the Kurtz Bros. Quasar Energy Group facility, where the waste was converted by anaerobic digestion into sustainable, renewable resources such as electricity, compressed gas and fertilizer.

Reduced odor and fly issues at

the loading dock

Saved approximately $218 a month in waste liner costs Reduced tipping fees from $52

to $37 per ton for organic materials

digest

Blackwell Inn

waste management

Issue #19 Summer 2012

waste management

News and information about better food waste management

Cost Comparisons (Estimated monthly basis, approximately five tons of materials per week) Landfill Trash Management Organics Removal Liners Total $1,717.48 $0.00 $218.40 $1,935.88 Composting Pilot $383.14 $2,771.70 $0.00 $3,154.84 Grind2Energy Pilot $383.14 $1,241.50 $0.00 $1,624.64

Benefits

Representatives for The Ohio State University learned a lot about the benefits of composting from participating in these pilot programs. While the initial compost pilot was costly and contamination management proved difficult, the InSinkErator Grind2Energy pilot helped the University achieve its goal of reducing landfill waste and creating renewable resources for the community. Also, the cost versus benefit analysis comparing the original program (sending all waste to landfill) and the composting pilot versus the InSinkErator pilot showed that the InSinkErator Grind2Energy solution reduces landfill waste while still being more cost effective for the University. This partnership with InSinkErator demonstrates Ohio States commitment to being a leader in sustainability and supporting a society of global citizens, said Corey Hawkey, Sustainability Coordinator, Ohio State. We couldnt be more pleased with the success and savings of the program from both an economical and environmental standpoint.

Eliminated costly hauling of the toters, pest problems and odor.

1,600-gallon tank holds food materials before waste is converted into renewable resources.

The Emerson logo is a trademark and a service mark of Emerson Electric Co. InSinkErator may make improvements and/or changes in the specifications at any time, in its sole discretion, without notice or obligation and further reserves the right to change or discontinue models. G2E004-12B-06-02 2013 InSinkErator, a division of Emerson Electric Co. All Rights Reserved.

digest

Blackwell Inn

Você também pode gostar

- Environmental Engineering (Volume-1) Water Supply Engineering by B.C.punmiaDocumento257 páginasEnvironmental Engineering (Volume-1) Water Supply Engineering by B.C.punmiaManoah JohnsonAinda não há avaliações

- Carbon Footprints Sustainable SolutionsDocumento48 páginasCarbon Footprints Sustainable Solutionsksbbs100% (1)

- Sustainable Development Project Class 10th PDFDocumento14 páginasSustainable Development Project Class 10th PDFSD P91% (23)

- Umantod Chad Module 1 AssessmentDocumento3 páginasUmantod Chad Module 1 AssessmentLong EAinda não há avaliações

- 1 Coca-Cola SocialDocumento20 páginas1 Coca-Cola SocialAnne D'souzaAinda não há avaliações

- Circular InnovationDocumento6 páginasCircular InnovationSARTHAK BHARGAVAAinda não há avaliações

- Coca Cola Environment InitiativeDocumento4 páginasCoca Cola Environment InitiativeDushyant KumarAinda não há avaliações

- Ecodesign PDFDocumento2 páginasEcodesign PDFitamarcostAinda não há avaliações

- DickinsonDocumento4 páginasDickinsonapi-283206091Ainda não há avaliações

- Waste Mangement 1. Materials Management Overview: Executive Order 13514Documento11 páginasWaste Mangement 1. Materials Management Overview: Executive Order 13514Pompy JoeAinda não há avaliações

- Sree Sastha Institute of Engineering and Technology: Green Audit ReportDocumento11 páginasSree Sastha Institute of Engineering and Technology: Green Audit ReportCandida DhasonAinda não há avaliações

- Pa Environment Digest May 2, 2011Documento58 páginasPa Environment Digest May 2, 2011www.PaEnvironmentDigest.comAinda não há avaliações

- Anaerobic Digestion ExtractDocumento6 páginasAnaerobic Digestion ExtractAdrian SmeuAinda não há avaliações

- Updated Ii - Solidwaste Management Report-Kdk-CampusDocumento5 páginasUpdated Ii - Solidwaste Management Report-Kdk-CampusKunal ChopadeAinda não há avaliações

- Bluewater Recycling Association: Putting Power in The Community's HandsDocumento5 páginasBluewater Recycling Association: Putting Power in The Community's HandsjohnribarAinda não há avaliações

- MJC Recycling Corp White Paper ProjectDocumento15 páginasMJC Recycling Corp White Paper Projectmaximokopp100% (2)

- Ced AngelDocumento8 páginasCed AngelTORRES , VENUSAinda não há avaliações

- Final Report Outpost Natural Foods Project FINAL 3-9-2010Documento26 páginasFinal Report Outpost Natural Foods Project FINAL 3-9-2010Evren KüçükkayaAinda não há avaliações

- Bluewater Recycling Association: Putting Power in The Community's HandsDocumento5 páginasBluewater Recycling Association: Putting Power in The Community's HandsjohnribarAinda não há avaliações

- 1st Draft Report 1 1Documento7 páginas1st Draft Report 1 1api-652524044Ainda não há avaliações

- A School Waste Reduction, Reuse, Recycling, Composting & Buy Recycled Resource BookDocumento34 páginasA School Waste Reduction, Reuse, Recycling, Composting & Buy Recycled Resource BookAaron Trev Paghasian TajerosAinda não há avaliações

- Executive Office of The President Council On Environmental Quality WASHINGTON, D.C. 20503Documento3 páginasExecutive Office of The President Council On Environmental Quality WASHINGTON, D.C. 20503Christopher DorobekAinda não há avaliações

- cgpp4 15 SupermacsDocumento2 páginascgpp4 15 Supermacsapi-286562658Ainda não há avaliações

- VGSC GrantDocumento7 páginasVGSC Grantapi-219404044Ainda não há avaliações

- Final Draft Business ProposalDocumento8 páginasFinal Draft Business Proposalapi-384392869Ainda não há avaliações

- Recycling and Waste (Practical Data)Documento8 páginasRecycling and Waste (Practical Data)PoojaSharmaAinda não há avaliações

- Team Green ProposalDocumento13 páginasTeam Green ProposalTiffany OndracekAinda não há avaliações

- State of Cleaner ProductionDocumento6 páginasState of Cleaner ProductionAbdul Rafai MasoodAinda não há avaliações

- Ass 3 - CH 9 Team - Almeida, Hernandez, Luis y RomeroDocumento7 páginasAss 3 - CH 9 Team - Almeida, Hernandez, Luis y RomeroEnid HernandezAinda não há avaliações

- Day1 PM Panel2 4philippines (Marikina) MateoDocumento24 páginasDay1 PM Panel2 4philippines (Marikina) Mateolito77Ainda não há avaliações

- Eia, Iso14000Documento33 páginasEia, Iso14000JominAinda não há avaliações

- Why Anaerobic DigestionDocumento5 páginasWhy Anaerobic DigestionMuhammad Ayik AbdillahAinda não há avaliações

- Mandatory Recycling Research PaperDocumento7 páginasMandatory Recycling Research Paperruvojbbkf100% (1)

- 2010 ET-CP-19 Logistics Optimisation and Energy Optimisation For Jack Cuthbert's BakeryDocumento2 páginas2010 ET-CP-19 Logistics Optimisation and Energy Optimisation For Jack Cuthbert's Bakeryapi-286562658Ainda não há avaliações

- Vail Green Business of The Year ApplicationDocumento5 páginasVail Green Business of The Year ApplicationmzalaznickAinda não há avaliações

- The Plastic Problem: Reducing Disposable Utensil Waste: Proposal by Cici LiuDocumento13 páginasThe Plastic Problem: Reducing Disposable Utensil Waste: Proposal by Cici Liuapi-532433553Ainda não há avaliações

- Detailed WMS PlanDocumento3 páginasDetailed WMS PlanMuhammad KazimAinda não há avaliações

- Gianyar Waste Project DescriptionDocumento4 páginasGianyar Waste Project Descriptionjustnoval1Ainda não há avaliações

- College Guide To Campus Wide Composting: Asucd Project CompostDocumento10 páginasCollege Guide To Campus Wide Composting: Asucd Project CompostNeil100% (3)

- Midterm Exam Project Climate Action: Business EthicsDocumento20 páginasMidterm Exam Project Climate Action: Business EthicsSofija JovchevaAinda não há avaliações

- GSCMDocumento11 páginasGSCMAjinkya SonawaneAinda não há avaliações

- MPS G G P: IS Oing Reen ResentationDocumento50 páginasMPS G G P: IS Oing Reen ResentationVaibhav PrasadAinda não há avaliações

- Ch-5, QA. XII, Green SkillDocumento7 páginasCh-5, QA. XII, Green SkillHiten ChaudharyAinda não há avaliações

- Green Supply Chain ManagementDocumento2 páginasGreen Supply Chain ManagementAYAN GHOSHAinda não há avaliações

- Week 10 - Sustainable DesignDocumento52 páginasWeek 10 - Sustainable DesignathulyabeenaraniAinda não há avaliações

- EE&RE Biomass ProgramDocumento4 páginasEE&RE Biomass ProgrammercygrayAinda não há avaliações

- Food Waste Stratergy V2Documento6 páginasFood Waste Stratergy V2Raisa BacanovAinda não há avaliações

- Leed Platinum BrochureDocumento2 páginasLeed Platinum BrochureBharath Reddy ChinthiReddyAinda não há avaliações

- An Evaluation of Feedstocks For Sustainable Energy and Circular Economy Practices in A Small..Documento13 páginasAn Evaluation of Feedstocks For Sustainable Energy and Circular Economy Practices in A Small..duo.zhang13Ainda não há avaliações

- Rethink Organic Waste Oct 2015 WebDocumento20 páginasRethink Organic Waste Oct 2015 WebCamelia RadulescuAinda não há avaliações

- Sustainable ProcurementDocumento66 páginasSustainable ProcurementSandeep ChatterjeeAinda não há avaliações

- TECH 4090 Class 3 2 UpDocumento37 páginasTECH 4090 Class 3 2 Up沈悦双Ainda não há avaliações

- RECP As Success Story of Green IndustryDocumento4 páginasRECP As Success Story of Green IndustryMochammad IqbalAinda não há avaliações

- International RRL: TitleDocumento6 páginasInternational RRL: TitleSpot LegendAinda não há avaliações

- Sustainability TerminologyDocumento18 páginasSustainability TerminologydaffnyAinda não há avaliações

- Concept - Closed-Loop EconomyDocumento6 páginasConcept - Closed-Loop EconomygumaiAinda não há avaliações

- Sustainability Brochure PagesDocumento15 páginasSustainability Brochure PagesvijichitAinda não há avaliações

- Scho0711buan e e PDFDocumento120 páginasScho0711buan e e PDFInnie PercilAinda não há avaliações

- Introduction to Green Living : A Course for Sustainable LifestylesNo EverandIntroduction to Green Living : A Course for Sustainable LifestylesAinda não há avaliações

- Regenerative Business: Mastering the Circular EconomyNo EverandRegenerative Business: Mastering the Circular EconomyAinda não há avaliações

- CaseDocumento21 páginasCasejulx0416Ainda não há avaliações

- Soil and Water Conservation EngineeringDocumento3 páginasSoil and Water Conservation EngineeringWayaya2009Ainda não há avaliações

- Concept PaperDocumento3 páginasConcept Papergladylou siocoAinda não há avaliações

- RNWDocumento1 páginaRNWnicel tootAinda não há avaliações

- Denr Vision MissonDocumento3 páginasDenr Vision MissonAlin ZivuanuAinda não há avaliações

- 2A - Dolosa, Jubeleen L. - Position PaperDocumento3 páginas2A - Dolosa, Jubeleen L. - Position PaperJubeleen DolosaAinda não há avaliações

- Soil Aquifer Treatment SystemDocumento36 páginasSoil Aquifer Treatment SystemRenu SAinda não há avaliações

- STP Water Balance Sheet PDFDocumento1 páginaSTP Water Balance Sheet PDFsohailAinda não há avaliações

- Hypothetical of Proposed Raba Tipot Nature-Based ResortDocumento2 páginasHypothetical of Proposed Raba Tipot Nature-Based ResortKhairil MaiminAinda não há avaliações

- Global WarmingDocumento2 páginasGlobal WarmingNicole Joyce Catabay FloresAinda não há avaliações

- Himalayan BlunderDocumento2 páginasHimalayan Blunderabu_ccgAinda não há avaliações

- Negative Impacts of WetlandsDocumento9 páginasNegative Impacts of WetlandsbutterfilyAinda não há avaliações

- 2019 TJC JC2 - H2 Geog Prelim P2 Insert (Final)Documento16 páginas2019 TJC JC2 - H2 Geog Prelim P2 Insert (Final)LorettaAinda não há avaliações

- Best Practices & Design Considerations For Wastewater Treatment With MBBR Technology.Documento4 páginasBest Practices & Design Considerations For Wastewater Treatment With MBBR Technology.Ravishankar AAinda não há avaliações

- Environmental Policies: Group IiDocumento4 páginasEnvironmental Policies: Group Iisdasd asdasdAinda não há avaliações

- Annotated BibliographyDocumento2 páginasAnnotated Bibliographyapi-272748853Ainda não há avaliações

- 1 IntrouductionDocumento31 páginas1 IntrouductionBazi habeshaAinda não há avaliações

- 5msa05 FV.24-38Documento15 páginas5msa05 FV.24-38Ronaldo Taylor100% (1)

- Water PollutionDocumento35 páginasWater PollutionTan Sin YiAinda não há avaliações

- Mother Nature Needs Us. Lyrics and Music By: PJ GrandDocumento2 páginasMother Nature Needs Us. Lyrics and Music By: PJ GrandJuliana BarbosaAinda não há avaliações

- Analytical Exposition Text BanjirDocumento3 páginasAnalytical Exposition Text BanjirDimalla PianAinda não há avaliações

- DisposalDocumento4 páginasDisposalrowatersAinda não há avaliações

- Tle9 q2 Mod1 Waste-Material-Management v5Documento15 páginasTle9 q2 Mod1 Waste-Material-Management v5MICHELLE RAFAELAinda não há avaliações

- Managing Crop Diseases Under Water Scarcity: Annual Review of PhytopathologyDocumento20 páginasManaging Crop Diseases Under Water Scarcity: Annual Review of Phytopathologycristian gaete essedinAinda não há avaliações

- Design Assignment TU Noord: February 2012Documento38 páginasDesign Assignment TU Noord: February 2012frankydadAinda não há avaliações

- WREDocumento25 páginasWREcj salesAinda não há avaliações

- Estimating Irrigation Diversion RequirmentDocumento23 páginasEstimating Irrigation Diversion RequirmentJuan BowmanAinda não há avaliações

- VulnerabilityDocumento1 páginaVulnerabilityKristine Joy Palayad MarinayAinda não há avaliações