Escolar Documentos

Profissional Documentos

Cultura Documentos

Design of Fiber-Reinforced Composite Pressure Vessels Under

Enviado por

huangjlDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Design of Fiber-Reinforced Composite Pressure Vessels Under

Enviado por

huangjlDireitos autorais:

Formatos disponíveis

Design of ber-reinforced composite pressure vessels under

various loading conditions

Levend Parnas

a,

*

, Nuran Katrc

b

a

Department of Mechanical Engineering, Middle East Technical University, 06531 Ankara, Turkey

b

ASELSAN Inc., P.O. Box 30, 06011 Etlik, Ankara, Turkey

Abstract

An analytical procedure is developed to design and predict the behavior of ber reinforced composite pressure vessels. The

classical lamination theory and generalized plane strain model is used in the formulation of the elasticity problem. Internal pressure,

axial force and body force due to rotation in addition to temperature and moisture variation throughout the body are considered.

Some 3D failure theories are applied to obtain the optimum values for the winding angle, burst pressure, maximum axial force and

the maximum angular speed of the pressure vessel. These parameters are also investigated considering hygrothermal eects.

2002 Elsevier Science Ltd. All rights reserved.

Keywords: Composite pressure vessels; Filament winding; Generalized plane strain problem; Hygrothermal eects; Burst pressure; Angular speed

1. Introduction

The use of ber reinforced and polymer-based

composites have been increasing. Various numbers of

applications have also been ourishing with this deve-

lopment. Fuel tanks, rocket motor cases, pipes are some

examples of pressure vessels made of composite mate-

rials. Ever increasing use of this new class of materials in

conventional applications is coupled with problems that

are intrinsic to the material itself. Diculties are many

folded. Determination of material properties, mechani-

cal analysis and design, failure of the structure are some

examples which all require a non-conventional ap-

proach.

Numerous applications concurrently are accompa-

nied by various researches in the related eld. Majority

of the studies in the analysis of composite pressure

vessels nds their origins in Lethnitskiis approach [1].

The application of the theory given in this book is later

applied to laminated composite structures in tubular

form Tsai [2]. The studies followed consider also dif-

ferent loading and environmental conditions. Recently,

there are some studies involved directly with tubes under

internal pressure [3,4]. In the study by Xia et al. [4], the

combined eect of thermomechanical loading in addi-

tion to internal pressure is considered.

In this study, an analytical procedure is developed

to design and predict the behavior of ber-reinforced

composite pressure vessels under combined mechanical

and hygrothermal loading. The mechanical part of

the analysis is similar to the study given in Ref. [5]. The

procedure is based on the classical laminated plate the-

ory. A cylindrical shell having a number of sub-layers,

each of which is cylindrically orthotropic, is treated as in

the state of plane strain. Internal pressure, axial force,

body force due to rotation in addition to temperature

and moisture variation throughout the body are con-

sidered as loading. In the study of Katrc [6], these

parameters are compared with the experimental results.

2. Formulation of problem

A thick-walled multi-layered lament wound cylin-

drical shell is considered in the analysis based on linear

elasticity solution. The following assumptions are made

for the formulation of the problem.

The pressure vessel is cylindrically orthotropic,

the pressure vessel has adjacent a angle lay-ups and

the adjacent a lay-ups act as a homogeneous and

orthotropic unit,

*

Corresponding author.

E-mail addresses: parnas@metu.edu.tr (L. Parnas), katirci@

mgeo.aselsan.com.tr (N. Katrc).

0263-8223/02/$ - see front matter 2002 Elsevier Science Ltd. All rights reserved.

PII: S0263- 8223( 02) 00037- 5

Composite Structures 58 (2002) 8395

www.elsevier.com/locate/compstruct

the vessel is in state of plane strain and only small

strains are considered through the analysis,

the length of the vessel is such that the longitudinal

bending deformation due to the end closures of the

vessel are limited to only small end portions of the

pressure vessel.

2.1. Eective elastic properties

A laminated composite with its own eective elastic

properties, contains a number of anisotropic plates.

When these eective elastic properties of the laminate

are used, the body is considered to responding to the

applied loads as a single unit. The eective elastic

properties of the laminate can be determined using the

theory of the laminated plates.

The lament wound structures, which is the subject of

this study, is assumed to be made of angle-ply laminates.

An angle-ply laminate has alternating lamina having a

and a winding angles. Therefore, a lament-wound

cylindrical shell, having a wind angle a can be treated

as an angle-ply laminate. For multi-layered cylinders,

each layer is an angle-ply laminate with its own wind

angle. Neglecting the eect of curvature, the eective

elastic properties of each of these layers can be formu-

lated as follows.

For an angle-ply lamina where bers are oriented at

an angle a with the positive x-axis as shown in Fig. 1, the

eective elastic properties are given by

1

E

x

0

x

0

cos

4

a

E

11

sin

4

a

E

22

1

G

12

_

2

m

12

E

11

_

cos

2

a sin

2

a

1

E

y

0

y

0

sin

4

a

E

11

cos

4

a

E

22

1

G

12

_

2

m

12

E

11

_

cos

2

a sin

2

a

1

G

x

0

y

0

1

E

11

2

m

12

E

11

1

E

22

1

E

11

_

2

m

12

E

11

1

E

22

1

G

12

_

cos

2

2a

m

x

0

y

0 E

x

0

x

0

m

12

E

11

_

1

E

11

_

2

m

12

E

11

1

E

22

1

G

12

_

cos

2

a sin

2

a

_

m

y

0

x

0

E

y

0

y

0

E

x

0

x

0

m

x

0

y

0 1

In this study, the elastic constants related to the

thickness coordinate however, are assumed as E

z

0

z

0

E

33

E

22

and G

y

0

z

0 G

x

0

z

0 G

x

0

y

0 .

In a lament-wound pressure vessel, the structure is

made-up of several angle lay-ups, each of which acts as

an orthotropic unit. The elastic constants of each layer is

assumed as equal to eective elastic constants of a bal-

anced and symmetric laminate which has two layers of

winding angles (a) and (a) with equal thicknesses.

The generalized Hookes law in cylindrical coordi-

nates can be written as

feg

r;h;z

afrg

r;h;z

2

For an angle-ply lamina, due to the (a) congura-

tion, the shear coupling terms are zero. Then the com-

pliance matrix [a] can be represented in cylindrical

coordinates as

a

1

E

rr

m

rh

E

rr

m

rz

E

rr

0 0 0

m

rh

E

rr

1

E

hh

m

hz

E

hh

0 0 0

m

rz

E

rr

m

hz

E

hh

1

E

zz

0 0 0

0 0 0

1

G

hz

0 0

0 0 0 0

1

G

rz

0

0 0 0 0 0

1

G

rh

_

_

_

_

3

The material properties in cylindrical coordinates can

be obtained by simply replacing cartesian coordinates,

x, y and z, with r, h and z, respectively (Fig. 1).

2.2. Plane stress problem for a body in cylindrical

anisotropy

Lethnitskii [1] started the formulation with the plane

stress condition then the problem is converted to the

generalized plane strain problem where axial strain of

the system is equal to a constant rather than being zero.

The equilibrium equations, disregarding r

zz

, and the

equations of generalized Hookes Law for a body in

cylindrical anisotropy in cylindrical coordinates are

given by the following equations.

or

rr

or

1

r

or

rh

oh

r

rr

r

hh

r

R 0 4

or

rh

or

1

r

or

hh

oh

2

r

rh

r

H 0 5

e

rr

a

11

r

rr

a

12

r

hh

a

16

r

rh

e

hh

a

12

r

rr

a

22

r

hh

a

26

r

rh

e

zz

a

13

r

rr

a

23

r

hh

a

36

r

rh

c

rh

a

16

r

rr

a

22

r

hh

a

66

r

rh

6

Fig. 1. Global, local and material coordinates.

84 L. Parnas, N. Katrc / Composite Structures 58 (2002) 8395

where R and H are the projections of the body forces

along r and h directions, respectively. The axial stress,

r

zz

, of the generalized plane strain problem will be ob-

tained by using generalized Hookes Law. The strain

displacement relations for the same body are:

e

rr

ou

r

or

e

hh

1

r

ou

h

oh

u

r

r

c

rh

1

r

ou

r

oh

ou

h

or

u

h

r

7

By eliminating displacements from Eq. (7), the

equation of compatibility is obtained, which is:

o

2

e

rr

oh

2

r

o

2

re

hh

or

2

o

2

rc

rh

oroh

r

oe

rr

or

0 8

The equilibrium equations given in Eq. (5) are satis-

ed with the following denition of the stress function,

F r; h:

r

rr

1

r

oF

or

1

r

2

o

2

F

oh

2

U

r

hh

o

2

F

or

2

U

r

rh

o

2

or oh

F

r

_ _

9

where U is the body force potential.

On the basis of equations of compatibility, stress

strain relations and equilibrium equations given above,

the following dierential equation for plane stress case

which is satised by the stress function F r; h, is ob-

tained

a

22

o

4

F

or

4

2a

26

o

4

F

or

3

oh

2a

12

a

66

1

r

2

o

4

F

or

2

oh

2

2a

16

1

r

3

o

4

F

or oh

3

a

11

1

r

4

o

4

F

oh

4

2a

22

1

r

o

3

F

or

3

2a

13

a

66

1

r

3

o

3

F

or oh

2

2a

16

1

r

4

o

3

F

oh

3

a

11

1

r

2

o

2

F

or

2

2 a

16

a

26

1

r

3

o

2

F

or oh

2 a

11

2a

12

a

66

1

r

4

o

2

F

oh

2

a

11

1

r

3

oF

or

2 a

16

a

26

1

r

4

oF

oh

a

12

a

22

o

2

U

or

2

a

16

a

26

1

r

o

2

U

or oh

a

11

a

12

1

r

2

o

2

U

oh

2

a

11

2a

22

a

12

1

r

oU

or

a

16

a

26

1

r

2

oU

oh

10

where a

16

and a

26

vanish for a body having a angle-ply

layers. After introducing the material properties for the

compliances and substituting them into Eq. (10), the

following non-homogeneous, fourth order dierential

equation is obtained for an orthotropic cylindrical body

for the state of plane stress.

1

E

hh

o

4

F

or

4

1

G

rh

_

2m

rh

E

rr

_

1

r

4

o

4

F

or

2

oh

2

1

E

rr

1

r

4

o

4

F

oh

4

2

E

hh

1

r

o

3

F

or

3

1

G

rh

_

2

m

rh

E

rr

_

1

r

3

o

2

F

or oh

1

E

rr

1

r

2

o

2

F

or

2

2

1 m

r

E

rr

_

1

G

rh

_

1

r

4

o

2

F

oh

2

1

E

rr

1

r

3

oF

or

1 m

hr

E

hh

o

2

U

or

2

_

1 m

rh

E

rr

1

r

2

o

2

U

oh

2

_

2

E

hh

_

1 m

rh

E

rr

_

1

r

oU

or

: 11

2.3. Stresses and displacements for a rotating anisotropic

cylinder

At this point, it is easy to obtain the stress distribu-

tion for an anisotropic rotating cylinder. It is assumed

that the cylinder is orthotropic, so that any radial plane

is an elastic symmetry plane. For a rotating cylinder, the

body force potential is given by:

U

qx

2

2

r

2

12

where x is the angular speed, q is the density of the

material and r is the radial position.

Since the problem is axisymmetric, the stress function

F depends only on r. Using this fact and Eq. (12), Eq.

(11) can be rearranged for the kth layer as follows:

1

E

k

hh

r

4

d

4

F

dr

4

2

E

k

hh

r

3

d

3

F

dr

3

1

E

k

rr

r

2

d

2

F

dr

2

1

E

k

rr

r

dF

dr

3

E

k

hh

_

2m

r

1

E

k

rr

_

qx

2

r

4

13

Eq. (13) is in the form of Eulers equation and its

solution yields the following expression for the stress

function F,

F r A

k

B

k

r

2

C

k

r

1g1

k

D

k

r

1g1

k

q

k

x

2

2

3

_

2m

k

rh

ee

2

k

_

E

k

rr

36E

k

rr

4E

k

hh

r

4

14

where ee

k

E

k

hh

=E

k

rr

1=2

.

Using the stress function F r and the body force

potential U in Eq. (9), the stresses can be obtained as:

L. Parnas, N. Katrc / Composite Structures 58 (2002) 8395 85

The structure is mechanically subjected to a radial

body force due to rotation, internal pressure and axial

force as shown in Fig. 2. Boundary conditions for the

given geometry and loading can be represented as fol-

lows,

For r r

int

) r

1

rr

P

int

and r

1

rh

0

For r r

ext

) r

n

rr

0 and r

n

rh

0

At the interface of adjacent layers, the following

boundary conditions are applied,

r b

k1

) r

k1

rr

r

k

rr

and u

k1

r

u

k

r

When the boundary conditions are applied, two un-

known coecients of the stress function, A

k

and B

k

are

obtained as zero, and other coecients as

C

k

1

1 g

k

b

k

b

g

k

k1

c

g

k

k

c

g

k

k

q

k

_

b

g

k

k

b

12g

k

k1

b

1g

k

k1

c

g

k

k

c

g

k

k

_

c

g

k

k

c

g

k

k

q

k1

q

k

x

2

3 m

k

hr

9 g

2

k

b

g

k

k

b

32g

k

k1

b

3

k

b

g

k

k1

c

g

k

k

c

g

k

k

_

b

3g

k

k1

__

16

D

k

1

1 g

k

q

k1

b

g

k

1

k

q

k

b

g

k

1

k1

_ _

b

k

b

k1

c

g

k

k

c

g

k

k

_

q

k

x

2

3 m

k

hr

9 g

2

k

b

2

k1

b

g

k

1

k

_

b

2

k

b

g

k

1

k1

_

b

k

b

k1

_

17

where c

k

b

k1

=b

k

, g

k

n

k

11

=n

k

22

1=2

and k denotes the

layer number. The reduced strain coecients, n

k

ij

, extend

the plane stress problem into the generalized plane strain

problem as proposed by Lekhnitskii [7]. They can be

dened for a multi-layered cylinder as,

n

k

ij

a

k

ij

a

k

i3

a

k

j3

a

k

33

i; j 1; 2

where a

k

ij

are the components of the compliance tensor in

cylindrical coordinates for the kth layer. Using the stress

function F r, layer stresses can be derived as:

r

k

rr

q

k

x

2

b

2

k

3 m

k

hr

9 g

2

k

_ _

1 c

g

k

3

k

1 c

2g

k

k

_ _

r

b

k

_ _

g

k

1

_

1 c

g

k

3

k

1 c

2g

k

k

_ _

c

g

k

3

k

b

k

r

_ _

g

k

1

r

b

k

_ _

2

_

q

k1

c

g

k

1

k

1 c

2g

k

k

_ _

r

b

k

_ _

g

k

1

_

b

k

r

_ _

g

k

1

_

q

k

1 c

2g

k

k

_ _

c

2g

k

k

b

k

r

_ _

g

k

1

_

r

b

k

_ _

g

k

1

_

18

r

k

hh

q

k

x

2

b

2

k

9 g

2

k

_ _

3

_

_

m

k

hr

_

g

k

1 c

g

k

3

k

1 c

2g

k

k

_ _

r

b

k

_ _

g

k

1

_

1 c

g

k

3

k

1 c

2g

k

k

_ _

c

g

k

3

k

b

k

r

_ _

g

k

1

_

g

2

k

_

3m

k

hr

_

r

b

k

_ _

2

_

q

k1

c

g

k

1

k

g

k

1 c

2g

k

k

_ _

r

b

k

_ _

g

k

1

_

b

k

r

_ _

g

k

1

_

q

k

g

k

1 c

2g

k

k

_ _

r

b

k

_ _

g

k

1

_

c

2g

k

k

b

k

r

_ _

g

k

1

_

19

In Eqs. (18) and (19), symbols q

k1

and q

k

denote the

internal and external forces in radial direction acting on

the kth layer as given in Fig. 3, and m

k

hr

n

k

12

=n

k

22

. Since

the pressure vessel is assumed to be in the state of gen-

eralized plane strain, axial strains of all layers is equal to

the constant, e

0

zz

. Then the axial stress can be obtained as:

r

k

zz

e

0

zz

a

k

33

1

a

k

33

a

k

13

r

k

rr

_

a

k

23

r

k

hh

_

20

The displacements are obtained as follows:

u

k

r

r n

k

12

r

k

rr

_

n

k

22

r

k

hh

m

k

zh

e

0

zz

_

;

u

k

h

0 and u

k

z

ze

0

zz

21

where m

k

zh

a

k

23

=a

k

33

. Fig. 2. Mechanical loading on a closed end cylindrical pressure vessel.

r

k

rr

2B

k

C

k

1

_

ee

k

_

r

ee

k

1

D

k

1

_

ee

k

_

r

ee

k

1

q

k

x

2

3 m

k

hr

9 ee

2

k

_ _

r

2

r

k

hh

2B

k

C

k

1

_

ee

k

_

ee

k

r

ee

k

1

D

k

1

_

ee

k

_

ee

k

r

ee

k

1

q

k

x

2

3m

k

hr

ee

2

k

9 ee

2

k

_ _

r

2

r

k

rh

0

15

86 L. Parnas, N. Katrc / Composite Structures 58 (2002) 8395

For a cylinder with closed ends, the axial equilibrium

is satised by the following relation,

n

k1

2p

_

b

k

b

k1

r

k

zz

r dr pr

2

int

P

int

P

ext

F

A

22

where r

int

is the internal radius of the cylinder. Substi-

tuting Eqs. (18) and (19) for r

k

rr

and r

k

hh

into Eq. (20) for

r

k

zz

and evaluating the integral in Eq. (22), the relation

for e

0

zz

is determined as:

e

0

zz

1

D

P

int

r

2

int

_

_

P

ext

r

2

ext

_

F

A

p

n

k1

q

k1

d

k

_

q

k

l

k

x

2

w

k

_

_

23

where, D

n

k1

b

2

k

b

2

k1

a

k

33

and

d

k

2

a

k

33

1 c

2g

k

k

_ _

b

k

c

g

k

1

k

1 g

k

a

k

13

_

_

g

k

a

k

23

_

b

k

c

g

k

k

b

k1

b

k1

1 g

k

a

k

13

_

g

k

a

k

23

_

b

k

c

g

k

k

b

k1

_

l

k

2

a

k

33

1 c

2g

k

k

_ _

b

k

1 g

k

a

k

13

_

_

g

k

a

k

23

_

b

k

c

g

k

k

b

k1

b

k

c

g

k

k

1 g

k

a

k

13

_

g

k

a

k

23

_

b

k

c

g

k

k

b

k1

_

w

k

2q

k

b

2

k

3 m

k

hr

_ _

9 g

2

k

a

k

13

a

k

33

_

_

a

k

23

a

k

33

g

k

_

1 c

g

k

3

k

1 c

2g

k

k

_ _

1 g

k

_ _

b

g

k

1

k

b

g

k

1

k1

_

b

2

k

_

a

k

13

a

k

33

_

a

k

23

a

k

33

g

k

_

1 c

g

k

3

k

_ _

c

g

k

3

k

1 c

2g

k

k

_ _

1 g

k

_ _

b

g

k

1

k

b

g

k

1

k1

_

b

2

k

_

a

k

13

a

k

33

_

a

k

23

a

k

33

g

2

k

3m

k

hr

_ _

3 m

k

hr

_

1

4b

2

k

_ _

b

4

k

_

b

4

k1

_

_

At each layer interface, radial displacements of ad-

jacent layers must be continuous, which follows that:

u

k

r

b

k

u

k1

r

b

k

24

Using Eqs. (23) and (24), a set of simultaneous

equations in terms of q

k

, one for each interface, is de-

termined as:

u

k

q

k1

v

k

q

k

g

k

q

k1

x

2

k

k

m

k

zh

m

k1

zh

D

_ _

n

i1

q

i1

d

i

_

_

q

i

l

i

x

2

w

i

_

_

m

k

zh

m

k1

zh

D

_ _

P

int

r

2

int

_

_

P

ext

r

2

ext

_

F

A

p

_

25

where, u

k

2g

k1

n

k1

22

c

g

k1

1

k1

=1 c

2g

k

1

k1

u

k

b

k

12

g

k

b

k

22

1 c

2g

k

k

_ _

1 c

2g

k

k

b

k1

12

g

k1

b

k1

22

1 c

2g

k1

k1

_ _

1 c

2g

k1

k1

g

k

2g

k

n

k

12

c

g

k

1

k

1 c

2g

k

k

k

k

b

2

k

q

k

n

k

22

9 g

2

k

g

k

3

_

_ _

m

k

hr

_

1 2c

g

k

3

k

c

2g

k

k

1 c

2g

k

k

_ _

g

2

k

_

3m

k

hr

_

_

b

2

k1

q

k1

n

k1

22

9 g

2

k1

g

k1

3

_

m

k1

hr

_

2c

g

k1

1

k1

c

2g

k1

2

k1

c

2

k1

1 c

2g

k1

k1

_ _

g

2

k1

_

3m

k1

hr

_

c

2

k1

_

Therefore, the unknown interface pressures, q

k

, are

solved by using Eq. (25), which eventually leads to the

complete solution of the elasticity problem.

2.4. Analysis of pressure vessels using thin wall theory

The thickness ratio is dened as the ratio between

external and internal radii of the pressure vessel. For

pressure vessels of thickness ratios less than 1.1, the thin

wall analysis can satisfactorily be used. In this theory,

the radial stress is assumed to be zero in addition to

hoop and axial stresses to be constant through the

thickness. The hoop and the axial stresses of a pressure

vessel subjected to internal and external pressure, and an

axial force can be calculated, respectively, as follows:

r

hh

P

int

P

ext

r

int

t

and

r

zz

P

int

P

ext

r

int

2t

F

A

2pr

int

t

26

where t is the wall thickness of the vessel.

Fig. 3. Multi-layered cylinder showing layer notation.

L. Parnas, N. Katrc / Composite Structures 58 (2002) 8395 87

2.5. Environmental eects on composite materials

The inuence of environmental factors, such as ele-

vated temperature, humidity and corrosive uids must

be taken into consideration since they aect mechanical

and physical properties of composite materials resulting

in a change of the mechanical performance. The eect of

the elevated temperature can be seen in the composite

material properties with a decrease in the modulus

and strength because of thermal softening. Especially

in polymer-based composites, the matrix-dominated

properties are more aected then the ber-dominated

properties. For example, the longitudinal strength and

modulus of a unidirectional composite specimen remain

almost constant but o-axis properties of the same

specimen are signicantly reduced as the temperature

approaches the glass transition temperature of the

polymer. When exposed to humid air or water envi-

ronment, many polymeric matrix composites absorb

moisture by instantaneous surface absorption followed

by diusion through the matrix. Analysis of moisture

absorption shows that for epoxy and polyester matrix

composites, the moisture concentration increases ini-

tially with time and approaches an equilibrium (satu-

ration) level after several days of exposure to humid

environments [2].

The analysis of composites due to elevated tempera-

ture and moisture absorption is called as hygrothermal

problem. It can be solved mainly in three steps: First,

the temperature distribution and the moisture content

inside the material are calculated. Then from known

temperature and moisture distribution, the hygrother-

mal deformations and stresses are calculated. Finally,

the changes in performance due to both aects are

determined. The assumptions used through these steps

are:

temperature and moisture content inside the material

vary only in the thickness direction,

thermal conductivity of the material is independent of

temperature and moisture level,

the environmental conditions (temperature and mois-

ture level) are constant.

The temperature distribution is obtained by using the

one dimensional steady-state heat conduction analy-

sis throughout the body. So for the kth layer, one can

write:

T

k

T

k1

qR

k

27

where q T

int

T

ext

=

n

i1

R

i

and R

k

K

k

=h

k

.

Here T

k

temperature, h

k

thickness and K

k

are the

thermal conductivity of the kth layer, respectively. In

this study, the moisture content is taken as constant and

equal to the saturated moisture level throughout the

material.

2.6. Hygrothermal degradation

In addition to creating stresses, temperature and

moisture degrade the material properties as well. By fol-

lowing the method given by Tsai [2], the non-dimen-

sional temperature T

can be dened as,

T

T

g

T

opr

T

g

T

rm

28

where T

g

is the glass-transition temperature, T

opr

is the

operation temperature and T

rm

is the room temperature.

It is also assumed that the moisture suppresses the glass

transition temperature by a simple moisture shift as,

T

g

T

0

g

gc 29

where T

0

g

is the glass-transition temperature at the dry

state, g is the temperature shift per unit moisture ab-

sorbed and c is the moisture absorption of the structure.

The term T

is used to empirically t the ber and ma-

trix stiness and strength data as functions of both

moisture and temperature.

Using empirical ber and matrix properties, the ply

stiness and strength properties are given here [2], rst

in terms of stiness ratios as

E

11

v

f

v

0

f

T

f

E

0

11

E

22

E

0

22

a

E

0

m

T

b

g

0

y

1

v

f

1

_ _

T

f

E

0

f

_ _

1

1

v

0

f

1

_ _

g

0

y

_ _

E

0

m

1

v

0

f

1

_ _

g

0

y

E

0

f

_ _

1

T

b

v

f

T

b

_ _

T

a

T

f

E

s

E

0

s

g

0

s

T

b

1v

f

v

f

1

_ _

1

G

0

f

g

0

s

1v

0

f

v

0

f

G

0

m

_ _

1

g

0

s

v

0

m

v

0

f

_ _

1

T

f

G

0

f

b

g

0

s

1v

f

v

f

T

b

G

0

m

_ _

30

and strength ratios as

X

X

0

v

f

v

0

f

T

h

X

0

X

00

v

f

v

0

f

T

h

E

s

E

0

s

_ _

e

Y

Y

0

Y

0

Y

00

S

S

0

T

d

31

where g is the mutual inuence coecient and subscripts

f and m denote ber and matrix, respectively. The

constants a, b, d, f and h are determined empirically and

the exponent for example on X

0

denotes the values of

the corresponding property X obtained at room tem-

perature with 0.5% moisture content.

2.7. Hygrothermal stresses

The hygrothermal and mechanical strains can be su-

perposed in strain level to obtain total strains as,

e

tot

ij

e

mech

ij

e

hygr

ij

32

88 L. Parnas, N. Katrc / Composite Structures 58 (2002) 8395

or

e

tot

ij

e

mech

ij

a

ij

DT b

ij

c

where a

ij

and b

ij

are thermal and moisture expansion

coecients, respectively.

Total stresses however, can be obtained using aniso-

tropic stressstrain relations. Total stresses due to hy-

grothermal and mechanical loads can be written as,

r

tot

ij

a

1

e

tot

ij

33

2.8. Failure analysis

The main reason for performing the stress analysis is

to determine the failure behavior of the pressure vessel.

Design of a structure or a component is performed by

comparing stresses (or strains) created by applied loads

with the allowable strength (or strain capacity) of the

material [2]. TsaiHill, TsaiWu [8], Homan [9] and

3D-Quadratic Failure Theories [2] are used in this study

for comparison and it is seen that 3D-Quadratic Failure

Criteria gives the most conservative results for strength.

3. Numerical solution

In order to see how structures behave, the numerical

results are necessary for a given material, geometry and

loading combination. A preliminary design package

program is developed using the derived formulation of

stresses. In order to determine the burst pressure, the

maximum axial force and the maximum angular speed,

the performance (load carrying capacity) of the specied

composite pressure vessel is taken as the only limiting

value. The strength ratio is the ratio between the maxi-

mum or ultimate strength and the applied stress. It must

be slightly larger than one because of the safety reason.

Burst pressure and maximum angular speed are deter-

mined by using the rst-ply failure criterion and maxi-

mum axial force is determined by using the last-ply

failure criterion.

The winding angle obtained by developed computer

program is called as optimum without using any opti-

mization procedure. This is not wrong because only one

constraint is taken into account, which has to be maxi-

mized in this case and all possible solutions are checked

every time to get the winding angle satisfying the con-

straints.

Since the winding angle varies between 0 and 90,

layer stresses are obtained for each angle with a step size

of 0.1. The strength ratios of the worst layers are

compared with each other. Then the angle having the

highest strength ratio is taken as the optimum winding

angle for the specied loading and geometry conditions.

4. Discussion of results

The design outputs of the computer program are

optimum winding angle, burst pressure and maximum

angular speed of the vessel for a given material, geo-

metry and loading combination. Also the aects of axial

force and hygrothermal forces on burst pressure and

angular speed are studied. In each of these analysis, the

material used is a graphite-epoxy composite (T300/

N5208). The properties of the unidirectional laminate of

this material are given in Table 1. Note that the residual

stresses due to material itself are not considered in this

study.

4.1. Optimum winding angle

In literature [5], the optimum winding angle for la-

ment wound composite pressure vessels is given as

54.74 by netting analysis. Using the current procedure

for the internal pressure loading, the optimum winding

angle is obtained as ranging between 52.1 and 54.2

depending on geometry and failure criteria used. 3D-

Quadratic Failure Criterion always gives greater opti-

mum winding angle than other theories, because the

circumferential stress or strain is more eective in this

criterion. If angular speed is applied at the same time

with the internal pressure, the optimum winding angle

values obtained for the pure internal pressure case are

increased and shifted to 90.

4.2. Stress distribution

The stress distribution through the thickness of a

lament wound vessel is not uniform but varying de-

pending on the geometry and loading. The stress graphs

for pure internal pressure and pure angular speed cases

with a constant winding angle of 53, are given in Figs. 4

and 5, respectively. The symbols a and b represent

Table 1

Properties of unidirectional laminate (T300/N5208)

Elastic modulus in ber direction (GPa) 181

Elastic modulus in matrix direction (GPa) 10.3

In plane shear modulus (GPa) 7.17

Major Poissons ratio 0.28

Ultimate tensile strength in ber direction (MPa) 1500

Ultimate compressive strength in ber direction (MPa) 1500

Ultimate tensile strength in matrix direction (MPa) 40

Ultimate compressive strength in matrix direction (MPa) 146

Ultimate in-plane shear strength (MPa) 68

Thermal expansion coecient in ber direction (10

6

/C) 0.02

Thermal expansion coecient in matrix direction (10

6

/C) 22.5

Moisture expansion coecient in ber direction 0

Moisture expansion coecient in matrix direction 0.6

Thermal conductivity normal to the thickness direction

(W/m per C)

0.865

L. Parnas, N. Katrc / Composite Structures 58 (2002) 8395 89

internal and external radii of the tube, respectively. The

stresses are normalized with the values of thin-wall so-

lution. In Fig. 4, the results for radial stresses and to

some degree with hoop stresses are similar with the ones

of Ref. [5]. However, the axial stress distributions show

a considerable dierence. The errors in the formulation

of Ref. [5] would be a reason for the dierence; another

reason might be originated from the fact that a variable

winding angle (5456) was considered in Ref. [5], con-

trary to the constant winding angle used in the current

study.

As it can be seen in Fig. 5, the thin-wall analysis gives

only an average result. When thickness increases, the

thick-wall analysis has to be used, instead. Radial stress

is zero at the inside and outside of the pressure vessel

and positive through the thickness. Its maximum value

is approximately at the mid-point of the thickness.

When the wall thickness is increased, the layer having

maximum radial stress becomes closer to the inner

boundary of the pressure vessel. Larger circumferential

and axial stresses are obtained at the inner layers of the

vessel. In Fig. 5, it is seen that axial stress always

changes sign at the point where the radial stress reaches

to a maximum.

4.3. Thick- and thin-walled solutions for burst pressure

The corresponding burst pressure values are obtained

using an iterative procedure where the loading is in-

creased until the failure of a single layer. In Fig. 6, the

burst pressure, P

burst

, by using both thin and thick-wal-

led solution techniques are plotted versus winding angle.

The burst pressure is normalized with that of 0 winding

angle. For the thin-wall tube, both thick and thin-wall

Fig. 4. Radial, axial and circumferential stress distributions for pure internal pressure.

90 L. Parnas, N. Katrc / Composite Structures 58 (2002) 8395

solutions predict almost the same burst pressure. Actu-

ally, since the thin-wall solution neglects the radial

stress, burst pressure values obtained with the thin-

walled analysis are slightly higher than those obtained

with thick-walled analysis. The agreement between these

two solutions is satised except for the values near the

Fig. 5. Radial, axial and circumferential stress distributions for pure angular speed.

Fig. 6. Variation of burst pressure with increasing winding angle [r

ext

=r

int

1:05].

L. Parnas, N. Katrc / Composite Structures 58 (2002) 8395 91

optimum winding angle where they dier for thick and

thin-wall solutions.

For a thick pressure vessel (Fig. 7), there is a signif-

icant dierence between thin-wall and thick-wall solu-

tions especially near the optimum winding angle. In this

wall thickness value (r

ext

=r

int

1:40), the thick-wall so-

lution gives higher burst pressure than the thin-wall

solution between angles 48 and 64.

To check the limiting value of the thin-wall solution

on the wall thickness, burst pressures are calculated for

increasing wall thickness Thin-wall and thick-wall so-

lutions yield very similar burst pressure values up to the

thickness ratio of r

ext

=r

int

1:1. For thicknesses with

r

ext

=r

int

P1:1, the deviation between thick and thin-wall

solutions becomes larger (Fig. 8).

4.4. Eect of angular speed and axial force on burst

pressure

The eect of angular speed and axial force on the

burst pressure can be seen in Fig. 9. The burst pressure

decreases with angular speed, when the winding angle is

less than its optimum value. It is not an expected result,

since the burst pressure increases with the speed for

angles greater than the optimum winding angle. The

burst pressure increases in negligible amount for in-

creasing axial tensile force for angles smaller than the

optimum winding angle. If the winding angle of the

structure is larger than its optimum value, the burst

pressure always decreases with increasing axial force.

4.5. Maximum angular speed

The eect of wall thickness and winding angle on the

maximum angular speed can be seen in Fig. 10. If only

angular speed is applied, the optimum winding angle is

obtained as ranging between 81 and 83 depending on

the wall thickness of the structure. For small winding

angles up to 30, the thin and thick-wall constructions

give almost the same maximum angular speed. As the

wall thickness increases, the maximum angular speed

decreases opposite to the case of burst pressure. It is an

expected result, since an increasing wall thickness means

more inertia that aects the speed in the negative sense.

4.6. Hygrothermal stresses and strains

Hygrothermal stresses in the macro-mechanical level

calculated by using the laminated plate theory. In order

to assess the eects of residual stresses on the failure of

Fig. 7. Variation of burst pressure with increasing winding angle [r

ext

=r

int

1:4].

Fig. 8. Burst pressure for increasing wall thickness.

92 L. Parnas, N. Katrc / Composite Structures 58 (2002) 8395

composite materials, the hygrothermal expansion coef-

cients have to be determined correctly. As a sample

calculation of hygrothermal stresses, the data given in

Table 2 for T300/N5208 [2] is used where DF is the

degradation factor.

Since the curing temperature is the stress free state for

composite materials, the operation temperature aects

the failure of the composite depending on whether it is

below or above the curing temperature. If the operation

temperature is less than zero or if it is less than the

curing temperature, the burst pressure is increased since

the thermal strains and mechanical strains for pure in-

ternal pressure case work in opposite senses. It should be

pointed out that, the negative temperature for constant

moisture content also cause an increase in the mechan-

ical properties of the composite material. It can be

concluded that if the operation temperature is less

than the curing temperature, burst pressure is increased.

If operation temperature is greater than the curing

Fig. 9. Eect of angular speed and axial force on burst pressure [r

ext

=r

int

1:05].

Fig. 10. Maximum angular velocity versus winding angle.

Table 2

Hygrothermal eects on burst pressure [r

ext

=r

int

1:05, a 53]

T

opr

(C) 22 22 122 122 122

c (%) 0 0 0 0 1

DF (%) 0 0 0 10 30

P

burst

(MPa) 18.3 20.3 16.3 14.4 12.1

L. Parnas, N. Katrc / Composite Structures 58 (2002) 8395 93

temperature, however, both thermal and mechanical

strains have a cumulative eect. This can be seen as a

decrease in burst pressure values in Fig. 11.

Although, the performance of the composite material

is negatively inuenced by the presence of moisture, it

creates less residual strains compared with the thermal

ones and does not change the burst pressure, signi-

cantly.

5. Conclusion

An analytical procedure is developed to assess the

behavior of a cylindrical composite structure under

loading conditions particular to a rocket motor case.

Available loading conditions are internal pressure, axial

force and body force due to rotation. Additionally,

temperature and moisture variations throughout the

body are considered in the analysis. The procedure is

based on the classical laminated plate theory. It models

the plane strain state of the cylindrical body, which

consists of a number of cylindrical sub-layers.

The cylindrical pressure vessel is analyzed using two

approaches, which are thin wall and thick wall solutions.

It is shown that for composite pressure vessels with a

ratio of outer to inner radius, up to 1.1, two approaches

give similar results in terms of the optimum winding

angle, the burst pressure, etc. As the ratio increases, the

thick wall analysis is required.

The optimum winding angle for the thick-wall pres-

sure vessel analysis with the pure internal pressure

loading case is obtained as ranging between 52.1 and

54.1 degrees depending on the material type. If the an-

gular speed is applied at the same time with the internal

pressure, optimum winding angle values obtained for

the pure internal pressure case are shifted towards

90. The inuence of the axial force is, however, opposite

to the one of the angular speed. The addition of the axial

force has a decreasing eect on the winding angle.

The burst pressure value is greatly depends on the

analysis type used. The deviation between thin and

thick-wall solutions is quite large especially near the

optimum winding angle. As the wall thickness is in-

creased, the thick-wall solution gives almost 30% higher

burst pressure values. Therefore, the thin-wall analysis is

said to be an average but a safe analysis.

If angular speed is applied, the maximum stress

occurs in the hoop direction. The optimum winding

angle of the analyzed body for this type of loading is

obtained as ranging between 81 and 83. The value of

the maximum angular speed that the system can be ro-

tated is greatly aected by the thickness of the pressure

vessel.

Hygrothermal eects are analyzed in this study in two

levels. The eect of temperature and moisture to the

performance of the materials is determined by using the

micromechanics of the composite materials. By taking a

linear variation of temperature and constant value for

moisture content throughout the body, hygrothermal

stresses and strains are determined. Since the thermal

and moisture expansion coecients of the materials

have to be determined experimentally, always some

amount of error is expected in these calculations.

If the material has a tendency of expanding due to a

positive temperature dierence, the increasing operating

temperature is shown to reduce the mechanical perfor-

mance of the system.

References

[1] Lekhnitskii SG. Anisotropic plates. New York, NY: Gordon and

Breach Science Publishers; 1968.

[2] Tsai SW. Composites design. USA, Think Composites, 1985.

[3] Xia M, Takayanagi H, Kemmochi K. Analysis of multi-layered

lament-wound composite pipes under internal pressure. Compos

Struct 2001;53(4):48391.

[4] Xia M, Kemmochi K, Takayanagi H. Analysis of lament-wound

ber-reinforced sandwich pipe under combined internal pressure

and thermomechanical loading. Compos Struct 2001;51(3):27383.

Fig. 11. Eect of temperature on burst pressure for dierent operating temperatures.

94 L. Parnas, N. Katrc / Composite Structures 58 (2002) 8395

[5] Wild PM, Vickers GW. Analysis of lament-wound cylindrical

shells under combined centrifugal, pressure and axial loading.

Compos Part A 1997;28(1):4755.

[6] Katrc N. Design of ber reinforced composite pressure ves-

sels. M.S. Thesis, Middle East Technical University, Turkey,

1998.

[7] Lekhnitskii SG. Theory of elasticity of an anisotropic body. USSR,

Moscow: Mir Publishers; 1981.

[8] Mallick PK. Fiber-reinforced composites, materials, manufacturing

and design. New York, NY: Marcel Dekker, Inc; 1988.

[9] Lee SM. Reference book for composite technology-2. Technomic

Publishing Company; 1989.

L. Parnas, N. Katrc / Composite Structures 58 (2002) 8395 95

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Heat TransferDocumento1 páginaHeat TransferhuangjlAinda não há avaliações

- Heat TransferDocumento1 páginaHeat TransferhuangjlAinda não há avaliações

- Vibration Analysis PDFDocumento6 páginasVibration Analysis PDFBipin RohitAinda não há avaliações

- Bolt Tension & Torque CalculationDocumento1 páginaBolt Tension & Torque CalculationhuangjlAinda não há avaliações

- 3210Q011 04gb PDFDocumento2 páginas3210Q011 04gb PDFDenim102100% (1)

- LS Circuit IntroductionDocumento18 páginasLS Circuit IntroductionMuhammad DaniAinda não há avaliações

- Atlas EbookDocumento48 páginasAtlas EbookVyas SrinivasanAinda não há avaliações

- Surge Tank Size and CostDocumento1 páginaSurge Tank Size and CosthuangjlAinda não há avaliações

- Pump CalculationDocumento4 páginasPump CalculationhuangjlAinda não há avaliações

- SVS Well hydraulic calculations and drilling parametersDocumento1 páginaSVS Well hydraulic calculations and drilling parametershuangjlAinda não há avaliações

- Estimating TemplateDocumento16 páginasEstimating TemplatehuangjlAinda não há avaliações

- LEKX6306 Torque CurvesDocumento11 páginasLEKX6306 Torque Curvesmijael1393100% (1)

- Load CalcDocumento69 páginasLoad Calcmyusuf_engineerAinda não há avaliações

- NPSH CalculationDocumento1 páginaNPSH CalculationhuangjlAinda não há avaliações

- API 650 Tank Data Sheet SummaryDocumento3 páginasAPI 650 Tank Data Sheet SummaryhuangjlAinda não há avaliações

- Mayer Stark and Ambrose 2000 Fatigue Design Procedures PDFDocumento7 páginasMayer Stark and Ambrose 2000 Fatigue Design Procedures PDFMas Arman TewoAinda não há avaliações

- Taneks Deutz CatalogueDocumento123 páginasTaneks Deutz CatalogueeCommerce SAJID AutoAinda não há avaliações

- Bolt Torques For ASME B16.5 Flanges With Sheet Gaskets To ASME B16.21Documento30 páginasBolt Torques For ASME B16.5 Flanges With Sheet Gaskets To ASME B16.21huangjlAinda não há avaliações

- Induced Draft Cooling Tower PM Emissions SpreadsheetDocumento1 páginaInduced Draft Cooling Tower PM Emissions SpreadsheethuangjlAinda não há avaliações

- Piping Design Maximun Flow Rate in Piping SystemDocumento1 páginaPiping Design Maximun Flow Rate in Piping SystemhuangjlAinda não há avaliações

- Fuel Pump HP CalculationsDocumento8 páginasFuel Pump HP CalculationshuangjlAinda não há avaliações

- 职场英语对话Documento21 páginas职场英语对话huangjlAinda não há avaliações

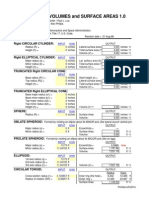

- Volumes AndweightsDocumento2 páginasVolumes AndweightsmohdnazirAinda não há avaliações

- GB5782 外形尺寸及重量表 六角头 -C级 GB5780Documento2 páginasGB5782 外形尺寸及重量表 六角头 -C级 GB5780huangjlAinda não há avaliações

- Tank Volumes & Surf AreasDocumento4 páginasTank Volumes & Surf AreashuangjlAinda não há avaliações

- 03 Heat ExchangerDocumento17 páginas03 Heat ExchangerhuangjlAinda não há avaliações

- Tank 2bDocumento1 páginaTank 2bMukeshSharmaAinda não há avaliações

- PipeData Rev ADocumento5 páginasPipeData Rev AhuangjlAinda não há avaliações

- Load Capacity Crack Length CalculationDocumento28 páginasLoad Capacity Crack Length Calculationharikrishnanpd3327Ainda não há avaliações

- Fuel Pump HP CalculationsDocumento8 páginasFuel Pump HP CalculationshuangjlAinda não há avaliações

- RIG TableDocumento258 páginasRIG TablehuangjlAinda não há avaliações

- insulation cal (绝热厚度计算)Documento4 páginasinsulation cal (绝热厚度计算)huangjlAinda não há avaliações

- Tank VolDocumento4 páginasTank VolgrabettyAinda não há avaliações

- Conical TankDocumento2 páginasConical TankhuangjlAinda não há avaliações

- Tanks Hell Min ThicknessDocumento1 páginaTanks Hell Min ThicknesshuangjlAinda não há avaliações

- User Instructions MOD 110SH: Warning!Documento2 páginasUser Instructions MOD 110SH: Warning!Jhon Fabio ParraAinda não há avaliações

- Operation & Service Manual: Models: 01-1189-0012 01A1189-0012 Custom Towbar CASA CN-235Documento13 páginasOperation & Service Manual: Models: 01-1189-0012 01A1189-0012 Custom Towbar CASA CN-235juan david lópez montalegreAinda não há avaliações

- ASTM A615 Grade 70 PDFDocumento2 páginasASTM A615 Grade 70 PDFAnonymous vRtCW4hszAinda não há avaliações

- Z2000 Modulating Zone Comfort System Control PanelDocumento4 páginasZ2000 Modulating Zone Comfort System Control PanelibrahimsirpiAinda não há avaliações

- Prying Forces in The Bolts Become Significant When Ninety Percent of The YieldDocumento2 páginasPrying Forces in The Bolts Become Significant When Ninety Percent of The YieldRC Dela RocaAinda não há avaliações

- QUY150C 150t Crawler Crane BrochureDocumento59 páginasQUY150C 150t Crawler Crane BrochureliftAinda não há avaliações

- A Mechanical Engineer S Handbook by ONGC PDFDocumento303 páginasA Mechanical Engineer S Handbook by ONGC PDFshujad77Ainda não há avaliações

- 416E Backhoe Loader Maintenance ScheduleDocumento4 páginas416E Backhoe Loader Maintenance ScheduleSain MezaAinda não há avaliações

- Catalogue: Creative SpiritDocumento88 páginasCatalogue: Creative Spiritedy105Ainda não há avaliações

- VRF Technical Data Book Highlights Key Specs (38k-61k BTU, 3-4.5 TonDocumento55 páginasVRF Technical Data Book Highlights Key Specs (38k-61k BTU, 3-4.5 TonFred BensimonAinda não há avaliações

- Chapter 2Documento35 páginasChapter 2Eba GetachewAinda não há avaliações

- OEM Viscosity Compensated Flowmeter Model VKA Specs & DetailsDocumento2 páginasOEM Viscosity Compensated Flowmeter Model VKA Specs & Details王敏Ainda não há avaliações

- 33Documento40 páginas33farida2020Ainda não há avaliações

- 1.C.1 Limitations On The Work That Can Be Supplied by A Heat EngineDocumento30 páginas1.C.1 Limitations On The Work That Can Be Supplied by A Heat EnginekamsAinda não há avaliações

- Form 5968 M MarathonDocumento16 páginasForm 5968 M MarathonDương Thế TínhAinda não há avaliações

- Friction and Friction Coefficients For Various MaterialsDocumento14 páginasFriction and Friction Coefficients For Various MaterialsGia Minh Tieu TuAinda não há avaliações

- Answers To EOC Questions: Cambridge International AS Level PhysicsDocumento2 páginasAnswers To EOC Questions: Cambridge International AS Level PhysicsSambandha SilwalAinda não há avaliações

- Nissan Design Specification (NDS) : (Contents)Documento6 páginasNissan Design Specification (NDS) : (Contents)Maryana cAinda não há avaliações

- Iso 3965 - 1990-02Documento6 páginasIso 3965 - 1990-02gkhnAinda não há avaliações

- Science 8 q1 w3Documento12 páginasScience 8 q1 w3Je-ann AcuAinda não há avaliações

- Hilti Profis Anchor calculation software provides tension load design values for anchorDocumento7 páginasHilti Profis Anchor calculation software provides tension load design values for anchorsamAinda não há avaliações

- Filtro Hidraulico 12 atDocumento8 páginasFiltro Hidraulico 12 atLankaster Flórez ChAinda não há avaliações

- FANUC Laser C1000-C6000 Operator's ManualDocumento166 páginasFANUC Laser C1000-C6000 Operator's ManualTec PachucaAinda não há avaliações