Escolar Documentos

Profissional Documentos

Cultura Documentos

Effect of Shape and Size on FRP Wrapped Concrete Columns

Enviado por

Ajith ChandranTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Effect of Shape and Size on FRP Wrapped Concrete Columns

Enviado por

Ajith ChandranDireitos autorais:

Formatos disponíveis

Effect of Shape and Size on Fiber Reinforced Polymer Composite Wrapped Concrete Columns

Dr. Abhay Bambole, Professor and Head, SPCE, Mumbai Kedar Joshi, Post Graduate Student, SPCE, Mumbai Abstract:

Rehabilitation of structures with FRP composites has proved to be cost effective method of enhancing the service life of structures. FRP composites are used for retrofitting and Rehabilitation of Columns and Bridge Piers. The shapes of the columns have a significant effect on confining strength of FRP Wraps. A lot of research has been carried out around the globe varying different parameters and finding usable data. This paper presents results of axial compression test conducted on over two hundred and forty concrete specimens having circular, square and rectangular cross sections. The effect of shapes, sizes and shape modification of the cross sections on the load carrying capacity of FRP wrapped concrete prisms and cylinders, has been studied. The project also studies the effect of shape modifications on enhancement in load carrying capacity in case of non circular cross section. Investigation was done on rectangular columns to increase the confinement effectiveness by modifying it into elliptical cross-sections. All the experimental results were compared with analytical values calculated as per the ACI-440.2R-08 code. The results of experiments and comparison are presented. Keywords: FRP, Fibre reinforced polymer, Shape, Size, Strengthening, Column

INTRODUCTION

In construction industry, over the last two decades, Fiber Reinforced Polymer (FRP) composites have become a primary choice for strengthening buildings and bridge components because of their high strength to weight ratio and stiffness-to-weight ratios, ease of application, cost effectiveness and such other salient traits. FRP composites are also considered as excellent substitutes for building components like concrete bridge decks, reinforcing bars and pre-stressing materials. These FRP composites are widely used for retrofitting and rehabilitation of building columns and bridge piers. Confinement of columns by means of FRP jackets is done by containing the dilation of concrete by wrapping the fibers in the hoop direction of concrete columns. In past decade research has been carried out taking into account possible parameters in strengthening using FRP wrapping. Mirmiran et al, tested fifty four concrete filled FRP tubes in uniaxial compression under displacement control mode to study the dilation characteristics of confined concrete. They found that the dilation rate finally stabilizes at an ultimate value which is a function of the jacket's stiffness 1. Tan et al tested to failure fifty two half scale rectangular columns with aspect ratio 3.65 under a concentric load to investigate the effect of fiber type configuration and fiber anchors on the strength enhancement of the columns2. Pan et al performed axial compression test on six FRP wrapped slender rectangular columns modified to elliptical shape having slenderness ratio L/b ranging from 4.5 to 17.5. The strengthening effect of FRP was observed to be decreasing with the increase in the slenderness ratio3. Yousef et al studied factors such as ultimate stress, rupture strain, jacket parameters, and cross-sectional geometry affecting the stressstrain behavior of FRPconfined concrete4. Silva et al studied the environmental effects such as humidity, UV rays, exposure to moisture, salt fogs, thermal cycles on mechanical properties of GFRP laminates and consequently on

strengthened columns5. Benzaid et al experimentally scrutinized the effects of increasing the corner radius and the no of GFRP layers on the confined compressive strength of square columns6. Shape of cross section, corner radius, grade of concrete, FRP volumetric ratio are some of the important factors that affect the confinement effectiveness of FRP wraps. The experiments presented here were formulated to make a comprehensive study to determine the extent these parameters can be used to enhance the load carrying capacity in case of non-circular columns.

Confining pressure for cylinders

In case of cylinders the whole cross sectional area is effectively confined because the confining pressure is uniformly distributed along the perimeter as shown in fig 1. The behavior of confined cylinders is similar to a thin walled cylinder. The equation for confining pressure7 is given as,

fl =

frp E frp 2

frp

(1a)

Where, Efrp = Youngs modulus of FRP wraps frp = strain in FRP wraps at failure frp = FRP volumetric ratio frp =

.d .n.t f .d 2 / 4

(1b)

where, d = diameter of cross section n = no of layers tf = thickness of FRP wrap

Confining pressure for non circular cross sections

In case of non circular cross sections the confining pressure is affected by the sharp edges. The dilation in non circular cross section is effectively contained by the FRP wraps only at the corners due to stress concentration as shown in fig 2. The effective confined area is reduced because stress concentration causes arching of concrete core along the sides. The equation for confining pressure for non circular cross section is given as7,

fl =

k a frp E frp frp 2

(2a)

In order to account for the reduced effective confined area, the confining pressure is reduced by a shape factor ka1 and is given by the following equation,

Ae b ka = Ac h

(2b)

where, Ae/Ac =

b (h 2r )2 + h (b 2r ) 2 b 1 h g 3 Ag 1 g

(2c)

in which, g = ratio of area of steel to gross cross sectional area The FRP volumetric ratio is given as,

2 .n .t f .( b + h ) bh

(2d)

Confining pressure for elliptical cross sections:

Shape modification of rectangular cross section to elliptical shapes is one of the effective method to increase the confining pressure provided by the FRP wraps. The confined compressive strength for elliptically modified non circular cross section is given as8,

b f 'cc = f 'co + 2 a

2 fl

(3a)

In the above equation for confining pressure is same as eq. (1a). The FRP volumetric ratio for elliptical cross section is given as following8,

frp

[1.5(a + b) - ab ] t f ab

(3b)

EXPERIMENTAL WORK

The primary aim of this experiment was to study the effects of shapes, sizes and shape modification (corners) on the confinement effectiveness of the FRP wraps and to achieve maximum confinement. The grade of concrete and the height on specimen was kept as M30 and 300mm for all specimen. The specimen were casted in the following manner. 1. For all the three cases i.e. circular, square and rectangular specimens were casted in three sizes in increasing order of the cross sections as shown in Table 1. 2. In the case of rectangular and square columns the cross sections were carefully decided so that each square column has a corresponding rectangular column having the same cross-sectional area. 3. The size of the rectangular columns were chosen in such a way that the aspect ratio is equal to 1.5 or greater than 1.5. This is to take care of the effect of aspect ratio in rectangular columns. All specimens were wrapped with one layer of glass fiber wraps. Glass fibers had an ultimate strength of 2400 MPa, elastic modulus of 80 kN/mm2 and a density of 2.78 g/cc as per manufacturers data sheet (R&M International Pvt. Ltd., Mumbai). Resin epoxy was used as matrix and had two component (base and hardener) mixed in the ratio of 100:35 as suggested by the manufacturer. All specimens were pretreated with resin primer in order to achieve a smooth surface and good bond between FRP and the specimen surface. FRP wraps were applied to both sharp edged and rounded edged prisms. The rounded edged non circular prisms had a corner radius of 37.5 mm. Rectangular prisms were also modified to elliptical shapes before FRP wrapping by placing them in elliptical moulds.

Compression test was carried out on all specimens on a 200T compression testing machine (CTM) under a load control mode with loading rate of 2.5 kN/sec. Electrical strain gauges were fixed in longitudinal and lateral direction at mid height to measure the ductility and dilation of concrete.

RESULTS AND DISCUSSIONS

Stress strain curves

It was observed from the axial stress vs. axial strain diagrams that the behavior of GFRP wrapped specimens was similar to control specimens till the lateral expansion of concrete started. As the concrete starts to dilate, GFRP wraps get activated and start containing the specimens from dilating laterally thereby providing passive confinement. The confining pressure provided by the jacket keeps increasing proportional to the applied axial load until failure. As the jacket gets completely activated the axial stress strain curve starts to flatten and is closer to a straight line in lateral direction until failure. Response of FRP wrapped cylinders and prisms to axial compression has been found to be bilinear. The elastic response of the specimens is represented by an initial straight portion of the axial stress vs. axial strain curve. This straight portion is followed by a transition stage in which the concrete starts to dilate and FRP wraps start providing confining pressure. This transition stage is then followed by a straight portion which continues till failure as the confining pressure keeps on increasing till failure. Axial stress vs. axial strain curve of FRP wrapped specimens does not have any descending branch as the confining pressure keeps increasing until failure. In case of circular cylinders, a significant increase in ductility has been observed as the values of axial strains and lateral strains of wrapped cylinders were much higher than the unwrapped cylinders as shown in Fig 3. Fig 4 shows that glass fibers effectively restrained the dilation in cylinders as the failure of wrapped cylinders occurred at a very high value of lateral strains. In case of GFRP wrapped non circular prisms with sharp edges, increase in ductility was negligible as compared to bare prisms which can be observed in Fig 5. It can be seen in Fig 6 that the dilation of prisms was contained at a lesser rate than GFRP wrapped non circular prisms with rounded edges. Rounding of edges greatly increased the ductility of wrapped square prisms which is evident from axial stress vs. axial strain diagrams. Also, in case of wrapped non circular prisms with rounded edges dilation of concrete was effectively contained as compared to sharp edged wrapped prisms as is seen in Fig 8. It can be read from Fig 7 that rectangular prisms modified to elliptical shapes exhibited excellent increase in strength and ductility as compared to bare and wrapped prisms with rounded edges

Percentage increase in strength

FRP wraps were very effective in confining circular cross sections compared to non circular cross sections as is evident from table 3. The sharp edges of a non circular prism adversely affect the confinement effectiveness of FRP wraps due to stress concentration at corners. It can be seen from table 4 and table 5 that the enhancement in strength was largest in case of non circular prism with the smallest cross sectional area (46.78% for 135 x 135 mm and 48% for 100 x 180 mm) and it was negligibly small in case of non circular prism with the largest cross sectional area (19.89% for 195 x 195 mm and 14.02% for 160 x 240 mm). The maximum corner radius that could be imparted to a non circular column depends upon the longitudinal reinforcement and the clear cover that is to be maintained. A constant corner radius of 37.5 mm was maintained for all the non circular prisms. The enhancement in strength due to rounding of edges was largest in case of columns with smallest cross sectional area (73.5% for 135 x 135 mm and 52% for 100 x 180 mm). The percentage increase in strength decreased with the increase in the cross sectional area of non circular prism and was lowest for largest cross sectional area (32.4% for 195 x 195 mm and 30.28% for 160 x 240

mm). The clear cover that is usually provided to columns is 40 mm (for severe exposure)10. Therefore the enhancement in strength that can be achieved by imparting corner radius is limited for large size columns as these columns will need a corner radius of higher value. In case of large no of columns, grinding of corners would prove to be a very cumbersome activity. In such cases, significant increase in strength can be achieved by modifying the non circular cross section into elliptical or circular shapes. The percentage increase in strength achieved by elliptical modification was higher than rounded edged prisms as can be seen in table 5 (78% for 100 x180 mm , 69% for 130 x 200 mm and 62% for 160 x 240 mm). The results in table 4 and 5 are displayed in graphical form in fig 9 and 10. Comparison as shown in fig 11 between enhancement in strength of specimens of three shapes circular, square and rectangular of same cross sectional areas showed that the increase was largest in case of cylinders and elliptically modified rectangular prisms. It was observed that the difference in enhancement in strength in case of non circular prisms with same cross sectional areas was not significant. It was observed that the enhancement in load carrying capacity depends upon the FRP volumetric ratio. FRP volumetric ratio depends upon the no of layers of FRP, thickness of each FRP layer and the ratio of circumference to c/s area. The load carrying capacity of FRP wrapped specimens decreased with the increase in size. This is because the FRP volumetric ratio decreases as the cross sectional size increases if the no of layers are not increased as shown in table 2. A straight line curve can be plotted showing +percentage increase in strength vs. cross sectional dimensions as shown in fig 14 and 15 representing the decrease in strength with increasing size. It is worthy to note that as the area of a particular column type increases the load carrying capacity per unit cross-section area increases. This is called pedestal effect11. The three cross-section area of circular columns which were used had shown that the percentage strength enhancement due to FRP decreases with increase in column cross-section area. The reason for this behavior is the percentage of FRP layer per unit cross-sectional area of column. This percentage decreases with increase in area i.e. 115% for 150 mm dia, 90% for 180mm dia and 75% for 220mm dia.

Comparison of experimental results with analytical values calculated as per ACI 440.2R-08 and J. G. Teng

The results obtained by experiments were compared with results calculated using analytical models suggested in ACI 440.2R-08(except elliptical columns) and J. G. Teng et al. (elliptical column). The experimental values were found to be more than the ones calculated by these models. For circular samples the experimental results were found to be more than 30% more than the analytical values calculated by models (Table 6). The difference was around 20% for square columns(Table7). For rectangular columns the results varied from 20% to 40%(Table 8).

Conclusions

Based on the results obtained from the experimental investigation following conclusions have been drawn: 1. The percentage increase in strength in the case of circular columns decreases due to decrease in the percentage FRP per unit area of column cross-section. If the percentage FRP per unit column crosssection is maintained by providing adequate layers the percentage increase in strength should become independent of the column cross section. This was observed in all types of columns. 2. Significant increase in strength was achieved due to rounding of edges of non circular prisms.

3. The enhancement in axial compressive strength achieved by modifying rectangular cross sections to elliptical shapes was remarkably high. It was significantly higher than the columns with cornered radius. 4. GFRP wraps effectively increased the ductility of cylinders, non circular prisms with rounded edges and elliptically modified rectangular prisms. Non circular prisms with sharp edges showed no significant improvement in ductility. Axial stress vs. axial strain diagrams obtained showed close confirmation with idealized curve suggested by Lam and Teng. 5. GFRP wraps were able to contain the dilation of concrete for a longer period which is evident from the axial stress vs. lateral strain diagrams. 6. The experimental results were compared with the calculated values predicted by analytical models. The results have shown the conservative nature of the codes and hence the values specified in the codes are safe to use.

Acknowledgements

This work has been sponsored by Sardar Patel College of Engg., Andheri, Mumbai and R&M International Ltd., Mumbai.

References

1. Mirmiran, A., and Shahawy, M., (1997), Effect of column parameters on FRP confined concrete, Journal of composite for construction, 2, 237-249. 2. Tan, K. H., (2002), Strength enhancement of rectangular RCC columns using Fiber reinforced polymers, Journal of composite for construction, 6:3, 175-183. 3. Pan, J. L., Xu, T., and Hu, Z. J., (2007), Experimental investigation of load carrying capacity of the slender reinforced concrete columns wrapped with FRP, Construction and building materials, 21, 1991-1996. 4. Yousef, M. N., Feng, M. Q., and Mosallam, A. S., (2006), Stressstrain model for concrete confined by FRP composites, Composites Part B: Engineering, 38, 614-628. 5. Silva, M. A. G., (2007), Aging of GFRP laminates and confinement of concrete columns, Composite Structures, 79, 97-106. 6. Benzaid, B., Chikh, N., and Mesbah, H., (2008), Behaviour of square concrete column confined with GFRP composite wraps, Journal of civil engineering and management, 14 (2), 115-120. 7. ACI 440.2R 08 Guide for the design and construction of externally bonded FRP systems for strengthening concrete structures. 8. Teng, J. G., Lam, L., (2002), Compressive Behavior of CFRP-Confined Concrete in Elliptical Columns, Journal of Structural Engineering, 128:12, 1535-1543. 9. IS 456 2000, Plain and reinforced concrete Code of practice. 10. Teng, J., G., Lam, L., Stress strain models for concrete confined by Fiber reinforced polymer composites, 17th Australasian conference on th mechanics of structures and materials. 11. IS 516 2000, Methods for strength of Concrete.

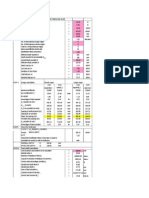

Table 1 Test Matrix

Circular (D) Shapes C1 Dimensions (mm) Area(cm2) Control FRP wrapped with sharp corners FRP wrapped with 3.75 cm (1.5") corner radius No of specimens FRP wrapped rectangular specimens modified to elliptical 220 1521 9 9 C2 180 1018 9 9 C3 150 707 9 9 S1 195 380 9 9 S2 160 256 9 9 S3 135 182 9 9 Square (a x a) Rectangular R1 b 160 384 9 9 R2 b 130 260 9 9 R3 B 100 180 9 9

a 240

a 200

a 180

Total specimens for FRP wrapping Total specimens for concreting

9 18

9 18

9 18

18 27

18 27

18 27

27 36

27 36

27 36

Table 2 FRP volumetric ratio for cross sections of different sizes

Table 3 Results of axial compression test on control and GFRP wrapped cylinders

Table 4 Results of axial compression test on control and GFRP wrapped square prisms

Table 5 Results of axial compression test on control and GFRP wrapped rectangular prisms

Table 6 Comparison of values of circular specimens Diameter (mm) Experimental Value (MPa) Value calculated as per ACI 440.2R-08 (MPa) 150 180 220 54.13 48.51 51.10 40.21 37.77 35.55

Table 7 Comparison of values of square specimens Value calculated as per ACI 440.2R-08 (MPa) 29.40 35.55 28.81 33.46 28.22 31.52

Size (mm) 135 x 135 160 x 160 195 x 195 Sharp edge Rounded edge Sharp edge Rounded edge Sharp edge Rounded edge

Experimental Value (MPa) 39.6 42.94 33.8 39.82 36.02 39.34

Table 8 Comparison of values of rectangular specimens Value calculated as per ACI 440.2R-08 (MPa) 26.67 28.45 31.82 26.87 28.72 31.95 26.50 28.10 30.96

Size (mm) Sharp edge Rounded edge *Elliptical Sharp edge Rounded edge *Elliptical Sharp edge Rounded edge *Elliptical

Experimental Value (MPa) 36.54 38.36 65.39 32.06 38.83 65.41 33.60 38.57

100 x 180

130 x 200 160 x 240

* Values of elliptical specimens calculated as per analytical model suggested by J G Teng

Fig 1 Lateral confining pressure in cylinders

Fig 2 Effective confined areas of sharp edged and rounded edged wrapped non circular c/s

Fig 3: Axial stress vs. axial strain graph for 180 dia circular cylinder

Fig 4: Axial stress vs. lateral strain graph for 220 dia circular cylinder

Fig 5: Axial stress vs. axial strain graph for 160 mm square prism

Fig 6: Axial stress vs. lateral strain graph for 195 mm square prism

Fig 7: Axial stress vs. axial strain graph for 100 x 180 mm rectangular prism

Fig 8: Axial stress vs. lateral strain graph for 130 x200 mm rectangular prism

Fig 9: Comparison of percentage increase in strength of square prisms

Fig 10: Comparison of percentage increase in strength of rectangular prisms

Fig 11: Comparison of percentage increase in strength of specimens of same areas

Fig 12: Percentage increase in strength vs. ratio of dimensions of cylinders

Fig 13: Percentage increase in strength vs. ratio of dimensions of square prisms

pt = percentage increase in strength of GFRP wrapped specimens over their respective control specimens t = ratio of the specimen dimension to the smallest dimension of the shape

Fig 14 GFRP wrapped cylinder 150 mm in diameter failure due to tearing of fibers

Fig 15 GFRP wrapped square prism with sharp edges 130 x 200 mm in size failure of fibers at corners due to stress concentration

Fig 16 GFRP wrapped square prism with rounded edges 100 x 180 mm in size

Fig 17 GFRP wrapped square prism with rounded edges 195 x 195 mm in size

Você também pode gostar

- Lecture Notes on Reinforced Concrete DesignNo EverandLecture Notes on Reinforced Concrete DesignAinda não há avaliações

- Regain in Strength of Reinforced Concrete Columns-Akash ChauhanDocumento6 páginasRegain in Strength of Reinforced Concrete Columns-Akash ChauhanAkash ChauhanAinda não há avaliações

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsAinda não há avaliações

- BehaviorOfAxiallyLoadedConcrete-FilledCircularFRPTubes Fam 2001Documento35 páginasBehaviorOfAxiallyLoadedConcrete-FilledCircularFRPTubes Fam 2001Matias GaitanAinda não há avaliações

- Kolonda Köşeleri Pahlama Yarıçapının Eksenel Yük Kapasitesine Etkisi Wang 2008Documento13 páginasKolonda Köşeleri Pahlama Yarıçapının Eksenel Yük Kapasitesine Etkisi Wang 2008aygunbayramAinda não há avaliações

- 7 Wu2010Documento14 páginas7 Wu2010Tú LêAinda não há avaliações

- Efficiency SFR 2003Documento10 páginasEfficiency SFR 2003Kemal Tuşat YücelAinda não há avaliações

- Ext_Abst_SHDocumento16 páginasExt_Abst_SHTiago GassmanAinda não há avaliações

- Strengthening of Reinforced Concrete Columns Using FRP-Akash Krupeshkumar ChauhanDocumento6 páginasStrengthening of Reinforced Concrete Columns Using FRP-Akash Krupeshkumar ChauhanAkash ChauhanAinda não há avaliações

- Ultimate Behavior of Axially Loaded RC Wall-Like Columns Confined With GFRPDocumento9 páginasUltimate Behavior of Axially Loaded RC Wall-Like Columns Confined With GFRPAsr FlowerAinda não há avaliações

- Research Article: Behavior and Performance of GFRP Reinforced Concrete Columns With Various Types of StirrupsDocumento10 páginasResearch Article: Behavior and Performance of GFRP Reinforced Concrete Columns With Various Types of StirrupsBernie G. CatarigAinda não há avaliações

- FRP Column AbaqusDocumento14 páginasFRP Column AbaqusAlvin PurmawinataAinda não há avaliações

- Strength of Short Concrete Columns Confined with CFRP SheetsDocumento9 páginasStrength of Short Concrete Columns Confined with CFRP SheetsSaddam Abdulrahman AlazzaniAinda não há avaliações

- Finite Element Analysis and Model Validation of Shear Deficient Reinforced Concrete Beams Strengthened With GFRP LaminatesDocumento11 páginasFinite Element Analysis and Model Validation of Shear Deficient Reinforced Concrete Beams Strengthened With GFRP LaminatesZiyad12Ainda não há avaliações

- Strengthening Design Limitation of Column PDFDocumento9 páginasStrengthening Design Limitation of Column PDFSushil DhunganaAinda não há avaliações

- Study On Repair Method Using CFRP For Corroded Steel Girder EndsDocumento12 páginasStudy On Repair Method Using CFRP For Corroded Steel Girder EndsRandi G JoviAinda não há avaliações

- Torsional Strengthening of Reinforced Concrete Box Beams Using Carbon Fiber Reinforced PolymerDocumento7 páginasTorsional Strengthening of Reinforced Concrete Box Beams Using Carbon Fiber Reinforced Polymernvel0006Ainda não há avaliações

- FRP Wrapped Concrete Finite Element AnalysisDocumento6 páginasFRP Wrapped Concrete Finite Element Analysisantony1993Ainda não há avaliações

- Hansen Et. Al. (Word 2003) Crack Propagation I Eset Specimens Strengthened With CFRP Sheets 20090602Documento12 páginasHansen Et. Al. (Word 2003) Crack Propagation I Eset Specimens Strengthened With CFRP Sheets 20090602Microb IraniAinda não há avaliações

- RoyalDocumento17 páginasRoyalshanthiraAinda não há avaliações

- 4 Lam2003Documento38 páginas4 Lam2003Tú LêAinda não há avaliações

- Different CFRP Strengthening Techniques For Prestressed Hollow Core Concrete Slabs Experimental Study and Analytical Investigation - Copy (211434589)Documento11 páginasDifferent CFRP Strengthening Techniques For Prestressed Hollow Core Concrete Slabs Experimental Study and Analytical Investigation - Copy (211434589)Sulaiman Mohsin AbdulAzizAinda não há avaliações

- Ductility and Strength Behavior of Reinforced Concrete Columns Confined by Glass and Carbon FRP SheetsDocumento23 páginasDuctility and Strength Behavior of Reinforced Concrete Columns Confined by Glass and Carbon FRP SheetsJm CampitanAinda não há avaliações

- Behaviour of CFRP-Strengthened Slender Square RC ColumnsDocumento11 páginasBehaviour of CFRP-Strengthened Slender Square RC Columnsy768673Ainda não há avaliações

- FRP-Strengthened RC Beams Fatigue TestDocumento18 páginasFRP-Strengthened RC Beams Fatigue TestAshish Kumar DashAinda não há avaliações

- 5236-Article Text-11399-1-10-20180831 - نسخDocumento9 páginas5236-Article Text-11399-1-10-20180831 - نسخThanoon AlmarwasyAinda não há avaliações

- Paper With Moshiri - Materials and StructuresDocumento18 páginasPaper With Moshiri - Materials and StructuresMehdi KhorasaniAinda não há avaliações

- Influence of Cross Section Geometry On The Confinement of Reinforced Concrete Columns With CFR CompositesDocumento11 páginasInfluence of Cross Section Geometry On The Confinement of Reinforced Concrete Columns With CFR CompositesOsamah MahmoodAinda não há avaliações

- Experimental Study of compressive strength of solid, hollow and PVC confined hollow cylindersDocumento31 páginasExperimental Study of compressive strength of solid, hollow and PVC confined hollow cylindersTabish IzharAinda não há avaliações

- Shear friction capacity of pre-cracked concrete strengthened with GFRPDocumento10 páginasShear friction capacity of pre-cracked concrete strengthened with GFRPCristian Camilo Londoño PiedrahítaAinda não há avaliações

- Strengthening of Columns by FRP ReportDocumento13 páginasStrengthening of Columns by FRP ReportAhmed KhalilAinda não há avaliações

- 10 5923 J Cmaterials 20180803 03Documento8 páginas10 5923 J Cmaterials 20180803 03Jamal Eddine HamiltonAinda não há avaliações

- Discussion on Bonding Performance between FRP Bars and ConcreteDocumento5 páginasDiscussion on Bonding Performance between FRP Bars and ConcreteEng-Alma AhmadAinda não há avaliações

- FRPConfinedCircularolumnsUnderSmallEccentricLoading Ghali Kassen FawzyDocumento10 páginasFRPConfinedCircularolumnsUnderSmallEccentricLoading Ghali Kassen FawzyAhmd MhmdAinda não há avaliações

- Optimized FRP Wrapping Schemes For Circular Concrete ColumnsDocumento34 páginasOptimized FRP Wrapping Schemes For Circular Concrete ColumnsTAMANA SHAMSIAinda não há avaliações

- Shear Behavior of MasonryDocumento11 páginasShear Behavior of MasonryRazvan IonAinda não há avaliações

- Archive of SIDDocumento13 páginasArchive of SIDmfhfhfAinda não há avaliações

- External Prestressing Concrete Columns With Fibrous Composite BeltsDocumento16 páginasExternal Prestressing Concrete Columns With Fibrous Composite BeltsmagdyamdbAinda não há avaliações

- Bi 2011Documento5 páginasBi 2011Zana QaderAinda não há avaliações

- Flexural Response of Reinforced Concrete (RC) Beams Strengthened With Near Surface Mounted (NSM) Fibre Reinforced Polymer (FRP) BarsDocumento15 páginasFlexural Response of Reinforced Concrete (RC) Beams Strengthened With Near Surface Mounted (NSM) Fibre Reinforced Polymer (FRP) Barsmohamed ellithyAinda não há avaliações

- Compressive Behaviour of CFRP-Confined Rectangular Concrete ColumnsDocumento11 páginasCompressive Behaviour of CFRP-Confined Rectangular Concrete Columnstyui7383Ainda não há avaliações

- Seismic Retrofit Techniques For Reinforced Concrete Bridge Columns ...Documento10 páginasSeismic Retrofit Techniques For Reinforced Concrete Bridge Columns ...오상진Ainda não há avaliações

- Strengthening Prestressed Concrete Girders with Externally Bonded Carbon Fiber SheetsDocumento10 páginasStrengthening Prestressed Concrete Girders with Externally Bonded Carbon Fiber SheetsRizki Nuursirullah MahibAinda não há avaliações

- 2003lam and Teng - Design-Oriented Stress-Strain Model For FRP-confined ConcreteDocumento19 páginas2003lam and Teng - Design-Oriented Stress-Strain Model For FRP-confined ConcreteFilipe RibeiroAinda não há avaliações

- J Jobe 2020 101526Documento41 páginasJ Jobe 2020 101526Emad RabadiAinda não há avaliações

- Axial Compressive Behaviour of Frp-Confined High-Strength ConcreteDocumento13 páginasAxial Compressive Behaviour of Frp-Confined High-Strength ConcreteyanimuhammadAinda não há avaliações

- 2013 Punching Shear Strengthening of TwoDocumento10 páginas2013 Punching Shear Strengthening of TwoMehdi KhorasaniAinda não há avaliações

- Ecentric LoadDocumento4 páginasEcentric LoadArun NesamAinda não há avaliações

- Behaviour of FRP Reinforced Concrete Beam-Column Joints Under Cyclic Loading PDFDocumento8 páginasBehaviour of FRP Reinforced Concrete Beam-Column Joints Under Cyclic Loading PDFAhmed NafieAinda não há avaliações

- Active Cfrp-Based Confinement Strategies For RC Columns With Rectangular Cross SectionsDocumento8 páginasActive Cfrp-Based Confinement Strategies For RC Columns With Rectangular Cross SectionsPedro CruzAinda não há avaliações

- Ubead Marzouk LyeDocumento6 páginasUbead Marzouk LyeAmmar A. AliAinda não há avaliações

- Strengthening of Reinforced Concrete Columns Using FRP: Akash K. Chauhan Nirav B. UmraviaDocumento6 páginasStrengthening of Reinforced Concrete Columns Using FRP: Akash K. Chauhan Nirav B. UmraviaNashid HasanAinda não há avaliações

- 2019 - Experimental Study of RC Deep Beam With Opening and FRP Composites Installed by Means of EBR and EBROGDocumento12 páginas2019 - Experimental Study of RC Deep Beam With Opening and FRP Composites Installed by Means of EBR and EBROGARNABAinda não há avaliações

- 15 PDFDocumento28 páginas15 PDFNathanAinda não há avaliações

- Secm 2013 0227.aopDocumento13 páginasSecm 2013 0227.aopShital ChaudhariAinda não há avaliações

- Shear Capacity of Reinforced Concrete Columns Strengthened With CFRP SheetDocumento6 páginasShear Capacity of Reinforced Concrete Columns Strengthened With CFRP SheetAzhar PLAinda não há avaliações

- A New Method For Improving Ductility in Existing RC Ordinary Moment Resisting Frames Using FrpsDocumento15 páginasA New Method For Improving Ductility in Existing RC Ordinary Moment Resisting Frames Using Frpsrachellej_436066654Ainda não há avaliações

- ACI 318-05 GFRP Reinforced Concrete ColumnsDocumento10 páginasACI 318-05 GFRP Reinforced Concrete ColumnssrividyaAinda não há avaliações

- Repair of Earthquake-Damaged RC Columns With FRP Wraps: Aci Structural Journal Technical PaperDocumento9 páginasRepair of Earthquake-Damaged RC Columns With FRP Wraps: Aci Structural Journal Technical PaperD Raul CfAinda não há avaliações

- Buckling of Stiffened Steel Plates - A Parametric Study: ArticleDocumento26 páginasBuckling of Stiffened Steel Plates - A Parametric Study: Articlekhudhayer1970Ainda não há avaliações

- T Beam DesignDocumento3 páginasT Beam DesignAjith ChandranAinda não há avaliações

- Two Way Slab DesignDocumento2 páginasTwo Way Slab DesignAjith Chandran100% (1)

- Water ProofingDocumento1 páginaWater ProofingAjith ChandranAinda não há avaliações

- Effect of Shape and Size on FRP Wrapped Concrete ColumnsDocumento14 páginasEffect of Shape and Size on FRP Wrapped Concrete ColumnsAjith ChandranAinda não há avaliações

- Beam Design Final (VISWANATHAN)Documento12 páginasBeam Design Final (VISWANATHAN)Ajith ChandranAinda não há avaliações

- Hilti Hy150 Post Installed BarsDocumento8 páginasHilti Hy150 Post Installed BarsAjith ChandranAinda não há avaliações

- RCC JACKETING ProceduresDocumento2 páginasRCC JACKETING ProceduresAjith Chandran100% (1)

- Wound Healing (BOOK 71P)Documento71 páginasWound Healing (BOOK 71P)Ahmed KhairyAinda não há avaliações

- Unit 4 Trade Discounts Cash Discounts MarkupDocumento42 páginasUnit 4 Trade Discounts Cash Discounts MarkupChimwemwe MaoleAinda não há avaliações

- Social Media Marketing - AssignmentDocumento8 páginasSocial Media Marketing - AssignmentAllen RodaAinda não há avaliações

- Community Action and Core Values and Principles of Community-Action InitiativesDocumento5 páginasCommunity Action and Core Values and Principles of Community-Action Initiativeskimberson alacyangAinda não há avaliações

- So Neither or NorDocumento2 páginasSo Neither or NorMita KusniasariAinda não há avaliações

- Ductile Brittle TransitionDocumento7 páginasDuctile Brittle TransitionAndrea CalderaAinda não há avaliações

- Para Kay BDocumento1 páginaPara Kay BFeLy DipOn63% (8)

- Basic Statistical Tools for Data Analysis and Quality EvaluationDocumento45 páginasBasic Statistical Tools for Data Analysis and Quality EvaluationfarjanaAinda não há avaliações

- UntitledDocumento17 páginasUntitledВладислав ПроскураAinda não há avaliações

- 1000 Electronic Devices & Circuits MCQsDocumento467 páginas1000 Electronic Devices & Circuits MCQskibrom atsbha67% (3)

- Fs Casas FinalDocumento55 páginasFs Casas FinalGwen Araña BalgomaAinda não há avaliações

- 1st PU Chemistry Test Sep 2014 PDFDocumento1 página1st PU Chemistry Test Sep 2014 PDFPrasad C M86% (7)

- Veerabhadra Swamy MantrasDocumento6 páginasVeerabhadra Swamy Mantrasगणेश पराजुलीAinda não há avaliações

- 14 - Habeas Corpus PetitionDocumento4 páginas14 - Habeas Corpus PetitionJalaj AgarwalAinda não há avaliações

- Planning Levels and Types for Organizational SuccessDocumento20 páginasPlanning Levels and Types for Organizational SuccessLala Ckee100% (1)

- AREVA Directional Over Current Relay MiCOM P12x en TechDataDocumento28 páginasAREVA Directional Over Current Relay MiCOM P12x en TechDatadeccanelecAinda não há avaliações

- 01 Particle Sizing by Laser DifractionDocumento145 páginas01 Particle Sizing by Laser DifractionPramesvara NaoriAinda não há avaliações

- Engineering: Ronnapee Chaichaowarat, Jun Kinugawa, Kazuhiro KosugeDocumento8 páginasEngineering: Ronnapee Chaichaowarat, Jun Kinugawa, Kazuhiro Kosugelaura bemudezAinda não há avaliações

- Listening LP1Documento6 páginasListening LP1Zee KimAinda não há avaliações

- CV Jan 2015 SDocumento4 páginasCV Jan 2015 Sapi-276142935Ainda não há avaliações

- Corneal Ulcers: What Is The Cornea?Documento1 páginaCorneal Ulcers: What Is The Cornea?me2_howardAinda não há avaliações

- Earth-Song WorksheetDocumento2 páginasEarth-Song WorksheetMuhammad FarizAinda não há avaliações

- Practical and Mathematical Skills BookletDocumento30 páginasPractical and Mathematical Skills BookletZarqaYasminAinda não há avaliações

- Challengue 2 Simpe P.P TenseDocumento7 páginasChallengue 2 Simpe P.P TenseAngel AngelAinda não há avaliações

- PNP P.A.T.R.O.L. 2030 Score Card Dashboard FormulationDocumento89 páginasPNP P.A.T.R.O.L. 2030 Score Card Dashboard FormulationMark Payumo83% (41)

- John R. Van Wazer's concise overview of phosphorus compound nomenclatureDocumento7 páginasJohn R. Van Wazer's concise overview of phosphorus compound nomenclatureFernanda Stuani PereiraAinda não há avaliações

- James A. Mcnamara JR.: An Interview WithDocumento22 páginasJames A. Mcnamara JR.: An Interview WithMiguel candelaAinda não há avaliações

- Second Periodic Test - 2018-2019Documento21 páginasSecond Periodic Test - 2018-2019JUVELYN BELLITAAinda não há avaliações

- Unit 11 LeadershipDocumento4 páginasUnit 11 LeadershipMarijana DragašAinda não há avaliações

- Module 1 Ba Core 11 LessonsDocumento37 páginasModule 1 Ba Core 11 LessonsLolita AlbaAinda não há avaliações

- Transmission Pipeline Calculations and Simulations ManualNo EverandTransmission Pipeline Calculations and Simulations ManualNota: 4.5 de 5 estrelas4.5/5 (10)

- To Engineer Is Human: The Role of Failure in Successful DesignNo EverandTo Engineer Is Human: The Role of Failure in Successful DesignNota: 4 de 5 estrelas4/5 (137)

- Matrix Methods for Advanced Structural AnalysisNo EverandMatrix Methods for Advanced Structural AnalysisNota: 5 de 5 estrelas5/5 (1)

- Pile Design and Construction Rules of ThumbNo EverandPile Design and Construction Rules of ThumbNota: 4.5 de 5 estrelas4.5/5 (15)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsAinda não há avaliações

- Offshore Pipelines: Design, Installation, and MaintenanceNo EverandOffshore Pipelines: Design, Installation, and MaintenanceNota: 4.5 de 5 estrelas4.5/5 (2)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingAinda não há avaliações

- Building Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareNo EverandBuilding Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareNota: 4.5 de 5 estrelas4.5/5 (15)

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsNo EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsNota: 4 de 5 estrelas4/5 (16)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsNo EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsAinda não há avaliações

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesNo EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraNota: 4.5 de 5 estrelas4.5/5 (4)

- Concrete Structures: Repair, Rehabilitation and StrengtheningNo EverandConcrete Structures: Repair, Rehabilitation and StrengtheningAinda não há avaliações

- Topology Design Methods for Structural OptimizationNo EverandTopology Design Methods for Structural OptimizationNota: 2 de 5 estrelas2/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresNo EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresNota: 1 de 5 estrelas1/5 (2)

- Computational Rheology for Pipeline and Annular Flow: Non-Newtonian Flow Modeling for Drilling and Production, and Flow Assurance Methods in Subsea Pipeline DesignNo EverandComputational Rheology for Pipeline and Annular Flow: Non-Newtonian Flow Modeling for Drilling and Production, and Flow Assurance Methods in Subsea Pipeline DesignNota: 3.5 de 5 estrelas3.5/5 (2)