Escolar Documentos

Profissional Documentos

Cultura Documentos

Is 2002 2009

Enviado por

pitoulabeteDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Is 2002 2009

Enviado por

pitoulabeteDireitos autorais:

Formatos disponíveis

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 2002 (2009): Steel plates for pressure vessels for

intermediate and high temperature service including

boilers [MTD 4: Wrought Steel Products]

IS 2002:2009

amtil@wTadwr?

($fjfr

3@9-)

Indian Standard

STEEL PLATE FOR PRESSURE VESSEL FOR

INTERMEDIATE AND HIGH TEMPERATURE SERVICE

INCLUDING BOILERS

( Third Revision

ICS 77. 140.30; 77.140.50

@ BIS 2009

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

March 2009 Pried Group 4

Wrought Steel Products Sectional Committee, MTD 4

FOREWORD

This Indian Standard (Third Revision) was adopted by the Bureau of Indian Standards, after thedraft finalized

by the Wrought Steel Products Sectional Committee had been approved by the Metallurgical Engineering Division

Council.

This standard was first published in 1962 and subsequently revised in 1982 and 1992. While reviewing this

standard, in the light of experience gained during these years, the Committee decided to revise it to bring.in line

with the present practices being followed by the Indian industry and ovmeas statidards of hot rolled steel plates

for pressure vessels including boilers. .

In this revision the ,following changes have &en made ~ ~

a)

b)

c)

d)

e)

f)

Clauses on scope, terminology, manufacture, heat treatment, tolerances, tensil,e test and re-tests have

. been modified;

Definitions of Normalizing and Normalizing Rolling have been added;

Amendment Nos. 1, 2, 3 and 4 have been incorporated;

A new clause on references has been incorporated;

Requirements of tolerances on dimensions and shape has been added and adopted 1S0 7452:2002

Hot-rolled structural steel plates Tolerances on dimensions and shape; and

Figure for position of test strips in rolled plates has been deleted.

For the tests specified in this standard (chemical/ physical/ others), the method as specified in the relevant 1S0

Standard may also be followed as an alternate method.

The composition of the Committee responsible for formulation of this standard is given in Annex A.

For the purpose of deciding whether a particular requirement of this standard is complied with, the final value,

observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance with IS 2:1960

Rules for rounding off numerical values (revised). The number of significant places retained in the rounded off

value should be the same as that of the specified value in this standard.

AMENDMENT NO. 1 NOVEMBER 2012

TO

IS 2002 : 2009 STEEL PLATE FOR PRESSURE VESSEL

FOR INTERMEDIATE AND HIGH TEMPERATURE

SERVICE INCLUDING BOILERS

(1hird Revision)

( 3, 9.3) Substitute the Iollowing Ior the existing clause:

9.3 Rolling Mass

Permissible upper deviation Irom the theoretical mass shall comply to Table 2.

Whereas, the permissible lower deviation shall be calculated based on the

negative tolerance on the thickness as per 9.1.`

(MTD 4)

Reprography Unit, BIS, New Delhi, India

IS 2002:2009

Indimz Standard

STEEL PLATE FOR PRESSURE VESSEL FOR

INTERMEDIATE AND HIGH TEMPERATURE SERVICE

INCLUDING BOILERS

( Third Revision)

1 SCOPE

This standard covers the requirements of plain carbon

steel plates produced in discrete cut lengths of flat

product or plates that have been leveled and flatlencd

and cut to length from a coiled product. These plates

are intended for use in pressure vessels for intermediate

and high temperature service which include boilers.

Plates under this standard are available in three grades

as follows:

a)

b)

c)

Grade I Low tensile steel plates for fire

boxes and boiler plates which require welding,

flanging or flame cutting;

Grade 2 Medium tensile plates which can

be used for welding, flanging and flame

cutting; and

Grade 3 High tensile steel plates which

can be used for welding, flame cutting, and

hot flanging under controlled conditions.

~ REFERENCES

The following standards contain provisions which

through reference in this text, constitute provisions of

this stanciard. At the time of publication, the editions

indicated were valid. All standards are subject to

revision and parties to agreements based on this

standard are encouraged to investigate the possibility

of applying the most recent editions of the standards

indicated below:

IS No.

~z~ (relevant

parts)

1599:1985

1608:2005

1956 (Part 4):

1975

4225:2004

4748:1988

Title

Methods of chemical analysis of steel

Method for bend test (second

revision)

Metallic materials Tensile [.esting

at ambient temperature (third

revision)

Glossary of terms relating to iron and

steel: Part 4 Steel sheet and strip

Recommended practice for stmight

beam ultrasonic testing of steel plates

(second revision)

Methods for estimating average grain

size of metals (@t revision)

IS No. 71tle

8910:1978 General technical delivery require-

ments for steel and steel products

12457:1988 Code of practice for evaluation,

repairs and acceptance limits of

surface defects in steel plates and

wide flats

EVISO 7452: Hot-rolled structural steel plates

2002 Tolerances on dimensions and shape

3 TERMINOLOGY

For the purpose of this standard, the following

definitions in addition to those given in IS 1956 (Part 4)

shall apply.

3.1 Plate as Rolled This term refers to the unit plate

(5 mm thick and above) as rolled from the slab or

directly from an ingot, in its relation to the location

and number of specimens, and not to its condition.

Plates produced from coil means the plates which have

been levelled or flattened and cut to length.

3.2 Normalizing It is a heat treating process in

which a steel plate is reheated to a uniform temperature

above the upper critical temperature and then cooled

in air to below the transformation range.

3.3 Normalizing Rolling A hot rolling process in

which the final rolling passes are carried out at a

suitable higher temperature, followed by cooling in

natural air to a temperature below the transformation

temperature, in order to produce a structure, analogous

to that obtained by a separate normalizing treatment

of hot rolIed product.

4 GENERAL REQUIREMENTS

General requirements relating to the supply of steel

plates for pressure vessels shall conform to IS 8910.

5 MANUFACTURE

5.1 Steel shall be manufactured by any process of steel

making except Bessemer process. It may be followed

by secondary refining or secondary vacuum treatment.

5.1.1 The steel shall be fully killed and made to coarse

grain practice.

I

IS 2002:2009

5.1.2 The material shall have acarburized austenitic

grain size number in the range 1 to 5 as determined by

the carburizing method specified in IS 4748. However,

the above grain size requirement shall he deemed as

fulfilled if, on ladle analysis, the total aluminium

content is not more than 0.020 percent.

5.1.3 The plates are produced in either discrete cut

lengths of flat product or from coils.

6 CHEMICAL COMPOSITION

6.1 The ladle analysis of the material, when carried

out either by the method specified in the relevant parts

of IS 228 or any other established instrumental/

chemical method shall be as given in Table 1. In case

of dispute the procedure given in IS 228 and its relevant

parts shall be the referee method.

6.2 Permissible variation in case of product analysis

from the limits specified in 6.1 shall ix as follows:

Constituent Variation Over the Specified

Maximum or Under the Minimum

Limits Percent

(1) (2)

Carbon 0.03

Silicon 0.03

Sulphur 0.005

Phosphorus 0.005

Manganese 0.05

NOTE Variation shall be applicable both over and under

the specified limits in several determinations in a heat.

7 HEAT TREATMENT

7.1 Unless specified otherwise, plates shall be supplied

in normalized condition/controlled rolled condition.

7,2 Subject to agreement between the purchaser and

the manufacturer, normalizing may be replaced with

normalizing rolling process.

7.3 Plate in coiled form rolled under controlled rolling

condition in a hot strip mill and straightened by

ievelling as plates up to ~2 mm thickness are considered

self normalized and accepted as-rolled condition.

8 FREEDOM FROM DEFECTS

8.1 The plates shall be rolled to the dimensions

specified. The material shall be free from harmful

defects. Scale pits am! other minor surface defects may

be removed by grinding. The depth of grinding being

such that the thickness of the plate shall not go below

the specified value at the spot where the dressing is

done. The grinding shall be even and smooth and shall

be widened enough to remove sharp ridges. Dressing

with a hammer or welding of defective spots shall not

be permitted.

8.2 Edge imperfection may be rectified subject to

mutual agreement between the purchaser and the

manufacturer.

8.2.1 Laminar type discontinuities, 25 mm and less in

length and visible to the unaided eye on the edges of

plate, as prepared for shipment by the manufacturer

are acceptable and do not require exploration.

Table 1 Chemical Composition

(Clause 6.1 )

SI Grade Carbon Manganese Silicon Sulphur Phosphorus

No. Percent Percent Percent Percent Percent

Max Max Max Max

(1) (2) (3) (4) (5) (6) (7)

i)

1 0.18 0,50-1.20 0.15-0.35 0.040 0.035

ii) 2 0.20 0.50-1.20 0.15-0.35 0.040 0.035

iii) 3 0.22 0,50-1.20 0. I 5-0.35 0.040 0.035

NOTES

1 Carbon content over the maximum specified shall be increased by:

a) For plates over 25 mm up to and including 65 mm thick 0.02 percent Max; and

b) For plates over 65 mm thick 0.04 percent Max.

2 Total aluminium content shall not exceed 0.020 percent for all thicknesses.

3 Nitrogen content, shall not exceed 0.012 percent. This should be ensured by the manufacturer by occasional check analysis.

4 Residual copper shall not exceed 0.10 percent.

5 Whenever any alloying elements are added for achieving strength, maximum carbon equivalent shall not exceed 0.44 for steels

used f>r welding.

Carboh equivalent (CE) based on ladle analysis:

C + Mn Cr+Mo+V Ni+Cu

CE=

6+5+ 15

2

1

8.2.2 All larger discontintrities shall be explored to

determine their depth and extent. Discontinuities shall

be considered continuous when located in the same

plate within 5 percent of the plate thickness and

separated by a distance less than the length of the

smaller of two adjacent discontinuities.

8.2.3 Repair by Welding

Repair welding shall be permitted only with the

approval of the purchaser. Preparation for repair

welding shall include inspection to assure complete

removal of the defect. Repair if permitted shall be done

as per IS 12457.

9 DIMENSIONS AND TOLERANCES,

9.1 Unless otherwise agreed the dimensional tolerances

for hot-rolled steel sheet shall be as given in

IS/fSO 7452.

9.2 Unless otherwise agreed the restricted thickness

tolerances shall be as given in 1S/1S0 7452.

9.3 Rolling Mass

Permissible deviation from the theoretical mass shall

comply to Table 2.

10 CALCULATION OF MASS

The mass of plate shall be calculated on the basis that

steel weighs 7.85 g/cm~.

11 SELECTION OF TEST SAMPLES

11.1 For plates produced from plate mill, one test

IS 2002:2009

sample shall be taken from corner of each plate as-

rolled in transverse to the rolling direction.

11.2 For plates produced from coils one sample from

each coil should be drawn. All the plates produced from

the coil are acceptable if the sample meets the

requirements of the specification. The size of the

sample should be such that a retest specimen, if

necessary, may be prepared from it,

12 TENSILE TEST

12.1 Test sample shall be selected as per 11.

12.2 The tensile strength, yield stress and percentage

elongation, when determined in accordance with

1S 1608, shall conform to the requirements specified

in Table 3.

12.2.1 The rolled surfaces shall be retained on the two

opposite faces of the test piece where practicable. If

the test specimen has to be reduced in thickness for

testing purposes, at least one surface should be as

rolled. For plates over 20 mm in thickness, round

specimens are permitted, where the axis of the

specimen shall be located, as nearly as possible,

midway between the centre of the thickness and top or

bottom surface of the plate.

12.2.2 Should the test piece break outside the middle

half of the gauge length and the percentage elongation

is less than that specified, the test may be discarded at

the option of the supplier and another test made from

the same test sample.

12.3 Subject to mutual agreement between the

Table 2 Permissible Upper Deviation from the Theoretical Mass

(The Values Shown in the Table Apply to Consignments Weighing 25 tonne,

Up to but not Including 75 tonne)

(Clause 9.3)

Nominal Permissible Upper Permissible Upper Deviation from the Theoretical Weight in Percentage for

Thickness Deviation Nominal Width

mm from the Nominal mm

Thickness

From Up to but

mm

From 600 From 2000 From2500 From3000 From

not up to but Up to but UP to but Up to but 3500

Including not Including not Including oot Including not Including up to

2000 2500 3000 3500 4000

(1) (2) (3) (4) (5) (6) (7)

(8)

5 8 1.1 7 7.5 8.5 9

8 15 1.2 6 6 6.5 7 7.5

15 25 I .3 45 4.5 5 5 5.5

25 40 1.4 3.5 3.5 4 4 4

40 80 1.8 3.5 3.5 4 4 4

80 150 2.2 3.5 3.5 3.5 3.5 3.5

including

Over I 50 To be agreed between the supplier and tbe purchaser

3

IS 2002:2009

Table 3 Mechanical Properties

(Clause 12.2)

Grade Tensile Strength Yield Stress 0/0 Elongation on

Thickness MPa MPa, &fin Gange Length

II I

60 60 to 100 100 to 350 s 16 >16to >40 to >60 to 100 to z 60 >60 to

40 60 100 350 350

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11)

1 360-480 360-480 350-480 235 225 215 200 185 24 23

2 410-530 410-530 400-530 265 255 245 215 200 22 21

3 460-580 450-570 440-570 290 285 280 255 230 21 20

purchaser and the supplier, the supplier shall guarantee

the required yield stress at any higher temperature (E,).

12.3.1 The plate manufacturer should satisfy the boiler

maker and his representative that the steel supplied is

capable of meeting the value (Et).

a) By producing adequate record of test results

on the type of steel concerned; and

b) By showing that the steel supplied actually

conforms to the requirements by ladle analysis

and by a statement that, the manufacturing

process has remained comparable; or In

absence of data mentioned in (a) i) by proof

stress test at the design temperature stated on

the individual order.

NOTES

1 By special arrangement between the plate manufacturer

and the boiler maker and/or his representative, proof stress

test may be required for the individual order.

2 For all steels (Carbon):

a) When the steel maker has collected a sufficient number

of tests for application to a statistical definition of E,,

on the grade of steel; E, should be equal to the average

value of the test results at temperature r less two

standard deviation.

b) When a sufficient number of test results are not

available E, should be taken as a minimum value

guaranteed by the steel maker which should be checked

at the time of acceptance. For carbon steels the value

of the proof stress given by the ratio EJR2{)(taken from

Table 4) may be taken without verification at the time

of acceptance.

13 BEND TEST

13.1 Test samples shall be selected as per 11.

13.2 The bend test shall be carried out in accordance

with IS 1599.

13.2.1 The test piece shall be about 230 mm long and

not less than 40 mm wide. The test piece, when cold,

shall withstand without fracture being bent over

through 180 either by pressure or by slow and steady

blows from a hammer till the internal diameter is not

greater than twice the thickness of the test piece in the

case of Grade 1 and Grade 2 plates and three times the

thickness of the test piece in the case of Grade 3 plates.

13.2.2 During the test, the rolled surface shall be on

the tension side.

14 HOMOGENEITY TEST (FOR GRADE 1

PLATE FOR FIRE BOXES ONLY)

14.1 The object of this testis to open and render visible

to the eye any internal defect in the steel, like blow

holes, inclusions, etc. The test shall be done at the rate

of one test per cast.

14.2 One test piece 230 mm long and not less than

40 mm wide, shall be prepared as given under 13.2.1.

For plates 20 mm and under in thickness, the test piece

shall be nicked or grooved, about 1.5 mm deep,

transversely in three places at 50 mm intervals starting

at 50 mm from one end. The first and third grooves

shall be on one face and the middle one on the opposite

face. For plates over 20 mm in thickness, the grooves

shall be about 3 mm deep. The test piece shall be broken

at each groove by hammering or by pressing.

14.3 The fracture shall be clean and shall not show

any seam, lamination, blow holes or inclusions more

than 6 mm in length in the case of plates 20 mm and

under in thickness and not more than 10 mm in length

in the case of plates over 20 mm in thickness.

14.4 Three typical photographs (Fig. 1, 2 and 3)

showing boiler plates of 10 mm thickness indicating

acceptance and unacceptable limits are given below

for guidance only.

15 ULTRASONIC TESTING (25 MM THICK

AND ABOVE)

15.1 If agreed between the manufacturer and consumer,

plates (25 mm thick and above) shall be tested for

ultrasonic testing in accordance with IS 4225 for

internal soundness.

15.2 Acceptance Standards

15.2.1 Any discontinuity indication causing a total 10SS

4

IS 2002: 2009

FIG. 1 PHOTOGRAPH 0F30mm THICK PLATE sHOWING FRACTURE wITHOUT ANY DEFECT -ACCEPTABL

E

FIG. 2 PHOTOGRAPH OF 30 mm THICK PLATE SHOWINGFRACTUREWITHPERMISSIBLE

FIG. 3 PHOTOGRAPHOF 40 mm THICK PLATE SHOWINGPRESENCEOF LAMINATION NOT ACCEPTABLE

5

IS 2002:2009

Table 4 Minimum Values for the Ratio of the Stress at Proof Limit 0.2 Percent

at Elevated Temperature (EJ to the Minimum Specified Tensile Strength

at Room Temperature ( R ) of Carbon Steel Boiler Plates

[Clause 12.3.1 (Note 2)]

Temperature, C 250 275 300 325 350 375 400 425

(see Note)

EJ RIQ 0.40 0,38 0.36 0.34 0.33 0.32 0.31 0.30

NOTE For temperature lower than 300C, any test required for acceptance purposes (in default of records of previous tests at

these temperatures) should be made at 300C in which cme the proof stress should be not less than the value obtained by calculation

from the specified minimum tensile strength,

of back reflection which cannot be contained within a

circle of, the diameter of which is 75 mm or one half

of the plate thickness, whichever is greater is

unacceptable.

15.2.2 Acceptable adjacent discontinuity indications

shall be separated from each other by a distance equal

to or larger than the larger of the adjacent discontinuity

indications unless the adjacent defects can be contained

in a circle of diameter equal to the acceptance standard

for a single defect.

15.3 Supplementary Requirements

Supplementary requirements if any, will be specified

in the purchase order.

16 OTHER TESTS

Any test other than those specified above, may be

agreed upon at the time of inquiry and order.

17 RE-TESTS

If a test does not give the specified results, two additional

tests shall be carried out at random on the same lot.

Both re-tests shall conform to the requirements of this

standard, otherwise, the lot shall be rejected.

18 RUST PROTECTION

If so desired by the purchaser, each plate shall be

painted with one coat of boiled linseed oil or a suitable

rust preventive material (as agreed to between the

supplier and the purchaser) after inspection and

acceptance.

19 TOLERANCES ON DIMENSIC)NS AND

SHAPE

Unless otherwise agreed the tolerances on dimensions

and shape shall be as given in 1S/1S0 7452.

20 MARKING

20.1 Every plate shall be legibly marked with the

following:

a) Manufacturers name or trade-mark, if any;

b) Cast number or identification mark by which

the steel can be traced to the cast from which

it was made and Plate number so that

correlation with T.C. is possible; and

c) Direction of final rolling.

20.2 BIS Certification Marking

The material may also be marked with the Standard

Mark.

20,2.1 The use of the Standard Mark is governed by

the provisions of the Bureau of Indian Standards Act,

1986 and the Rules and Regulations made thereunder.

The details of conditions under which the licence for

the use of the Standard Mark may be granted to

manufacturers or producers may be obtained from the

Bureau of Indian Standards

IS 2002:2009

ANNEX A

(Foreword)

COMMITTEE COMPOSITION

Wrought Steel Products Sectional Committee, MTD 4

Orgunizaf ion

Tata Steel Ltd. Jamshedpur

Representative(s)

DR D. BHAITACHRJIX(CJsairaran)

SHRI INORANILCHAKRABORTY (Alternate I)

DR A. N. BHAG/ir (A/tema~e11)

AH India Induction Furnace Association, New Delhi

Bharat Heavy Electrical Ltd. Tiruchirapalli

Central Boilers Board, New Delhi

DGS& D, Bhilai Nagar/Delhi

Escorts Knowledge Management Centre, Faridabad

Essar Steels Ltd, Hazira

SHRI R. P. VARSHNEY

SHRI V. RAJASEKHARAN

REPRESENTATIVE

SHRI ALOK NAYAR

DR A, K. DAS

SHRI R. K. BALASUBRAMANIAM (Alternate)

DR R. K. P. SINGH

SHRI JAYANTAKUMARSAHA(Alternate)

Institute of Steel Development and Growth, Kolkata

Jindal South West Ltd. Vasind

M. N. Dastur & Co Ltd. Kolkata /Delhi

SHRI M. K. MAHELSHWARI

SHRI SUBHABRATASF.NGUPTA

SHRI V. K. TYAGI(Alternate)

SHRI P. S. BANDHOPADHYAY

SHRI T. BASU (Alternate)

Ministry of Defence (DGOFB), Kolkata

Ministry of Defence (DGQA), Ichapur SHRI S. K. KHILNANEY

SHRI P. MEENA(Ahernafe)

Ministry of Railways (RDSO), Lucknow SHRI RADHEYSHAM

SHRI R. K. NAYYAR(Alternate)

SHIUA. C. R. DAS

SHRi B. D. GHOSH(Alfernate)

Ministry of Steel (Government of India), New Delhi

Powergrid Corporation of India Ltd, Gurgaon

Rashtriya Ispat Nigam Ltd (VSP), Vkhakhapatnam

REPRESENTATIVE

SHRI P. K. S~N

SHRI P. SRINIVAS(Alternate)

SHRI S. BHAITACHARYA

SHRI P. K. DATrA(Alrernafe)

SAIL, Bhilai Steel Plant, Bhilai

SAIL, Bokaro Steel Plant, Bokaro

DR M. M. S. SODHI

SHRI P. S. REDDY(Alternate)

SAIL, Central Marketing Organization, Kolkata

SHRI P. C. JHA

Ssrrrt B. V. S. PANDIT(Alternate)

SHRI A. KANAN

SAIL, Durgapur Steel Plant, Durgapur

SAIL, IISCO Steel Plant, Burnpur

SAIL, Research & Development Centre for Iron & Steel, Ranchi

SHRI A. K. SINGH

DR RAMENDATTA

DR B. K. JHA (Alternate)

SHRIC. hftSTHUSWAMY

SHRI S. MUKHOPADHYAYA (Ahernare)

SAIL, Rourkela Steel Plant, Rourkela

Steel Furnace Association of India, New Delhi

Steel Re-rolling Mills Association of India, Mandi Gobindgarh

REPRESENTATIVE

SHRI B. M. BERIWALA

COL SURINDERSINGH(Alternate)

TCE Consulting Engineers, Jamshedpur

Tata Motors Limited, Pune

DR M. D. MAHESHWARI

SHRI B. R. GALGALI

7

F

IS 2002:2009

Organization

Representative(s)

In personal capacity [403, Udaigiri, Kausharnbi, Disrt Gksziabad

SHRI N. MITRA

(u. /?)]

BIS Directorate General

DR(SHJUMATI)SN~HBHAm.A, Scientist Fand Head(MTD)

[Representing Director General (Ex-oficio)]

Member Secretary

SHRI DM:PAKJAIN

Scientist E (Director) (MTD), BIS

Flat Steel Products Subcommittee, MTD 4:3

TCE Consulting Engineers, Jamshedpur

DR M. D. MAHESHWAR[ (Convener)

Apex Chambers of Commerce, Lrsdhiana

SHRI 1? D. SHARMA

Bhushtm Power and Steel Ltd, Hooghly

t%R1 P. S. PAU1.

Federation of Engineering Industries of India, hlew Delhi

SHRI H. L. BHARrJWAJ

Stnu H. L. BANSAI.(Ahernute)

Indian Oil Corporation Limited. Noida

SHIU M. K. JHA

SHRJT. BANDHOPAOHYAY(A/fernate)

[spat Industries Limited, Dolvi

SHRI RAMJSJUKSHSIN~H

SHKI RAJ~N~~RAK. V~JtMA(Alfernate)

SAIL, Bhilai Steel Plant, Bbilai

SAIL, Salem Steel Plant, Salem

Tata Blue Scope Steel Ltd, Pune

Tata Steel Ltd, Jamshedpur

The Tln Plate Company of India Ltd, Jamshedpur

Tbyssenkrupp Electrical Steel India Pvt Ltd. Nasik

SHIUA. DASCWPIA

SHRI K. L. BAi.ASUI~RAMANIAN (Alternate)

SHRI S, S. SISOOIA

SHRI H. K. AROItA(Abernafe)

SHRI RAJ~SHMAHESHWARI

DR N. GoPt;

SHRI M. SHOML(AUernufe)

SHRI T. K. GHOSH

SHRI A. K. GHOSH(Ahernate)

SI~RIJ. SRINJVAS

SHRI KAPU KAPOOR(Aherntsfe)

8

MGIPF%3DeDtt. ofBISiOS-27-2J3%300Bcoks

Bureau of Indian Standards

1

BIS is a statutory institution established under the Bureau of /ndian Standards Act, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods

and attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permission in writing of BIS. This does not preclude the free use, in the course of

implementing the standard, of necessary details, such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of

BIS Catalogue and Standards: Monthly Additions.

This Indian Standard has been developed from Dot: No. MTD 4 (4733).

Amendments Issued Since Publication

Amend No. Date of Issue Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters :

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002 Telegrams : Manaksanstha

Telephones :23230131,23233375,2323 9402 (Common to all offices)

Regional Offices: Telephone

Central :

Eastern :

Northern :

Southern :

Western :

Branches :

Manak Bhavan, 9 Bahadur Shah Zafar Marg

{

23237617

NEW DELHI 110002 23233841

1/14 C.I.T. Scheme VII M, V. I. P. Road, Kankurgachi

{

23378499,23378561

KOLKATA 700054 23378626,23379120

SCO 335-336, Sector 34-A, CHANDIGARH 160022

{

2603843

2609285

C.I.T. Campus, IV Cross Road, CHENNAI 600113

{

22541216,22541442

22542519,22542315

Manakalaya, E9 MIDC, Marol, Andheri (East)

{

28329295,28327858

MUMBAI 400093 28327891,28327892

AHMEDABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE. FARIDABAD.

GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR.

PARWANOO. PATNA. PUNE. RAJKOT. THIRUVANANTHAPURAM.

Printed by the Manager, Govt. of India Press, Faridabad

VISAKHAPATNAM.

Você também pode gostar

- Astm E45 PDFDocumento19 páginasAstm E45 PDFGaurav100% (6)

- Heat Resitant Steel Castings MaterialsDocumento2 páginasHeat Resitant Steel Castings MaterialssusisaravananAinda não há avaliações

- CRISP - Novel Hatch Steelmaking ProcessDocumento10 páginasCRISP - Novel Hatch Steelmaking ProcessSobu GeorgeAinda não há avaliações

- Astm A234 PDFDocumento8 páginasAstm A234 PDFhans30Ainda não há avaliações

- Preventing Scale Loss During Heat Treatment & Hot Forging - With ImagesDocumento17 páginasPreventing Scale Loss During Heat Treatment & Hot Forging - With ImagesSrikar Shenoy100% (1)

- Stainless Steel Grades 2008 01 PDFDocumento2 páginasStainless Steel Grades 2008 01 PDFRahul LavandAinda não há avaliações

- SAE J434 1986 Automotive Ductile Iron Castings Nodular Iron CastingsDocumento10 páginasSAE J434 1986 Automotive Ductile Iron Castings Nodular Iron Castingsvinicius_bacellarAinda não há avaliações

- X65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Documento2 páginasX65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Jim SmithAinda não há avaliações

- Topic 1.2 Analytical ProcessDocumento52 páginasTopic 1.2 Analytical ProcessEyzah75% (8)

- Stainless Steel GX4CrNi13-4 Material Data SheetDocumento5 páginasStainless Steel GX4CrNi13-4 Material Data SheetAlex007Ainda não há avaliações

- A1028-03 (2015) Standard Specification For Stainless Steel Bars For Compressor and Turbine AirfoilsDocumento4 páginasA1028-03 (2015) Standard Specification For Stainless Steel Bars For Compressor and Turbine Airfoilstjt4779Ainda não há avaliações

- JBT6396 2006 (English Version)Documento18 páginasJBT6396 2006 (English Version)Anonymous l5yF0VAinda não há avaliações

- A 732/a732m-02Documento8 páginasA 732/a732m-02mutluAinda não há avaliações

- Product Catalog: Your Formula For SuccessDocumento70 páginasProduct Catalog: Your Formula For Successtotamtam8339Ainda não há avaliações

- A 646 PDFDocumento6 páginasA 646 PDFGustavo SuarezAinda não há avaliações

- Aerospace Material SpecificationDocumento6 páginasAerospace Material Specificationvsraju2Ainda não há avaliações

- Old and New DINDocumento6 páginasOld and New DINDianaAinda não há avaliações

- Aisi 4340 Alloy Steel (Uns g43400)Documento4 páginasAisi 4340 Alloy Steel (Uns g43400)Muhamad Ikbal TrismanaAinda não há avaliações

- 8630Documento24 páginas8630sunsirAinda não há avaliações

- 8 Wear Testing - ASTM G65 PDFDocumento1 página8 Wear Testing - ASTM G65 PDFyamenAinda não há avaliações

- Heat Treatment: Prepared by Approved byDocumento20 páginasHeat Treatment: Prepared by Approved byBhanu Pratap ChoudhuryAinda não há avaliações

- Aa10208 FINAL - 1Documento139 páginasAa10208 FINAL - 1Surendra MalasaneAinda não há avaliações

- Iso 4948 2 en PDFDocumento6 páginasIso 4948 2 en PDFKalpeshAinda não há avaliações

- A723A723M-18a 1.05 PDFDocumento5 páginasA723A723M-18a 1.05 PDFist93993Ainda não há avaliações

- Correlation of Hardness Values To Tensile Strength: Semih Genculu, P.EDocumento9 páginasCorrelation of Hardness Values To Tensile Strength: Semih Genculu, P.ERakesh DasAinda não há avaliações

- 13-8 MoDocumento2 páginas13-8 MofedaquiAinda não há avaliações

- ASTM A159 - Standard Specification For Automotive Gray Iron CastingsDocumento2 páginasASTM A159 - Standard Specification For Automotive Gray Iron Castingsjaskaran singhAinda não há avaliações

- Din 24540-2Documento6 páginasDin 24540-2Lucian DragosAinda não há avaliações

- About En19Documento1 páginaAbout En19ramanamurtytv7176Ainda não há avaliações

- Aisi 4140 Alloy Steel (Uns g41400)Documento3 páginasAisi 4140 Alloy Steel (Uns g41400)diogolabegAinda não há avaliações

- Astm A 668 A668m 2013 PDFDocumento10 páginasAstm A 668 A668m 2013 PDFCarlos GuerraAinda não há avaliações

- Din 24540-1Documento8 páginasDin 24540-1Lucian DragosAinda não há avaliações

- Din 10140Documento3 páginasDin 10140Diego CamargoAinda não há avaliações

- A 487Documento6 páginasA 487arockia1977100% (2)

- Aerospace Material SpecificationDocumento6 páginasAerospace Material SpecificationAnonymous T6GllLl0Ainda não há avaliações

- Electric Arc and Ladle Furnaces PDFDocumento27 páginasElectric Arc and Ladle Furnaces PDFrodolfo_tome8275Ainda não há avaliações

- Din en 10132-4Documento14 páginasDin en 10132-4Guilherme MendesAinda não há avaliações

- Induction Hardening PDFDocumento9 páginasInduction Hardening PDFkapilparyaniAinda não há avaliações

- Ductile IronDocumento159 páginasDuctile IronPrabhakar KattulaAinda não há avaliações

- Grey Cast Iron CompareDocumento4 páginasGrey Cast Iron CompareagustingrtAinda não há avaliações

- A597 Standard Specification For Cast Tool Steel1Documento2 páginasA597 Standard Specification For Cast Tool Steel1tsliaAinda não há avaliações

- ASTM E 140 FOR Standard Hardness Conversioin Table PDFDocumento21 páginasASTM E 140 FOR Standard Hardness Conversioin Table PDFFabian Armando Barragan RamirezAinda não há avaliações

- Typical Casting DefectsDocumento16 páginasTypical Casting DefectsSeah Ying ZhiAinda não há avaliações

- AISI 4340 NitridingDocumento8 páginasAISI 4340 NitridingVlad Craciun100% (1)

- 11 CR-CB Data SheetDocumento2 páginas11 CR-CB Data SheetJLZ972Ainda não há avaliações

- Inconel 625 Alloy Guide: Composition, Properties & UsesDocumento3 páginasInconel 625 Alloy Guide: Composition, Properties & UsesalokbdasAinda não há avaliações

- Morflo 170Documento2 páginasMorflo 170baselAinda não há avaliações

- A 915 - A915m - 93 R98 Qtkxns05m1i5oa - PDFDocumento3 páginasA 915 - A915m - 93 R98 Qtkxns05m1i5oa - PDFMung Duong XuanAinda não há avaliações

- Incoloy 901 PDFDocumento14 páginasIncoloy 901 PDF孙俊磊Ainda não há avaliações

- Cast Iron StandardsDocumento2 páginasCast Iron StandardsBao Duy NguyenAinda não há avaliações

- ASTM A192, ASME SA192 American StandardDocumento1 páginaASTM A192, ASME SA192 American StandardXamir Suarez AlejandroAinda não há avaliações

- Jis G4053-2008 PDFDocumento14 páginasJis G4053-2008 PDFhbook100% (1)

- 18 Ni CR Mo 5Documento2 páginas18 Ni CR Mo 5lavius_mAinda não há avaliações

- A New Role For Microalloyed SteelsDocumento11 páginasA New Role For Microalloyed SteelsMuhammed SulfeekAinda não há avaliações

- Equivalent Grades of Gray Iron, Ductile Iron, SG Iron, Nodular Graphite IronDocumento2 páginasEquivalent Grades of Gray Iron, Ductile Iron, SG Iron, Nodular Graphite IronBao Duy Nguyen100% (3)

- Stellite 6Documento3 páginasStellite 6Jessicalba LouAinda não há avaliações

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocumento4 páginasSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsSriniramu SriniramuAinda não há avaliações

- Is.10748.2004 0 PDFDocumento13 páginasIs.10748.2004 0 PDFPinku100% (3)

- Disclosure To Promote The Right To InformationDocumento22 páginasDisclosure To Promote The Right To InformationVoyants Solution pvt. ltd.Ainda não há avaliações

- IS:2002Documento14 páginasIS:2002Madhavi YerurAinda não há avaliações

- Is 8110 2000Documento23 páginasIs 8110 2000Sidharth SinghAinda não há avaliações

- Test Certificate Meft: Peenya - BangaloreDocumento1 páginaTest Certificate Meft: Peenya - BangaloreK.s. Raghavendra KumarAinda não há avaliações

- Test Certificate Meft Peenya - BangaloreDocumento1 páginaTest Certificate Meft Peenya - BangaloreK.s. Raghavendra KumarAinda não há avaliações

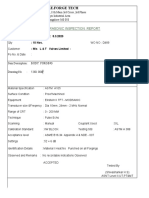

- M.E.Forge Tech: Ultrasonic Inspection ReportDocumento1 páginaM.E.Forge Tech: Ultrasonic Inspection ReportK.s. Raghavendra KumarAinda não há avaliações

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocumento1 páginaM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarAinda não há avaliações

- Mpi D212Documento1 páginaMpi D212K.s. Raghavendra KumarAinda não há avaliações

- Revised Asme Items: SL - No PO No. Material No. Po. SL No. WO. No Material Qty InspectionDocumento1 páginaRevised Asme Items: SL - No PO No. Material No. Po. SL No. WO. No Material Qty InspectionK.s. Raghavendra KumarAinda não há avaliações

- M.E.Forge Tech: Ultrasonic Inspection ReportDocumento1 páginaM.E.Forge Tech: Ultrasonic Inspection ReportK.s. Raghavendra KumarAinda não há avaliações

- Test Certificate Meft Peenya - BangaloreDocumento1 páginaTest Certificate Meft Peenya - BangaloreK.s. Raghavendra KumarAinda não há avaliações

- M.E.Forge Tech: Ultrasonic Inspection ReportDocumento1 páginaM.E.Forge Tech: Ultrasonic Inspection ReportK.s. Raghavendra KumarAinda não há avaliações

- Weight Witness Report-D212Documento1 páginaWeight Witness Report-D212K.s. Raghavendra KumarAinda não há avaliações

- Mpi D212Documento1 páginaMpi D212K.s. Raghavendra KumarAinda não há avaliações

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocumento1 páginaM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarAinda não há avaliações

- Mechanical Test Report for TUN 400 MachineDocumento2 páginasMechanical Test Report for TUN 400 MachineK.s. Raghavendra KumarAinda não há avaliações

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocumento1 páginaM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarAinda não há avaliações

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocumento1 páginaM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarAinda não há avaliações

- M.E.Forge TechDocumento1 páginaM.E.Forge TechK.s. Raghavendra KumarAinda não há avaliações

- M.E.Forge TechDocumento1 páginaM.E.Forge TechK.s. Raghavendra KumarAinda não há avaliações

- En353 3753 5948Documento1 páginaEn353 3753 5948K.s. Raghavendra KumarAinda não há avaliações

- Srividya Sadhana EbookDocumento69 páginasSrividya Sadhana EbookDSSidgiddi50% (2)

- 6766UDocumento1 página6766UK.s. Raghavendra KumarAinda não há avaliações

- 35NiCrMoV 125Documento1 página35NiCrMoV 125K.s. Raghavendra KumarAinda não há avaliações

- Quality Assurance Plan03Documento2 páginasQuality Assurance Plan03K.s. Raghavendra KumarAinda não há avaliações

- What NextDocumento10 páginasWhat NextbalajiAinda não há avaliações

- IBR - Central Boilers BoardDocumento1 páginaIBR - Central Boilers BoardK.s. Raghavendra KumarAinda não há avaliações

- 7 - Vishnu Smriti (Dharma Sutras)Documento396 páginas7 - Vishnu Smriti (Dharma Sutras)12kars86% (7)

- JOMINY42crmo4 PDFDocumento2 páginasJOMINY42crmo4 PDFK.s. Raghavendra KumarAinda não há avaliações

- QuizeDocumento8 páginasQuizeK.s. Raghavendra KumarAinda não há avaliações

- Iball Decibel Android Alexa UserManualSetup v1 PDFDocumento7 páginasIball Decibel Android Alexa UserManualSetup v1 PDFVyrax FalconAinda não há avaliações

- Jominy Hardness TessDocumento3 páginasJominy Hardness TessIqbal BashiruAinda não há avaliações

- TemperatureDocumento51 páginasTemperaturekartheek viswanathAinda não há avaliações

- Luminell Datasheet English Version2.0Documento4 páginasLuminell Datasheet English Version2.0marius_brkt6284Ainda não há avaliações

- Analisis Karbohidrat MetodeDocumento28 páginasAnalisis Karbohidrat MetodearikuraAinda não há avaliações

- Microbiology Exam QuestionsDocumento23 páginasMicrobiology Exam Questionswhitewave25Ainda não há avaliações

- 3404 10153 1 PBDocumento6 páginas3404 10153 1 PBSergio Fabian NavarroAinda não há avaliações

- An114 Hand Soldering Tutorial For The Fine Pitch QFP DevicesDocumento22 páginasAn114 Hand Soldering Tutorial For The Fine Pitch QFP DevicesPat Jojo SadavongvivadAinda não há avaliações

- Iron Sulfides - Effect On Amine PlantsDocumento6 páginasIron Sulfides - Effect On Amine PlantsHsien Yu100% (1)

- V - Performance and Safety Issues Regarding The Use of PlasticDocumento31 páginasV - Performance and Safety Issues Regarding The Use of PlasticEQviniciusAinda não há avaliações

- Underground Pipe Stress Check CalculationsDocumento6 páginasUnderground Pipe Stress Check Calculationsani_datAinda não há avaliações

- ELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinDocumento2 páginasELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinLeductoan LeAinda não há avaliações

- Heinrich2001 EconomicGeologyOfTheSandAndSandstoneResourcesOfMichigan PDFDocumento31 páginasHeinrich2001 EconomicGeologyOfTheSandAndSandstoneResourcesOfMichigan PDFkarma2011Ainda não há avaliações

- Flexible PavementsDocumento13 páginasFlexible PavementsAhmad NajiAinda não há avaliações

- MSDS - Robond L-330 - ISS130910Documento7 páginasMSDS - Robond L-330 - ISS130910Anonymous pXU4tefJAinda não há avaliações

- Applying Vat Dyes to Cotton FibersDocumento3 páginasApplying Vat Dyes to Cotton FibersMuhammad Jawad Ul RehmanAinda não há avaliações

- Steel QuizDocumento2 páginasSteel Quizjakeer7Ainda não há avaliações

- Drilling Formulas Calculation Sheet Verson 1.4Documento190 páginasDrilling Formulas Calculation Sheet Verson 1.4Adedire FisayoAinda não há avaliações

- Etch Rates For Micromachining Processing PDFDocumento2 páginasEtch Rates For Micromachining Processing PDFJohnathanAinda não há avaliações

- 0808231109005091Documento2 páginas0808231109005091tinitnthesaiyanAinda não há avaliações

- Industrial Visit Report LatestDocumento11 páginasIndustrial Visit Report Latesthanif100% (2)

- Chemistry Form 4 Lesson 12Documento8 páginasChemistry Form 4 Lesson 12Sakinah SaadAinda não há avaliações

- ASAT Class 7Documento16 páginasASAT Class 7kamalsharma2014100% (1)

- Mona Sarastasi Tugas Pengantar Ilmu Dan Teknologi KebumianDocumento10 páginasMona Sarastasi Tugas Pengantar Ilmu Dan Teknologi KebumianAdrian MaratiAinda não há avaliações

- Experiment No. 1 Rockwell Hardness Group 1 Final - PaperDocumento3 páginasExperiment No. 1 Rockwell Hardness Group 1 Final - PaperThomas Jefferson AntonioAinda não há avaliações

- Hardsurfacing HandbookDocumento24 páginasHardsurfacing HandbookscribdphinAinda não há avaliações

- Dubai Municipality G+12 Concrete & Shoring QuestionsDocumento7 páginasDubai Municipality G+12 Concrete & Shoring QuestionsMohammed Nasih Vettathur100% (2)

- CARB in Industrial FansDocumento8 páginasCARB in Industrial FansJurun_Bidanshi100% (1)

- Solubility of Titanium Dioxide in Cosmetic FormulationsDocumento10 páginasSolubility of Titanium Dioxide in Cosmetic FormulationsMeiAinda não há avaliações

- Cyliani's Hermes UnveiledDocumento31 páginasCyliani's Hermes UnveiledAndre Bambu100% (2)

- Fluid Mechanics Basics for ECW 211Documento53 páginasFluid Mechanics Basics for ECW 211dixn__Ainda não há avaliações