Escolar Documentos

Profissional Documentos

Cultura Documentos

QMS

Enviado por

nitin_798443935Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

QMS

Enviado por

nitin_798443935Direitos autorais:

Formatos disponíveis

Company name:- Sajjan India Limited

Sajjan is one of India's leading Specialty Chemicals companies group consisting of Sajjan India Limited, OM Intercontinental, Priyata Intercontinental, Sajjan Specialty Ltd, Agrasen Impex Pvt. Ltd, Agrasen Dyes & Intermediates Pvt. Ltd. We are headquartered in Mumbai and our manufacturing site & technical operationsare located in Ankleshwar (Gujarat) with over 600 people employed. 100% Export Oriented company with customers in western Europe, USA & the Far East. Our customers include 10 of the world's top chemical companies.

Core Competency

Sajjan India has expertise in large scale production of organic, specialty chemicals which involve complex chemistry, management & handling of hazardous chemical substances. PYRIMIDINE DERIVATIVES : Our processes are extremely efficient with minimum waste. CONTAINMENT of ETHYL & BENZYL MERCAPTANS : CYANOGEN CHLORIDE : DRY HCL GAS : CHLORINATION : HYDROGENATION

Products:- Sajjan specializes in contract manufacturing of intermediates and Specialty Chemicals,

which have applications in Agrochemicals, Pharmaceuticals, Material Sciences, Dyes & Pigments. We are a strategic supplier to some of the world's leading chemical companies.

Other Products

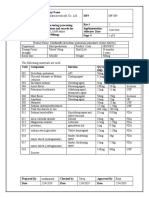

S.No 1 2 3 4 5 6 Products 4,6-Dimethoxy-2-(Phenoxy Carbonyl)-Amino Pyrimidine 2-Amino-4,6-dimethoxypyrimidine 2,4,6-Trichloropyrimidine 2,4,5,6-Tetrachloropyrimidine 2,4-Diamino-6-chloropyrimidine 2,4,6-Trimethylbenzoyl Chloride Cas No. 89392-03-0 36315-01-2 3764-01-0 1780-40-1 156-83-2

LAB / PILOT SCALE

S.No 1 2 3 4 5 6 7 Products Cloquintocet-Mexyl 2-Chloro-4,6-Dimethoxy-1,3,5-Triazine 4-Amino-2,5-Dimethyl Phenol 2-Benzyl Thio Nicotinic Acid 4-Chloro-2,6-Dimethyl Bromobenzene 2-Amino-4.6-Dihydroxy-pyrimdin 2-Amino-4-Methyl-6-Hydroxypyrimidine Cas No. 99607-70-2 3140-73-6 3096-71-7 112811-90-2 103724-99-8 56-09-7

The above mentioned products are few of the many products.

INTERVIEW:1) and 2) Quality is paramount at sajjan India and it is one of the reasons the company has grown from strength to strength in the international market, even in the face of growing competition and stringent customer demands. Sajjan india has a strict and ever-vigilant system in place to monitor and oversee quality at regular stages throughout the process. Some of the instruments and equipments installed for this purpose include: -Atomic absorption spectrophotometer. -Muller machine -UV/VIS spectrophotometer -Dosimat trio -HPLC -Dye baths -HPTLC -Padding mangles -Gas Chromatography -Rapidager -Karl Fischer Titrators -Jar mill -Auto titrators -Laundrometer -Color matching Spectrophotometer -Leather Dyeing Machine Hence a high importance is definitely given to quality in our organization but still then quality of a product also depends on its application. Quality depends on the standards which we have kept. If a competitor sells a same product then one who has tighter norms and specifications w.r.t quality may win the order. For e.g a product which is required to say dyes and pigments category supplier. He takes the products from sajjan and further processes to say manufacture clothes, fabrics, paints and textiles to supply it to the customers (final consumers). For dye and pigment customer quality may be in terms of the composition of the chemical so that color do not fade away easily or quality is of not much important. Since its worn outside the specifications for heavy metals or carcinogenic matters will be loose (not so strict). But if that same product with same composition and same raw materials is bought by the cosmetic industry customer (which actually does) then for him the quality is of utmost important as it is applied on the body and should not have any carcinogenic or cancer causing agents or should not have a negative reaction with the skin. Any chemical synthesis will have certain impurities but in cosmetic industry they will have tighter requirement specifications and much more stringent specifications in terms of its impurity profile (Heavy metals, carcinogenic materials). No insoluble matter. So depending upon the applications in the industry requirement specifications will change. In many cases the specifications are so strict that impurities should not exceed 0.05%. Quality is not only of the product but quality is of employees (important for an employee to know why they are doing a particular thing in a particular way, what is their job), raw material, various processes and after sales. Quality also depends on an individual. Quality depends on the input raw materials, stages of manufacturing process it goes through, having a quality check (QC) at each and every stage of the process.

Environment..this is tqm.This is cam ein much later when it came after the college. ISO certification came in the year 90s What process do you conduct to maintain optimum quality ? There is nothing ideal quality . A product named discatistic used by two different customer and the quality requirement for both of them would be different based on variables like their environmental factors and their processes ,equipments used for manufacturing operational parameters and their internal standard of quality which means the product if used and approved by one client doesnt mean it would be approved by another client. IN Sajjan,the basic properties of product would be same but little enhancement is done in product based on requirement from the customer. Define quality specification parameters of the input , quality of the intermediatir then at end .So as to maintain consistent quality in the product. At each and every step the quality is checked. Else create checkpoints to keep a check in quality and also maintain environment of the chemical in manufacturing process. Keep dials ,readings to check the quality of the product to be manufactured. Concept of iso says u will do consistently in marinating quality. To educate the industrialist to bring consistency in organization. Training program Most environment parameters of organization are analyzed on machines . Ongoing programme for operating people .People are sent to seminar. For general things expert(equipment manufacturer) are called so as to make people aware of what is going in global. To ensure people open training programme is required.It compulsory to keep employees upbreast with technology so as to achieve success in quality. Training of new ideas., training people to adapt with the environment. For example a testing machine has come . which requirement would be in future for production so the if the knowledge is given now it would come handy during the upcoming period . Any regular audits to keep check on quality ? Internal audits are there. Typically in all places when something goes wrong then only audits come into picture. Back tracking is doneto check where problem is come But in reality one must practice the auditing in a specific timeframe. Since lot of contract manufacturing is done with customers at sajjan , 10 days or 20 days. By default auditing is done. Routine audit on process which is directly related to the quality Documented policy ? How the process is to be done Each product there is a manual. A manual of recent contract 2 months back. Manuals are made for each product.A chemical scheme. Each and every step of the process . Details is given then work is done. Work is compeletely based on the environment.Based in japan. Different skill manpower different equipment. Challenge in adopting the advance technology of developed countries in developing countries

Revision happens what changes have been done.until fine tune happens until a SOP STANDARD OPERATING PROCEDURE OF EACH PRODUCT BASIC DOSSIER FOR ALL PRODUCTS. How are the damaged products treated and what are the return policies ? Is the same product is being used by many clients ,each customer has different specification. So we narrow down to the requirements . Write indirectly is a one step approach which is used . If it is within hi specification then .4 blocks something meets the quality of customer X will be resrved for him and when he orders then the whole order will be dispatched. OFF SPEC which does not meet the specification ,but it is closer to that so we write a request of stock, is it acceptable, then the buyer carries the test and acccepts whether he wants to order the product . In worst case scenario return the product and do changes, reblend the product and provide a new product which is done in most of manufacturing industry Along with ISO what other certifications does sajjan have ? AND STANDARDS IT MUST FOLLOW ? Chemical company has to follow three standards ISO PART FOR SYSTEM,ISO 14000 for environment OHSAH (orGANIZATIONAL HEALTH SAFETY) 8000. FDA. Standards. ISO 9001 qms organization ,14001 - environmental ISO means you have certified systems . ALSO its done for pharmaceutical then standards like cgmp,us fd . Only if approved by us fd then u can use gmp else cgmp MAJOR PRODUCT IS IN AGRICULTURAL AND DYES AND PIGMENTS Mininum criteria required for the recruitment of employee in qulaity management department ? Only for qulaity control A chemical company- person should have a chemical background , knowledge in processess. VET ANALYSIS - TITRATION , MELTING POINT SHOULD BE SCIENE GRADUATE ETC., INTRUMENTAL ANALYSIS WHAT MACHINES HE CAN OPERATE, CAN HE RUN SENSITIVE DEMOISTURE DEVICES, ETC. very precise in measuring and should do test in a very closed atmosphere. Good enough to know alluent whther the solid or liquid could dissolve in it and run it into machine to generate by products. Equipments are user friendly. Human part is measure 5gm and inject insystem. Knowledge on troubleshooting is also important. Knowledge of chemical CAD softwares

Você também pode gostar

- QA & RA ProfessionalDocumento2 páginasQA & RA ProfessionalaksshinyAinda não há avaliações

- Water Testing Quotation of R.v.briggsDocumento1 páginaWater Testing Quotation of R.v.briggsSuvojit DasAinda não há avaliações

- Data Sheet: Solvent Retention Data For DB-624, DB-1, and DB-WAX ColumnsDocumento12 páginasData Sheet: Solvent Retention Data For DB-624, DB-1, and DB-WAX ColumnsUroboroszAinda não há avaliações

- LirDocumento5 páginasLirHimatushAinda não há avaliações

- Change Control Form: Giva Olviana YudhistaDocumento4 páginasChange Control Form: Giva Olviana YudhistaFajarRachmadiAinda não há avaliações

- HPLC Training in Hyderabad, IndiaDocumento6 páginasHPLC Training in Hyderabad, IndiakattarambabuAinda não há avaliações

- 001 AbbrevationsDocumento86 páginas001 AbbrevationssreeniAinda não há avaliações

- Winthrox Laboratories Pvt. LTD: Quality Assurance DepartmentDocumento2 páginasWinthrox Laboratories Pvt. LTD: Quality Assurance Departmentanoushia alviAinda não há avaliações

- DRA Intro and ScopeDocumento12 páginasDRA Intro and ScopeJbelsen DavidAinda não há avaliações

- Salom Pharmacy LTD: Quality Control Laboratory SPL-SOP-QC-DISS-001 Operation of Dissolution Rate ApparatusDocumento2 páginasSalom Pharmacy LTD: Quality Control Laboratory SPL-SOP-QC-DISS-001 Operation of Dissolution Rate ApparatusPaolo Peps100% (1)

- WI No. QC 003Documento2 páginasWI No. QC 003Khrystin BerdosAinda não há avaliações

- Saving Time in The HPLC Lab: SoftwareDocumento12 páginasSaving Time in The HPLC Lab: SoftwareMerck Millipore Brasil - Lab Supply BrasilAinda não há avaliações

- Testing Procedure of Caps: Ferozsons Laboratories Limited Work InstructionsDocumento8 páginasTesting Procedure of Caps: Ferozsons Laboratories Limited Work InstructionsaKureishiAinda não há avaliações

- 01 Cleaning Validation of Vibratory Sifter CLV 01Documento2 páginas01 Cleaning Validation of Vibratory Sifter CLV 01Ravi YadavAinda não há avaliações

- Sterille Production AreaDocumento12 páginasSterille Production AreaNavdeep ChaudharyAinda não há avaliações

- Acyclovir Topical Cream Draft GuidanceDocumento26 páginasAcyclovir Topical Cream Draft Guidancefad12345Ainda não há avaliações

- Extraneous Peaks in HPLCDocumento40 páginasExtraneous Peaks in HPLCshulalevin0% (1)

- Rajiv Gandhi University of Health Sciences: ST NDDocumento10 páginasRajiv Gandhi University of Health Sciences: ST NDkumar_chemicalAinda não há avaliações

- Attachment 13 Analytical Equipment Calibration Certificate v3 PDFDocumento40 páginasAttachment 13 Analytical Equipment Calibration Certificate v3 PDFGnanaSunderAinda não há avaliações

- VeerDocumento19 páginasVeerRam KprAinda não há avaliações

- Assignment 1 PDFDocumento6 páginasAssignment 1 PDFSajib Chandra Roy0% (1)

- Standard Operating Procedure Department: ProductionDocumento2 páginasStandard Operating Procedure Department: Productionasit_mAinda não há avaliações

- HPLC Analytical Method Development ValidationDocumento4 páginasHPLC Analytical Method Development ValidationJoshua CastilloAinda não há avaliações

- Lovex RegistrDocumento64 páginasLovex RegistrbishopshehadehAinda não há avaliações

- HPLC CalculatorDocumento16 páginasHPLC Calculatorwindli2014Ainda não há avaliações

- Malaysia PRP Pharmaceutical Industry LogbookDocumento77 páginasMalaysia PRP Pharmaceutical Industry LogbookAiWeiAinda não há avaliações

- Check List For Technical Audit: Surge Lab. (PVT) LTDDocumento20 páginasCheck List For Technical Audit: Surge Lab. (PVT) LTDTahir IbrahimAinda não há avaliações

- Raw Data Report of TabletDocumento11 páginasRaw Data Report of TabletShubam SharmaAinda não há avaliações

- Minutes of 290th Meeting of Registration BoardDocumento1.286 páginasMinutes of 290th Meeting of Registration BoardUsman DarAinda não há avaliações

- For Re-Classification of Sample Only Differential Test To Be PerformedDocumento4 páginasFor Re-Classification of Sample Only Differential Test To Be PerformedGlobela2 QCAinda não há avaliações

- CC SopDocumento6 páginasCC SopSagar ChavanAinda não há avaliações

- No. of SOP Pending in All Cross Functional DepartmentDocumento64 páginasNo. of SOP Pending in All Cross Functional DepartmentNishit SuvaAinda não há avaliações

- Good Laboratory PracticesDocumento24 páginasGood Laboratory PracticesGerald Limo Arap ChebiiAinda não há avaliações

- Pyriproxyfen Papaya Draft ProtocolDocumento16 páginasPyriproxyfen Papaya Draft ProtocolprecauteAinda não há avaliações

- Pharmaceutical Industries at A Glance: Bandung, September 2016 Ni Nyoman Wiwik SutrisniDocumento17 páginasPharmaceutical Industries at A Glance: Bandung, September 2016 Ni Nyoman Wiwik SutrisniBunbun BunAinda não há avaliações

- Genetica Laboratory Pvt. LTD: Standard Operating ProcedureDocumento2 páginasGenetica Laboratory Pvt. LTD: Standard Operating ProcedureRajendra ChaudharyAinda não há avaliações

- OQ Raw Materials Sample TentDocumento18 páginasOQ Raw Materials Sample TentAnup BajracharyaAinda não há avaliações

- For Editable or Customized Versions of This 5S Training Exercise ContactDocumento60 páginasFor Editable or Customized Versions of This 5S Training Exercise Contact1debaAinda não há avaliações

- Operational Qualification Report For Syringe Assembling Machine Machine Identification Name: - Report NoDocumento3 páginasOperational Qualification Report For Syringe Assembling Machine Machine Identification Name: - Report NoMusyoka UrbanusAinda não há avaliações

- s1005 Cagewash OperationDocumento7 páginass1005 Cagewash OperationMalathi SathivelAinda não há avaliações

- Simultaneous Determination of Methylparaben + Propylparaben + Hidrocortisone Topical Cream PDFDocumento7 páginasSimultaneous Determination of Methylparaben + Propylparaben + Hidrocortisone Topical Cream PDFNájla KassabAinda não há avaliações

- VMP Proses Rev.13 2018Documento19 páginasVMP Proses Rev.13 2018fajarRS69Ainda não há avaliações

- Print 24.1.18 Sop LlistDocumento11 páginasPrint 24.1.18 Sop Llistkalaiarasi ravichandranAinda não há avaliações

- Standard Operating Procedure: Darsh Pharmachem Pvt. LTDDocumento4 páginasStandard Operating Procedure: Darsh Pharmachem Pvt. LTDNishit SuvaAinda não há avaliações

- Care of HPLC ColumnsDocumento4 páginasCare of HPLC ColumnsKavisa GhoshAinda não há avaliações

- APPENDIX-I (Request Sheet)Documento2 páginasAPPENDIX-I (Request Sheet)iloveit52252Ainda não há avaliações

- Sampling Procedures & Sampling Plan: I. Sampling Procedure: A) - For Swab SamplingDocumento7 páginasSampling Procedures & Sampling Plan: I. Sampling Procedure: A) - For Swab SamplingziadddAinda não há avaliações

- Ag009 05 01Documento1 páginaAg009 05 01Nishit SuvaAinda não há avaliações

- Understanding Quality Assurance in Construction: Pages 3-10Documento4 páginasUnderstanding Quality Assurance in Construction: Pages 3-10hmd rasikaAinda não há avaliações

- Quality ControlDocumento78 páginasQuality ControlAhmad Yusrizal FaizinAinda não há avaliações

- Guideline On Active Substance Master File Procedure - EuropeanDocumento22 páginasGuideline On Active Substance Master File Procedure - EuropeanNhonPhanThanhAinda não há avaliações

- Operating Procedure of Fume Hood Model No.: EDU1200ABP, ChinaDocumento4 páginasOperating Procedure of Fume Hood Model No.: EDU1200ABP, ChinaBejoy KarimAinda não há avaliações

- LEAN HandoutDocumento31 páginasLEAN Handouttri agustariaAinda não há avaliações

- Vibratory SifterDocumento1 páginaVibratory SifterananthAinda não há avaliações

- Raya Pharmaceuticals Co. LTD: Cataflam®Documento8 páginasRaya Pharmaceuticals Co. LTD: Cataflam®Mayson BaliAinda não há avaliações

- Eskag Pharma Pvt. LTD., Haridwar, Unit-I Department: Quality Assurance Product MatrixDocumento20 páginasEskag Pharma Pvt. LTD., Haridwar, Unit-I Department: Quality Assurance Product MatrixMohit ChauhanAinda não há avaliações

- Range Brochure 2009-Sampling TechnologiesDocumento92 páginasRange Brochure 2009-Sampling Technologiesas_001Ainda não há avaliações

- Weather Folds Pharmaceutical Standard Operating Procedures Good Laboratory PracticesDocumento5 páginasWeather Folds Pharmaceutical Standard Operating Procedures Good Laboratory PracticesWeatherfolds PharmaAinda não há avaliações

- SOP For Preparation and Standardization of Volumetric SolutionsDocumento3 páginasSOP For Preparation and Standardization of Volumetric SolutionsSolomonAinda não há avaliações

- Mediequip TradeshowDocumento5 páginasMediequip Tradeshownitin_798443935Ainda não há avaliações

- Henry Ford PersonalityDocumento4 páginasHenry Ford Personalitynitin_798443935Ainda não há avaliações

- Designing Micro-Loan ProductsDocumento16 páginasDesigning Micro-Loan ProductsDan Teleyo KibetAinda não há avaliações

- DTTL LSHC 2014 Global Health Care Sector Report PDFDocumento28 páginasDTTL LSHC 2014 Global Health Care Sector Report PDFColby CarsonAinda não há avaliações

- GanttDocumento2 páginasGanttnitin_798443935Ainda não há avaliações

- RiskDocumento1 páginaRisknitin_798443935Ainda não há avaliações

- Factor AnalysisDocumento5 páginasFactor Analysisnitin_798443935Ainda não há avaliações

- 4 Definition PhaseDocumento25 páginas4 Definition Phasenitin_798443935Ainda não há avaliações

- Health Care in IndiaDocumento22 páginasHealth Care in Indiaapi-19858442Ainda não há avaliações

- PromotionDocumento6 páginasPromotionnitin_798443935Ainda não há avaliações

- Ip LaplacianDocumento34 páginasIp Laplaciannitin_798443935Ainda não há avaliações

- Tcp-Ip DetailsDocumento44 páginasTcp-Ip Detailsnitin_798443935Ainda não há avaliações

- XR2206Documento6 páginasXR2206Devi HasanahAinda não há avaliações

- Histogram EqualizationDocumento3 páginasHistogram Equalizationnitin_798443935Ainda não há avaliações

- Se-K QFDDocumento20 páginasSe-K QFDnitin_798443935Ainda não há avaliações

- MSL Industrial MarketingDocumento2 páginasMSL Industrial Marketingnitin_798443935Ainda não há avaliações

- Havaldar Case StudyDocumento2 páginasHavaldar Case Studynitin_798443935Ainda não há avaliações

- Network ManagementDocumento20 páginasNetwork Managementnitin_798443935Ainda não há avaliações

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Documento1 páginaIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)nitin_798443935Ainda não há avaliações

- VcoDocumento2 páginasVconitin_798443935Ainda não há avaliações

- 4 Definition PhaseDocumento25 páginas4 Definition Phasenitin_798443935Ainda não há avaliações

- Random AccessDocumento21 páginasRandom Accessnitin_798443935Ainda não há avaliações

- SVKM'S NMIMS University: Mukesh Patel School of Technology Management & EngineeringDocumento3 páginasSVKM'S NMIMS University: Mukesh Patel School of Technology Management & Engineeringnitin_798443935Ainda não há avaliações

- Radar Pulse CompressionDocumento19 páginasRadar Pulse Compressionmalek1p2Ainda não há avaliações

- Bit Byte StuffDocumento13 páginasBit Byte StuffSahil TandonAinda não há avaliações

- Havaldar Case StudyDocumento2 páginasHavaldar Case Studynitin_798443935Ainda não há avaliações

- Havaldar Case StudyDocumento2 páginasHavaldar Case Studynitin_798443935Ainda não há avaliações

- Moi-Pond's Toothpaste FinalDocumento13 páginasMoi-Pond's Toothpaste Finalnitin_798443935100% (1)

- Mint 1Documento23 páginasMint 1nitin_798443935Ainda não há avaliações

- Blender 04Documento38 páginasBlender 04Ana Maria100% (1)

- Manual New AswanDocumento18 páginasManual New AswanmohamedmosallamAinda não há avaliações

- Est-Pergola Octogonal 21-03-2022Documento1 páginaEst-Pergola Octogonal 21-03-2022Victor MuñozAinda não há avaliações

- APL APOLLO - Chaukhat - Catalogue A4 English - 04 03 2022 - Low ResDocumento48 páginasAPL APOLLO - Chaukhat - Catalogue A4 English - 04 03 2022 - Low ResarrsshaAinda não há avaliações

- ICEpublishing Complete 2014 Books CatalogueDocumento44 páginasICEpublishing Complete 2014 Books CatalogueLamija LamyAinda não há avaliações

- Tool PresettingDocumento22 páginasTool PresettingAtulMaurya100% (1)

- 816D Specalog (Small)Documento2 páginas816D Specalog (Small)Arvind HarryAinda não há avaliações

- ConnectorsDocumento3 páginasConnectorsmatrixworld20Ainda não há avaliações

- A01 04 Assessmentk UndercarriageDocumento7 páginasA01 04 Assessmentk UndercarriageMARIO DEL PINO MUÑOZAinda não há avaliações

- Lowry Hill East Residential Historic DistrictDocumento14 páginasLowry Hill East Residential Historic DistrictWedgeLIVEAinda não há avaliações

- Session 2A JonkerDocumento15 páginasSession 2A JonkerD_D_AAinda não há avaliações

- KN3906Documento3 páginasKN3906ingucvAinda não há avaliações

- Cabezas de Rotulas-RotulasDocumento64 páginasCabezas de Rotulas-RotulasFRANCISCO100% (1)

- Erita Astrid - UPBDocumento25 páginasErita Astrid - UPBmas_kinooooAinda não há avaliações

- SB658Documento3 páginasSB658ricardo novoa saraviaAinda não há avaliações

- Oisd STD-141Documento31 páginasOisd STD-141Jyotsana Rawat83% (6)

- Chpt6 Taylor Made HONDocumento23 páginasChpt6 Taylor Made HONManju MudakaviAinda não há avaliações

- Server and Workstation AdministrationDocumento454 páginasServer and Workstation AdministrationScott CarneyAinda não há avaliações

- Barrett Light 50Documento23 páginasBarrett Light 50Zayd Iskandar Dzolkarnain Al-HadramiAinda não há avaliações

- Checklists 4yrDocumento2 páginasChecklists 4yrKarla TreviñoAinda não há avaliações

- Detailed Lesson Log in MathematicsDocumento7 páginasDetailed Lesson Log in MathematicsChan Chan100% (1)

- Thesis FYPDocumento50 páginasThesis FYPEyka ZulaikaAinda não há avaliações

- Lab No 8Documento5 páginasLab No 8LO Ver JG100% (1)

- Contoh Ringkasan Mengajar Bahasa Inggeris Tahun 2 Dan 3Documento2 páginasContoh Ringkasan Mengajar Bahasa Inggeris Tahun 2 Dan 3Izla MajidAinda não há avaliações

- Assessing The Impact of Premier Information Systems Research OverDocumento20 páginasAssessing The Impact of Premier Information Systems Research OvergasibuteaAinda não há avaliações

- Transport ModellingDocumento37 páginasTransport ModellingRiza Atiq Abdullah Rahmat100% (6)

- AMAZONE ZA-F 604 Uputstvo Za Koristenje I OdrzavanjeDocumento32 páginasAMAZONE ZA-F 604 Uputstvo Za Koristenje I OdrzavanjeIvonaLepir100% (1)

- L1 Differential AmplifiersDocumento21 páginasL1 Differential AmplifiersTemesgen ZelekeAinda não há avaliações

- Electric Fan RepairDocumento12 páginasElectric Fan RepairYsabelle Tagaruma33% (3)

- Truck Parking Areas 2009Documento147 páginasTruck Parking Areas 2009IRUAinda não há avaliações