Escolar Documentos

Profissional Documentos

Cultura Documentos

The Behaviour of Bioplastic Films in Mechanical Recycling Streams

Enviado por

Ralyn BasisDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

The Behaviour of Bioplastic Films in Mechanical Recycling Streams

Enviado por

Ralyn BasisDireitos autorais:

Formatos disponíveis

META STUDY

DEC 2013

THE BEHAVIOUR OF BIOPLASTIC FILMS IN MECHANICAL RECYCLING STREAMS

META STUDY DEC 2013

SUMMARY

Biobased (non-compostable) plastic lms are chemically identical to conventional plastics and are no more difcult to manage in plastic recycling streams. Compostable plastics are designed for organic recycling. They are clearly marked for this purpose with logos such as the Seedling logo. When residual amounts remain, they are similarly or more easily handled than current residual wastes in the PE stream (e.g. PS, PP, PET). They should not then add signicantly to the cost or complexity of recycling processes or the recovery of valuable, recycled PE. This remains true up to a share of 10% compostable plastics in the waste stream. At this level or below, studies show negligible impact on the technical performance of recycled PE. As the market share of compostable plastics increases it will be economically rewarding to sort them out positively. This is technically possible today and should create new and valuable markets for the waste management industry.

FIGURE 1: EXAMPLE OF A COMPOSTABILITY LOGO: THE SEEDLING LOGO OF EUROPEAN BIOPLASTICS, AWARDED BY INDEPENDENT CERTIFICATION INSTITUTES

In the event that compostable plastics do end up in regular plastic recycling streams, the prevalent sorting technologies are able to sort them with little residual waste.

Aside from the social and environmental benets of bioplastics, the best evidence clearly shows that these materials present an economic opportunity and not a threat to the waste management industry.

DEFINITIONS

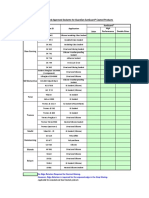

Bioplastics are plastics that are biobased, biodegradable, or both. This large family of materials can be simplied into two groups: 1. Biobased non-biodegradable plastics (also: durable bioplastics) Materials: Biobased polyethylene (PE), biobased polyethylene terephthalate (PET), biobased polyamides, and materials such as starch-polyolen blends etc. Uses: Packaging sector or durable applications, for example in vehicles, buildings, household appliances, interior design, lifestyle goods and electronics. 2. Biobased biodegradable and compostable plastics Materials: Thermoplastic starch, polylactic acid (PLA) or polyhydroxyalkanoates etc. Uses: Short-lived applications such as in agriculture, catering products, packaging, or thin bags. Suitable for organic recycling, especially industrial composting. Standards: Within the EU compostable products are certied under EN 13432 and EN 14995. Bioplastics in mixed waste streams Modern waste recovery systems cope with intermingled materials, including a variety of different polymer types. Automated plants sort out the protable parts of the waste stream (for example PE and PET). The promising polymers are separated. The remainder is sorted into another container, usually marked and resold as mixed plastics. To achieve this, advanced sorting systems use a variety of analytical methods including near infrared, ultraviolet, x-ray, laser, polarized light, uorescent light, electrostatic, melting point and other techniques. These methods are effective in keeping contamination of the main recycling streams with unwanted material low. Compostable plastics should be sorted into biowaste bins. If such bins are not available Compostable plastics can still be clearly identied from their labels and sorted out for delivery to a biowaste processer.

META STUDY DEC 2013

However, even in efcient systems, the mixing of waste streams cannot be completely avoided. Non-compostable plastics can enter the organic waste stream (e.g. misthrows) and biodegradable, compostable plastics might be found in mechanical recycling systems (e.g. misidenticationa). It is already the case that conventional plastics nd their way into the wrong stream in small volumes. In well-run waste management facilities most residual bioplastic will be handled as mixed plastic until such a time as recovery is protable. Today, even when bioplastics are sorted incorrectly, they do not enter the waste stream in sufcient volume to cause concern more than any other type of plastic. The case against bioplastics is not evidence-based Voices in some parts of the waste management industry claim that bioplastics can cause a serious disturbance in the established recycling streams, for example of PE and PET. The following research and evidence refutes these assertions. It suggests the inuence on the collection and processing of protable materials is negligible. Biobased Polyethylene (PE, not biodegradable or compostable) Biobased PE is obtained by polymerisation of ethylene monomers. Depending on the polymerisation process biobased LDPE or biobased HDPE can be produced. The only difference to fossil-based PE is the source, which is bioethanol, e.g. made from sugar cane, sugar beet, or wheat. As a result fossil and biobased PE are chemically identical. They share exactly the same physical properties. Therefore, biobased PE can be recycled mechanically with fossil-based PE in the corresponding recycling streams. PLA/PBAT blends (compostable according to EN 13432) Studies by the University of Hannover [1], [2] examined the inuence of different compostable plastics on low-density polyethylene (LDPE). The mixtures tested contained between 0.5% to 10% foreign material. The LDPE contaminants were a PLA/PBATb blend, pure PBAT and a starch blend. They found: Mixtures of LDPE with PLA/PBAT showed the same viscosity behaviour, elasticity, and tensile strength as pure LDPE.

No optical (i.e. transparency or appearance) changes could be observed. There was a slight decrease in the melt-flow rate at 10% foreign mate rial. The biodegradable polyester PBAT was also tested as a possible contaminant for LDPE. The blending of pure PBAT with LDPE had no effect on the viscosity behaviour compared with pure LDPE and was afrmed to have no effect on the processing properties. The melt ow rate values were close to those of pure LDPE and were found to cause no distinctive disturbances during processing of the material. Optical changes could also not be observed. Contamination below 10% has no effect. Starch blends (compostable according to EN 13432) A study by BIOTEC [3] has evaluated tensile strength, elongation at break and specic impact resistance for mixtures of PE with possible contaminations with a starch/PBATc blend as well as PP and PS. It was shown that the biodegradable starch blend contaminates PE no more than contamination with conventional plastics such as PS or PP. In most cases the properties of the mixtures of PE with PS or PP contaminants performed worse than mixtures of PE with a starch blend contaminant. However, the same study found that even extremely low PET shares (2%) in a PE recycling stream cause serious problems. Due to the comparatively high melting temperature of PET (approx. 250C), it was impossible to run a PE-based blown-lm. These results suggest that the contaminating effect of a compostable plastic on PE is actually less than the contaminating effect of PET on PE. A study by the University of Hannover [1] also examined a starch blend used in exible packaging applications. It found that the inuence on the viscosity and ow characteristics was only marginal up to the tested ratio of 10%. The inuence on the melt ow rate processing properties was described as low compared to the pure LDPE. A change of colour was observed with an increasing amount of starch blend.

Certied biodegradable plastics are marked with a corresponding label, e.g. the Seedling logo. This makes compostable plastics clearly identiable and distinguishable from conventional and non-biodegradable plastics. Blend of polylactic acid and poly(butyleneadipate-co-terephthalate); Tradename: ecovio Tradename: BIOPLAST d Blend of polylactic acid and poly(butyleneadipate-co-terephthalate); Tradename: ecovio

a b c

META STUDY DEC 2013

Tests carried out at the Plastics Testing Laboratory Foundation of the Polytechnic Institute of Milan and the Proplast Laboratories in Tortona/Italy (on behalf of CONAI, the National Packaging Consortium in Italy) [4] conrmed that it is possible to reprocess and recycle bags made of a starch-based materiald and traditional plastic shopping bag waste up to a concentration of 10% of starch-blends as input material.

CONAI found that exible, compostable packaging can be recycled with common plastics packaging materials up to a content of 10% without any problems [5]. CONAI concluded that even if biodegradable bags are not disposed off properly, they do not interfere with the recycling stream of conventional plastics.

LITERATURE

[1] A. Kitzler, Bioplastics in Waste Management Streams, Dissertation, University of Hannover, 2013 [2] H.-J. Endres, A.-A. de la Cruz, Inuence of PLA/PBAT material (ecovio) on the recycling of conventional LD PE, University of Hannover, 2013 [3] C. He, Inuence of BIOPLAST-Material and conventional non-PE Plastics on the mechanical Properties of recycled PE-Film, BIOTEC, Presented at K Fair 2013 [4] Italian National Packaging Consortium CONAI, Findings of Biodegradable Packaging Recovery Project. Presented at the European Bioplastics Conference, Berlin, 2013. [5] http://www.ecodallecitta.it/notizie.php?id=114824, retrieved on December 8th, 2013

December 2013 European Bioplastics e.V. Marienstrae 19/20 10117 Berlin Phone: +49 (0) 30 284 82 350 Fax: +49 (0) 30 284 84 359 info@european-bioplastics.org www.european-bioplastics.org

Tradename: Mater-Bi

Você também pode gostar

- Vent Guide 2017 - 0 PDFDocumento36 páginasVent Guide 2017 - 0 PDFGozuengineer GozuAinda não há avaliações

- Pump SizingDocumento7 páginasPump Sizingrvkumar61Ainda não há avaliações

- Introduction To Different Types of Strainers PDFDocumento7 páginasIntroduction To Different Types of Strainers PDFRalyn BasisAinda não há avaliações

- Vol 1 CLUP 2020 (REVISED) PDFDocumento81 páginasVol 1 CLUP 2020 (REVISED) PDFRalyn BasisAinda não há avaliações

- National Accommodation Standards HotelDocumento59 páginasNational Accommodation Standards HotelFauziah Hanum AbdullahAinda não há avaliações

- SRB JointsDocumento62 páginasSRB JointsRalyn BasisAinda não há avaliações

- Plant Utilities - Instrument Air Systems PDFDocumento5 páginasPlant Utilities - Instrument Air Systems PDFAnurag TripathiAinda não há avaliações

- Aging in The PhilippinesDocumento2 páginasAging in The PhilippinesRalyn BasisAinda não há avaliações

- Flamearrestor LiteratureDocumento7 páginasFlamearrestor LiteratureNoor Ul HaqAinda não há avaliações

- Local Development Investment Program 2017Documento34 páginasLocal Development Investment Program 2017Ralyn BasisAinda não há avaliações

- National Accommodation Standards HotelDocumento59 páginasNational Accommodation Standards HotelFauziah Hanum AbdullahAinda não há avaliações

- General Presentation PDFDocumento112 páginasGeneral Presentation PDFRalyn BasisAinda não há avaliações

- Dynamic Mechanical Properties and Thermal Stability ofDocumento10 páginasDynamic Mechanical Properties and Thermal Stability ofRalyn BasisAinda não há avaliações

- The Oxygen-Carbon Dioxide CycleDocumento11 páginasThe Oxygen-Carbon Dioxide CycleRalyn BasisAinda não há avaliações

- National Accommodation Standards HotelDocumento59 páginasNational Accommodation Standards HotelFauziah Hanum AbdullahAinda não há avaliações

- Mechanical Characterization of Commercial Biodegradable Plastic FDocumento91 páginasMechanical Characterization of Commercial Biodegradable Plastic FRalyn BasisAinda não há avaliações

- Aspen Tutorial 1Documento14 páginasAspen Tutorial 1Ralyn BasisAinda não há avaliações

- Tehnologija Pirolize Auto GumaDocumento10 páginasTehnologija Pirolize Auto Gumastratmen.sinisa8966Ainda não há avaliações

- HydrolysisOfCelluloseAndHemicellulose ReviewDocumento39 páginasHydrolysisOfCelluloseAndHemicellulose ReviewRalyn BasisAinda não há avaliações

- Analytic ChemistryDocumento115 páginasAnalytic ChemistryRalyn BasisAinda não há avaliações

- Processing Technologies For Poly (Lactic Acid)Documento33 páginasProcessing Technologies For Poly (Lactic Acid)Aero Fortia NaturaAinda não há avaliações

- An Overview of Starch Based Plastic Blends From Reactive ExtrusionDocumento21 páginasAn Overview of Starch Based Plastic Blends From Reactive ExtrusionRalyn BasisAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- FormingAndShapingPlasticsDocumento30 páginasFormingAndShapingPlasticsM PraveenAinda não há avaliações

- Composite Materials Used For UAVDocumento3 páginasComposite Materials Used For UAVAkashAinda não há avaliações

- Methods, Processes and Equipment Involved in Manufacturing GlassDocumento29 páginasMethods, Processes and Equipment Involved in Manufacturing GlassNiño Gerard JabagatAinda não há avaliações

- Fibre Trade MarksDocumento10 páginasFibre Trade MarksnitishkohliAinda não há avaliações

- Plastics Compatibility with Sterilization Methods ChartDocumento2 páginasPlastics Compatibility with Sterilization Methods ChartJohn SmithAinda não há avaliações

- CompositesDocumento58 páginasCompositeskasvikrajAinda não há avaliações

- Wip 17Documento18 páginasWip 17Ankit BinjolaAinda não há avaliações

- Yadr I ClassesDocumento20 páginasYadr I ClassesRiya JaiswalAinda não há avaliações

- CH 13Documento102 páginasCH 13Alex BjAinda não há avaliações

- Tabla de Caracteristicas de Los PlasticosDocumento12 páginasTabla de Caracteristicas de Los PlasticosBetty JadueAinda não há avaliações

- Polymer Matrix CompositesDocumento3 páginasPolymer Matrix CompositesTalib AleemAinda não há avaliações

- What Are Long Fiber CompositesDocumento1 páginaWhat Are Long Fiber CompositesSanket BansalAinda não há avaliações

- Engage List of Products With Different GradesDocumento4 páginasEngage List of Products With Different Gradesmusmanghani70scribdAinda não há avaliações

- Covestro PoliuretanoDocumento24 páginasCovestro PoliuretanoRAFAEL MIERES100% (1)

- CH 15Documento27 páginasCH 15Thays Nogueira RodriguesAinda não há avaliações

- Pembuatan Recycle Plastik Hdpe Sederhana Menjadi AsbakDocumento11 páginasPembuatan Recycle Plastik Hdpe Sederhana Menjadi AsbakFebri Muhamad RoziAinda não há avaliações

- 1 1 3-CHS-555Documento2 páginas1 1 3-CHS-555Alee AsgharAinda não há avaliações

- Specification For Polyethylene Material For Moulding and ExtrusionDocumento18 páginasSpecification For Polyethylene Material For Moulding and ExtrusionSAURAVENDRA TOMARAinda não há avaliações

- 56 - Effective Pages: Beechcraft CorporationDocumento26 páginas56 - Effective Pages: Beechcraft Corporationaviacion gnaAinda não há avaliações

- Aditivi Materiale PlasticeDocumento4 páginasAditivi Materiale PlasticeLavinia CalinAinda não há avaliações

- Evr Frekote Mold Release BrochureDocumento18 páginasEvr Frekote Mold Release BrochureHugo Wizenberg100% (1)

- Bergerthane P.U. Ral 7004Documento1 páginaBergerthane P.U. Ral 7004Kandula RajuAinda não há avaliações

- Identifying Polymers Through Physical and Chemical TestsDocumento5 páginasIdentifying Polymers Through Physical and Chemical TestsNitin HansaliaAinda não há avaliações

- Chap 1Documento53 páginasChap 1patilamardip0078122Ainda não há avaliações

- Raw Material Incoming StatusDocumento22 páginasRaw Material Incoming StatusKANIAinda não há avaliações

- Guardian Approved Sealants List PDFDocumento1 páginaGuardian Approved Sealants List PDFWaqas FareedAinda não há avaliações

- NCERT Solutions For Class 8 Science Chapter 3Documento5 páginasNCERT Solutions For Class 8 Science Chapter 3ishaanAinda não há avaliações

- Modifikacija I Stabilnost Višefaznih Polimernih Sustava: Fakultet Kemijskog Inţenjerstva I TehnologijeDocumento21 páginasModifikacija I Stabilnost Višefaznih Polimernih Sustava: Fakultet Kemijskog Inţenjerstva I Tehnologijemecemacox65Ainda não há avaliações

- 17 FoamingDocumento32 páginas17 Foamingsuhas deshpande100% (4)

- The Study of Natural Rubber - Polyethylene Polymer Mixing MethodDocumento24 páginasThe Study of Natural Rubber - Polyethylene Polymer Mixing MethodJefri YusofAinda não há avaliações