Escolar Documentos

Profissional Documentos

Cultura Documentos

Geosynthetic Stone Column Floating in Soft Clay

Enviado por

Bipradip DasTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Geosynthetic Stone Column Floating in Soft Clay

Enviado por

Bipradip DasDireitos autorais:

Formatos disponíveis

1.

0 Introduction Structures on soft clay deposits confront many problems like excessive settlement, lateral movement of soft clay beneath the structure. These problems occur mainly due to low strength and high compressibility of soft clay. Hence to enhance the properties of the soft clay, insertion of stone column into the soft clay deposits is found to be handy approach. Stone columns are nothing but vertical column formed by compacting stone fragments or gravels. It is found out that with insertion of stone column clays performance is enhanced by 3.5 fold. Generally stone columns are constructed within a range of 3 to 15 m in length. The main strength of stone column comes from lateral confinement pressure offered by the surrounding soils. The presence of stone columns creates a composite material which is stiffer and stronger than the original soil. Fig.1.1 Encased Stone column Though there are some problems associates with stone column too. When stone columns are installed in soft clays they may not derive their strength (load capacity) due to low lateral confinement. Mckanna et al. (1975) reported that stone column fails due to excessive bulging and also due to the soft clay squeezed into the void of the aggregate. Hence to overcome this problem a suitable geosynthetic can be wrapped around the stone column to support the column gaining that additional confining pressure. Advantages of using geosynthetic is that it provides stiffness to the stone column, helps stones to be in same place without losing into the surrounding soft clay. It also helps in preserving the drainage and frictional properties of the stone aggregates. The concept of wrapping geotextile was first proposed by Van Impe in 1985. Using of stiffer geogrid encasement is found to be

more advantageous than flexile geogrids due to more stiffness provided by the stiffer geogrid encasement.

1.1 Objective Objective of this whole project is to observe the influence of geosynthetic encasement on the performance of the stone column floating in soft clay. Increase in the performance of the stone column is analyzed. Specific Objectives: i. ii. iii. iv. To observe the effect of different geosynthetic varying in tensile strength To observe the effect of length in the performance of reinforced stone column To analyze the settlement and bearing pressure of reinforced stone column To compare performance between only clay deposit, clay deposit with stone column and clay deposit with reinforced stone column

1.2 Scope of Work The above stated objectives were fulfilled by extensive literature survey on the proposed theories about geosynthetic encased stone column. Different factors that affect stone column and reinforced stone columns performance were studied. Studies were also carried on to see different formulas that have been derived to formulate soft clays performance with insertion of reinforced stone column. Once the literature survey is completed, an experimental set up was built to perform experiments to observe the behavior of geosynthetic encased stone column.

2.0 Literature Survey Literature survey was carried out to see the existing theories on geosynthetic encased stone columns, to observe effects of different parameters on the performance of reinforced stone column. 2.1 Parameters influencing reinforced stone columns performance Parameters which influence the performance of the stone column are i) Length of the stone column, ii) Diameter of the stone column and iii) Strength of geogrid. 2.1.1 Length of stone column Generally if we increase the length of the stone column then performance of the stone column increases substantially. This is due to the fact that with increase in length of the stone column, mobilization of skin resistance and end bearing capacity increase through an increase in peripheral area and overburden pressure. Even though it has been observed that length beyond five times the diameter of the stone column does not make any difference to the performance of the stone column. This fact is because additional resistance due to increase in length remains immobilized due to excessive bulging of the top of the stone column. Due to excessive bulging, the stone aggregate lose their interlocking properties and continue to deform at their residual strength leading to no significant additional performance improvement. 2.1.2 Diameter of the stone column With increase in diameter, load carrying capacity of the reinforced stone column decreases. This is due to the fact that with increase in diameter additional lateral confining stress Pc (hoop compression) exerted by the Geosynthetic decreases. If we know the tensile load (T) in the Geosynthetic (It is generally obtained by load strain response), we can calculate confining stress as follows: Pc = 2T/d

Where T is the tensile load in Geosynthetic and d is the diameter of Stone column. From the equation it can be observed that the additional lateral confining pressure

Pc is inversely proportional to diameter of the stone column, d. This suggests that if we increase d then lateral confining pressure due to the geosynthetic will decrease. 2.1.3 Strength of geogrid Stiffer the geogrid more stiffness it provides to the stone column. Higher strength of geogrid gives better performance. Vertical stress on reinforced stone column can be given as follows: v = (ro + 4cu + Pc) x Kpcol Where v is Total vertical stress, ro is Initial effective radial stress, cu is Cohesive strength, Kpcol = tan2(45+/2) and = angle of internal friction. Hence it can be seen that the stiffness of the column increases due to higher confining pressure exerted by the geosynthetic. Which leads to the conclusion that higher modulus of geosynthetic induces larger confining pressures leading to stiffer and stronger response of the stone column. 2.2 Hoop strain Hoop strains are higher near the top of the stone column where the predominant bulging takes place. Hoop strain generally decreases with increase in depth of the stone column due to lesser straining of stone column in deeper depth. Hoop strain is given by the following equation Pc = 2T/d Where, T being the tensile strength of the geogrid and d is the diameter of the stone column. 2.3 Design of a geosyntetic reinforced stone column Generally geosynthetic reinforced stone column are used to enhance the soil property of a very soft clay deposit. 2.3.1 Applied Pressure Lets say applied external pressure on the stone column is Po. Step.1 We need to find out the limiting stress that a stone column can take. This can be found by the following equation

v = (ro + 4cu) x Kpcol Step.2 Once we get the limiting stress value we can easily find the extra stress that we need to develop by the following expression Pc = Step.3 Now corresponding hoop tension force in the encasement (T) can be estimated as T = Pc d/2 Lets say the external pressure is subjected to a group of stone column having spacing s and diameter d. Hence, Load on the stone column = applied pressure Po x Area of the unit cell A. Where, A = { I.e. Load on stone column = load on the unit cell = Po x A. Pressure on the stone column = load on the unit cell/ area of the stone column Ac. 2.3.2 Settlement Lets say for a stone column, allowable settlement is . Now we need to calculate required tensile strength of the geosynthetic. Step.1 We need to first calculate the axial strain due to allowable settlement, a which is a = Step.2 Once we get the axial strain we need to find out hoop strain in the geosynthetic, c which is c

Step.3 Calculation of additional confining pressure follows the following equation

Pc = Applied load and allowable settlement are the two constraints to design a stone column and for that matter a reinforced stone column.

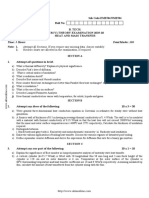

3. Experimental Set up Tests have been performed on reinforced clay bed, unreinforced clay bed and on a clay bed without stone column. 3.1 Details of model tests Table 3.1.1 Details of the model test Test Series 1 2 3 4 Reinforcement Type Unreinforced clay Stone Column Stone Column Encased Stone Column Details of test parameters Constant parameters: cu = 5kPa Constant Parameters: cu = 5kPa, S/d =2.5 Variable parameters: L/d = 1, 3, 5, 7 Constant Parameters: cu = 5kPa, L/d = 5 Variable Parameters: S/d = 1.5, 2.5, 3.5 Constant Parameters: cu = 5kPa, L/d =5, S/d =2.5; Variable parameters: Lesc/d = 1, 3, 5

Fig. 3.1.1 Arrangement of stone column

Diameter, d of column is kept constant at 100 mm. Spacing between the column is S. Length of the stone column is L and length of the encasement is Lesc.

3.2 Materials Used Table 3.2.1 Aggregate and soil properties Aggregate Properties Size range = 2-10 mm Uniformity coefficient = 2.32 Curvature coefficient = .88 D50 = 4.9 mm Classification = GP (Poorly graded gravel) Dry density = 15.3 kN/m3 Peak angle of internal friction = 48o 3.3 Test setup Schematic diagram of the test set up is shown below. Fig. 3.3.1 Schematic diagram of test setup Load is applied through an automated hydraulic system. Load transferred to the foundation is recorded through as electronic load cell of 20 kN capacity with an accuracy of .01 N least count. Settlement of the footing is measured by two transducers. All the sensors are connected to a data acquisition system. Soil Properties Liquid Limit = 40% Plastic Limit = 21% Classification = CL (Clay with low plasticity) Geogrid Encasement Material = un-oriented polymer Shape = diamond shape with aperture opening of 2 mm x 2 mm Ultimate tensile strength = 2.9 kN/m Seam tensile stress = 2.45 kN/m

3.4 Test bed preparation The soil was mixed with desired amount of water and kept for 1 week. The clay test bed was prepared in layers of .05 m thickness. Each layer is leveled and compacted using a wooden board and a drop hammer. Undisturbed soil sample is collected from different location and evaluated for their properties like average moisture content, degree of saturation; bulk unit weight and vane shear strength. Stone columns were formed by replacement technique. 3.5 Test Procedure Load was strain controlled and applied at a rate of 2 mm/ min. The footing was loaded until a settlement of 40 mm was reached. The load and displaced data was continuously recorded through the computerized data acquisition system. Deformed shapes of the stone columns were recorded.

4.0 Results and Discussion Results are formulated as below: Fig. 4.1 Influence of length on the stone column

From the diagram it can be seen that with increase in length footing settlement decreases and bearing pressure increases.

Fig. 4.2 Influence of spacing on the stone column From the figure it is clear that with increased spacing Improvement factor decreases. Improvement factor is the ratio of earing pressure with stone columns at a given settlement to that of unreinforced soil at the same settlement.

Fig. 4.3 Influence of encasement on the stone column From the figure it is clear that full encasement does not show better performance than 20% and 60% partial encasement. This due to fact that for floating stone column endearing resistance is low and the column punches down leaving much of its strength immobilized.

4.1 Works to be carried out The results found by the experiment will be analyzed and compared with the results obtained from the theoretical calculations. Hence to do that a MATLAB code will be formulated based on the theoretical assumptions and formulas. Steps will be followed as written in the literature survey. Once results obtained from this analysis, we can easily see the viability of the formulas that have been proposed to analyze the behavior of reinforced stone column for different conditions. 5.0 Summary and Conclusion It can be observed from the experimental results that insertion of floating stone column improves the bearing capacity of a foundation in soft clay by about 3.5 times. It is also observed that for floating stone column, encasement of geosynthetic up to 60% of the total length of the stone column, improves the bearing capacity of a foundation by 5 times. But for full encasement improvement is about 3.5 times. This is due to the fact that for floating stone column end bearing resistance is low and hence most of the strengths become immobilized. Spacing of 2.5d between the stone columns gives rise to a significant improvement in bearing capacity. Long stone column reduces differential settlement of the footing. 6.0 References [1] Murugesan, S., and Rajagopal, K., Studies on the behavior of single and group of geosyntetic encased stone column. Journal of Geotechnical and Geoenvironmental Engineering [2] Dash, S.K., and Bora, M.C., Influence of geosynthetic encasement on the performance of stone columns floating in soft clay. NRC Research Press.

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Business ProposalDocumento35 páginasBusiness ProposalMJ MacapagalAinda não há avaliações

- 1) About The Pandemic COVID-19Documento2 páginas1) About The Pandemic COVID-19محسين اشيكAinda não há avaliações

- ENG11H Realism 6-Outcasts of Poker FlatDocumento3 páginasENG11H Realism 6-Outcasts of Poker FlatJosh Cauhorn100% (1)

- CSMP77: en Es FRDocumento38 páginasCSMP77: en Es FRGerson FelipeAinda não há avaliações

- PostmanPat Activity PackDocumento5 páginasPostmanPat Activity PackCorto Maltese100% (1)

- Btech Me 5 Sem Heat and Mass Transfer Eme504 2020Documento2 páginasBtech Me 5 Sem Heat and Mass Transfer Eme504 2020SuryaAinda não há avaliações

- Rights of An Accused Under Custodial InvestigationDocumento17 páginasRights of An Accused Under Custodial Investigationadrianfrancis9100% (1)

- Clay & Shale Industries in OntarioDocumento193 páginasClay & Shale Industries in OntarioJohn JohnsonAinda não há avaliações

- Watt AC-DC Converters: FeaturesDocumento3 páginasWatt AC-DC Converters: FeatureskofidAinda não há avaliações

- Youth and Moral ValuesDocumento6 páginasYouth and Moral ValuesAlka SinghAinda não há avaliações

- Empowerment TechnologyDocumento2 páginasEmpowerment TechnologyRegina Mambaje Alferez100% (1)

- Bruner, Jerome - The Growth of MindDocumento11 páginasBruner, Jerome - The Growth of MindTalia Tijero100% (1)

- The Necessary Art of PersuasionDocumento14 páginasThe Necessary Art of PersuasionAnugragha SundarAinda não há avaliações

- Mechanical Energy Storage: Created by Nick StroudDocumento24 páginasMechanical Energy Storage: Created by Nick StroudAli ShazanAinda não há avaliações

- Lesson 3: Letters of RequestDocumento4 páginasLesson 3: Letters of RequestMinh HiếuAinda não há avaliações

- Etymological Wordplay in Ovid's Pyramus and ThisbeDocumento5 páginasEtymological Wordplay in Ovid's Pyramus and Thisbeignoramus83Ainda não há avaliações

- PWC - Digital Pocket Tax Book 2023 - SlovakiaDocumento52 páginasPWC - Digital Pocket Tax Book 2023 - SlovakiaRoman SlovinecAinda não há avaliações

- FORM 2 Enrolment Form CTU SF 2 v.4 1Documento1 páginaFORM 2 Enrolment Form CTU SF 2 v.4 1Ivy Mie HerdaAinda não há avaliações

- Adobe Scan 23-Feb-2024Documento4 páginasAdobe Scan 23-Feb-2024muzwalimub4104Ainda não há avaliações

- 1 Raven's™ Standard Progressive Matrices Plus (SPM Plus) - PSI OnlineDocumento1 página1 Raven's™ Standard Progressive Matrices Plus (SPM Plus) - PSI OnlineVINEET GAIROLAAinda não há avaliações

- Koehring ManualDocumento56 páginasKoehring ManualKyle A. Nolan100% (3)

- National Article Writing Competition 2020: Centre For Competition and Investment Laws and PolicyDocumento8 páginasNational Article Writing Competition 2020: Centre For Competition and Investment Laws and PolicyNisha PasariAinda não há avaliações

- Water Quality MonitoringDocumento3 páginasWater Quality MonitoringJoa YupAinda não há avaliações

- Manual en TC1 TD4 Curr 2018-07-16Documento39 páginasManual en TC1 TD4 Curr 2018-07-16Daniel Peña100% (1)

- REF615 PG 756379 ENs PDFDocumento96 páginasREF615 PG 756379 ENs PDFandi mulyanaAinda não há avaliações

- Quiz Application in Visual BasicDocumento20 páginasQuiz Application in Visual BasicShivangi SahaAinda não há avaliações

- Characteristics of Victorian BritainDocumento3 páginasCharacteristics of Victorian BritainmwaqasenggAinda não há avaliações

- Compuware DCRUM Intro 2012 Version 12.00Documento142 páginasCompuware DCRUM Intro 2012 Version 12.00JanAinda não há avaliações

- System Software Mind MapDocumento1 páginaSystem Software Mind MapRena AllenAinda não há avaliações

- Umihara Et Al-2017-Chemistry - A European JournalDocumento3 páginasUmihara Et Al-2017-Chemistry - A European JournalNathalia MojicaAinda não há avaliações