Escolar Documentos

Profissional Documentos

Cultura Documentos

Otc19451Multilateral Wells To Improve Production Performance in Heavy Oil Reservoirs-The Challenges of The ZAM-408ML Well

Enviado por

zouke2002Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Otc19451Multilateral Wells To Improve Production Performance in Heavy Oil Reservoirs-The Challenges of The ZAM-408ML Well

Enviado por

zouke2002Direitos autorais:

Formatos disponíveis

OTC 19451

Multilateral Wells to Improve Production Performance in Heavy-Oil

Reservoirs: The Challenges of the ZAM-408ML Well

D. Baldini, L. Tealdi, F. Okassa, L. Riccobon, D. Isella, A. Baioni, G. Obondoko, H. Malonga, F. Itoua Konga, M.

Rampoldi, Eni Congo

Copyright 2008, Offshore Technology Conference

This paper was prepared for presentation at the 2008 Offshore Technology Conference held in Houston, Texas, U.S.A., 58May2008.

This paper was selected for presentation by an OTC program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been

reviewed by the Offshore Technology Conference and are subject to correction by the author(s). The material does not necessarily reflect any position of the Offshore Technology Conference, its

officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Offshore Technology Conference is prohibited. Permission to

reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of OTC copyright.

Abstract

The Zatchi field, located in the Lower Congo Basin offshore, is a multi-layer reservoir of Cenomanian/Albian age

operated by Eni Congo in partnership with Total Congo.

The Zatchi B reservoir is 30 m thick sand characterized by a large accumulation of heavy and highly viscous oil

(15 API, 1000 cP) trapped in the marine-transgressive sands of the Gres de Tchala formation. Three aspects

make the successful development of such reservoir an extreme challenge: the presence of both bottom water and

a gas cap, the very low reservoir pressure, the very high viscosity of the oil. As a matter of fact, over the 27-year

life of the field, only three wells were put in production from the B layer, with not satisfying results due to the

heaviness and viscosity of the oil and the severe problem of gas coning and cresting.

The multilateral technology generally allows increasing the reservoir exposure with fewer wellbores, reducing and

spreading the drawdown along the drains reducing the potential for coning. This technology has been proven

effective in several heavy oil deposits recovery worldwide. For this reason, in order to improve the reservoir

drainage reducing times and costs, the layer B was selected as the optimal candidate for the first multilateral well

in the Congo basin: well ZAM 408 ML.

This paper will review the Zatchi B reservoir history and development challenges with a focus on the multilateral

well reservoir modeling, the TAML6 completion and artificial lift design. Furthermore, the challenges encountered

during the operations in terms of reservoir properties sampling, operations geology, drilling, completions and

production will be described in detail.

Introduction

Heavy oil has become an important theme in hydrocarbon industry with an increasing number of operators getting

involved or expanding their plans in this market around the world.

A huge number of non conventional oil reservoirs have been discovered worldwide, but only a small percentage

of them is producing or is under active development.

Heavy oil represents a massive world resource, but the great challenge is to find the best way to produce,

transport and process it.

Eni Congo is taking part to this challenge, concentrating the efforts on the heavy oil of the Zatchi B reservoir.

The Zatchi field is located in the Congo offshore basin, with water depth ranging from 55 to 57 meters and an

areal extension of about 34 km

2

(fig.1)

The field is characterized by multiple stacked reservoirs (from A down to E) belonging to the Gres de Tchala and

Carbonates de Sendji formations (Cenomanian/Albian age).

Like many other commercial reservoirs in offshore Congo, the Zatchi fied is characterized by sandy and dolomitic

rocks deposited during the early drift phase in the mid-Cretaceous, with structural-stratigraphic traps created by

movement of the transition-phase Aptian salts (fig. 2 and 3).

The Zatchi field was discovered in 1980 with the first exploratory well ZAM-1, which found oil accumulations in the

Cenomanian/Albian section.

2 OTC 19451

Since then, around 90 wells were drilled from four different platforms, mainly to produce from C, D and E

reservoirs.

The A layer (gas bearing) was never taken into consideration because it was uneconomical, while the B

reservoir, in spite of the interesting hydrocarbon accumulations, was targeted only by three wells mainly due to

the heaviness of the oil.

Reservoir B Description and production challenges

Sedimentological Model and Diagenesis

The Zatchi B is a shallow reservoir (average top @ -400 mTVDSS) of Cenomanian age characterized by

homogeneous tchickness of about 90 meters.

The whole Albian-Cenomanian series of the Zatchi field is interpreted as transgressive complex of littoral bars that

delimit areas with lagoon characteristics landward; inside the lagoon areas, there are some minor delta areas and

zones characterized by deposition in typical low energy sand conditions, The complex of littoral bars is locally cut

by tidal channels.

A larger deltaic system that cannot be recognized in the reservoir area is probably responsible for the letting in of

the most of the clastic sediments in the area. These sediments, redistributed along the coast by littoral currents,

give origin to the longshore bar complex.

From a lithological point of view, it is possible to observe a cyclic alternation of mainly sand and dolomite levels;

this alternation respectively corresponds to periods of high and poor terrigenous supply in the main deposition

system. In general, the main reservoir levels of Zatchi field correspond to significant regressive episodes in a

main transgressive framework.

A schematic representation of the sedimentilogical interpretation of the deposits of Zatchi Reservoir B is shown in

figures 2, 3, 4 and 5.

Production Challenges

The Zatchi B, although it is characterized by good porosity (>30% in sandy facies) and permeability, in some

cases is higher than 1 Darcy, is a very difficult reservoir to deal. In fact the extreme challenge is the high density

(15 API) and viscosity (1000 cP) of the oil, the presence of both bottom water and gas cap and the very low

reservoir pressure.

Since 1980, Reservoir B was put in production only on three Zatchi well: ZAM 116, ZAM 406 and ZAM 111 ST.

The production from these wells was soon stopped due to the early increase in GOR (Gas Coning effect).

The huge oil accumulation within the B reservoir induced the partnership to search for alternative-innovative

solutions to exploit the potential of this layer. On the base of this, the Pilot project ZAM-408ML was launched in

order to evaluate the potential for multilateral wells in such reservoir.

The ZAM-408ML multilateral well design

Reservoir modeling and Geological aspect

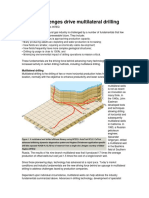

The multilateral technology has been one of the most rapidly evolving over the last decade.

It has been proven effective worldwide in terms of costs reduction, improving sweep efficiency (by delaying gas

and water breakthrough), facilitating drainage of heterogeneous reservoirs, increasing reservoir exposure and

reducing coning effects.

In few words, multilateral are wells in which a single hole (parent wellbore) is drilled to a pre-determined depth,

then multiple branches are drilled out from the original wellbore. These laterals may extend in opposite directions

from each other in the same zone, or they may be drilled into different zones or formations.

The lesson learn from former wells put in production from this level has pushed to considering, at the project

implementation fase, in opposition to what was previously done, to optimize the positioning of the well in order to

take into consideration the artificial lift system which will be installed.

Due to the high viscosity of the oil implementing the drilling of multilateral well will allow the increase the surface

contact between the well and the formation which will therefore homogenize and reduce the drawdown apply to

the formation. In a nutshell, the major purpose is to enhance reservoir contact and thereby enhancing the well

productivity.

OTC 19451 3

In practice, the well has been projected to be in the North Est part of the structure of the Zatchi where the gas cap

is localized far enough from the projected well. Each leg of the multilateral will be on opposite each other in order

to minimize interferences between them.The maximum length of each leg has been defined as been 1,380 ft.

The presence of zones of low dolomite with low porosity, due to phenomenon of secondary dolomitization

occurred close to the oil water contact (dolomite bacteria), have been taken also into consideration to optimize the

well trajectory (see FIG.5 bis).

Driling & Completion design

At first glance the multilateral option offers immediate advantages over single bore wells since it provides

increased reservoir exposure at a reduced cost. The critical component of a multilateral well is the J unction, which

is the interface between the main bore and the branches

Multilateral wells are classified into different forms or levels namely on the basis of the junction structure.

The Level 6 Formation J unction run on ZAM-408ML consists of two adjacent tubular joints at the bottom end of a

parent casing. The dual-leg junction is run in the hole at the bottom of the parent casing, with leg #1 in the

collapsed position. The junction leg was expanded downhole to their original outer diameter, using expandable

metal forming techniques. The system provides a wide range of completion options for the two branches.

The purpose of the junction is to achive a structural link between a parent casing and the two lateral legs, while

providing hydraulic isolation from the wellbore. During the forming process, the geometry of the junction is

collapsed to fit entirely inside a 13 3/8 68#L-80 BTC casing and only the ductile legs sustain plastic deformation

while the stiffener remains underformed

Three tubulars are used to build the indexing casing coupling. The assembly is essentially a short casing pup joint

with an orientating keyway and a locating profile in its inner upper diameter. The tools that need to be oriented

with respect to the junction outlets have an orienting key that rides the casing couplings orienting keyway

The drilling diverter is set in place and the 6 drilling BHA is run in the hole to drill each one of the two laterals.

These drilling phases use standard techniques and equipment

Both branches were cemented at the same time, leg #2 has cement shoe already installed when running in hole.

The ZAM-408ML multilateral well execution

The ZAM 408 ML was drilled from the ZAF-4 Platform by the SSD 18which is a Modular Offshore & fast Moving

Rig.

The well spudded on April 8

th

, 2007 and the rig was released 65 days later. The whole operations sequence is

described in the following paragraphs.

4 OTC 19451

Reservoir Evaluation While Drilling

The formation evaluation on ZAM-408ML well was entirely performed by means of Logging While Drilling (LWD).

The main challenge related to this decision was to obtain a valid CPI in both 6 sections without the support of

wire-line logs, sparing on rig time and costs.

A Gamma Ray-Resistivity tool (GR-ARC) was run during the 12 section, mainly for correlation purpose. The

top of the 9 5/8 formation junction assembly was set 3 meters below the top of B reservoir, in order to keep the

two drains as far as possible from the overlaying gas cap.

A Density-Neutron tool (ADN) was added in both 6 legs, with the aim of computing a detailed formation

evaluation.

The final output was more than satisfying. The quality of the logs was very good for both 6 sections, allowing the

petrophysics team to compute a reliable CPI.

From a reservoir point of view, all formation tops (including the top of Reservoir B) were encountered in accord

with the initial well prognosis.

Reservoir B showed very good petrophysical properties (Poro Av =26-30%, So Av =84-86%) and a total Net Pay

of about 385 mMD for each leg, with corresponding Net/Gross ratio of 98%.

Legs A and B were stopped respectively 12 and 14 verical meters above the OWC, in order to keep water

saturations as low as possible.

Drilling

Well schematics

Main Wellbore

The 26 phase was drilled to 184m and a 20 CP was landed and cemented

A 12 Pilot Hole was drilled to 460m (63 angle) and the section was enlarged to 17 with a dedicated under-

reaming BHA. The 13 3/8 casing was landed & cemented at 451m

The 12 slant well was drilled to measured depth of 760m MD (439m TVD 89 angle) using standard

technology and drilling practices. A 70m (ROP: 5-8m/hr) Interval of the drilled section was under-reamed to 17

using standard under-reaming technology and procedures. After POOH under-reaming assy a clean out BHA with

7 Bull Nose was run to where Formation J unction would be set

Landing & Orienting the 9 5/8 Formation Junction Assy

The Double Leg J unction plus the 9 5/8 casing was Run in Hole to Total Depth of 12 Section (751m Bottom

Leg #1 and 685m Bottom Leg #2). The orientation of the Casing String was done by Formation J unction Device

and checked by MWD taking as a reference the casing collar locator

Swagging & Cementing the Formation Junction

OTC 19451 5

The Formation J unction Expansion Tool was activated and the lowest part of Leg #1 was expanded with a

Working Pressure between 2,000psi and 3,500psi. The entire operation from beginning to the end takes 35min. A

cement stinger assy was run to 724m and after sting-in a cement job was performed using double slurry: 1.9sg

Lead Gas Tight plus 1.97sg Tail Latex cement slurry. After Bump Plug the 1,800psi Pressure was held for 5min.

This cement off both legs of the formation junction and drilling of the legs could now be performed once the

cementing string was removed from the well.

Building and Completion of the Two Parents / Branches

The First 6 Section was drilled through Leg #1 to 1,173m MD (449m TVD 86 angle) and after landed a 3

Poromax Screens below a 7 Packer, a cleaning acid job was performed. The Leg #1 was displaced to filtered

1.1sg Brine

The Second 6 Section was drilled through Leg #2 to 1,104m MD (446m TVD 90 angle) and after landed a 3

Poromax Screens below a 7 Liner Hanger packer, a cleaning acid job was performed. Also Leg #2 was

displaced to filtered 1.1sg Brine

The 2 7/8 Completion string was run in parent well with an ESPCP Gearbox mod. 9-1 Submersible Pump and

both strings were put on production without isolating the 2 zones ( fig.6).

Well challenges

The most challenging part of the project was starting from the 12 TD section:

1) Enlarge the last 100ft to 17 and be sure to clean very well the hole just opened (If the hole collapsed

the entire project could be jeopardized)

2) Run and land at the correct / required depth the Multilateral J unction without bend or break it

3) Perform a correct cement job with a specific Plastic Slurry

All that above-mentioned was performed in the best way possible thanks to the Professional work done by

personnel present in Eni Congo offices and who phisically perform / supervise the job on-board We have to

keep in mind that all the operations have been performed for the first time in Eni Congo successfully.

0

200

400

600

800

1,000

1,200

1,400

0 10 20 30 40 50 60

Ti me (days)

D

e

p

t

h

(

m

)

12 1/4" PH

26" Section

ESP Completion

(Contingency 15%)

ZAM 408 ML - Time Vs Depth

17 1/2" HO

12 1/4" Section

6" Section

6" Section

17 1/2" HO

6 OTC 19451

DATE:

SINGLE COMPLETION VERTICAL DEVIATED HORIZONTAL SELECTIVE

ICGP OHGP GRAVEL SIZE: 20/40 40/60

String weight up [t] CasingSize: [in] Type of packer fluid:

String weight down [t] Top: [m] Bottom: [m] Density: [kg/l]

Make up report yes [y/n]

SHEAR RELEASE VALUE: 60.000 -lbs.

SHEAR RELEASE VALUE: lbs.

Steel Gr. %

MAKE UP TORQUE : GREASE :

REF Tools EPTH

ADJ UST. SUB 3-1/2" HYD CS pin xpin

Thd S. Grade Top (m)

CSG/LIN OD

TOP AT mt PUMP 538 PM FER 6 MNL 118P31

SHOE AT mt SEAL SECTION Mod GSB3DB FER HL H6 AB PFSA

CEM UP mt GEAR BOX SERIE 525/562

LINER HANGER : CENTRILIFT MOTOR KMHTC 63 HP 721 V 53A

LINER HANGER :

LINER HANGER : LEG B

ODNOM

679.8

PUP J OINT 3-1/2" NU

Top (mMD) Bottom(mMD O - RING SEAL SUB 3-1/2" NU X 2-1/2" ID

BLANK PIPE 3-1/2'' NU

TYPE OF CHARGE :

SHOOT DENSITY :

Top(m) Bottom(m)

BLANK PIPE 3-1/2" HYD-CS 1 jt

X-OVER 3-1/2" HYD-CS X NEW VAM

HALLIBURTON POROMAX SCREENS 3-1/2" N.VAM N 6

TD

41 BLANK PIPE 3-1/2'' NU

O RING SEAL SUB 3-1/2" NU X 2-1/2" ID

1 098.18

3.500 1 096.86

2.500 3.500 1 098.03

NO -GO SUB BELOW

LEG # B NEW SC-1R 70B-40 PACKER

683.77

CASING SUB 5-1/2" SLHT box X 5" BTC pin

COUPLING 5" BTC Box x 5" VAM Box

5.500

CASING PUP J T 5-1/2" SHLT pin x pin

682.30

5.000

OPEN HOLE ZONE ZONE

35

2.992

2.990

Level

683.50

5.437

36

34

32

30

31

Rig Supervisors

3.500

684.45

685.01

694.51

33

" B" / LEG B 1104 X-OVER 5" VAM boxx 3-1/2" HYD-CS pin

FRANCOIS POUNGA

Superintendant

2.992

2.990

3-1/2" NU PUP J OINT 2.990

X-OVER 3-1/2" NEW VAM box x3-1/2" NU pin

2.990

2.990 3.500

3-1/2" NU CIRCULATING SHOE

38

39

40

29

LEG A

569.15

711.00

20"

684.46

F.J = Formation Junction top @673,55 m

for more details see Baker drawing

C

A

S

IN

G

9

-5

/8

"

5

3

,5

#

L

-8

0

A

M

S

9-5/8" AMS 53,5/ 47 L-80 WHD/668 668 / 673

7" /LEG B

H.MANTINOU/-PRADA/ELSAYED

N. VAM

OPENIG Press = psi Press = 600 psi

NOTES :

COMPLETION J OB PURPOSE

LEG # A SLPR HANGER

29 L-80 F.J 684

ID mm

182 K-55 AMS 106.5

3.900 695.07 37

1 104.00

3.900 1 096.33

753 1173 " B" / LEG A 3.500

1 100.60

PERFORATED ZONE

28 New SC-1R 70B-40 W/5-1/2" 17# SLHT Box Down 4.00 6.010 679.76

NO -GO SUB ABOVE

TYPE OF GUNS :

ISOLATION METHOD

682.82

CMT RETAINER DEPTH SIZE

1 173.00

27 3.50 1 171.30

3.50

3.50

CIRCULATING SHOE 3-1/2" NU

26

3.50 1 168.01 25 Level

24

Old Perforated intervals 23

1 166.84

X-OVER 3-1/2" N.VAM boxx 3-1/2" NU PIN 2.99 3.90

22 HALLIB. POROMAX SCREENS 3-1/2" N.vam N 67 jts

3.50 758.26

2.99 3.90 758.83

21 X-OVER 3-1/2" HYD-CS boxx 3-1/2" NEW VAM pin

20 BLANK PIPE 3-1/2" HYD-CS N 4jts 2.99 3.50

29 157.1 7" /LEG A 753

7" /LEG B 684

L-80 N.VAM

L-80 N.VAM

9-5/8" 673 L-80 N.VAM

AMS 53.5 216.8

29 157.1

47 220.5

9-5/8" 668

42

2.99

2.99

2.99

2.50

2.99

L-80

13-3/8" 451 L-80 AMS

482.6

68 315.3

TO m STEEL THRD lbf/ft

568.73

16 L, CENT 2'' LP,W/DOUBLE INJ CHECK VALVE _ 8.20 569.15

15 _ 5.90

_ 5.13 565.83

14 5.13 566.23 _

553.29

12 _ 5.13 563.73

20" 13-3/8" 9-5/8"

552.81

11 X-OVER 3-1/2" EU BOX X 2-3/8" PIN 2.44 2.88

3.75 552.31

182 451 673

10 UPPER CENT. 3-1/2EU P X BOX 2.44 8.26

9 X-OVER 3-1/2" EU pin X 2-7/8" HYD-CS box 2.44

7 2.44 2.88 542.50 2-7/8#6,5 HYD CS PUP J OINT

2.44 2.88 552.03

2.44 4.64 539.58 DPG-TA' DOWN HOLE CARRIER 2-7/8 " HYD

TD

8 2-7/8#6,5 HYD CS TUBING L-80 N 1

13

CASINGS CHARACTERISTICS

17

WHD WHD WHD

2.44 2.88 536.60

7" /LEG A N. VAM 29 L-80 F.J 753

6 NomOD lb/ft Bottom(m)

PRODUCTION CASING

1 BREDA TBG-HGR 3-1/2" EU UP X3-1/2 hyd DOWN

4 2-7/8#6,5 HYD CS TUBING L-80 N 55

3.50 13.35 TUBING HANGER 11'' X 2-9/16 EU U X VAMD.

WELL HEAD 3K CONVENTIONAL BREDA

2 2.99

3 2.44 X-OVER 3-1/2" HYD-CS BOX x 2-7/8" HYD-CS PIN

11.80

11 12.09 2.99 BACK PRES, VALVE Size 3" Type TSB2

BONNET 11" x3-1/8" 3,000-psi RT SSD 18 TIE DOWN ELEVATION

WELL HEAD DESCRIPTION 2200 ftlb

X-MAS TREE 3-1/8" x 3,000-psi ID OD

API 5A-2

GEOG COORD LONG m

6.5 L-80 7 552.00 GEOG COORD LAT m 2,875" HYD

TOTAL DRILL 1500 MM/RT Nom. O.D. Thread lb/ft Down to

ANNULUS FLUID 1.03-Kg/lt filtered S-Water Tubing

BRIDGE PLUG mMDORKB COMPLETION STRING

BRIDGE PLUG M/RT SIZE

1500 mMDORKB

RT/TIE DOWN 11,8 mMDORKB 7" BKR SLP 4.42 711.0

TOTAL DEPTH

WELL HEAD RATING 3,000-psi workingpressure

Model type I.D. Depth

NewSC-1R 4.00 679.76 RIG USED SSD 18 7" BKR

DRILLING PERIOD juin-06 Nom. O.D. Manufact.

1.13

Well deviation [max.] @ mMD/RT Well deviation

GENERAL INFORMATIONS PACKER

11

11J5B9002

ESP

14 7" NACL

ARPO 20 / C Account

ZATCHI

ENI CONGO WELL NAME ZAM - 408 ML

FIELD NAME

E & P

7 jui n 2007

SAND CONTROL ASSEMBLY

3.75 13.70

2.88 534.70 2.44

5 2-7/8#6,5 HYD CS PUP J OINT

5.96

5.56

5.44

18

19

5" x7" 26-29# LINER HANGER PACKER BTC pin

CASING EXTENSION 5" BTC

X-OVER 5" BTC box x 3-1/2" HYD-CS pin

4.42

4.40

711.00

715.40

720.01

720.33

1 166.32

1 168.17

COMPLETION SKETCH

Fig 6.: Well Schematic

Completion & Artificial Lifting Design

The multilateral well ZAM-408ML represents the fourth well which is attempting the production of such reservoir.

The well architecture and trajectory was designed to optimize reservoir recovery, productivity index while reducing

the drawdown at the wellbore to avoid gas coning phenomena. In parallel, it has been decided to develop an

innovative system to improve the ESPCP performances by increasing and homogenising the temperature

distribution around the artificial system planned to be installed. The original scope was not to improve the well

productivity, but only to have a better handling of the flow at the pump interface and maximizing the pump

efficiency.

ESPCP are pumps made especially for ash environment or handling high viscous fluids but handling a viscous

fluid of 1300 cp or 500 cp is not the same thing. An ESPCP will react better handling a fluid with 500 cp than 1300

cp if we consider the same equipment (see table 1 and graph.1).

OTC 19451 7

Frequency Freq Hz 44.2 45.1 47.5 52.5

Dead Oil Viscosity

@BHT DOilVisc Cp 502 1004 1507 2009

Total Dynamic

Head TDH FT 2093 2275 2449 2620

Viscosity Pump

intake VISin Cp 333 649 959 1266

Viscosity Pump

discharge VISout Cp 228 434 636 837

Motor Load MtrLoad % 57.41 62.69 67.02 70.68

Pump Efficiency PmpEff % 64.83 61.59 57.56 51.58

Table 1: relationship between the increase in fluid viscosity compared with the pump efficiency &

Motor load at a given speed. The flow rate is kept constant at 610bfpd.

T

Data from this level show a viscosity of 1343 cp @ 34.5C (reservoir temperature)

Graph.1: Relationship between the decreases in viscosity compared with the temperature.

Therefore, to improve the pump efficiency, one solution can be reducing the oil viscosity surrounding the ESPCP

in order a have a lighter fluid at the pump suction section. The fluid temperature distribution around the

electrical motor could give important clues on this perspective.

An electrical motor immerged in a viscous oil put in motion by a pump in this upper part of the system induces a

thermal propagation due to conduction and forced convection.

The tool has been made of different pieces of sleeve with external fins. The geometry of the fin has been made in

a way to give them an edge shape. A total of 11 external fins per sleeve.The number of fins has been chosen

according to the minimum fluid velocity in order to cool the motor (1ft/sec is the recommended value from the

manufacturer). A total of 5 sleeves have been threaded along the motor (this association of sleeves with fins is

called Motor J acket). Each fins sleeve positioning has been set in such a way to allow the distortion of the fluid

in motion. To avoid any motion of the sleeve, eight (8) screws were used to tighten up along the sleeve without

impacting on the motor internal structure.Therefore the Motor J acket has no impact on the motor structure.It is

just a heat exchanger. The Motor J acket is able to protect the motor lead extension (MLE) during the running of

completion (Fig7).

Temperature VS Viscosity

0

200

400

600

800

1000

1200

1400

1600

30 40 50 60 70 80

Temper at ur e (C)

V

i

s

c

o

s

i

t

y

(

C

p

)

8 OTC 19451

Fig.7: Motor J acket

The thermal source is coming from the motor external temperature. Principally we are using the motor inefficiency

or in other words, the J oules effect losses. I could be noticed that the more the motor is inefficient, the higher will

be the motor external temperature. Hence, to have a sufficient thermal source from the motor.The solutions could

be playing with the motor inefficiency or reducing the fluid velocity in order to reduce the cooling of the motor.

Pratically, it is nessesary to install an oversized motor (ranging from 20 to 30% HP extra) although at the same

time making sure not to shorten the motor run life and also avoiding electrical insulation losses of the downhole

motor.

In J une 2007, the well ZAM-408ML has been completed with an artificial lift system composed of:

- Electrical submersible progressive cavity pump (ESPCP)

- Gas separator,

- Seal section

- Motor shrouded by Motor J acket

The well is now producing an average fluid rate of 760 bfpd, with 570 bopd of oil production (see graph.2).

ZAM /408ML B HOR

300

350

400

450

500

550

600

650

700

750

800

1-juin-07 16-juin-07 1-juil.-07 16-juil.-07 31-juil.-07 15-aot-07 30-aot-07 14-sept.-07 29-sept.-07 14-oct.-07 29-oct.-07 13-nov.-07 28-nov.-07

Q

t

o

t

&

Q

o

i

l

0

10

20

30

40

50

60

70

80

90

100

W

C

Qtot [bfpd] Qhuile[bopd] WC[%]

0

100

200

300

400

500

600

janv-

07

janv-

08

janv-

09

janv-

10

janv-

11

j anv-

12

janv-

13

janv-

14

janv-

15

janv-

16

janv-

17

janv-

18

janv-

19

janv-

20

D

b

i

t

j

o

u

r

n

a

l

i

e

r

[

B

O

P

D

]

GOR li m = 250 Sm3/Sm3

NO GOR limi t

GOR li m = 1000 Sm3/Sm3

Graph.2: well production history Graph.3: .Production forecast

OTC 19451 9

Such results are very encouraging since they are above the production forecast (see Graph.3).

In this pilot project of the first Motor J acket these main results are observed:

The pump hydraulic efficiency obtained is 70% instead of the 35% on the well ZAM-406 and 30% on

ZAM-116.

The temperature increment of the fluid given by the motor shrouded with the Motor J acket is of an

average of 5C which implies that the thermal propagation expected is positive for the ESPCP Motor

J acket application.

The ZAM-408ML multilateral well production performance

A 56hour hour build up of the well has been done in order to evaluate precisely the well potentially. The analysis

highlights showed the following results:

The pressure derivative trend is similar in its final part of a normal single drain well having 5000 ft long

length (see graph.4).

The skin factor is equal to zero

The productivity index is 6.7m

3

/d/bar.

Graph.4: Log-log plot of the pressure and the derivative

With respect to the former producing wells from this level, the PI is twice bigger which shows the positive results

in terms productivity index of the ZAM-408ML TAM6.

The Zatchi B potential

At the present time an ongoing study is being done in order to increase reservoir recovery factor. In fact, the level

B has an estimate OOIP of 435 MMstb and a GOIP of 1262 MMsm

3

for only a total volume produced of 370,000

stb @ 2005. It has been evaluated that the maximum recovery factor with a traditional method will not go beyond

2%. Hence, the study was oriented on the EOR methods which will allow to have, as objective, a minimum

recovery factor of 10%.

10

100

1000

0.1 1 10 100

P

r

e

s

s

u

r

e

C

h

a

n

g

e

a

n

d

D

e

r

iv

a

tiv

e

(

p

s

i)

Elapsedtime (hrs)

Log-Log Match - FlowPeriod 2

Effective length

Distortion due to interference b/w drains

10 OTC 19451

The actual EOR methods which are under instigation are the following:

Thermal methods:

CSS

CSS +gas injection

in-situ combustion

Steam assisted gravity drainage

Chemicals:

Polymer injection

VAPEX

Complex well geometry (CHOPS)

All these different options will be addressed by taking into account the cost issues learned from previous studies.

Since the best hope for recovery of this viscous oil appears to be a thermal application, a special care will be

taken on the core analysis with special analysis on rock compressibility, wet ability, thermal capacity and

transmissibility. In addition, the fluid sampling and pressure testing of the B zone will be performed in order to

have a clear view on viscosity, barrier location and depletion. This study will increase the field perspective.

Conclusions

With the purpose of optimizing heavy oil production from Zatchi B Reservoir, ZAM 408 ML was the first successful

multilateral well ever drilled in West Africa.

The most critical drilling challenges were faced with extremely satisfying results and the whole operations

sequence from spud until rig release were performed in only 65 days.

The formation evaluation process, performed by means of Logging While Drilling technology, allowed the

computation of a reliable CPI which pointed out very good reservoir properties in both drilled legs (high porosity

and oil saturations).

An innovative system called Motor J acket was also installed in order to optimize the artificial lift system.

The first production data are encouraging, the well performances are satisfying and the TAML6 technology allows

mitigating premature water and gas breakthrough, or coning.

The ZAM 408 ML well opens new development perspectives for the Zatchi B Reservoir and the ongoing studies

should support the optimization of the heavy oil recovery, with new dedicated wells to be drilled in the near future.

Acknowledgements

The authors wish to thank the Eni Congo management, its different technical departments for permission and

encouraging the implementation of the ZAM-408ML project.

We would also like to thank everyone who has contributed to the said project with their constructive comments.

References

1. Fluid mecanics, L.Landau, E. Lifchitz Mir edition Moscow.

2. webb,Eckert, ERG and golstein, J R. heat transfert and friction in tubes with repated-rib roughness, int

J . heat and Mass transfer, vol 14, pp601-617, (1971)

3. Gee, DL, , and Webb, RL, Forced convection heat transfert in helically rib-roughened tubes, Int,

J .Heat and Mass Transfer, vol.23 pp1127-1136, (1980)

4. Garimella, S., Chandrachood, V., Christensen, R.N and Richards, D.E, Investigation of heat transfer and

pressure drop augmentation for turbulent flow in spirally enhances tubes, ASHRAE transactions, Vol. 94,

Part 2, pp. 1119-1131 (1988).

5. Farina, A. and Palgiarini, G., un apparato per lanalisi sperimentale dello scambio termico convettivo in

condotti con parete corrugata, atti del XII congresso Nazionale sula trasmissione del Calore, pp.151-162,

LAquila, 23-24 giugno 1994.

6. Piero De biase, Andrea Fedullo, Nazmul Hug, Zatchi Marine field Layer B (November 2005).

7. Sada D.J oshi, Horizontal well technology.

8. A. Banioni, D. Baldini, R. Riccobon; Drilling and completion program of ZAM-408ML (Eni Congo).

OTC 19451 11

Fig. 1: Zatchi Location Map: the field is located in the Fig. 2: Schematic stratigraphic chart showing the

Congo offshore, with water depth ranging between 55 gross lithological compostion of the Zatchi field.

and 57 meters .

Fig. 3: Schematic cross section highlighting the main tectono-depositional domains of the West African margin. The lower

sedimentary sequences are strongl y deformed by salt tectonics while the upper ones are relati vel y undeformed or characterized by

a low tectonic control (from Brownfield and Charpentier, 2006)

Zatchi Field

Zatchi Zatchi

12 OTC 19451

Fig. 4: Facies Sequence of the typical Zatchi well, with GR and Dendity/Neutron response.

The B Reservoir is characterized by the prevalence of sands alternated with thinner dolomitic

Layers.

Fig. 5: Deposition Model for Zatchi field. The serie is interpreted as a transgressive complex of littoral bars that delimit

areas with lagoon characteristics landward

OTC 19451 13

Fig. 5 bis: NS Cross section passing along the two legs of ZAM 408ML well. The top of the 9 5/8 Multijunction assembl y was set 2.5

meters below the top of B reservoir in order to keep the 2 drains as far as possible from the gas cap. Leg A and B ended

respecti vel y 12.5 and 14.5 above the OWC.

OWC -434

B

L

a

y

e

r

N S

20 CSG @ -155

13 3/8 CSG @ -380

9 5/8 multijunction Ass. @ -409

LEG A / TD -421.5

LEG B/ TD -419.5

Top B @ -406.5

14 OTC 19451

Composite showing the logs recorded on the LEG A of ZAM 408 ML (6 phase). Record of the Resisti vity and Density/Neutron while

drilling.

The overall quality of the logs is good and allows the computation of a reliable CPI (last three tracks of the composite).

The B Reservoir characteristics are excellent, with average porosity around 26% and oil saturation higher than 80%..

In this reservoir section onl y Sand seems to be present with negligible amount of Carbonates

OTC 19451 15

Composite showing the logs recorded on the LEG B of ZAM 408 ML (6 phase). Record of the Resisti vity and Density/Neutron while

drilling.

The overall quality of the logs is good as in LEGA allowing the computation of a reliable CPI (last three tracks of the composite).

The B Reservoir characteristics are excellent, with average porosity around 26% and oil saturation higher than 80%..

In this reservoir section onl y Sand seems to be present with negligible amount of Carbonates

Você também pode gostar

- API - Guidance - Document Hydraulic Fracturing Operations-Well Construction and Integrity GuidelinesDocumento6 páginasAPI - Guidance - Document Hydraulic Fracturing Operations-Well Construction and Integrity Guidelineszouke2002Ainda não há avaliações

- Surface BOP Kill SheetDocumento12 páginasSurface BOP Kill Sheetzouke2002Ainda não há avaliações

- 哈里伯顿钻井水力学培训 PDFDocumento17 páginas哈里伯顿钻井水力学培训 PDFzouke2002Ainda não há avaliações

- Pore Pressure Prediction From Well Log - Earth Sci Rev - 2011Documento33 páginasPore Pressure Prediction From Well Log - Earth Sci Rev - 2011srpadronAinda não há avaliações

- Managed Pressure Drilling (MPD) Technology OverviewDocumento28 páginasManaged Pressure Drilling (MPD) Technology Overviewzouke2002Ainda não há avaliações

- Modeling Flow in Geometrically Complex Reservoirs Using Hexahedral Multiblock Grids - Jenny - 2002 - Chevron-UStanfordDocumento9 páginasModeling Flow in Geometrically Complex Reservoirs Using Hexahedral Multiblock Grids - Jenny - 2002 - Chevron-UStanfordzouke2002Ainda não há avaliações

- In-Depth Investigation of Casing-Cement System Failure Modes in Geothermal Wells ConsideringDocumento8 páginasIn-Depth Investigation of Casing-Cement System Failure Modes in Geothermal Wells Consideringzouke2002Ainda não há avaliações

- EP (Extreme Pressure) Lubricity Tester Model 212 Instruction ManualDocumento43 páginasEP (Extreme Pressure) Lubricity Tester Model 212 Instruction Manualzouke2002Ainda não há avaliações

- Paper - 4.expansion of Tubular With Elastomers in Multilateral WellDocumento9 páginasPaper - 4.expansion of Tubular With Elastomers in Multilateral Wellzouke2002Ainda não há avaliações

- Fishbone Multilateral Well Productivity in A Five Spot PatternDocumento7 páginasFishbone Multilateral Well Productivity in A Five Spot Patternzouke2002Ainda não há avaliações

- Ijita21-02-p05.Wireless Data Transmission Options in Rotary In-Drilling Alignment (R-Ida) Setups For Multilateral Oil Drilling ApplicationsDocumento8 páginasIjita21-02-p05.Wireless Data Transmission Options in Rotary In-Drilling Alignment (R-Ida) Setups For Multilateral Oil Drilling Applicationszouke2002Ainda não há avaliações

- 5587-11853-2-PB - Productivity Prediction For Stacked Multilateral Horizontal Well Under OpenDocumento6 páginas5587-11853-2-PB - Productivity Prediction For Stacked Multilateral Horizontal Well Under Openzouke2002Ainda não há avaliações

- 1.new Method of Productivity Equation For Multibranch Horizontal Well in Three-Dimensional Anisotropic Oil ReservoirsDocumento5 páginas1.new Method of Productivity Equation For Multibranch Horizontal Well in Three-Dimensional Anisotropic Oil Reservoirszouke2002Ainda não há avaliações

- M3-Schlumberger - World's First Level 6 Intelligent Completion DrilledDocumento2 páginasM3-Schlumberger - World's First Level 6 Intelligent Completion Drilledzouke2002Ainda não há avaliações

- Paper - 4.expansion of Tubular With Elastomers in Multilateral WellDocumento9 páginasPaper - 4.expansion of Tubular With Elastomers in Multilateral Wellzouke2002Ainda não há avaliações

- NG2-5 AndApplication and Needs For Advanced Multilateral TechnologiesDocumento9 páginasNG2-5 AndApplication and Needs For Advanced Multilateral Technologieszouke2002Ainda não há avaliações

- SPE-123955-MS.an Overview to Applicability of Multilateral Drilling in the Middle East Fields (好)Documento11 páginasSPE-123955-MS.an Overview to Applicability of Multilateral Drilling in the Middle East Fields (好)zouke2002Ainda não há avaliações

- Logging AbrDocumento1 páginaLogging Abrzouke2002Ainda não há avaliações

- 分支井构型对临界生产压差Effect of the Multilateral Well Configuration on the Critical Production Drawdown Pressure in Loose Sandstone ReservoirsDocumento5 páginas分支井构型对临界生产压差Effect of the Multilateral Well Configuration on the Critical Production Drawdown Pressure in Loose Sandstone Reservoirszouke2002Ainda não há avaliações

- Costs, Requirements & Deadlines for Studying in Calgary SchoolsDocumento5 páginasCosts, Requirements & Deadlines for Studying in Calgary Schoolszouke2002Ainda não há avaliações

- Costs, Requirements & Deadlines for Studying in Calgary SchoolsDocumento5 páginasCosts, Requirements & Deadlines for Studying in Calgary Schoolszouke2002Ainda não há avaliações

- Global Challenges Drive Multilateral DrillingDocumento4 páginasGlobal Challenges Drive Multilateral Drillingzouke2002Ainda não há avaliações

- DavisDocumento8 páginasDavisHendi RofiansyahAinda não há avaliações

- EDM Reporting User ManualDocumento63 páginasEDM Reporting User Manualzouke2002Ainda não há avaliações

- New BatDocumento1 páginaNew Batzouke2002Ainda não há avaliações

- SPE 142622 Achieving Excellence in Well Completion Projects in Iraq's South Oil FieldsDocumento9 páginasSPE 142622 Achieving Excellence in Well Completion Projects in Iraq's South Oil Fieldszouke2002Ainda não há avaliações

- 3 Monday Iraq Service ContractsDocumento5 páginas3 Monday Iraq Service Contractszouke2002Ainda não há avaliações

- Wellpath For CS-FTDocumento5 páginasWellpath For CS-FTzouke2002Ainda não há avaliações

- Ajdustment of K0397H1Documento7 páginasAjdustment of K0397H1zouke2002Ainda não há avaliações

- Protobuf Lite LICENSEDocumento1 páginaProtobuf Lite LICENSEzouke2002Ainda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Primus Operation FS6 To FS23Documento50 páginasPrimus Operation FS6 To FS23Arun George50% (2)

- Pharmacological and Toxicological Screening Methods I (MPL 103T)Documento50 páginasPharmacological and Toxicological Screening Methods I (MPL 103T)Sandeep MewadaAinda não há avaliações

- Dynamic model of offshore water treatmentDocumento114 páginasDynamic model of offshore water treatmentferchosb12Ainda não há avaliações

- 11th Chemistry EM Minimum Study Material English Medium PDF DownloadDocumento8 páginas11th Chemistry EM Minimum Study Material English Medium PDF Downloadjencys16Ainda não há avaliações

- Types of SewerDocumento14 páginasTypes of SewerAmbalal DhongadiAinda não há avaliações

- Analytical Methods For The Determination of N-NitrosaminesDocumento14 páginasAnalytical Methods For The Determination of N-NitrosaminesZekai BingolAinda não há avaliações

- Elsanhouty Pharma Hold Time Study NotesDocumento6 páginasElsanhouty Pharma Hold Time Study NotesHuỳnh Ngọc SángAinda não há avaliações

- Ladder Inspection Form: Company Name: Ladder Reference Number: Inspector Dept. DateDocumento2 páginasLadder Inspection Form: Company Name: Ladder Reference Number: Inspector Dept. DatesantoshjayantiAinda não há avaliações

- Ecological Effects Test Guidelines: OPPTS 850.3020 Honey Bee Acute Contact ToxicityDocumento8 páginasEcological Effects Test Guidelines: OPPTS 850.3020 Honey Bee Acute Contact ToxicityNatalie Torres AnguloAinda não há avaliações

- Microplastic Communities in Different Environments Differenc - 2021 - Water R PDFDocumento11 páginasMicroplastic Communities in Different Environments Differenc - 2021 - Water R PDFSunita ChayalAinda não há avaliações

- Sensory and nutritional value of flatbread with banana peelsWheat flourBanana peels12.2010.1011.203.201.2111.201.500.800.601.20Documento7 páginasSensory and nutritional value of flatbread with banana peelsWheat flourBanana peels12.2010.1011.203.201.2111.201.500.800.601.20Bagas Aryo SasongkoAinda não há avaliações

- TGN-M-04 Weld Procedure Comparison Struc SteelDocumento5 páginasTGN-M-04 Weld Procedure Comparison Struc Steelmanoj983@gmail.comAinda não há avaliações

- International Abbreviations For Polymers and Polymer ProcessingDocumento226 páginasInternational Abbreviations For Polymers and Polymer ProcessingTrevor J. HutleyAinda não há avaliações

- Module 4 - Chemical Kinetics Prelab Study GuideDocumento5 páginasModule 4 - Chemical Kinetics Prelab Study GuideJustine UrbanAinda não há avaliações

- MSDS Mindray M-30 LyseDocumento2 páginasMSDS Mindray M-30 LyseSandra HubayaAinda não há avaliações

- Principles of Mineral ProcessingDocumento1 páginaPrinciples of Mineral ProcessingMohamed HassanAinda não há avaliações

- NAF-Check Tilting Disc Check Valves FK 30.70 (11) GB: CharacteristicsDocumento8 páginasNAF-Check Tilting Disc Check Valves FK 30.70 (11) GB: CharacteristicsRobovenAinda não há avaliações

- Bp704t Ndds IVDocumento18 páginasBp704t Ndds IVMILI G.Ainda não há avaliações

- ASME B31.3 Process Piping Code GuideDocumento7 páginasASME B31.3 Process Piping Code Guideshreyash bhadirkeAinda não há avaliações

- Chapter 14Documento11 páginasChapter 14Marco LuigiAinda não há avaliações

- Solid, Liquid, Gas Explanation TextDocumento2 páginasSolid, Liquid, Gas Explanation Textnettexts100% (1)

- Waldner Fume Cupboard Default ValuesDocumento16 páginasWaldner Fume Cupboard Default ValuestuzlucayirAinda não há avaliações

- Item Codes for Pokémon Items & ModifiersDocumento13 páginasItem Codes for Pokémon Items & ModifiersIsaccAinda não há avaliações

- Purpose of Master Batch PPA in PEDocumento49 páginasPurpose of Master Batch PPA in PEin_abhay2706Ainda não há avaliações

- Volumetric Analysis 7Documento3 páginasVolumetric Analysis 7vijay kumarAinda não há avaliações

- 2019 Cre Ii L24-26Documento32 páginas2019 Cre Ii L24-26Aman PrasadAinda não há avaliações

- Atmospheric Water GeneratorDocumento3 páginasAtmospheric Water GeneratorKhusnil MujibAinda não há avaliações

- Sesv8002 PDFDocumento97 páginasSesv8002 PDFali100% (2)

- Gen Chem 2 DAILY LESSON LOGDocumento8 páginasGen Chem 2 DAILY LESSON LOGMaricriz Bioco100% (1)

- Chemistry TextDocumento45 páginasChemistry Textariel yana morgaAinda não há avaliações