Escolar Documentos

Profissional Documentos

Cultura Documentos

Case Study - 440

Enviado por

Rohan ViswanathDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Case Study - 440

Enviado por

Rohan ViswanathDireitos autorais:

Formatos disponíveis

Sport Obermeyer

Purpose of the Case

The purpose of this article is to determine the number of units of each style Sport Obermeyer should produce during its initial phase of production i.e before the prior to the Las Vegas show in March 2014 (November through March) and during its second phase of production i.e after the Las Vegas Show (March through October). Factors that need to be considered in this decision are the risk associated with each style, from where each product will be sourced (Hong Kong or China), and the costs associated with the sourcing decision. The changes that could be made to operate efficiently and, at a late stage, Operational changes are also recommended in order to improve performance in the short and long-term.

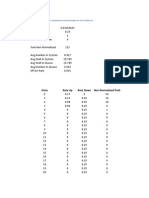

a) Whole sale Selling Price of Parka (p) Cost of Producing each Parka (c ) Salvage Value (s) Expected Profit from each parka sold Loss CSL Since demand is normally distributed,

112.5 85.5 76.5 27 9 0.75

Using Goal Seek we obtain this value, by keeping total order quantity = 10000

a) Initial Phase of Production - all units are made in Hong Kong 1.0608 Average Std 2*Std Order Integer Order Coefficient of Style Price Forecast Dev Dev Quantities Quantities Variation Gail 110 1017 194 388 605.4096 605 0.190757129 Isis 99 1042 323 646 356.7232 600 0.309980806 Entice 80 1358 248 496 831.8432 831 0.182621502 Assault 90 2525 340 680 1803.656 1803 0.134653465 Teri 123 1100 381 762 291.6704 600 0.346363636 Electra 173 2150 404 808 1292.8736 1292 0.187906977 Stephanie 133 1113 524 1048 1.2816 600 0.470799641 Seduced 73 4017 556 1112 2837.3904 2837 0.13841175 Anita 93 3296 1047 2094 1074.6848 1074 0.317657767 Daphne 148 2383 697 1394 904.2448 904 0.29248846 Total 1122 20001 10000 11146

MOQ for Hong kong is 600 units. Therefore we take maximum of Order quantity and MOQ

Question 4) RECOMMENDATIONS FOR OPERATIONAL CHANGES

1. Decrease lead times for both raw materials and finished goods, thereby allowing more time to utilize existing capacity. Since the business strategy should emphasize Dependability more than Cost, lead-times can be reduced using some or all of the following methods: Choose suppliers of raw materials more on the basis of Dependability than Cost. Speed up orders through information sharing with suppliers as well as transparency of information within the supply chain Speed up shipments using faster (but more expensive) shippers. Establish some local (but more expensive) production capacity for last minute production. Other ways to reduce lead times include: From the items with long lead times, increase the amount of safety stock inventory for those items that are inexpensive (e.g., buttons) and/or shared by many parkas (e.g., black fabric). Simplify the parkas designs so that they can share as many components as possible. For example, are 100,000 varieties of zippers really necessary? 2. Obtain market feedback earlier than March i.e Las Vegas event, thereby converting some Speculative Production to Reactive Production. One way of doing this is by not waiting upto march, Sport Obermeyer can invite selected retailers to come in January to Aspen for an Early Order Weekend, where they can have a look at the new line, and an order can be placed early, probably qualifying for a discount placement of orders at a discount. Aslo by meeting early , the end time production and spending more on transportation at the last minute could be avoided. To achieve a lot out of the early meeting, it should include both small as well as big retailers to gain a lot of exposure. 3. Improve the demand forecasts made internally by the Buying Committee in November (1992) just before Speculative Production. Instead of using just a simple average of the individual forecasts made by Laura, Carolyn, Greg, Wendy, Tom and Wally use a weighted average, with

the weights reflecting past accuracy. Speedup data/information analysis and utilize historical data / Committee forecasting / Research and Trend & Market Movement 4. Increase production capacity by using more subcontractors, using more overtime in China.

5. Decrease minimum order quantities, thereby improving the ability to fine tune during Reactive Production. Minimum order quantities occur because there are long set-up times when switching from the production of one style of parka to another, thereby making it uneconomical to have short runs. 6) We could also consider the fact of reducing number of styles handled and to predict customer demand for individual style. 7) Also on a secondary basis, the company could create promotion strategy to persuade retailers to order. 8) Increase bargaining power with suppliers by ordering via big supplier that can commit on timeline

Question 5)

Sourcing in Hong Kong versus Sourcing in China

A) i)Long-term Changes They could train Chinese employees and make them as efficient and the ones in Hong Kong to increase production in China, Also since the labor cost in China is lower , they could make a lot of savings if China could produce more efficiently. ii) Short-term Changes The maximum production of 20,000 set by Wally should be increased. For example, because there is a maximum of 21,000 available units for the production period (30,000 production capacity x 7 months), extra quantity of Gail could be produced without having to cut into production of other styles. This would be preferable because sourcing Gail from China would require 813 more units to be produced than what is forecasted to be sold. However the cost savings of producing them in China outweigh the cost of selling the extra at an 8% loss. (However, when we mention that Gail was produced in Hong Kong in order to adhere to Wallys 20,000 maximum production guidelines). In reality, the company produces about 200,000 parkas yearly and has production capacity of 210,000 parkas; therefore, it is more cost efficient to overproduce from China in cases such as Gail.

B) It is recommended that higher risk items be produced at the Hong Kong plant because these items will be produced more quickly and be of higher quality. It is also beneficial because a

majority of the higher risk lines require smaller Minimum Order Quantities which Hong Kong is better able to produce because of their smaller unit requirements versus China (600 versus 1,200 units minimum respectively). This means that the high risk items should be produced at Hong Kong including: Daphne, Isis, Anita, Teri, and Stephanie (having higher values of COVs). The Gail line must also be produced at the Hong Kong plant because the total units forecasted is less than the required minimum production at the China plant. Production of styles such as Gail can be over produced. It has a lower COV and is less risky so production in China seems to make more sense at first assessment. However, because the minimum amount of 1,200 required for production in China exceeds the average forecast for Gail, or 1,017, it must be sourced in Hong Kong in order to not go over 20,000 items as specified by Wally. Therefore, all five high risk items and one low risk item should be produced at the Hong Kong plant. The remaining low risk items should be produced at the China plant including: Assault, Seduced, Entice, and Electra. (For high risk items we have assumed a COV of 2 or 2.5 and above.)

Você também pode gostar

- Sport Obermeyer Final PDFDocumento10 páginasSport Obermeyer Final PDFpiyushAinda não há avaliações

- Sport Obermeyer CaseDocumento4 páginasSport Obermeyer CaseNamita DeyAinda não há avaliações

- Sport ObermeyerDocumento4 páginasSport ObermeyerGui NunesAinda não há avaliações

- Sports Obermeyer LTDDocumento12 páginasSports Obermeyer LTDharsh0322Ainda não há avaliações

- Group 10 - Sport ObermeyerDocumento5 páginasGroup 10 - Sport ObermeyerAbhishek SahuAinda não há avaliações

- Sport Obermeyer Case Solution PDFDocumento33 páginasSport Obermeyer Case Solution PDFsreejuviswanathAinda não há avaliações

- Sport ObermeyerDocumento12 páginasSport ObermeyerAhsan JalalAinda não há avaliações

- Sport Obermeyer: Written Analysis of CaseDocumento9 páginasSport Obermeyer: Written Analysis of CaseIzzahIkramIllahiAinda não há avaliações

- Sport Obermeyer Case SolutionDocumento33 páginasSport Obermeyer Case Solutionsharadkumar0378% (9)

- Sport Obermeyer CaseDocumento7 páginasSport Obermeyer CaseAndy VibgyorAinda não há avaliações

- Sport Obermeyer PaperDocumento10 páginasSport Obermeyer PaperagarwalankurkAinda não há avaliações

- Group 1 - Sports ObermeyerDocumento8 páginasGroup 1 - Sports ObermeyerSuyash BajpaiAinda não há avaliações

- Sport Obermeyer PaperDocumento10 páginasSport Obermeyer PaperDarkhorse MbaorgreAinda não há avaliações

- Case SportsDocumento2 páginasCase SportsMickey Haldia50% (2)

- Sport ObermeyerDocumento3 páginasSport ObermeyerindupriyaaAinda não há avaliações

- Case-Sports ObermeyerDocumento56 páginasCase-Sports ObermeyerSiddharth MehtaAinda não há avaliações

- Solution To Sport Obermeyer Case Study: IntroductionDocumento5 páginasSolution To Sport Obermeyer Case Study: IntroductionZeen khan100% (1)

- ObermeyerDocumento6 páginasObermeyerMatthew JamesAinda não há avaliações

- Sport Obermeyer SpreadsheetDocumento2 páginasSport Obermeyer SpreadsheetKim Seto50% (4)

- Sport Obermeyer CaseDocumento2 páginasSport Obermeyer CaseklubnikaN69% (13)

- Sport Obermeyer CaseanswersDocumento33 páginasSport Obermeyer CaseanswersCansu Kapanşahin100% (1)

- Sport Obermeyer (Handout)Documento24 páginasSport Obermeyer (Handout)06818908d100% (2)

- Sport ObermeyerDocumento3 páginasSport ObermeyerAshutosh Mishra100% (2)

- Sport Obermeyer SolutionDocumento7 páginasSport Obermeyer Solutionsrinathvl100% (2)

- Study Case Obermeyer LTD12Documento4 páginasStudy Case Obermeyer LTD12Adelua HutaraAinda não há avaliações

- Sport ObermeyerDocumento3 páginasSport ObermeyerSam Liwei Chen80% (5)

- SCDP ObermeyerDocumento19 páginasSCDP ObermeyergbpiepenburgAinda não há avaliações

- Sport Obermeyer, LTDDocumento11 páginasSport Obermeyer, LTDsaad107Ainda não há avaliações

- Sport Obermeyer (Handout)Documento24 páginasSport Obermeyer (Handout)Sajjad AhmadAinda não há avaliações

- Case Discussion Questions:: Calculations - SportsobermeyerDocumento3 páginasCase Discussion Questions:: Calculations - SportsobermeyerClaire ZhengAinda não há avaliações

- Sport Obermeyer Presentation SlidesDocumento39 páginasSport Obermeyer Presentation Slidesapi-262786574Ainda não há avaliações

- Sports Obermeyer WACCDocumento10 páginasSports Obermeyer WACCAyesha TahirAinda não há avaliações

- Sport Obermeyer Case SolutionDocumento5 páginasSport Obermeyer Case SolutionSanthosh Selvam75% (4)

- Operation Management Sports Obermeyer, LTDDocumento3 páginasOperation Management Sports Obermeyer, LTDSachin BalahediAinda não há avaliações

- Sport Obermeyer LTDDocumento16 páginasSport Obermeyer LTDAnup John ManiAinda não há avaliações

- Sport Obermeyer Case StudyDocumento14 páginasSport Obermeyer Case Studye3testerAinda não há avaliações

- Analysis of The Sport Obermeyer Case EXECUTIVE SUMMARYDocumento1 páginaAnalysis of The Sport Obermeyer Case EXECUTIVE SUMMARYAmisha SinghAinda não há avaliações

- Grocery Gateway (Ivey 902D03)Documento1 páginaGrocery Gateway (Ivey 902D03)First SpotifyAinda não há avaliações

- Le Club Francais CaseDocumento8 páginasLe Club Francais CaseTushar GoelAinda não há avaliações

- Sports ObermeyerDocumento4 páginasSports ObermeyerXanBrunoAinda não há avaliações

- OM2 LeitaxCase GroupE7Documento9 páginasOM2 LeitaxCase GroupE7Ashfaq Shaikh50% (2)

- Grocery Gateway QuestionsDocumento1 páginaGrocery Gateway QuestionsPankaj RaiAinda não há avaliações

- Case3-Obermeyer Case StudyDocumento20 páginasCase3-Obermeyer Case StudyAbhilash PatniAinda não há avaliações

- A-CAT Corp. MRP SolnDocumento13 páginasA-CAT Corp. MRP SolnAbhishta SharmaAinda não há avaliações

- Sports ObermeyerDocumento13 páginasSports Obermeyermaulikparekh09100% (3)

- The Beer Distribution GameDocumento4 páginasThe Beer Distribution GameAbhishek SrivastavaAinda não há avaliações

- Barilla Spa: A Case On Supply Chain IntegrationDocumento5 páginasBarilla Spa: A Case On Supply Chain IntegrationSanthosh SelvamAinda não há avaliações

- Barilla SpA Case StudyDocumento5 páginasBarilla SpA Case Studybinzidd007Ainda não há avaliações

- (C7) HP Deskjet Printer Supply ChainDocumento26 páginas(C7) HP Deskjet Printer Supply Chain06818908d100% (1)

- Sport Obermeyer: Case AnalysisDocumento23 páginasSport Obermeyer: Case Analysisgadde bharat100% (1)

- Barilla Case StudyDocumento3 páginasBarilla Case StudyRebecca Teo100% (1)

- Sport Obermeyer Case Study: Problems IdentifiedDocumento4 páginasSport Obermeyer Case Study: Problems Identifiedyouxin.cuiAinda não há avaliações

- WAC On Sport Obermeyer, LTD.: 1) IntroductionDocumento3 páginasWAC On Sport Obermeyer, LTD.: 1) IntroductionNimrah ZubairyAinda não há avaliações

- Case 1 Sport ObermeyerDocumento2 páginasCase 1 Sport Obermeyervabs81Ainda não há avaliações

- Obermayer CaseDocumento4 páginasObermayer CasePetr BlazekAinda não há avaliações

- SCM - Case Assin Group 2 Sec - BDocumento8 páginasSCM - Case Assin Group 2 Sec - BHarmeet kapoorAinda não há avaliações

- Chapter Vi. Inventory Models Part 1Documento36 páginasChapter Vi. Inventory Models Part 1pekka172Ainda não há avaliações

- ObermeyerDocumento4 páginasObermeyerTim RosenbergAinda não há avaliações

- Case Solution: Sports Obermeyer: Submitted by Group A06Documento7 páginasCase Solution: Sports Obermeyer: Submitted by Group A06Anvesh PotlaAinda não há avaliações

- Sports Obermeyer Awesome SlidesDocumento7 páginasSports Obermeyer Awesome Slidesdkotulski12Ainda não há avaliações

- Ioe 419 ExamDocumento6 páginasIoe 419 ExamRohan ViswanathAinda não há avaliações

- Case SCMDocumento9 páginasCase SCMbarkha_agarwal_4Ainda não há avaliações

- Sai Sameer Tammana, Rohan ViswanathDocumento1 páginaSai Sameer Tammana, Rohan ViswanathRohan ViswanathAinda não há avaliações

- SK II Japan Marketing Plan - Group 1-LibreDocumento23 páginasSK II Japan Marketing Plan - Group 1-LibreRohan ViswanathAinda não há avaliações

- Alpha Delay Overtime Objective 0.999 20 240 20.22 0.001 140 60 60.08 0.5 100 100 100Documento1 páginaAlpha Delay Overtime Objective 0.999 20 240 20.22 0.001 140 60 60.08 0.5 100 100 100Rohan ViswanathAinda não há avaliações

- PDCA CyclesDocumento9 páginasPDCA CyclesRohan ViswanathAinda não há avaliações

- Answers Are Due Before Start of Class On Thursday, March 27, 2014Documento2 páginasAnswers Are Due Before Start of Class On Thursday, March 27, 2014Rohan ViswanathAinda não há avaliações

- 591 DiagramDocumento1 página591 DiagramRohan ViswanathAinda não há avaliações

- Whats AppDocumento4 páginasWhats AppPetruAinda não há avaliações

- Cross-Docking: Scheduling of Incoming and Outgoing Semi TrailersDocumento6 páginasCross-Docking: Scheduling of Incoming and Outgoing Semi TrailersRohan ViswanathAinda não há avaliações

- Assignment 6Documento1 páginaAssignment 6Rohan ViswanathAinda não há avaliações

- 第六單元:Inventory Management: Safety Inventory (I)Documento54 páginas第六單元:Inventory Management: Safety Inventory (I)Rohan ViswanathAinda não há avaliações

- IOE 510 FinalsDocumento1 páginaIOE 510 FinalsRohan ViswanathAinda não há avaliações

- Sai Sameer Tammana, Rohan ViswanathDocumento1 páginaSai Sameer Tammana, Rohan ViswanathRohan ViswanathAinda não há avaliações

- Notice ConcerningDocumento87 páginasNotice ConcerningRohan ViswanathAinda não há avaliações

- An Example of Dantzig-Wolfe DecompositionDocumento7 páginasAn Example of Dantzig-Wolfe DecompositionRohan ViswanathAinda não há avaliações

- Test of Significance - : 3-Standard Error of DifferenceDocumento4 páginasTest of Significance - : 3-Standard Error of Differenceavinash13071211Ainda não há avaliações

- Do CC CadburyDocumento42 páginasDo CC CadburySaahil LedwaniAinda não há avaliações

- Deborah K Chasanow Financial Disclosure Report For 2010Documento20 páginasDeborah K Chasanow Financial Disclosure Report For 2010Judicial Watch, Inc.Ainda não há avaliações

- Presented By:: Pranav V Shenoy Gairik Chatterjee Kripa Shankar JhaDocumento20 páginasPresented By:: Pranav V Shenoy Gairik Chatterjee Kripa Shankar JhaPranav ShenoyAinda não há avaliações

- Wipro Internship ExperienceDocumento3 páginasWipro Internship ExperienceSimranjeet SinghAinda não há avaliações

- 220221-Atom Diesel-Vietnam..Documento1 página220221-Atom Diesel-Vietnam..Tonny NguyenAinda não há avaliações

- Solved Astrostar Inc Has A Board of Directors Consisting of Three Members PDFDocumento1 páginaSolved Astrostar Inc Has A Board of Directors Consisting of Three Members PDFAnbu jaromiaAinda não há avaliações

- The Shopping Mall As Consumer Habitat: Peter H. Bloch Nancy M. Ridgway Scott A. DawsonDocumento20 páginasThe Shopping Mall As Consumer Habitat: Peter H. Bloch Nancy M. Ridgway Scott A. Dawsonpasalperda100% (1)

- TR FormsDocumento105 páginasTR FormsDebashis Chakraborty100% (1)

- FAQ International StudentsDocumento2 páginasFAQ International StudentsНенадЗекавицаAinda não há avaliações

- Activity 2 Lesson 1 - Operations and Productivity AssessmentDocumento3 páginasActivity 2 Lesson 1 - Operations and Productivity AssessmentGianne Ruth MabaoAinda não há avaliações

- Literature ReviewDocumento6 páginasLiterature Reviewanon_230550501Ainda não há avaliações

- BUS 5110 Managerial Accounting-Portfolio Activity Unit 3Documento5 páginasBUS 5110 Managerial Accounting-Portfolio Activity Unit 3LaVida LocaAinda não há avaliações

- Spread Trading Guide PDFDocumento18 páginasSpread Trading Guide PDFMiguel Teixeira CouteiroAinda não há avaliações

- Fact Sheet en June 2019 1 PDFDocumento3 páginasFact Sheet en June 2019 1 PDFalexandru_cornea01Ainda não há avaliações

- NewBold Technologies Rural SourcingDocumento8 páginasNewBold Technologies Rural SourcingJeryl SchreinerAinda não há avaliações

- Test Pattern Changed For Promotion To MMGS-II & IIIDocumento3 páginasTest Pattern Changed For Promotion To MMGS-II & IIIsamuelkishAinda não há avaliações

- Sap BW Cheat SheetDocumento2 páginasSap BW Cheat Sheetrohit80042Ainda não há avaliações

- The Demand Curve Facing A Competitive Firm The ...Documento3 páginasThe Demand Curve Facing A Competitive Firm The ...BLESSEDAinda não há avaliações

- Unit 7 Test. 1 Complete The Sentences With A Word From The BoxDocumento2 páginasUnit 7 Test. 1 Complete The Sentences With A Word From The BoxGleb ParkAinda não há avaliações

- Is The Really Ford's Way Forward?Documento23 páginasIs The Really Ford's Way Forward?Gisela Vania AlineAinda não há avaliações

- ValGenesis Case Study With Global Pharma - Golbal Rollout With Pharma - Validation Software Solution - ValGenesis ReviewDocumento2 páginasValGenesis Case Study With Global Pharma - Golbal Rollout With Pharma - Validation Software Solution - ValGenesis Reviewmary taylorAinda não há avaliações

- Iso Iatf 16949 FaqsDocumento3 páginasIso Iatf 16949 Faqsasdqwerty123Ainda não há avaliações

- Dear SirDocumento2 páginasDear SircaressaAinda não há avaliações

- HIMeeting2 KOM3364Documento28 páginasHIMeeting2 KOM3364Susan ChongAinda não há avaliações

- PM 2019 Marjun Q PDFDocumento43 páginasPM 2019 Marjun Q PDFMiran TariqAinda não há avaliações

- Acca F2 Management Accounting Mock Test Dec 2008 Prepared By: Ben LeeDocumento17 páginasAcca F2 Management Accounting Mock Test Dec 2008 Prepared By: Ben Leesomica100% (4)

- GPP in IndonesiaDocumento5 páginasGPP in IndonesiaAconk FirmansyahAinda não há avaliações

- Chapt Er: Nature and Scope of Investment DecisionsDocumento21 páginasChapt Er: Nature and Scope of Investment DecisionschitkarashellyAinda não há avaliações

- Textured Soy Protein ProductsDocumento13 páginasTextured Soy Protein ProductsAmit MishraAinda não há avaliações