Escolar Documentos

Profissional Documentos

Cultura Documentos

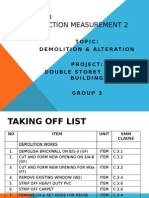

Demolition

Enviado por

jayadushDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Demolition

Enviado por

jayadushDireitos autorais:

Formatos disponíveis

SAG Refresher Course No.

12203

A PROJECT REPORT on

DEMOLITION OF STRUCTURES

!

A. AC"UTA RAO#

CGE$U%L

Gu&'e( S) %ANSAL#

SP$Pro*e+,s CONTENTS

1. INTRODUCTION

2. PLANNING 3. PRECAUTIONAR- MEASURES .. PRINCIPLES OF STRUCTURAL DEMOLITION /. MET"ODS OF DEMOLITION 0. SPECIAL STRUCTURES 1. COMPLETION OF 2OR)S CASE STUD- 3 DEMOLITION %- IMPLOSION 1. INTRODUCTION

Many of the structures on Indian Railways have already passed their design life and need to be reconstructed for safety and operational requirements. For this purpose, the old structures need to be demolished for replacement by new structures. Small structures can be demolished by manual methods but machinery and advanced techniques are required for demolition of bigger structures. Advanced techniques are also required for faster demolition and demolition in confined areas. emolition means dismantling, ra!ing, destroying or wrec"ing any building or structure or any part thereof by pre#planned and controlled methods. emolition methods can vary depending on the area where it will be held on, time available, the building material, the purpose of the demolition and the way that debris is going to be disposed. $ime saving methods are more e%pensive than the slower ones. If noise, dust, and vibrations are to be restricted, it will add to the cost of demolition. $he growing importance of recycling and practicing environmental sustainability in demolition has even given rise to new industry bu!!words such as deconstruction. econstruction is the selective dismantlement of building components, specifically for re#use, recycling, and waste management. It differs from demolition where a site is cleared of its building by the most e%pedient means. &arious demolition methods, such as the use of the mechanical equipment and the employment of e%plosives to 'implode( buildings, have evolved. )oth were used in con*unction with more traditional methods such as hand tools. +se of any of these

methods requires a proper understanding of the structure and the use of appropriate methods at minimising the ris"s of causing damage to persons, properties and the neighbourhood environment. $his paper covers the methods commonly used in demolition of structures giving attention to the planning and e%ecution of the demolition wor", ensuring safety at the wor" place.

2. PLANNING

)efore beginning the actual wor" of demolition a structure, a careful study shall be made of the structure which is to be pulled down and also of all its surroundings. $his shall, in particular, include study of the manner in which the various parts of the structure to be demolished are supported and how far the stage by stage demolition will affect the safety of the ad*oining structures. A definite plan of procedure for the demolition wor", depending upon the manner in which the loads of the various structural parts are supported, shall be prepared and approved by the engineer#in#charge and this shall be followed as closely as possible, in actual e%ecution of the demolition wor". )efore the commencement of each stage of demolition, the engineer shall brief the wor"men in detail regarding the safety aspects to be "ept in view. It should be ensured that the demolition operations do not, at any stage, endanger the safety of the ad*oining structures. Moreover, the nuisance effect of the demolishing wor" on the surrounding structures should be "ept to the minimum. 2.1 %u&4'&n5 A66r7&s74 7n' De8o4&,&on P47n $he study of the structure, before demolition, shall be carried out by means of surveys which shall include a General Survey and a Structural Survey, with photographs or videos ta"en for future reference. )ased on the findings of these surveys, a demolition plan shall then be prepared and got approved by the competent Authority. $he demolition plan must also be accompanied by a report together with structural calculations assessing the stability of the building to be demolished and all affected buildings, structures, streets, land and services. 2.1.1 Gener74 Sur9e! $he ,eneral Survey shall cover the followinga. construction materials b. e%isting use and, if possible, the past uses of the structure prior to demolition c. presence of wastewater, ha!ardous materials, asbestos, flammable or e%plosive materials, radioactive materials etc. and possible presence of materials which can contribute to air pollution and soil contamination d. ad*oining properties, site conditions such as the e%istence of slopes and retaining walls, illegal structures, bridges, overhead railway structures, overhead cables, and other utility service connections e. drainage conditions and possible problems on water pollution especially on sloping sites and water receiving bodies f. shared facilities with ad*oining building, including common staircases, party walls, and possible effect on them, such as self#enclosed walls to the ad*oining buildings, during demolition g. sidewal" requirements h. ad*oining pedestrian and vehicular traffic conditions

i. available headroom, clear spaces and distance of structure from boundary which may affect the loading and transportation of debris during demolition *. sensitivity of neighbourhood with respect to noise, dust, vibration and traffic impact ". removal of any ha!ardous materials on the site li"e e%plosives, chemicals, petroleum etc. l. available site area to allow on#site sorting of building debris and m. street features such as par"ing space, street light, and haw"ers( stalls which could be affected by the demolition pro*ect 2.1.2 S,ru+,ur74 Sur9e! /rior to the Structural Survey, the e%isting records li"e layout, structural plans and structural details shall be studied. A Structural 0ngineer shall chec" these records for presence of any unusual detailing that may cause abnormal structural behaviour during demolition, e.g., upward anchor of tensile reinforcement in cantilevered structures. $he Structural Survey shall cover the followinga. structural materials used b. structural system employed in the design c. method of construction d. any dilapidation and degree of deterioration on any structural elements e. structural conditions of ad*oining structures and its shoring which may be affected by the proposed demolition wor" f. presence of continuous structures that may be truncated by the demolition g. nature of walls, whether it is masonry walls, reinforced concrete walls, load bearing walls or partition walls h. cantilevered structures such as canopies, balconies, or other forms of architectural features i. possibilities of structural modification for demolition and *. any limitation on shoring and other temporary supports. In the case when no structural details are available, the Structural Survey shall include on site measurement and retrieve any structural details, as much as practicable, by performing tests and e%posing some "ey structural elements to facilitate chec"ing on e%isting structure. $his will allow the development of procedures that ensure the stability of the building at all stages during demolition. 2.1.3 De8o4&,&on P47n 7n' S,7 &4&,! Re6or, &n+4u'&n5 C74+u47,&ons 1A. emolition /lan A emolition /lan shall include the following 12. A plan showinga. the location of the building to be demolished b. a detailed topography of the site and its surrounds together with ground level contours and sections of the slopes and ground supported by the building where appropriate c. details of ground removal and3or bac"filling and d. the distances from the building to be demolished to its ad*acent buildings, streets, and structures. 14. A layout plan of all floors of the building to be demolished, with adequate sections, showing-

a. the occupancy usage of the floors b. the structural support systems c. principal materials of construction d. the condition of the building e.g. the degree of deterioration and e. the relationship of the building to be demolished with neighbouring properties affected by the demolition, which include all ad*oining buildings and unauthori!ed structures, shared staircases, party walls, truncating continuous frames, slopes, retaining wall, overhead cables, and underground utility services. 15. A plan showing the structural arrangement and construction of all unconventional structural elements, such as prestressed concrete structures, precast concrete members, steel framed structures, trusses, long span beams, arches, earth retaining structures, buildings which also act as earth#retaining structures supporting ad*acent ground and large cantilevered structures. 16. A plan showing the procedure for the demolition of the building, detailed sequence of demolishing particular structural members and the method of demolition to be adopted including the restrictions on the use of any particular type of equipment. 17. In the case when powered mechanical plants and equipment are used, a plan showing the route of movement of powered mechanical plants and equipment including the method of lifting mechanical plant, where necessary, onto the top floors of the structure8 any structural alterations required to suit the demolition, e.g. temporary strengthening to suit early removal of any ground floor structure to facilitate vehicular movement at ground floor, or strengthening of deteriorated "ey structural members and any shoring, temporary supports and3or floor propping required. 19. A plan showing all precautionary measures for the protection of the public including sidewal"s, scaffolding, protective screens and safety nets. 1:. A plan showing the proposed shoring and precautionary measures for all affected ad*acent buildings, slopes, retaining structures and services at each stage of the demolition wor"s. 1;. A plan showing the proposed shoring and temporary support to be provided to the building to be demolished 1<. A plan or descriptive notes on the proposed methods for handling and disposal of debris including 1a. the permissible temporary accumulation of building debris at upper floors and at ground floor 1b. method of handling demolished building debris 1c. the routing and movement of debris from each floor to ground holding area prior to leaving the site 1d. means of transportation of debris off the site 1e. time and frequency of debris disposal off site 1f. record scheme on the tonnage of each truc" load, truc" licence plate, driver(s name and location of dump site. 1). Stability Report including calculations $he Stability Report shall include the following parts12. a report on the stability of the building to be demolished during all stages of demolition

14. in the case when powered mechanical plants or equipment are used, a report on the stability of the building with supporting calculations to demonstrate that the use of the plants and equipment will not cause damage to any building, structure, street, land and services 15. in the case when powered mechanical plants or equipment are used, structural calculations for all temporary supports and bracings 16. a report on the stability of neighbouring buildings, ad*oining properties, party walls, streets, land and services which may be affected by the demolition wor" 17. in the case when temporary or permanent supports are required to these neighbouring buildings, ad*oining properties, and party walls, structural calculations for these temporary and permanent supports and 19. a report with calculations demonstrating that the demolition wor" will not render inadequate the margin of safety of, or cause damage to any building, structure, street, land and services. 2.2 U,&4&,&es $he common utilities encountered in building demolition generally include 0lectricity, =ater, ,as, $elecommunication, rainage and its accessories, and >verhead and +nderground ?ables. /rior to actual demolition, concerned Authority shall be consulted so as to cause all utilities to be terminated. $he demolition plan shall ensure that during the course of demolition, no e%isting utilities in the vicinity of the demolition sites are affected by the demolition operation. uring demolition, basic utilities li"e water for water spraying to abate dust, telecommunication lin" and electricity for lighting etc. shall be required to provide a safe and healthy wor"ing environment. 2.3 "7:7r'ous M7,er&74 If ha!ardous materials, such as asbestos containing materials, petroleum contamination and radioactive contamination, e%ist in the building, further investigation and removal of such ha!ardous material or contamination by specialist shall be considered.

3. PRECAUTIONAR- MEASURES

3.1 Gener74 Site safety features shall emphasise protection of the public, particularly, the pedestrian and vehicular traffic and the ad*acent properties. /roper safety features shall be designed to ma"e sure that the demolition can be carried out safely and the site personnel are protected. $he demolition wor"s including precautionary measures shall be carried out in accordance with the approved plans and other related documents, with continuous supervision to the wor"s. >n every demolition *ob, danger signs shall be conspicuously posted all around the structure and all doors and openings giving access to the structure shall be "ept barricaded or manned e%cept during the actual passage of wor"men or equipment. @owever, provision shall be made for at least two independent e%its for escape of wor"men during any emergency. uring nights, red lights shall be placed on or about all the barricades. =here in any wor" of demolition it is imperative, because of danger e%isting, to ensure that no unauthori!ed person shall enter the site of demolition outside wor"ing hours, a watchman should be employed. In addition to watching the site, he shall also be responsible for maintaining all notices, lights and barricades.

All the necessary safety appliances shall be issued to the wor"ers and their use e%plained. It shall be ensured that the wor"ers are using all the safety appliances while at wor". ,oggles preferably made of celluloid lens shall be worn at the time of demolition of walls, floors, tearing of plaster, etc, especially when instruments li"e *ac" hammers are employed in demolition wor", to protect the eyes from in*uries from flying pieces, dirt, dust, etc, that may be blown up by the wind. Aeather or rubber gloves should be worn by the wor"ers while demolishing R?? wor" or removing steel wor", etc, where the hands of the wor"ers are li"ely to be in*ured. =ater may be used to reduce dust while demolishing. If this is impracticable, wor"men shall cover the face and nose with piece of muslin or alternatively respirators. Bo unnecessary wor" shall go on below when demolition is in progress above. =hen some wor" is to be done at the lower level, adequate protection shall be provided for all the wor"men so engaged. Safety belts shall be used by labourers while wor"ing at higher level to prevent falling from the structure. First#aid equipment shall be got available at all demolition wor"s of any magnitude. Also, by prior arrangement, a qualified doctor shall be available at call. =hen there is a possibility of fire brea"ing out, appropriate portable first#aid fire appliances shall be "ept at hand. All utilities li"e water supply, electricity and other service connections shall be disconnected temporarily as discussed in 4.4. If a structure to be demolished has been partially wrec"ed by fire, e%plosion or other catastrophe, the walls and damaged roofs shall be shored or braced suitably. 3.2 274;<7!s 7n' s&'e<74;s =al"ways shall be provided for the use of the wor"men who shall be instructed to use them and all such wal"ways shall be "ept adequately lighted, free from debris and other materials. )efore any demolition wor" is started, every sidewal" or road ad*acent to the wor" li"ely to be affected shall be closed or protected. ?hildren and members of the public shall be "ept out of the building and the ad*oining yard. If the structure to be demolished is more than two storeyed or :.7 m high, measured from the sidewal" or street which cannot be closed or safely diverted, and the hori!ontal distance from the inside of the sidewal" to the structure is 6.7 m or less, a substantial sidewal" shed shall be constructed over the entire length of the sidewal" ad*acent to the structure of sufficient width with a view to accommodating the pedestrian traffic without causing congestion. $he sidewal" shed shall be lighted sufficiently to ensure safety at all times. A toe board of at least 2m high above the roof of shed shall be provided on the outside edge and ends of the sidewal" shed. Such boards may be vertical or inclined outward at not more than 67 degrees. 0%cept where the roof of a sidewal" shed solidly abuts the structure, the face of the sidewal" shed towards the building shall be completely closed by providing sheeting plan"ing to prevent falling material from penetrating into the shed. As per IS#625C, the roof of sidewal" sheds shall be capable of sustaining a load of :5 B3mm41very high D may be :.5 EB3m4.. >nly in e%ceptional cases, say due to lac" of other space, the storing of material on a sidewal" shed may be permitted in which case the shed shall be designed for a load of 269 B3mm41very high D may be 26.9 EB3m4..

Roof of sidewal" shed shall be designed ta"ing into account the impact of the falling debris. $he height of sidewal" shed shall be such as to give a minimum clearance of 4.6m. $he dec" flooring of the sidewal" shed shall consist of plan" of not less than 4Cmm in thic"ness, closely laid and dec" made watertight. All members of the shed shall be adequately braced and connected to resist displacement of members or distortion of framewor". =hen the hori!ontal distance from the inside of the sidewal" to the structure is more than 6.7 m and less than :.7 m, a sidewal" shed or fence may be built or in place of such a shed or fence a substantial railing shall be constructed on the inside of the sidewal" or roadway along the entire length of the demolition side of the property with movable bars as may be necessary for the proper e%ecution of the wor". =here wor"ers( entrances to the building being demolished are not completely protected by sidewal" sheds, all such entrances shall be protected by canopies e%tending from the face of the building to a point not less than 4.7 m from it. In such case, such overhead protection shall be at least C.9 m wider than the building entrance or opening and every canopy shall be as strong as the sidewal" shed. 3.3 C7,+h 647,for8s In demolition of e%terior wall of multi#storeyed structure, catch platform of heavy plan"ing shall be provided to prevent in*uries to the wor"er wor"ing below and to the public, when the e%ternal walls are more than4C m in height. Such catch platform shall be constructed and maintained not more than 5 storeys below the storey from which e%terior wall is being demolished. =hen demolition has progressed to within 5 storeys of ground level, catch platform will not be considered necessary. ?atch platforms shall not be less than 2.7m in width and shall consist of outriggers and plan"s laid tight together. ?atch platform shall be provided with a continuous solid parapet along its outer edge of at least 2 m height. Materials shall not be dumped on catch platform nor shall such catch platform be used for the storage of materials. 3.. Pro,e+,&9e s+reens /rotective screen covers shall be placed, where necessary, to prevent flying pieces from in*uring the fellow wor"men. )amboo scaffolds or metal scaffolds shall be used for providing protective screens to completely enclose the building structure for retaining dust and small debris. $arpaulin and heavy duty nets shall be used to cover the e%terior face of the scaffold. $he protective screens shall be secured to the scaffoldings at intervals in both hori!ontal and vertical directions. 3./ Te86or7r! Su66or,s $emporary supports are required to cater for the loads due the machinery used in demolition, debris accumulated, impact from fallen debris and lateral loads due to the fallen debris and wind force etc. A suitable factor of safety shall be considered. $hey are also provided when any part of the structure or any element being demolished is not self#supporting or when the temporary stability of the structure or its elements could be impaired as a result of the demolition activities. $emporary supports shall not be removed until its supporting loads are completely removed. >n the other hand, temporary supports shall be removed as much as possible

and practicable after demolition. In the case when temporary supports have to remain, routine inspection and maintenance of such temporary wor"s shall be done until they are completely removed. $emporary supports shall also be provided to ad*acent properties including buildings, public or private utilities, slopes, retaining walls or land when the removal of the building or any part of the building being demolished could affect the stability of such properties. ?ommon features, such as truncated continuous beams, e%posed party walls and common staircases, shall be protected and stabilised. =hen a demolition pro*ect is shut down for a prolonged period before its completion, the remaining structure, if any, shall be stabilised by temporary support and3or bracing systems. $he temporary supports used for demolition shall be built with structural steel, heavy timber, or other material which is considered to be appropriate for the purpose. /re#manufactured components such as tubular shores, telescope steel props, framed towers, etc., may be used as temporary supports provided their design capacity and their erection and maintenance requirements are followed in strict accordance with manufacturerFs recommendations. All temporary support systems shall be supported on adequate foundations or floors. In the case when the immediate floor below the floor under demolition is not adequate to carry the imposed loading from the demolition activities, shoring shall be carried down to the lower floors until adequate support is achieved. 3.0 Pro,e+,&on of Pro6er,&es 3.0.1 P7r,! 2744s 7n' E=,ern74 2744s /arty walls that separate the ad*oining building and the demolition pro*ect shall remain and be protected during and after the demolition pro*ect. Redundant party wall shall be removed as far as possible. $he e%posed party walls or unprotected e%ternal wall may be temporarily supported and shall be maintained until the application of the permanent treatment which may be incorporated in the construction of the new building. emolition of structural elements ad*acent to the party wall or the e%ternal wall of ad*oining building shall be performed by manual method with e%treme care to prevent any damage to the party wall or the e%ternal wall. $he party wall or e%ternal wall shall be protected against infiltration and water seepage, by cement mortar treatments, when it is e%posed to the weather. All loose bric"s or fill materials shall be removed. All openings and voids shall be filled up. 3.0.2 Foun'7,&on Su66or, A thorough evaluation shall be conducted for demolition involving any structure that may affect the foundation of the ad*oining properties. Appropriate shoring, underpinning or other protective measures shall be installed if necessary. 3.1 Pro,e+,&on of Tr7ff&+ Any closure of roads and wal"ways may seriously impact the traffic3pedestrian circulation and, as far as practicable, shall be avoided. If unavoidable, prior permission3 arrangement of the $ransport epartment and the /olice shall be obtained. $emporary closure of a traffic lane may be considered for night wor". /roper headroom, segregation, loading3unloading location, illumination etc. shall be provided for the protection of vehicular and pedestrian traffic from the ingress and egress of construction vehicles.

3.> S6e+&74 S7fe,! Cons&'er7,&ons 3.>.1 Tr7&n&n5 7n' Co88un&+7,&on emolition wor"ers, including plant or equipment operators, shall go through proper *ob safety training and be informed of the potential ha!ards by attending training sessions as well as on#the#*ob training. $hey shall be trained regarding wor"ing at heights, wor"ing in confined spaces, wor"ing with lifting appliances, use of personal protective equipment, handling of chemicals, health ha!ards in demolition wor"s and safe operating !ones. Site safety and pro*ect understanding shall be promoted through an induction meeting at the beginning of the pro*ect, where information related to the pro*ect such as the proposed method and procedures, potential danger during the operation, safety measures and pro*ect specifics can be disseminated to all on site personnel. $he safety concept can be maintained by regular safety meetings throughout the pro*ect period. 3.>.2 E?u&68en, M7&n,en7n+e All equipment shall be tested and e%amined before use. $hey shall be properly stored and maintained. $he equipment shall be inspected daily and results of the inspection shall be recorded accordingly. A detailed safety instruction shall be provided to cater for specific situations of the pro*ect, if necessary. 3.>.3 E4e+,r&+74 S7fe,! A properly connected power source from a local electric utility supplier or a mobile electricity generator shall be utilised in demolition sites. $he safety requirements given in the 0lectricity Regulations shall be adhered to. 3.>.. F&re All flammable goods shall be removed from site unless they are necessary for the wor"s involved. Any remaining flammable goods shall be stored in proper storage facilities. All furniture, timber, doors, etc. shall be removed before any welding wor" is performed. Fire fighting appliances shall be provided and maintained in wor"ing conditions. 0mergency access to site shall be provided. 3.>./ O++u67,&on74 "e74,h $he health of wor"ers on site shall be properly protected in accordance with the relevant subsidiary regulations of the Factories Act with particular attention to 0%posure to ust, ?hemical 0%posure, &entilation, Boise 0%posure, Medical and First Aid Facilities, Sanitation and >ccupational iseases. 3.>.0 @& r7,&on emolition wor" will cause vibration to neighbouring buildings or structures to various e%tent, depending on the method of demolition, which should be controlled by suitable monitoring. $he most serious vibration is caused by implosion. 3.A En9&ron8en,74 Pre+7u,&ons $he general requirements to minimise environmental impacts from construction sites can also be applied to demolition processes. $he following sections contain some of the procedures to be adopted3.A.1 A&r Po44u,&on ?oncrete brea"ing, handling of debris and hauling process are main sources of dust from building demolition. ust mitigation measures, such as water spray, shall be adopted to minimise dust emissions. )urning of waste shall not be allowed. iesel fumes generated by mechanical plant or equipment shall be controlled.

3.A.2 No&se Boise pollution arising from the demolition wor"s due the use of powered mechanical equipment such as pneumatic brea"ers, e%cavators and generators, loading and transportation of debris, etc. affects the wor"ers, and the sensitive receivers in the vicinity of the demolition site. Silent type equipment shall be used to reduce noise impact as much as practicable. emolition activity shall not be performed within the restricted hours established. 3.A.3 27,er $he discharge of wastewater from demolition sites shall be controlled by a licence. 0ffluent shall be treated to the standards as stipulated in the licence before discharge. $he emolition ?ontractor shall maintain proper control of temporary water supply and an effective temporary drainage system. 3.A.. "7:7r'ous M7,er&74s A suitable plan shall be made for removal of any asbestos containing material. >ther materials such as A/, cylinders in domestic flats, to%ic and corrosive chemicals for industrial underta"ings, and any other ha!ardous materials have to be identified and properly handled and removed, as per Regulations, prior to the commencement of the demolition of the building. 3.10 De r&s 7n' 27s,e "7n'4&n5 3.10.1 Chu,es ebris, waste and other materials shall not be thrown, tipped or shot down from a height where they are liable to cause in*ury to any person on or near the site. 0%isting lift shaft, light well and openings on floor may be used to convey debris down the building floors. Areas ad*acent to the openings of these features used as a chute shall be barricaded when they are not in use. =arning signs shall be posted to prevent wor"ers from entering the area. As an option, plastic chutes may be used inside the floor openings and lift wells to minimise noise and confine the falling debris. a. Aift Shaft- Aift shaft may be used to convey debris inside the building. $he openings to the elevator shall be adequately enclosed to prevent spilling out of debris. b. Aight =ell- All the glass windows in the light well shall be ta"en out or protected before using the light well for conveyance of debris in order to minimise any dangerous situation. c. >pening on Floor- >penings on the floor may be used to convey debris. If openings are created on the floor, the total openings shall be less than 47G of the total aggregate floor area. $he si!e of opening shall be substantiated with structural *ustifications with regard to the safety of the remaining structure and minimi!ing the possible ris"s arising from the impact force induced. >penings shall not cut through structural support elements that may affect the stability of any structural components. d. 0%terior ?hutes- Bo demolition materials shall be allowed to fall freely outside the building unless it is confined within a chute. If e%terior chutes are used, adequate clear spaces shall be provided for their operation. $he chutes shall not cause any obstruction to the public. A dust barrier shall be provided if the chute outlet is near public access. $he chute shall be designed and constructed with adequate strength and support to allow safe

conveyance of debris. 3.10.2 De r&s Re+!+4&n5 )etter site management and practice would not only prevent the mi%ing of the inert portion together with the non#inert portion of construction and demolition waste, but could also facilitate and allow on site sorting, and separation at source of construction. $he method of 'se4e+,&9e 'e8o4&,&onB should be adopted as far as practicable. It involves demolition and removal of wastes of the same category one at a time. $he goal is to facilitate recycling of wastes for beneficial reuse, thus minimi!ing the burden on municipal landfills and public filling areas. In general, domestic wastes such as furniture, household appliances, etc., metal components such as window frames, pipes, etc., timber components such as doors, wooden floors, etc., other wastes such as tiles, asphaltic materials, ceramic products should be removed first. Most of these materials may be recycled. $he building demolition shall begin after all the above non#structural materials have been stripped and removed. $he sequence of demolition shall be planned to allow the separation and sorting of building materials. ?oncrete and3or bric" debris shall be bro"en down into smaller si!es and separated from reinforced steel for disposal. ?oncrete debris may be pulverised into aggregate si!e and used for road base, temporary haul roads, fill materials or aggregates for concrete. >ld bric"s may be salvaged for reuse as architectural features or other uses. )ro"en concrete may be disposed of at construction and demolition 1?H . materials recycling facilities for processing into recycled products and aggregates for beneficial reuse. In the event that bro"en concrete is mi%ed with some other wastes, bro"en concrete should be sorted out at site from the mi%ture of wastes, before disposal at a ?H materials recycling facilities. 3.10.3 Dus, M&n&8&:7,&on $o prevent dust generation during the debris hauling, water spraying shall be applied during the hauling process. @owever, the contractor shall ensure proper control of water supply and floor drainage system in order to avoid flooding which is a nuisance and may cause overloading of floors. 3.10.. De r&s A++u8u47,&on In general, the debris accumulation on the floors is not allowed unless the debris accumulation is *ustified by engineering calculations. ebris shall not accumulate against the hoarding or e%ternal wall. 0%cessive accumulation of debris may cause overloading condition and may induce lateral loading on the walls and shall be avoided. $he propping design shall include the debris loading. 3.10./ De r&s D&s6os74 7n' M7n75e8en, S!s,e8 $o avoid accumulation of debris and to ma"e sure that they are disposed of promptly, a debris disposal and management system should be made out clearly laying down the following detailsa. method of handling demolished building debris b. movement of debris from each floor to holding area prior to leaving the site c. means of transportation of debris off site d. time and frequency of debris disposal off site e. record scheme on the tonnage of each truc" load, truc" licence plate, driver(s

name and location of dump site and f. site supervisory personnel responsible for the debris management system. 3.10.0 27s,e M7n75e8en, >n#site sorting of surplus construction and demolition 1?H . material is strongly recommended so that inert material can be disposed of at public filling areas as far as practicable, and the remaining ?H waste disposed of at landfills. All construction and demolition materials arising from or in connection with demolition wor" shall be sorted on#site and be separated into different groups for disposal at landfills, public filling areas, filling areas provided by the ?ontractor, or recycling as appropriate. All public fills to be disposed of at public filling areas shall be sorted and bro"en down according to the licence conditions for dumping. 3.11 Pos,CDe8o4&,&on Pre+7u,&ons >nce the demolition is completed, the site shall be reinstated to eliminate any potential ha!ard to the public. $he site shall be levelled and cleared of any debris and adequate drainage shall be provided. If the new development after demolition is not immediately commenced, the site shall be completely enclosed to prevent public trespassing. Supports to ad*acent building structures, weather#proofing and stabilisation of e%posed party walls shall be completed. Any e%cavation shall be braced and stabilised.

. PRINCIPLES OF STRUCTURAL DEMOLITION

..1 Gener74 =hen selecting the most suitable method of demolition, the "nowledge of the site should be applied and the interdependency of elements and the nature of the structure should be ta"en into account. 0ach of the basic principles of structural demolition, i.e. progressive, deliberate collapse or deliberate removal should be considered. $he strategic use of inherent forces should be considered as an aid to efficient demolition. $hese same principles should be applied whether there is full or partial demolition, or where structural alterations are to be carried out. ..2 T!6es of s,ru+,ur74 'e8o4&,&on( (a) Progressive demolition /rogressive demolition is the controlled removal of sections of the structure, whilst retaining the stability of the remainder and avoiding collapse of the whole or part of the building to be demolished. =here progressive demolition is adopted, it is essential that the "ey structural members on which the integrity of the structure relies should, together with their sequence of removal, be clearly indicated in the method statement and also on site. /rogressive demolition should be considered for the ma*ority of sites and is particularly useful in confined and restricted areas. (b) Deliberate collapse mechanisms emolition by deliberate collapse is the removal of "ey structural members to cause complete collapse of the whole or part of the building or structure. =here deliberate collapse demolition is adopted, the "ey structural members to be removed should be clearly indicated, together with the sequence of removal, in the method statement and also on site. $his method should be employed only on detached, isolated, reasonably level sites where the whole structure is to be demolished. $here should be sufficient space to enable equipment and personnel to be removed to a safe distance. =here parts of a structure are to be demolished

by deliberate collapse in separate operations, there should be no potential instability of the remaining structure to cause a ha!ard to personnel on the site and to other people near the structure being demolished. (c) Deliberate removal of elements $he deliberate removal of elements should be considered to be the removal of selected parts of the structure by dismantling or deconstruction. $he elements to be removed should be identified and the effects of removal on the remaining structure fully understood and included in the method statement, with the elements to be removed mar"ed on site. Sections of the structure should not be removed if instability of any of the remainder could result in a possible ris" to personnel on the site and to other people nearby. 0%pert advice should be sought. ..3 Lo7'C e7r&n5 s,ru+,ur74 e4e8en,s (a) Roof trusses =here a pitched roof is to be removed progressively, the roof structure should be removed upto bearing plate level. 0nough purlins and bracing should be retained to ensure stability of the remaining roof trusses while each individual truss is removed progressively. $emporary bracing should be added where necessary to maintain stability. $he end frame opposite to the end where dismantling is commenced, or a convenient intermediate frame, should be independently and securely guyed in both directions before wor" starts. ,enerally, the bottom ties of trusses should not be cut in situ. (b) Cantilevers ?antilevers such as cantilevered retaining walls, propped cantilevers, balanced bridge construction, canopies, cornices, staircases and balconies rely on superimposed loads or balancing restraining loads for their stability. $hey should be either demolished or supported before the counterbalancing loads are removed. (c) Columns $he engineered removal of columns can aid efficient demolition but the degree and type of fi%ity of the connections at the top and bottom should be determined as these can be crucial to the predictability of collapse patterns and thus the safety of the demolition. (d) Reinforced concrete slabs )efore demolition is commenced the load bearing characteristics of the slab should be confirmed by first establishing the reinforcement details including the direction of the main reinforcement by, e.g. electronic sensing or by ma"ing small trial holes. $he strength and quality of the concrete should also be determined. $he method of demolition should ta"e into account the pattern of reinforcement, e.g. whether it is one#way or two#way spanning. Additionally, account should be ta"en of any stress reversal, which can occur in slabs or beams propped at, e.g. mid span, because the main steel reinforcement will not be situated in the appropriate position to form part of a continuous structure. (e) Beams =hen removing beams by cutting or dismantling, the method adopted should consider any wea"ening of the structure by, say, increasing the effective length of columns, effects of stress reversal if continuous beams are to be reduced to

shorter lengths, and effect of the demolished loads on the structure. (f) ac! arches =here tie rods are present, they should not be cut until the hori!ontal thrusts have been removed by, e.g. removal of the arch or series of arches in the floor. $he floor should be demolished in strips parallel to the span of the arch rings 1i.e. at right angles to the beams supporting the arches.. (g) Portal frames A single portal frame should be considered a combination of two columns and a beam 1which can be continuous or pin#*ointed. forming a frame in a vertical plane, where the *oint between each column and beam is designed to be moment#resisting. $he type of rigidity at the base can differ as can the rigidity of the connection where the lengths of beam are *oined and should therefore be established. (h) "rches Arches carry load by e%erting hori!ontal thrusts outwards at their spring points over the length of the construction. $o ensure that the stability of the arch is maintained, the hori!ontal thrusts should be resisted. Methods to maintain stability during demolition in the vicinity of arches and of the arches themselves should ensure the balance of the forces by shoring to transmit hori!ontal thrusts to the ground, providing temporary tie bars, reducing vertical imposed loads and demolition of the arch in whole strips. (i) #alls $he verticality of walls should be ascertained, load#bearing walls identified and the security of bonding at the ends of cross walls should be established. $he structural condition of walls which are to remain, including the walls of any ad*oining property, should be established. $he method decided upon for demolishing cantilevered retaining walls should ta"e account of their dependency on loading from above, or the propping action from floors or other structural members which can affect their stability. ($) Composite structures (slabs and beams) Some basic structural elements have little inherent strength and rely for their stiffness upon the composite nature of the complementary members. $he nature of any dependency can be bro"en by early demolition activities and this should be identified as it might be necessary for temporary supports to be used. Any demolition sequence involving composite structures should ta"e account of the factors li"e lateral restraints to the compression flange provided by friction between the slab and the top flange or otherwise. ... S,ru+,ur74 87,er&74s Steel behaves in a ductile way under load, and will deflect before failure occurs in a member8 however, care should be ta"en to avoid catastrophic failure which can occur at the connections without warning. ?oncrete can be sub*ect to instantaneous failure and collapse. ?oncrete can be wea"er than might be assessed from e%ternal inspection because of, say,. internal deterioration, and the potential for this should be assessed and ta"en into account. In case of ?ast iron and wrought iron columns and beams, the type of iron should

be identified because sudden collapse can occur, e.g. due to brittle failure, in cast iron. 0%plosives generally should not be employed in the demolition of this type of construction unless it is proposed to demolish the building as a whole. In case of /restressed material, effective measures should be ta"en, during the demolition of any structure or elements, to ensure the control of inherent stored energy. In selecting a demolition technique, the potential consequences of sudden release of stress within the immediate wor"ing area and beyond should be considered. It is to be considered if the member is /retensioned or post#tensioned and if it(s grouted. ../ A9o&'7n+e of un647nne' s,ru+,ur74 +o4476ses $he potential for structural collapses should be foreseeable and avoided by planning suitable methods and sequences of demolition. +nplanned collapse, which includes the collapse of an entire structure or, more li"ely, parts of a structure or building, generally occur prematurely 1i.e. unintentional at that time. because of inadequate residual structural integrity, e.g. when pre#wea"ened or unintentionally 1i.e. not intended for demolition. because of inadequate stability resulting in part of the structure or building to collapse or fall. $o predict the possibility of premature and unintentional collapse, an assessment of the structure should be underta"en and the effects on the structure of the proposed methods and sequences of wor" determined before wor" commences. Floors should not be overloaded with machinery and3or debris resulting from the demolition process. Some floor slabs are wea"er in one direction and are therefore sensitive to the orientation of loading from machines and thus more susceptible to the potential for unplanned premature collapse. >ne method which should be considered for avoiding premature collapse is the provision of temporary structural support with proper assessment for any changing load patterns, including any induced reversal of stresses in the structure as demolition progresses. =hen the structure is wea"ened in the demolition process 1e.g. by the removal of internal members. and wor" cannot be completed during the wor"ing day, the structure should be left in a condition capable of withstanding appropriate wind loads, if local conditions dictate. ..0 Des&5n&n5 s7fe 'e4& er7,e +o4476se 8e+h7n&s8s As creating instability in a structure to initiate collapse or partial collapse is a fundamental principle of demolition, deliberate pre#wea"ening or pre#strengthening should be competently designed following assessment of the ris"s, including structural assessment. As certain types of structure are inherently strong and can require %ea!ening to ensure that they collapse successfully, consideration should be given to the removal of load#bearing members or walls, as necessary, to ensure a successful full or partial demolition. Any operation that requires the disturbance or removal of "ey elements should be fully assessed, with calculations carried out by a competent engineer to obviate the danger of une%pected or premature collapse. ?onsideration should also be given to carrying out structural strengthening before demolition wor" begins, in order to enhance temporary stability. =hen partial demolition of a structure ta"es place, the structural integrity of the

remaining parts of the structure and any ad*acent structures should be maintained. A detailed assessment of all imposed loads acting on the remaining part of the structure should be made. 0nvironmental loadings, e.g. wind, should be assessed. &ibration and impact from traffic or ad*acent demolition activities should also be considered. Foundation details of load#bearing and retaining walls should be established. $he demolition method should avoid adversely affecting ad*oining buildings and structures that can become unstable where common elements such as party walls, combined foundations, continuous beams and basements are affected.

/. MET"ODS OF DEMOLITION

/.1 Gener74 $here are multiple types of demolition procedures used to ta"e down structures. $he choice of demolition method depends on the pro*ect conditions, site constraints, and sensitivity of the neighbourhood and availability of equipment. Several methods of demolition can be used in combination or at different parts of the demolition site. In general, the choice of technique should enable the re#use and3or the recycling of materials arising from the demolition. Irrespective of which demolition method is adopted, its choice should be based on minimi!ing the ris" to personnel. Simple manual demolition is indicated for smaller buildings such as single story homes. Manual demolition usually involves pulling the structure down. ?losely related is mechanical demolition. Iuite often smaller buildings use a combination of manual and mechanical methods. Mechanical demolition involves both the pulling down and the "noc"ing down of the structure by machines. Mechanical demolition uses such machinery as bulldo!ers, cranes, and e%cavators. Aarger structures involve wrec"ing balls. Most of these methods are top down methods where the demolition starts from the top floor and proceeds towards the ground. For structural pro*ections, such as balconies, canopies and verandahs e%tending beyond the building lines, demolition by hand held tools or the cut and lift process may be a safe solution. $he most dramatic type of demolition is implosion. $his involves a controlled series of e%plosions that causes a collapse of the structure. $he e%plosive charges are placed and fired in a controlled manner that causes the building to come down into its own JfootprintJ, minimi!ing damage to surrounding structures. Implosion is only used as a last resort because of the high safety ris" involved. $his type of demolition ta"es a long time to set up and a long time to clean up, but the actual implosion process ta"es mere seconds to unfold. A new type of demolition that is growing in popularity is called Jdeconstruction.J $his is the most environmentally sound method of demolition and it is sometimes called J,reen demolitionJ for this reason. It involves a slow and careful process that is almost the reverse of the construction method. $he building is slowly ta"en apart and as much material as possible is salvaged for reuse elsewhere. $his lightens the load on the landfills that usually receive the debris of a building destroyed by conventional demolition procedures. /.2 M7nu74 Me,ho' /.2.1 Gener74 Manual methods are carried out top down, proceeding, in general, from the roof to ground. $he particular sequence of demolition may vary, depending on site conditions

and structural elements to be demolished. For reinforced concrete buildings, *ac" hammers are commonly used to brea" down the concrete. >%y#acetylene torch could be used to cut the reinforcements. $he reinforcements shall remain until all the concrete connecting to or supported by the reinforcement is bro"en away or when its support is no longer required. ?antilevered canopies, balconies and e%terior walls are critical elements in building demolition. In congested areas, these features could have critical impact on the safety of the public. emolition of these features shall be performed with e%treme caution. If rope or tie wires are used to pull down the structural elements, the pulling wire must be at least 6 times stronger than the anticipated pulling force. In addition, wor"ers shall be shielded from the rope or tie wires. $he rope or tie wire shall be chec"ed at least twice per day. /.2.2 De8o4&,&on Se?uen+e emolition sequence shall be determined according to actual site conditions, restraints, the building layout, the structural layout and its construction. In general, the following sequence shall applya. All cantilevered structures, canopies, verandahs and features attached to the e%ternal walls shall first be demolished prior to demolition of main building and its internal structures on each floor b. =hen demolishing the roof structure, all lift machine rooms and water tan"s at high level shall be demolished in Ktop downL sequence to the main roof level c. emolition of the floor slabs shall begin at mid span and wor" towards the supporting beams d. Floor beams shall be demolished in the order of cantilevered beams, secondary beams and then main beams e. Bon#load bearing walls shall be removed prior to demolition of load bearing walls f. ?olumns and load bearing walls shall be demolished after removal of beams on top and g. If site conditions permit, the first floor slab directly above the ground floor may be demolished by machine standing on ground. /.2.3 C7n,&4e9ere' S,ru+,ures 7n' %74+on&es ?antilevered structures, balconies and canopies may pro*ect out of the building over the pedestrian footpath or in some cases over a portion of the traffic lane. $emporary supporting structures shall be placed directly underneath them as precautionary measures. $he general sequence of dismantling cantilevered slabs and beams is described in the followinga. $he e%terior wall shall be demolished first b. Any structure or dead load supported by the cantilevered system shall be removed prior to demolishing the cantilevered slabs and beams c. $he concrete shall be bro"en down gradually starting from the e%terior edge of the cantilevered floor, wor"ing inwards and toward its supporting beams. Figure 7.2 illustrates the demolition of cantilevered slab d. $he cantilevered beam shall be demolished after the demolition of the connecting floor slab. emolition of the cantilevered beam shall not advance further than the floor slab so that the support for the slab is

always maintained. Figure 7.4 illustrates the demolition of cantilevered beam with the slab and e. Saw cut and lift may be used to dismantle the cantilevered features. $he slab shall be cut into a manageable si!e and lifted away. $he cantilevered beams shall be cut and removed after the removal of the slab load and any load supported by them. $he cut and lift applications are discussed in 7.:.5. F&5 /.1 De8o4&,&on of +7n,&4e9ere' RCC s47 DM7nu74 8e,ho'E F&5 /.2 De8o4&,&on of +7n,&4e9ere' RCC s47 7n' %e78DM7nu74 8e,ho'E /.2.. E=,er&or 2744s# %e78s 7n' Co4u8ns (a) Bric! in&fill #all' $o avoid any potential ha!ard of bric"s falling out of the building, all the bric" in#fill shall be removed by pushing inward, before dismantling the reinforced concrete framing. =or"ing platforms outside the building shall be used for removal of the walls. )ric" removal shall begin from the top layer downwards. $he wor"s shall be carried out layer by layer. (b) ()terior Beam' $he e%terior beam may be demolished by gradually brea"ing away the concrete or by dismantling the entire beam section. emolition of the e%terior beams is illustrated in Figure 7.5 and described in the followingi. =ire and winch or other systems shall be used to secure the cross beam to other structural members ii. $he concrete is first bro"en away at both ends near its column supports to e%pose the reinforcement iii. Reinforcement shall be cut at one end to allow the beam to partially drop. $he wire shall safely winch the beam down to the building floor in a controlled manner and iv. $he dismantling would be completed by cutting the reinforcement at the remaining end, and the beam will then be lowered completely in a controlled manner. (c) ()terior Column 0%terior column may be demolished by the following procedure and as illustrated in Figure 7.6. i. $he top of the column shall first be secured to a structural member by wire and winch ii. /re#wea"ening shall be performed at the bottom of the column to reduce the pulling force and to ensure that the brea" occurs at the desired location. $he concrete cover of the reinforcement shall first be removed. Reinforcement at the interior face shall remain. Reinforcement at the e%terior face shall be cut immediately before the pulling of the column and iii. After pre#wea"ening, the column shall be pulled down by the wire and winch towards the interior in a controlled manner. F&5 /.3 De8o4&,&on of E=,ern74 %e78 DM7nu74 Me,ho'E F&5 /.. PreC<e7;en&n5 7n' '&s87n,4&n5 of Co4u8n DM7nu74 Me,ho'E (d) ()terior Reinforced Concrete *rame

$he e%terior reinforced concrete frame may be demolished in sections. $he demolition procedures are generally described in the followingi. $he optimum section of the frame to be demolished shall be a bay between the two ad*acent columns ii. $he frame section shall be secured to other structural members with wire and winch before disconnecting the framing from the remaining structure iii. /re#wea"ening shall be performed at the bottom of the two columns and iv. $he reinforcing bars connecting the beams shall be cut off after pre#wea"ening. $he framing shall be pulled down by e%erting force through winch and pulley system. (e) Reinforced Concrete #all 12. Aoad )earing =all Reinforced concrete walls may be demolished by cutting down the wall into manageable sections. $he width of the wall shall not be wider than 4 m. emolition of the reinforced concrete wall sections is illustrated in Figure 7.7 and described in the followingi. )efore demolition begins, wire and winch systems shall be used to secure the wall section8 ii. /re#wea"ening at the bottom of the wall shall be performed, particularly if the wall section contains columns. $he concrete along the cut line of the interior face of the wall section shall be bro"en away by hand held tools. /re#wea"ening shall follow the similar details as for columns and iii. After the concrete along the cut line is removed, the reinforcing bars along the vertical cut line shall be separated. Force shall be e%erted through the wire and winch systems to pull the wall down into the building. 14. Bon#Aoad )earing =all For non#load bearing walls or walls with heavy cross beams, the dismantling procedures are similar to that of the load bearing wall e%cept that the cross beams are dismantled separately from the building walls. F&5 /./ D&s87n,4&n5 of RCC <744 /.2./ F4oor S47 s Reinforced concrete floor slab shall be demolished by gradually brea"ing away the concrete. $he reinforcement shall remain and be cut off after the concrete is bro"en away. $he sequence for demolition of typical floor slabs is discussed in the following1a. $wo =ay Slab $he two way slab is supported by beams on all four sides. emolition of the slab shall begin in the middle of the slab and advance towards the sides in all 6 directions. Figure 7.9 illustrates the demolition of two way slab. F&5 /.0 De8o4&,&on of T<o 27! s47 1b. >ne =ay Slab $he brea"ing of concrete shall begin at the unsupported end and proceed in strips perpendicular to the supporting beam or structural member. $he

strips shall be demolished from centre to the supports in both directions. /.2.0 In,er&or %e78s 7n' Co4u8ns $he dismantling of interior beams and columns is similar to that of e%terior beams and columns, e%cept that the interior beams, normally, support slabs on both sides and the supporting beam shall not be removed until all other dead loads imposed on the beam are removed, including the slabs supported by the beam. /.3 To6 Do<n F %! M7+h&nes /.3.1 Gener74 $he sequence of demolition by machine is typically the same as the top down manual method, e%cept that most of the demolition is done by mechanical plant. $he demolition begins with the lifting of the mechanical plant on to the building top floor. =hen rope or tie wire is used for pulling, the wor"ers shall be protected or stay away from the area within reach of the rope or tie wire. Adequate propping shall be installed at floor levels below the wor"ing floor to safely support the operation of the mechanical plant. $he movement of the mechanical plant shall only be within the propped area. $he propped areas shall be suitably mar"ed. $he movement of the mechanical plant shall be prohibited within 4 m of the building edge, within 2 m of any floor openings or any cantilevered structures. $he mechanical plant shall be lifted onto the roof of the building by the use of mobile crane or other appropriate means as approved. $he machine shall descend down to the ne%t floor by means of a ramp. $he ramp may be a temporary structure or other appropriate design. $he slope of the ramp shall be no steeper that 2.:7 to 2 or as recommended by the machine manufacturer. As an alternative, the machine may also be lowered to the ne%t floor by the use of mobile crane. emolition sequence shall Min general, be as for manual methods. In general, the following sequence shall applya. prior to demolition of internal floors, all cantilevered slabs and beams, canopies, and verandahs shall first be demolished b. the structural elements, in general, shall be demolished in the sequence of slab, secondary beams and then main beams c. mechanical plant shall descend from the floors with temporary access ramp, or be lowered to the ne%t floor by lifting machinery or by other appropriate means d. when a mechanical plant has *ust descended from the floor above, the slabs and beams, in two consecutive floors may be demolished by the mechanical plant simultaneously. $he mechanical plant may wor" on structural elements on the same floor and brea"ing up the slabs on the floor above e. the beams and columns shall be demolished by gradually brea"ing down the concrete or by pulling them down in a controlled manner. Figure 7.: illustrates the sequence of top down method with mechanical equipment. /.3.2 C7n,&4e9ere' C7no6&es 7n' %74+on&es In general, cantilevered structures shall be demolished prior to the demolition of the main structure of the building for each floor and before the removal of their supports or holding down loads. In the case when this cannot be satisfied, cantilevered structures shall be properly shored until they are completely demolished, considering the effects of removal of ant loads. A cantilever counterbalanced by top load on beams will

collapse if top load is removed. =hen one side of balanced cantilever is removed, the remaining cantilever will topple. emolition of the cantilevered structures is described in the following1Fig 7.;.a. $he e%terior wall lin"ing the cantilevered structure shall be removed first. $he floor slab and cantilevered beam may be demolished in sections. b. $he machine arm with wire passing through the slab section shall be used to stabilise the structure while the cutting is performed8 c. ?uttings may be performed by *ac" hammer or pneumatic hammer for the concrete and o%y#acetylene flame cutter for the reinforcements. $he concrete shall be bro"en away first before the cutting of reinforcement. Alternatively the reinforced concrete slab may be cut by saw cutting8 and d. $he slab shall be lifted into the building by a derric" arm. 2. emolish slab H beam 4. ?ontinue demolishing slab H beam 4. Access ramp to lower floor 6. emolition of interior column 7. ?ut e%ternal wall H column 9. /ull down wall section F&5 /.1 T!6&+74 se?uen+e of 'e8o4&,&on ! ,o6 'o<n 8e,ho' <&,h M7+h&nes 1.M$C 8oun,e' on sus6en'e' f4oor 2. M$C 8oun,e' on 5roun' 3. Cu,,&n5 of +7n,&4e9ere' s47 .. L&f,&n5 of +7n,&4e9er s47 F&5 /.> De8o4&,&on of +7n,&4e9er s47 ! M7+h&ne /.3.3 E=,er&or 2744s# %e78s 7n' Co4u8ns (a) Bric! in&fill %all emolition of the bric"#in#fill wall is generally described in the followingi. $he in#fill bric"s shall first be manually removed. $he bric" shall be removed from the top layer down by pushing in from outside wor" and ii. then, the reinforced concrete frame may be demolished by dismantling the framing sections. (b) ()terior Column i. $he e%cavator arm with wire or hydraulic crusher attachment shall be used to brace the column ii. /re#wea"ening shall be performed at the bottom of the columns iii. After pre#wea"ening, the column shall be pulled down in a controlled motion into the building by the e%cavator arm8 then iv. emolition inside the building by the e%cavator arm. (c) ()terior Reinforced Concrete *rame i. $he concrete along the proposed cut#line shall be bro"en first. $he reinforcing bars shall be "ept to stabilise the structure. $he e%cavator arm shall secure the reinforced concrete framing ii. /re#wea"ening may be performed at the bottom of the columns. $he e%cavator arm shall continue to stabilise the frame while cutting the reinforcing steel at the disconnecting points and iii. $he e%cavator arm shall pull and guide the frame safely onto the floor. 1d. Reinforced ?oncrete =all $he process of demolishing a reinforced concrete wall section is similar

to that of a reinforced concrete frame. emolition of a reinforced concrete wall section is illustrated in Figure 7.< and is described in the followingi. $he reinforced concrete wall shall be vertically separated from the remaining wall by brea"ing away the concrete. $he width of the wall section shall be determined by the Structural 0ngineer. $he reinforcing bars shall remain to provide support to the wall section ii. If the wall section contains columns, pre#wea"ening shall be performed at the level where the wall is to be separated. iii. $he machine arm shall be used to secure the wall section during the cutting of the reinforcements along both sides of the wall section and iv. After the reinforcing bars are severed, the machine arm shall steadily guide and pull down the wall section into the building for further brea" down. 2. )rea"ing away concrete vertically to separate wall section 4. 0%cavator arm with wire to brace wall, while pre#wea"ening column bottoms 5. 0%cavator pulls down wall, after cutting reinforcement F&5 /.A De8o4&,&on of RCC <744 ! E=+797,or /.3.. F4oor S47 s Floor slabs may be dismantled by brea"ing down the concrete gradually with machine mounted attachments. Reinforcing bars shall be cut afterwards. $he slab may be demolished by machine with brea"er, hydraulic crusher or other appropriate attachments. /.3./ In,er&or %e78s 7n' Co4u8ns Interior )eam and ?olumns may be demolished by using the same procedures as for the e%terior beam and column. /.. Me+h7n&+74 Me,ho' ! "!'r7u4&+ Crusher <&,h Lon5 %oo8 Ar8 $he crusher attachment brea"s the concrete and the reinforcement by the hydraulic thrust through the long boom arm system. $he hydraulic crusher can be operated from the ground outside the building. $his method is also suitable for dangerous buildings, silos and other industrial facilities. Figure 7.2C illustrates the typical operation of hydraulic crusher with long boom arm. For environmental reason, it should be used wherever practicable because of its quietness. $he operation shall have a minimum clear space of N the building height as a safety !one for the falling debris. $he e%cavator shall operate on firm ground that can support the machine during the crusher operation. 0ach section of the structure shall be demolished in a top down sequence to ensure stability of the structure. ebris may be used to build up a platform for the e%cavator to e%tend the range of reach, by dense compacting, upto 5m. $he width in both directions of the platform shall be at least one and one#half the length of the machine to allow safe manoeuvre during the demolition operation. $o minimise the dust impact, the structure shall be pre#soa"ed with water before demolition. =ater shall be continuously sprayed during the crushing operation. ebris may fall out of the building during the demolition. $he site shall be completely fenced off and guarded. F&5 /.10 De8o4&,&on ! "!'r7u4&+ Crusher <&,h 4on5 oo8 /./ 2re+;&n5 %744

$he wrec"ing ball application consists of a crane equipped with a steel ball. $he destruction of the building is by the impact energy of the steel ball suspended from the crawler crane. $he wrec"ing ball operates outside the building. $his method is suitable for dilapidated buildings, silos and other industrial facilities. @owever, the operation requires substantial clear space. $he application also demands high level s"ill operators and well#maintained equipment. Figure 7.22 illustrates the operation of =rec"ing )all. $he balling of each section of the structure shall proceed from top to bottom. Recommended techniques for the wrec"ing ball operations include 12. &ertical rop # free falling of the wrec"ing ball onto the structure and 14. Swing in line # swinging of the ball in#line with the *ib. A second dragline will normally connect to the ball hori!ontally to control the ball motion. $he ball shall be swung into the building and shall stri"e at the top of the member so as to avoid the member from falling outside the building. $he *ib or boom shall be operated with no less than 5 m above the portion of the structure being demolished. ?lear space for operation between the crane and the structure being demolished shall be N of the height of structure, with additional distance between crane and boundary wall for manoeuvrability. @igh strength wire shall be used to allow pullout of the wrec"ing ball from potential traps. $o minimise the dust impact on the surrounding area, the structure to be demolished shall be pre#soa"ed with water before demolition. =ater spraying shall continue on the structure during demolition. $he operation shall not be performed ad*acent to overhead power lines. $he site shall be entirely fenced off to forbid public access. F&5 /.11 O6er7,&on of 2re+;&n5 %744 /.0 I864os&on Implosion is the strategic placing of e%plosive material and timing of its detonation so that a structure collapses on itself in a matter of seconds, minimi!ing the physical damage to its immediate surroundings. $he technique wea"ens or removes critical supports so that the building can no longer withstand the force of gravity and falls under its own weight. $he e%plosives are *ust the trigger for the demolition. ItFs gravity that brings the building down. 0%plosives are loaded and progressively detonated on several different levels of the building so that the building structure falls down on itself at multiple points. =hen everything is planned and e%ecuted correctly, the total damage of the e%plosives and falling building material is sufficient to collapse the structure entirely, so cleanup crews are left with only a pile of rubble. The Re7'&n5 Gr7&n F7+&4&,!# Ph&47'e46h&7# 47s,e' &n 1AAA In order to demolish a building safely, each element of the implosion must be studied ahead of time. $his is done by a blasting e%pert. $he first step is to e%amine architectural blueprints of the building to determine how the building is put together. Be%t, the building is surveyed to study about the support structure on each floor. )ased on this data and drawing from past e%periences with similar buildings, the e%pert decides what e%plosives to use, where to position them in the building and how to time their detonations. $he main challenge in bringing a building down is controlling which way it falls.

Ideally, a blasting crew will be able to tumble the building over on one side, into a par"ing lot or other open area. $his sort of blast is the easiest to e%ecute, and it is generally the safest way to go. $ipping a building over is something li"e felling a tree. $o topple the building to the north, the blasters detonate e%plosives on the north side of the building first, in the same way a tree would be chopped into from the north side if it is to fall in that direction. )lasters may also secure steel cables to support columns in the building, so that they are pulled a certain way as they crumble. Sometimes, a building is surrounded by structures that must be preserved. In this case, the blasters proceed with a true implosion, demolishing the building so that it collapses straight down into its own footprint 1the total area at the base of the building.. $he basic idea in implosion is to thin" of the building as a collection of separate towers. $he blasters set the e%plosives so that each JtowerJ falls toward the centre of the building. =hen they are detonated in the right order, the toppling towers crash against each other and all of the rubble collects at the centre of the building. Another option is to detonate the columns at the centre of the building before the other columns so that the buildingFs sides fall inward. ,enerally spea"ing, blasters will e%plode the ma*or support columns on the lower floors first and then a few upper stories. In a 4C#story building, for e%ample, the blasters might blow the columns on the first and second floor, as well as the 24th and 27th floors. In most cases, blowing the support structures on the lower floors is sufficient for collapsing the building, but loading columns on upper floors helps brea" the building material into smaller pieces as it falls. $his ma"es for easier cleanup following the blast. >nce the blasters have a clear idea of how the structure should fall, any debris is cleared out of the building and non#load#bearing walls within the building are ta"en out. If these walls were left intact, they would stiffen the building, hindering its collapse. Some materials, such as glass, that can form deadly pro*ectiles, and insulation that can scatter over a wide area must be removed. estruction crews may also wea"en the supporting columns with sledge hammers or steel#cutters, so that they give way more easily. Be%t, blasters can start 4o7'&n5 the columns with e%plosives. )lasters use different e%plosives for different materials, and determine the amount of e%plosives needed based on the thic"ness of the material. For concrete columns, blasters use traditional dynamite or a similar e%plosive material. ynamite is *ust absorbent stuffing soa"ed in a highly combustible chemical or mi%ture of chemicals. =hen the chemical is ignited, it burns quic"ly, producing a large volume of hot gas in a short amount of time. $his gas e%pands rapidly, applying immense outward pressure on whatever is around it. )lasters cram this e%plosive material into narrow ore ho4es drilled in the concrete columns. =hen the e%plosives are ignited, the sudden outward pressure sends a powerful shoc" wave busting through the column at supersonic speed, shattering the concrete into tiny chun"s. For buildings with a steel support structure, blasters typically use the speciali!ed e%plosive material cyclotrimethylenetrinitramine, called RDG for short. R O#based e%plosive compounds e%pand at a very high rate of speed, ;,45C meters per second. Instead of disintegrating the entire column, the concentrated, high#velocity pressure slices right through the steel, splitting it in half. Additionally, blasters may ignite dynamite on one side of the column to push it over in a particular direction. Con+re,e +o4u8ns Don ,he 4ef,E 7re 4o<n 767r, <&,h D!n78&,e.

S,ee4 +o4u8ns Don ,he r&5h,E 7re s4&+e' &n h74f us&n5 RDG. $o ignite both R O and dynamite, a severe shoc" needs to be applied. In building demolition, this is accomplished with a blasting cap, a small amount of e%plosive material 1called the primer charge. connected to some sort of fuse. $he traditional fuse design is a long cord with e%plosive material inside. =hen one end of the cord is ignited, the e%plosive material inside it burns at a steady pace, and the flame travels down the cord to the detonator on the other end. =hen it reaches this point, it sets off the primary charge. )lasting caps are used as a catalyst to set off the e%plosives loaded in support columns. $hese days, an electrical detonator is used instead of a traditional fuse. An electrical detonator fuse, called a lead line, is a long length of electrical wire. At the detonator end, the wire is surrounded by a layer of e%plosive material. $his detonator is attached directly to the primer charge affi%ed to the main e%plosives. =hen current is sent through the wire 1by hoo"ing it up to a battery, for e%ample., electrical resistance causes the wire to heat up. $his heat ignites the flammable substance on the detonator end, which in turn sets off the primer charge, which triggers the main e%plosives. $o control the e%plosion sequence, blasters configure the blast caps with simple 'e47! mechanisms, sections of slow#burning material positioned between the fuse and the primer charge. )y using a longer or shorter length of delay material, the blasters can ad*ust how long it ta"es each e%plosive to go off. $he length of the fuse itself is also a factor, since it will ta"e much longer for the charge to move down a longer fuse than a shorter one. +sing these timing devices, the blasters precisely dictate the order of the e%plosions. Co4u8ns 7re fu44! 4o7'e' <&,h e=64os&9es 7n' hoo;e' u6 ,o 47s,&n5 +76s 7n' fuses. )lasters determine how much e%plosive material to use based largely on their own e%perience and the information provided by the architects and engineers, who originally built the building. $o ma"e sure they donFt overload or under#load the support structure, the blasters perform a test blast on a few of the columns, which they wrap in a shield for safety. $he blasters try out varying degrees of e%plosive material, and based on the effectiveness of each e%plosion, they determine the minimum e%plosive charge needed to demolish the columns. )y using only the necessary amount of e%plosive material, the blasters minimi!e flying debris, reducing the li"elihood of damaging nearby structures. $o further reduce flying debris, blasters may wrap chain#lin" fencing and geote%tile fabric around each column. $he fence "eeps the large chun"s of concrete from flying out, and the fabric catches most of the smaller bits. )lasters may also wrap fabric around the outside of each floor that is rigged with e%plosives. $his acts as an e%tra net to contain any e%ploding concrete that tears through the material around each individual column. Structures surrounding the building may also be covered to protect them from flying debris and the pressure of the e%plosions. In addition to these measures, the blasters must prepare the people in the area for the blast, assuring local authorities and neighbouring businesses that the demolition wonFt seriously damage nearby structures. If there are slopes and earth retaining walls or features, a geotechnical assessment shall be conducted to ensure that the blasting will not affect the stability of these features. $he surrounding structures are inspected prior