Escolar Documentos

Profissional Documentos

Cultura Documentos

FUP1010 Manual

Enviado por

Joshi DhvanitDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

FUP1010 Manual

Enviado por

Joshi DhvanitDireitos autorais:

Formatos disponíveis

lntroduction

1

lnstallation

2

Commissioning

3

Troubleshooting/FAQs

4

Appendix

A

SlTRANS

Flowmeter

SlTRANS FUP1010

Quick Start Guide

Operating lnstructions

1/2009

CQO:QSG003 Revision B

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNlNG

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTlON

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTlON

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTlCE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

lf more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Proper use of Siemens products

Note the following:

WARNlNG

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. lf products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

lndustry Sector

Postfach 48 48

90026 NRNBERG

GERMANY

CQO:QSG003 Revision B

01/2009

Copyright Siemens AG 2009.

Technical data subject to change

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 3

Table of contents

1 lntroduction................................................................................................................................................ 5

1.1 ltems supplied................................................................................................................................5

2 lnstallation ................................................................................................................................................. 7

2.1 Application Guidelines ...................................................................................................................7

3 Commissioning........................................................................................................................................ 13

3.1 Navigating the Menu....................................................................................................................14

3.2 Setting the Parameters ................................................................................................................16

3.3 Transducer lnstallation.................................................................................................................21

3.3.1 General information .....................................................................................................................21

3.3.2 lnstalling the Transducers............................................................................................................22

3.3.3 Final Setup...................................................................................................................................25

4 Troubleshooting/FAQs............................................................................................................................. 27

4.1 Troubleshooting ...........................................................................................................................27

4.2 Alarm Letter Codes and Descriptions..........................................................................................28

A Appendix.................................................................................................................................................. 31

A.1 l/O Connections and Wiring.........................................................................................................31

Tables

Table 3- 1 Key Pad Function Chart..............................................................................................................15

Table 3- 2 Pipe Configuration Option List Definitions ...................................................................................20

Table 4- 1 Troubleshooting Tips ...................................................................................................................27

Table 4- 2 Alarm Codes and Descriptions ....................................................................................................28

Table A- 1 Part Numbers and Connection Data............................................................................................31

Table A- 2 2l Channel/2 Path lnput/Output Terminal Block Wiring ...............................................................31

Table A- 3 Part Numbers and Connection Data............................................................................................32

Table A- 4 2 Channel/2 Path lnput/Output Terminal Block Wiring................................................................33

Figures

Figure 2-1 Power Adapter/Battery Charger.....................................................................................................8

Figure 2-2 External Battery Pack ..................................................................................................................10

Figure 2-3 1015BCK-2 and 1015BCA-2 Battery Chargers ...........................................................................11

Figure 3-1 Power Adapter/AC Charger for Single & Dual Channel Flowmeters...........................................13

Table of contents

SlTRANS FUP1010 Quick Start Guide

4 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

Figure 3-2 Key Pad....................................................................................................................................... 15

Figure 3-3 Typical lnstallation Menu Screen Example................................................................................. 16

Figure 3-4 Reflect Mount with Mounting Frames and Spacer Bar (Front View) .......................................... 22

Figure 3-5 Transducer .................................................................................................................................. 24

Figure 3-6 Transducer lnstallation................................................................................................................ 24

Figure 3-7 Connecting Transducers to Flowmeter ....................................................................................... 25

Figure 3-8 Final Setup.................................................................................................................................. 26

Figure 3-9 Measuring Flow........................................................................................................................... 26

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 5

lntroduction

1

This Quick Start Guide is for the Siemens SlTRANS FUP1010 lP40 (NEMA 1) and FUP1010

Weatherproof lP67 Portable flowmeters. lt includes procedures to form and charge the

battery pack and use the AC Power Adapter. lt also illustrates a typical set using D-Series

transducers in the Reflect operating mode (for Direct mode see flowmeter manual). These

procedures can also be applied to the single or multi-channel models as well.

Note

lmportant Safety Note: For complete lmportant Safety considerations and Ratings, refer to

the flowmeter manual included with the unit.

Note

This Quick Start Guide applies to the following FUP1010 lP40 (NEMA 1) and FUP1010 lP67

(weather proof) operating systems: Version 3.02.02 and later and version 4.03.00 and later.

1.1 ltems supplied

* SlTRANS F Flowmeter

* SlTRANS F literature CD

* Quick Start

* For additional items refer to your packing slip.

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 7

lnstallation

2

2.1 Application Guidelines

Basic Requirements

* Determine pipe material and dimensions.

* Avoid vertical pipes flowing in a downward direction.

* Avoid installation of transducers on the top and bottom of horizontal pipes, if possible.

* Select a location with the longest straight run of pipe.

* ldentify upstream piping configuration (elbow, reducer, etc.).

* Pipe surface should be smooth and, if necessary, free of paint.

* Avoid pressure reduction components upstream.

* Avoid mounting on or near weld seams.

Additonal Requirements for Liquid Applications

* Pipe must be full during set-up.

Additonal Requirements for Gas Applications

* Pipe must be fully pressurized during set-up.

Charging the Battery

The flowmeter has an optional battery charger that operates from a 100, 110 or 220 VAC

(50Hz or 60Hz) power source. lt has a universal power input that requires no user switching.

Optional cords can be provided for connection to AC outlets in most countries.

CAUTlON

The 1015BCK-1 Power Adapter/Battery charger is NOT waterproof or water resistant. Do

not allow it to become wet, or attempt to use it when wet. Exposure to a wet or submerged

environment will result in damage to the unit that cannot be repaired and could expose the

user to the risk of electric shock.

lnstallation

2.1 Application Guidelines

SlTRANS FUP1010 Quick Start Guide

8 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

1

3

4

5

2

30 mm

(1.20")

58 mm

(2.30")

30 mm

(5.30")

lEC 320 Power lnlet

. Connector

0,9 meters minimum (3 ft)

NEMA 5 - 15P

lEC 320 Plug

Figure 2-1 Power Adapter/Battery Charger

Battery Operation

All portable systems include battery chargers that operate from an AC voltage source. We

strongly recommend that you "form" and charge the battery before operating the system for

the first time.

lnstallation

2.1 Application Guidelines

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 9

The Charge lndicator LED

A battery status indicator shows the status of its internal battery and charging circuits. The

indicator LED color switches between red or green based upon the flowmeter operation.

LED Battery Condition

Green Trickle charge in progress

Red Rapid Charge in progress

Forming the lnternal Battery

The flowmeter uses a special Ni-Cad internal battery pack designed for a rapid charge cycle.

Ni-Cad batteries have to be "formed" to deliver their optimum operating time. This is

accomplished by performing a minimum of two complete discharge/charge cycles.

To Produce a Charge/Discharge Cycle:

1. Press the ON keypad to turn the flowmeter ON without connecting an external power

source. Leave it ON until an automatic shutdown occurs.

2. Connect the charger and charge the internal battery until the charge indicator LED

changes from red to green. The battery requires approximately 8 hours to fully charge.

3. Repeat the charge/discharge cycle again. The battery should now be "formed" to provide

its maximum operating time.

To maintain the battery "forming," whenever possible, discharge the battery completely

before recharging. lf the operating time during battery use appears to be unusually short,

then a discharge/charge cycle should lengthen the operating time. lf this does not correct a

short operating time, then the internal battery should be replaced.

Using the External Battery Pack and Battery Charger

The 1015BB (7ME39403BB00) Battery Pack and 1015BCK-2 (USA) (7ME39403BC10) and

1015BCA-2 (EUR) (7ME39403BC20) Power Adapter/Battery Chargers are designed

specifically for use with the FUP1010 lP40 (NEMA 1) flow meters. The 1015BB Battery Pack

uses a special Lead/Acid battery design that features a deep discharge cycle for extended

operation.

CAUTlON

Do not use any other external Battery Charger/Pack combination with the flowmeter unless

reviewed and pre-approved by Siemens.

CAUTlON

Do not leave the Battery Charger connected to the Battery Pack during transportation or

storage. Damage to the Battery/charger connector may occur or the battery may be

discharged.

lnstallation

2.1 Application Guidelines

SlTRANS FUP1010 Quick Start Guide

10 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

1

2

3

13,97 cm

(5.5")

7,62 cm (3")

7,62 cm (3")

Battery Lead Acid Gel (12VDC, 3 AH)

Female "Cigarette" Connector

Adapter Cable 1.22 meters Extended (4 ft)

Figure 2-2 External Battery Pack

Charging the External Battery Pack

DANGER

Attempting to use the unit in a submerged environment with the cover open or latches not

engaged will result in damage to the unit that cannot be repaired and could expose the user

to the risk of electric shock.

CAUTlON

Charge the 1015BB Battery Pack (7ME39403BB00) in a completely dry environment only.

Do not close the battery pack cover while battery pack is being charged.

lnstallation

2.1 Application Guidelines

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 11

To charge the 1015BB Battery Pack:

1. Referring to the cautions above, place the 1015BB Battery Pack on a flat surface (such

as a table or bench). Ensure that an AC outlet is available at or close to the location.

2. Open the Battery Pack cover. Leave it open for the entire charge time.

3. Plug the 1015BCK-2 Adapter/Battery Charger (USA) (7ME39403BC10) or 1015BCA-2

(EURO) (7ME39403BC20) AC power cord into a proper AC source. Plug the Battery

Charger DC output cable into the DC input connector on the 1015BB Battery Pack.

4. Charge the Battery Pack for at least 8 hours before using it for the first time.

1

2

3

4

H a u p p a u g e , N Y 1 1 7 8 8

H a u p p a u g e , N Y 1 1 7 8 8

AC ADAPTER

S i e m e n s

M o d e l

V M A 1 1 2 3 4S N

1 0 1 5 B C A - 2

S i e m e n s

M o d e l 1 0 1 5 B C K - 2

1 2 3 4S NA 1V M

CAUTION:

Model No. DV-1250

Output: 12VDC 60Hz 12W

BESCOR

INDOOR USE ONLY

Input: 120VAC 60Hz 12W

Part No. BC500

Class 2 Transformer

60 mm

(2.38")

38 mm

(1.50")

51 mm

(2.00")

Plug Type CEE 7/16 (EUR)

Plug Type NEMA 1-15P (USA)

Cord 1829 mm (6 ft)

Male "Cigarette" Connector

Figure 2-3 1015BCK-2 and 1015BCA-2 Battery Chargers

lnstallation

2.1 Application Guidelines

SlTRANS FUP1010 Quick Start Guide

12 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

Note

A [LOBAT] flag appears on the flowmeter graphic screen when the remaining battery

operating time is less than 20 minutes

Status lndication Action

Battery Warning Beeper Normal operation, periodic audible alarm Connect a Battery Charger for

continued operation.

Battery Discharge Unit will not turn on (no display screen) Connect to Battery Charger for at least

1.5 hours before attempting to operate.

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 13

Commissioning

3

Connecting AC Power

Using the 1015BCK-1 (7ME39404PG00) Power Adapter/Charger

1. Connect the AC power cord to the AC Cord input of the Power Adapter/Charger.

2. Plug the Power adapter connector into the rear panel Power input connector.

Siemens

1

2

3

4

3

4

AC Cord lnput

Connect to Rear Panel Power lnput Connector

Auxiliary Power/Battery Charger lnput

Battery Status lndicator

Figure 3-1 Power Adapter/AC Charger for Single & Dual Channel Flowmeters

Commissioning

3.1 Navigating the Menu

SlTRANS FUP1010 Quick Start Guide

14 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

3. Plug charger into an AC outlet. Within 10 seconds of power-up the flowmeter main display

will become active and a typical Siemens graphic will briefly appear. The screen also

identifies the software version of the unit.

1

ver. 4.03.00G

Software Version (x.xx.xx)

4. Press the <MENU> key and the Main Menu will appear.

Select Meter Type

Meter Type >2 Channel Flow

Meter Facilites 2 Path Flow

Language Ch 1 + 2 Flow

Ch 1 - 2 Flow

Thickness Gauge

Siemens 2 Channel [1] Channel 1

3.1 Navigating the Menu

lnstallation Menu Navigation

The lnstallation Menu Chart is a multi-level structure divided into three columns from left to right

Level A - lists the major menu categories.

Level B - list the menu cells associated with Level A. You can enter data into Level B menu cells that

are display parameters in a column at the right of the screen.

Level C - lists the Level B data

Level B Level C

Recall Site Setup Pump 1

Pump 2

Channel Enable

Create/name Site

Site Security

Delete Site Setup

Level A

Save/Rename Site

Commissioning

3.1 Navigating the Menu

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 15

+

-

= +

X

F1 F3 F2 F4

MENU CLR ENT

DATA

LOG

ALT CTL

HELP

1 2 3

0

7 8 9

4 5 6

Figure 3-2 Key Pad

Note

Use <Left Arrow> key to return to previous menus.

Table 3- 1 Key Pad Function Chart

Keys Description

MENU Press to activate the lnstallation Menu.

ENT Store numeric data, select from option lists, etc.

*Left / Right Arrows Menu navigation keys move cursor.

Up / Down Arrows Same as <Left> and <Right> arrows. Scrolls option lists and graphic display screen.

CLR Erases data or selects list options.

Numbers 0 - 9 Use to type numeric data.

Decimal Point Use for decimal points in numeric data.

Math Operators 4-function math operations in numeric entry cells.

"F" Keys 1, 2, and 3 Caution: System Reset Key (use during power up).

CTL and ALT Used as shift keys for alternative key functions.

DATALOG Triggers immediate Datalogger report.

Plus and Minus [+ / -] Changes the sign of numeric data.

Commissioning

3.2 Setting the Parameters

SlTRANS FUP1010 Quick Start Guide

16 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

1

2

3

8

7

6

4 5

Pipe Data

Siemens 2 Channel [1] SlTE1

Pick Pipe Class

Pick Pipe Class Manual Entry

Select Pipe Size N/A

Pipe OD <in> 0.500

Pipe Material Steel

Wall Thickness 0.100

Liner Material None

Linear Thickness 0.000

Menu Cell Data (left-hand column) Current Selected Measurement Channel

Highlighted Menu Cell Site Name ldentified

Menu Prompt Line (Reverse Video) Highlighted Data

Current Selected Meter Type Menu Cell Data (right-hand column)

Figure 3-3 Typical lnstallation Menu Screen Example

3.2 Setting the Parameters

Select Language and Units

Note

Before creating a site select a language and then English or Metric units from the Meter

Facilities menu.

Commissioning

3.2 Setting the Parameters

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 17

Select a Meter Type

1. Press the <MENU> key and select the Meter Type.

2. Press the Right Arrow> and scroll to [Dual Chan Flow]

Note

Select [2 Chan Flow] if measuring two different pipes and [2 Path Flow] if sensors are

mounted on the same pipe.

3. Press <ENT> to select. Press <Right Arrow> to select meter function. Press <ENT>.

1

2

3

Siemens 2 Channel [1] Channel 1

Select Meter Type

Meter Type >2 Channel Flow

Meter Facilities 2 Path Flow

Language Ch 1 + 2 Flow

Ch 1 - 2 Flow

Thickness Gauge

Select for measuring two different pipes. (Not available for all models.)

Select if two sensors are mounted on the same pipe.

Select for summing or subtracting flow from two different pipes.

Create a Site

1. Before proceeding make sure that English or Metric units have been selected.

2. At the [Channel Setup] Menu press <Right Arrow> and enter a Site name.

3. Press <ENT> to create Site name (e.g., ABC). (See figure below.)

Note

To set English or Metric units: ln the Meter Type menu, scroll to Meter Facilities Menu.

Press <Right Arrow> and select desired units. Press <ENT> to select. Press <Left Arrow>

and <Up Arrow> to return to Meter Type menu.

Note

To select letters: Press <Right Arrow> to cursor and then press <Up/Down Arrow> to

select letters and numbers. Press <ENT> when done.

Commissioning

3.2 Setting the Parameters

SlTRANS FUP1010 Quick Start Guide

18 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

1

Right Arrow & Enter Creates a new Site

Channel Setup

Recall Site Setup No sites

Channel Enable No

Site Security Off

Delete Site Setup No sites

Save/Rename Site

Create/Name Site ?

Siemens Channel [1] Channel 1

lnsert desired name (8 characters max.)

4. Scroll to [Save/Rename Site]. Press <Right Arrow> then press <ENT> to save site.

5. Press the <Left Arrow> and return to the main menu.

Select Pipe Class

1. Press the <Right Arrow> to select Pipe Class. Press <Right Arrow> again and scroll to

desired Pipe Class.

2. Press <ENT> to select.

3. Pre-programmed Pipe Size and relevant pipe parameters will appear in menu cells. Press

<Right Arrow> and scroll to desired pipe size. Press <ENT>. Enter dimensions manually

if pre-programmed dimensions do not match application.

Pipe Data

Siemens 2 Channel [1] ABC

Select Pipe Class

Select Pipe Class ASA Carb. Steel

Select Pipe Size 8CS40

Pipe OD <in> 8.625

Pipe Material Steel

Wall Thickness 0.322

Liner Material None

Linear Thickness 0.000

4. Press the <Left Arrow> and return to the main menu.

Commissioning

3.2 Setting the Parameters

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 19

Select Liquid Class

1. Press the <Down Arrow> and scroll to [Application Data].

2. Press the <Right Arrow> to select [Liquid Class].

3. Press the <Right Arrow> again and scroll to desired liquid.

4. Press <ENT> to save selection.

1

Select Liquid Class from Liquid Table

Liquid Class Water 20C/68F

UniMass Table Disabled

Temp. Range -40F to 250F

Pipe Config Fully Developed

Anomaly Diams 10

Application Data

Siemens 2 Channel [1] ABC

Select from list.

Select Pipe Configuration

1. Scroll down to [Pipe Config] and press the <Right Arrow>.

2. Select a configuration that approximates the conditions upstream of your transducer

mounting location. (Refer to the definitions below.)

3. Press <ENT> to save selection.

1

2

Designate Pipe Shape Near Transducers

Application Data

Liquid Class Water 20C/68F

UniMass Table Disabled

Temp. Range -40F to 250F

Anomaly Diams 1 Elbow

Dbl Elbow+

Dbl Elbow-

Valve

Expander

Reducer

Norm Entry

Header lnlet

lntrusions

Pipe Config Fully Developed

Siemens 2 Channel [1] ABC

Use this menu cell to enter the number of pipe diameters between the upstream

configuration and the transducer installation.

Use this menu cell to select the pipe configuration that most accurately represents the

upstream pipe condition.

4. Press the <Left Arrow> and return to the main menu.

Commissioning

3.2 Setting the Parameters

SlTRANS FUP1010 Quick Start Guide

20 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

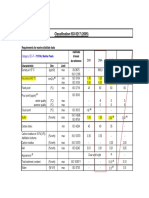

Table 3- 2 Pipe Configuration Option List Definitions

Options Definitions

Fully Developed Fully developed flow, as would be expected for very long

straight pipe runs or installation downstream of a flow

condition.

1 Elbow Single 90 degree Elbow upstream of transducer installation.

Dble Elbow+ Double out-of-plane Elbows upstream of transducer

installation.

Dble Elbow- Double in-plane Elbows upstream of transducer installation.

Valve Not available at this time.

Expander Pipe expansion upstream of transducer installation.

Reducer Pipe reduction upstream of transducer installation.

Norm Entry Not available at this time.

Header lnlet Header or pipe manifold upstream of transducer installation.

lntrusions Not available at this time.

Transducer Selection

The following is a typical transducer installation procedure for D1H High Precision

transducers.

1. Press <Left Arrow> to return to Main Menu. At the Main Menu, press the <Down Arrow>

to select [Pick/lnstall Xdcr].

2. Press the <Right Arrow> to [Transducer Model]. Press <Right Arrow> and scroll to

[1011HP-T1]. Press <ENT>.

3. To select Transducer Size, press <Right Arrow> and select [D1H]. Press <ENT>.

4. lMPORTANT: Record Number lndex and Spacing Method.

5. Transducers can now be mounted.

6. After transducers are mounted scroll to [lnstall Complete] and select [lnstall].

1

2

3

lnstall Xdcr

Siemens 2 Channel [1] ABC

Scroll List and select desired Model

Transducer Model 1011HP-T1

Transducer Size D1H

Xdcr Mount Mode Reflect

Spacing Offset Nominal

Number lndex 26

Spacing Method Spacer Bar 1012BN

Ltn Vaue (in) 7.499

lnstall Complete No

Empty Pipe Set MTYmatic

Zero Flow Adjust Actual Zero

Select based on type.

Select based on size.

After transducer is mounted select [lnstall].

Commissioning

3.3 Transducer lnstallation

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 21

Transducer ldentification

The transducer part number located on the front face provides a detailed identification. For

example, the Part Number: 1011PPS-D1 means:

1

2

1011PPS - D1

Model

Size

Note

Check to make sure that the transducers are a matched set with the same serial numbers

and marked with an "A" and "B" (e.g., 19256A and 19256B).

Note

Transducer Model names for Version 3 op systems are as follows: 1011H Hi Precision, 1011

Universal and 991 Universal

3.3 Transducer lnstallation

3.3.1 General information

Reflect and Direct Mounting Modes

Reflect and Direct mounting modes are supported for clamp-on transducers. The flowmeter

recommends a mounting mode after analyzing your pipe and liquid data entries.

Note

For Direct Mount refer to the flowmeter manual.

Mounting Supplies

The following items will be needed to mount the transducers:

* Flat blade screwdriver

* Mounting Frames or Mounting tracks

Commissioning

3.3 Transducer lnstallation

SlTRANS FUP1010 Quick Start Guide

22 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

* Tape, chalk and a ruler or measuring tape

* Mounting Straps

* Spacer Bar

* Mounting Guide (for Direct Mount)

* Ultrasonic coupling compound

* Transducers (matched set)

3.3.2 lnstalling the Transducers

Reflect Mount using Mounting Frames and Spacer Bar

1. After receiving the spacing index from the lnstallation Menu, prepare the pipe surface

area where the transducers will be mounted.

2. Degrease the surface and remove any grit, corrosion, rust, loose paint, etc.

Before beginning refer to the Reflect Mount lnstallation diagram example below.

1 2 3

4

5 6 7 8

Optional: On larger pipes, multiple lengths of

straps can be linked together to surround

pipe.

Space Bar Platform & Clamping Screw

Mounting Strap positioned around Mounting

Frame

Space Bar (Front View)

Transducer shown in the 9 o'clock position on

pipe

Metal Post

Mounting Frame Mounting Strap Adjusting Screw

Figure 3-4 Reflect Mount with Mounting Frames and Spacer Bar (Front View)

Commissioning

3.3 Transducer lnstallation

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 23

Note

Minimum Ltn 18mm (0.75 in)

lnstallation Procedure (See figure for reference)

1. On a flat surface, attach the Spacer Bar to a Mounting Frame so that the Reference Hole

on the Spacer Bar fits over the metal post on the platform of the frame. Tighten the

clamping screw.

2. Slide the second Mounting Frame onto the other end of the Spacer Bar and align the

Number lndex Hole with the metal post on the platform. Then tighten the clamping screw.

Ensure that the angled sides of both frames face away from each other.

3. Wrap a Mounting Strap around the pipe. Make sure to position it so there is easy access

to the Mounting Strap Adjusting Screw.

4. At the mounting location, place the Mounting Frame/Spacer Bar Assembly on the pipe so

that it rests on the top of the pipe.

5. Engage the end of the Mounting Strap with the Mounting Strap Adjusting Screw.

6. Slide strap under the spring clip of one of the Mounting Frames.

7. Tighten the Mounting Strap Screw enough to take up all of the slack, but not enough to

prevent rotation of the assembly. Repeat procedure for the other Mounting Frame.

8. Rotate the assembly on the pipe to the final conditioned location, ensuring that it is

straight along the pipe axis. (Refer to the transducer orientation diagram.)

9. Tighten the mounting straps to seat the assembly firmly on the pipe. Do not over tighten.

10. Take either transducer and apply a continuous lengthwise 1/8-inch bead of coupling

compound across the center of the transducer emitting surface.

Commissioning

3.3 Transducer lnstallation

SlTRANS FUP1010 Quick Start Guide

24 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

1

2

3

4

5

6

F-Connector Back End

Angled Edge Emitting Surface

Transducer Coupling Compound

Figure 3-5 Transducer

1

2

3

4

5

6

7

8

9

10

11

R

EF

Front View Mounting Strap

Spring Clip (Not present on some

models)

Note: Operational 2nd Mounting Strap

shown. Larger pipes may need an

additional strap for a more secure mount.

Transducer Clamping Screw Spacer Bar Platform and Clamping Screw

Spacer Bar Spacer Bar Reference Hole

1012 Series Mounting Frame Orientation for Single Beam Transducer at

9 o'clock position

Orientation for Dual Beam Transducer at 10

& 2 o'clock positions

Figure 3-6 Transducer lnstallation

Commissioning

3.3 Transducer lnstallation

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 25

11. Slide transducer into a mounting frame back end first aligning the angled edge of the

transducer with the angled edge of the mounting frame. Keep transducer from making

contact with the pipe until it butts up against the mounting frame stop. Push transducer

down to mate with pipe.

12.Tighten the transducer clamping screws to hold the transducer firmly in place. Repeat

procedure for the other transducer

13.Observing the upstream and downstream orientation, attach the UP and DN cables to the

transducers and make snug. Attach the other ends to the UP and DN terminals of the

Flow Display Computer (see figure below).

1

2

3

4

5

6

7

Flow Transducer Cable Connectors Channel 2 - Downstream Transducer

Temperature Sensor Cable Connectors Channel 1 - Upstream Transducer

To Temperature Sensors Channel 1 Flow Transducer Set

To Channel 2 Flow Transducer Set

Figure 3-7 Connecting Transducers to Flowmeter

3.3.3 Final Setup

1. At flowmeter, scroll down to [lnstall Complete]. Press the <Right Arrow> and select

[lnstall]. Press <ENT>. Flowmeter will go through drives.

2. Observe the Measured Vs window and verify a correct sound velocity measurement (if

known).

3. Press the <Down Arrow> to accept sound velocity value.

4. The meter is now ready to report flow. Press the <MENU> key twice to display flow.

Commissioning

3.3 Transducer lnstallation

SlTRANS FUP1010 Quick Start Guide

26 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

Siemens 2 Channel [1] SlTE1

Key [lnstall after mounting transducers

lnstall Xdcr

Transducer Model 1011HP-T1

Transducer Size D1H

Xdcr Mount Mode Reflect

Spacing Offset Normal

Number lndex 26

Spacing Method Spacer Bar 1012BN

Ltn Value (in) 7.499

Empty Pipe Set Channel Not Setup

Zero Flow Adjust Channel Not Setup

lnstall Complete Yes

Figure 3-8 Final Setup

Transducer Model 1011HP-T1

Transducer Size D1H

Xdcr Mount Mode Reflect

Spacing Offset Nominal

Number lndex 26

Spacing Method Spacer Bar 1012BN

Ltn Value (in) 7.499

lnstall Complete Yes

Empty Pipe Set Channel Not Setup

Zero Flow Adjust Channel Not Setup

Siemens 2 Channel [1] SlTE1

Drive 14 [06:---------------------:0]

Measured Vs m/s

1489

lnstall Xdcr

Figure 3-9 Measuring Flow

See also

Refer to l/O Connection tables for input/output wiring and Flow Display Computer field

manual for data spanning procedures.

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 27

Troubleshooting/FAQs

4

4.1 Troubleshooting

The following is list of troubleshooting tips and messages that you may encounter. They

include explanations and, in some cases, a recommended action. lf a problem seems

unsolvable, contact your local Siemens Ultrasonic Flow Representative for expert help at

www.siemens.com.

Table 4- 1 Troubleshooting Tips

Message Description

Memory Full! Response to an attempt to save site data, when data memory is full. Delete an obsolete

site or clear Datalogger memory to make room for the new data.

Memory Corrupted! Memory read error occurred while accessing the active site data.

Chan Not Setup Response to an attempt to invoke an operation that requires a channel to be enabled.

Enable the channel [Channel Setup - Channel Enable - Yes]. Note that a channel cannot

be enabled until its transducers are operating.

Clr Active Memory? Response to pressing the F4 key. Use the F4 function to restore operation if a severe

event (e.g., a violent power surge) disrupts system operation.

Clr Saved Data? Response to pressing the F4 key, then selecting [No] for Clr Saved Data? Yes/No

<EOT> Response to a request to output Datalogger data to the printer or the Graphics screen

when no Datalogger data exists. Set up the Datalogger.

Empty Pipe - Press <ENT> Prompt to empty the pipe during the Actual MTY procedure. After emptying pipe, press

<ENT>.

Fill Pipe - Press <ENT> Prompt to fill the pipe during the Actual MTY procedure. After filling the pipe, press [ENT]

No Sites - Press <ENT> Response while trying to recall/delete a site setup when no sites are stored.

Re-space lndex Upon measuring the liquid sonic velocity (Vs), the meter recommends re-spacing the

transducers to improve performance.

lnvalid Setup (use Direct

Mode)

During the lnitial Makeup the system detects invalid transducer spacing, erroneous liquid

pipe parameters, or some other factor that prevents it from completing the lnitial Makeup.

This may be due to one of the following:

x An out-of-range data entry.

x An invalid condition (e.g., overlapping transducers in Reflect Mode). lf selecting Direct

Mode does not resolve, review all site setup and transducer installation choices

particularly data entered for pipe and liquid.

x ln Reflect Mode the flow meter detects that the pipe wall signal may infringe upon the

liquid signal. Use Direct Mode instead.

x Press <ENT>, <Up Arrow>, <Down Arrow>, or <Left Arrow> to abort install routine.

Continue programming other site data in anticipation of resolving the difficulty later.

Call technical support for help if necessary.

Troubleshooting/FAQs

4.2 Alarm Letter Codes and Descriptions

SlTRANS FUP1010 Quick Start Guide

28 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

Message Description

Low Signal - Press <ENT> During the lnitial Makeup the flow meter decides that the level of the receive signal is

insufficient for proper operation. Some reasons for low signal are:

x lnvoking [lnstall completed?] on an empty pipe.

x Coupling compound insufficient; not applied or evaporated.

x A disconnected or broken transducer cable.

x The pipe needs to be conditioned at the mounting location.

x Flush out large air bubbles.

x The Xdcr cables are defective or not connected to the correct channel.

x The Set Empty routine performed when pipe was NOT actually empty.

Detection Mode lf you locate and correct the improper condition immediately, press <ENT> to resume the

installation procedure. Otherwise, press the <Left Arrow> to abort the installation and

conduct a thorough investigation.

lf it appears that the flow meter cannot complete an lnitial Makeup it means that the pipe

and/or liquid conditions do not permit a receive signal that meets the flow detection

standards. The system will not operate. Attempt to improve operating conditions by

reinstalling the transducers at a different spacing offset, or even at a different location on

the pipe.

Switching from Reflect to Direct Mount may solve the problem. However, operation may

not be possible if there is poor liquid or pipe wall sonic conductivity.

4.2 Alarm Letter Codes and Descriptions

The following alarm codes appear on the main display of the flowmeter.

Table 4- 2 Alarm Codes and Descriptions

Letter Codes Alarm Code Description

SPACE Spacing Transducer spacing may need adjustment

EMPTY Empty Pipe is empty

Hl/LO Rate Flow above High setting or below Low setting

FAULT Fault Three continuous seconds without new data update

AER Aeration Current aeration percentage exceeds the alarm set point

MEMRY Memory Last valid reading for a selected interval during Fault condition

MAKUP Makeup ln-Process Makeup occurred

The following alarm codes appear in the Datalogger status messages:

l lnterface Liquid Vs exceeds interface alarm set point

P Pig Pig passage detected (optional)

Z ZeroMatic ZeroMatic signal occurred

Troubleshooting/FAQs

4.2 Alarm Letter Codes and Descriptions

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 29

The displays shown below indicate where the Alarm Codes appear on the screen. Press

<UP> or <DOWN> Arrows to change screen views.

BAT 100%

1

FAULT

SPACE

MAKUP

Siemens 2 Channel [1] Unit#1

FLOW GAL/MlN

TOTAL GAL Vs

14.35

354.6597 14.27

100.0

0.0

31.74

Vf

Alarm Codes

1

9/26 12:45

68.10

112.38

30.0

-30.0

Vs ALC A ER

1288 63 2

Vs

G/M

NTOTAL: GAL

AER

Hl/LO

Siemens 2 Channel [1] Unit#1

FLOW: GAL/MlN

FAULT

Alarm Codes

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 31

Appendix

A

Techncial Data

Temperature Range Degree of Protection

Operating: 0C to 50C (32F to 122F)

Storage: -20C to 60C (-4F to 140F)

lP40 (NEMA 1

lP67 (weatherproof))

A.1 l/O Connections and Wiring

Terminal Block Wiring - FUP1010 NEMA lP40 (NEMA 1) Battery Powered 2 Channel/2 Path Flow

Flowmeter Wiring

(Refer to manual drawing 1010DP-7 sheet 2 of 2)

Note

Single Channel flowmeters have the same terminal pin numbers and signals.

The terminal block wiring table applies to the part numbers listed below.

Table A- 1 Part Numbers and Connection Data

1010DP-7 (Sheet 2 of 2) Drawing

FUP1010 7ME3531a-bc

where: a= 1

b= 1 or 2

c= A or C

Table A- 2 2l Channel/2 Path lnput/Output Terminal Block Wiring

Pin# Signal Description

1 GND Signal Return Terminal [24 GA. (Min) max. Length: 1000 ft.)

2 N/C No Connection

3 R1B External Control Signal (HlGH=5 to 3 Vdc; LOW= 1 to 0 Vdc)

4 N/C No Connection

5 R2B External Control Signal (HlGH=5 to 3 Vdc; LOW= 1 to 0 Vdc)

6 N/C No Connection

7 R3B External Control Signal (HlGH=5 to 3 Vdc; LOW= 1 to 0 Vdc)

Appendix

A.1 l/O Connections and Wiring

SlTRANS FUP1010 Quick Start Guide

32 Operating lnstructions, 1/2009, CQO:QSG003 Revision B

Pin# Signal Description

8 N/C No Connection

9 R4B External Control Signal (HlGH=5 to 3 Vdc; LOW= 1 to 0 Vdc)

10 PGEN1 Pulse Frequency Output (0 to 5 kHz); 5V TTL CMOS Logic

11 PGEN2 Pulse Frequency Output (0 to 5 kHz); 5V TTL CMOS Logic

12 Vo1 Voltage Output (0 to 10 Vdc) [Min. load=5k ohms]

13 Vo2 Voltage Output (0 to 10 Vdc) [Min. load=5k ohms]

14 lo1 4 to 20mA output [0 to 1k ohms @ 30Vdc; 0 to 450 ohms @18

Vdc]

15 lo2 4 to 20mA output [0 to 1k ohms @ 30Vdc; 0 to 450 ohms @18

Vdc]

16 lo PWR Loop power input for mA outputs [user supplied 18 to 30 Vdc

@ 25 mA min.]

17 GND Signal Return Terminal [24 GA. (Min) Max Length: 1000 ft.]

18 CNTRL1 NOTOT CH. 1 [Load=100k ohms, HlGH=5 to 3 Vdc; LOW=1 to

0 Vdc]

19 CNTRL2 NOTOT CH. 2 [Load=100k ohms, HlGH=5 to 3 Vdc; LOW=1 to

0 Vdc]

20 CNTRL3 NOTOT CH. 1 [Load=100k ohms, HlGH=5 to 3 Vdc; LOW=1 to

0 Vdc]

21 CNTRL4 NOTOT CH. 2 [Load=100k ohms, HlGH=5 to 3 Vdc; LOW=1 to

0 Vdc]

22 lin1 External sensor input (4-20 mA) [Load = 250 ohms]

23 lin2 External sensor input (4-20 mA) [Load = 250 ohms]

24 Vin1 External sensor input (0 to 10 Vdc) [Load = 100k ohms]

25 Vin2 External sensor input (0 to 10 Vdc) [Load = 100k ohms]

26 GND Return For Signals [24 GA. (Min) max. Length: 1000 ft.)

Terminal Block Wiring - FUP1010 lP67 Battery Powered 2 Channel/2 Path Flow Weatherproof

Flowmeter Wiring

(Refer to manual drawing 1010DP-7 sheet 2 of 2)

Note

Single Channel flowmeters have the same terminal pin numbers and signals.

The terminal block wiring table applies to the part numbers listed below.

Table A- 3 Part Numbers and Connection Data

1010DP-7 (Sheet 2 of 2) Drawing

FUP1010 7ME351a-bc

where: a= 0

b= 1 or 2

c= A or C

Appendix

A.1 l/O Connections and Wiring

SlTRANS FUP1010 Quick Start Guide

Operating lnstructions, 1/2009, CQO:QSG003 Revision B 33

Table A- 4 2 Channel/2 Path lnput/Output Terminal Block Wiring

Pin# Signal Function Description

A GND Signal Ground Return For Signals

B N/C N/C No Connection

C R1B Logic Out 1 Logic Level State (HlGH=5 to 3 Vdc; LOW= 1 to 0 Vdc)

D N/C N/C No Connection

E R2B Logic Out 2 Logic Level State (HlGH=5 to 3 Vdc; LOW= 1 to 0 Vdc)

F N/C N/C No Connection

G R3B Logic Out 3 Logic Level State (HlGH=5 to 3 Vdc; LOW= 1 to 0 Vdc)

H N/C N/C No Connection

J R4B Logic Out 4 Logic Level State (HlGH=5 to 3 Vdc; LOW= 1 to 0 Vdc)

K PGEN1 Frequency Output 1 Assignable Logic Level Pulse Train (5V TTL CMOS Logic)

L PGEN2 Frequency Output 2 Assignable Logic Level Pulse Train (5V TTL CMOS Logic)

M Vo1 Voltage Output 1 Assignable (0 to 10 Vdc) [Min. load=5k ohms]

N Vo2 Voltage Output 2 Assignable (0 to 10 Vdc) [Min. load=5k ohms]

P lo1 Current Output 1 Assignable 4 to 20mA output

R lo2 Current Output 2 Assignable 4 to 20mA output

S lo PWR External Current Loop User supplied 18 to 30 Vdc @ 25 mA min.

T GND Signal Ground Return For Signals

U CNTRL1 Logic ln 1 TTL Level State [HlGH=5 to 3 Vdc; LOW=1 to 0 Vdc]

V CNTRL2 Logic ln 2 TTL Level State [HlGH=5 to 3 Vdc; LOW=1 to 0 Vdc]

W CNTRL3 Logic ln 3 TTL Level State [HlGH=5 to 3 Vdc; LOW=1 to 0 Vdc]

Y CNTRL4 Logic ln 4 TTL Level State [HlGH=5 to 3 Vdc; LOW=1 to 0 Vdc]

Z lin1 Current lnput 1 External sensor input (4-20 mA) [Load = 250 ohms]

a lin2 Current lnput 2 External sensor input (4-20 mA) [Load = 250 ohms]

b Vin1 Voltage lnput 1 External sensor input (0 to 10 Vdc) [Load = 100k ohms]

c Vin2 Voltage lnput 2 External sensor input (0 to 10 Vdc) [Load = 100k ohms]

d GND Signal Ground Return For Signals

LEVEL A LEVEL B LEVEL C LEVEL D LEVEL E LEVEL F LEVEL G LEVEL H

Meter Type 2 Channel Flow Channel 1/2 Clamp-on FastStart Setup Pick Pipe Class Enter From List

Dual Path Flow Flowtube Select Pipe N/A

Ch 1+2 Flow Reflexor Install Xdcr Transducer Model Enter From List

Ch 1-2 Flow Transducer Size Enter From List

Thickness Gauge Xdcr Mount Mode Enter From List

Spacing Offset Enter From List

Number Index View only

Spacing Method View only

Ltn Value <in> View Only

Install Complete No/Install

Empty Pipe Set Enter From List

Zero FlowAdjust Enter From List

Full Site Setup Channel Setup Recall Site Enter From List

Channel Enable No/Yes

Create/Name Site Enter Site Name

Site Security On/Off

Delete Site Enter From List

Save/Rename Site Enter/Clear Site Name

Pipe Data Pick Pipe Class Enter From List

Select Pipe Size Enter From List

Pipe OD (in) Numeric Entry

Pipe Material Enter From List

Wall Thickness Numeric Entry

Liner Material Enter From List

Liner Thickness Numeric Entry

Application Data Liquid Class Select Liquid Enter from List

Estimated Vs M/S Numeric Entry

Viscosity (cS) Numeric Entry

Density S.G. Numeric Entry

Temp. Range Enter From List

Pipe Config Enter From List

Anomaly Diams Numeric Entry

Install Xdcr Transducer Model Enter From List

Transducer Size Enter From List

Xdcr Mount Mode Enter From List

Spacing Offset Enter From List

Number Index View Only

Spacing Method View Only

Ltn Value (in) View Only

Install Complete No/Install Select Install

Empty Pipe Set Enter From List

Zero Flow Adjust Enter From List

Operation Adjust Damping Control Time Average / SmartSlew

Deadband Control Numeric Entry

Memory/Fault Set Fault/Memory

Memory Delay (s) N/A

Flow/Total Units Flow Vol. Units Enter From List

Flow Time Units Enter From List

Flow Disp. Range Autorange/High

Flow Disp. Scale Enter From List

Total Vol. Units Enter From List

Totalizer Scale Enter From List

Total Resolution Enter From List

Totalizer Mode Enter From List

Batch/Sample Tot Numeric Entry

Span/Set/Cal Span Data Enter From List

Set Alarm Levels Enter From List

Calib. Flowrate Intrinsic

Kc

MultiPoint

Display Setup Select Data Enter From List

Data Display Enter From List

Time Base Enter From List

Stripchart Clear Yes/No

Logger Setup Logger Mode Enter From List

Logger Data Enter From List

Logger Interval Enter From List

Logger Events Enter From List

Display Logger Enter From List

I/O Data Control Analog Out Setup Enter From List

Relay Setup Relay 1,2

Analog Inp Setup Enter From List

Diagnostic Data Flow Data Enter From List

Application Info Enter From List

Liquid Data Enter From List

Site Setup Data Enter From List

Test Facilities Enter From List

Print Site Setup No/Yes

Site Created: View Only mm.dd.yy hh.mm.ss

FUP1010 IP40 (NEMA 1) Installation Menu Chart

)

O

M

)

)

P

N

)

)

Q

This Menu Chart applies to:

MLFB - 7ME3510

7ME3511

Siemens Energy & Automation

Hauppauge, New York

USA

Web: www.siemens.com/flow

FUP1010 IP40 (NEMA 1) Installation Menu Chart

LEVEL A LEVEL B LEVEL C LEVEL D LEVEL E LEVEL F

Meter Facilities Preferred Units English/Metric

Table Setups Pipe Table Create/Edit Pipe Enter From List

Delete Pipe Enter From List

Transducer Type Enter From List

Logger Control Display Logger Enter From list

Output Logger Yes/No

Circular Memory Yes/No

Est LogTime Left View Only

Clear Logger Yes/No

Memory Control Log Memory Left View Only

Memory Map Yes/No

Defragment Yes/No

Analog Out Trim Trim Io1 / Io2 Operate / Trim @ 4mA

Trim Vo1 / Vo2 Operate / Trim @ 2V

Trim Pgen1 / Pgen2 Operate / Trim @ 1 kHz

RTD Calibrate RTD 1 / RTD 2 Factory / User Cal

Clock Set Date (MM.DD.YY) Edit Date

Time ((HH.MM) Edit Time

RS-232 Setup Baud Rate Enter From List

Parity Enter From List

Data Bits 7/8

Line Feed Yes/No

Network ID Numeric Entry

RTS Key Time Enter From List

Backlight Enter from List

System Info Version View Only

Battery Capacity View Only

Reset Data/Time View Only mm.dd.yy hh.mm.ss

Op System P/N View Only

Checksum View Only

Code View Only

System Time View Only mm.dd.yy hh.mm.ss

Language Enter From list

C

L

A

S

S

5

0

N

o

m

i

n

a

l

D

i

a

m

e

t

e

r

3468

1

0

1

2

1

4

1

6

1

8

2

0

2

4

3

0

3

6

4

2

4

8

5

4

N

/

A

N

/

A

N

/

A

N

/

A

0

.

2

5

6

.

4

0

0

.

2

7

8

.

5

1

0

.

2

9

1

0

.

5

2

0

.

3

1

1

2

.

5

8

0

.

3

3

1

4

.

6

4

0

.

3

4

1

6

.

7

2

0

.

3

5

1

8

.

8

0

0

.

3

6

2

0

.

8

8

0

.

3

8

2

5

.

0

4

0

.

3

9

3

1

.

2

2

0

.

4

3

3

7

.

4

4

0

.

4

7

4

3

.

5

6

0

.

5

1

4

9

.

7

8

0

.

5

7

5

6

.

4

2

W

a

l

l

I

.

D

.

D

U

C

T

I

L

E

I

R

O

N

P

I

P

E

A

c

t

u

a

l

O

.

D

.

3

.

9

6

4

.

8

0

6

.

9

0

9

.

0

5

1

1

.

1

0

1

3

.

2

0

1

5

.

3

0

1

7

.

4

0

1

9

.

5

0

2

1

.

6

0

2

5

.

8

0

3

2

.

0

0

3

8

.

3

0

4

4

.

5

0

5

0

.

8

0

5

7

.

5

6

C

L

A

S

S

5

1

0

.

2

5

3

.

4

6

0

.

2

6

4

.

2

8

0

.

2

8

6

.

3

4

0

.

3

0

8

.

4

5

0

.

3

2

1

0

.

4

6

0

.

3

4

1

2

.

5

2

0

.

3

6

1

4

.

5

8

0

.

3

7

1

6

.

6

6

0

.

3

8

1

8

.

7

4

0

.

3

9

2

0

.

8

2

0

.

4

1

2

4

.

9

8

0

.

4

3

3

1

.

1

4

0

.

4

8

3

7

.

3

4

0

.

5

3

4

3

.

4

4

0

.

5

8

4

9

.

6

4

0

.

6

5

5

6

.

2

6

W

a

l

l

I

.

D

.

C

L

A

S

S

5

2

0

.

2

8

3

.

4

0

0

.

2

9

4

.

2

2

0

.

3

1

6

.

2

8

0

.

3

3

8

.

3

9

0

.

3

5

1

0

.

4

0

0

.

3

7

1

2

.

4

6

0

.

3

9

1

4

.

5

2

0

.

4

0

1

6

.

6

0

0

.

4

1

1

8

.

6

8

0

.

4

2

2

0

.

7

6

0

.

4

4

2

4

.

9

2

0

.

4

7

3

1

.

0

6

0

.

5

3

3

7

.

2

4

0

.

5

9

4

3

.

3

2

0

.

6

5

4

9

.

5

0

0

.

7

3

5

6

.

1

0

W

a

l

l

I

.

D

.

C

L

A

S

S

5

3

0

.

3

1

3

.

3

4

0

.

3

2

4

.

1

6

0

.

3

4

6

.

2

2

0

.

3

6

8

.

3

3

0

.

3

8

1

0

.

3

4

0

.

4

0

1

2

.

4

0

0

.

4

2

1

4

.

4

6

0

.

4

3

1

6

.

5

4

0

.

4

4

1

8

.

6

2

0

.

4

5

2

0

.

7

0

0

.

4

7

2

4

.

8

6

0

.

5

1

3

0

.

9

9

0

.

5

8

3

7

.

1

4

0

.

6

5

4

3

.

2

0

0

.

7

2

4

9

.

3

6

0

.

8

1

5

5

.

9

4

W

a

l

l

I

.

D

.

C

L

A

S

S

5

4

0

.

3

4

3

.

2

8

0

.

3

5

4

.

1

0

0

.

3

7

6

.

1

6

0

.

3

9

8

.

2

7

0

.

4

1

1

0

.

2

8

0

.

4

3

1

2

.

3

4

0

.

4

5

1

4

.

4

0

0

.

4

6

1

6

.

4

8

0

.

4

7

1

8

.

5

6

0

.

4

8

2

0

.

6

4

0

.

5

0

2

4

.

8

0

0

.

5

5

3

0

.

9

0

0

.

6

3

3

7

.

0

4

0

.

7

1

4

3

.

0

8

0

.

7

9

4

9

.

2

2

0

.

8

9

5

5

.

7

8

W

a

l

l

I

.

D

.

C

L

A

S

S

5

5

0

.

3

7

3

.

2

2

0

.

3

8

4

.

0

4

0

.

4

0

6

.

1

0

0

.

4

2

8

.

2

1

0

.

4

4

1

0

.

2

2

0

.

4

6

1

2

.

2

8

0

.

4

8

1

4

.

3

4

0

.

4

9

1

6

.

4

2

0

.

5

0

1

8

.

5

0

0

.

5

1

2

0

.

5

8

0

.

5

3

2

4

.

7

4

0

.

5

9

3

0

.

8

2

0

.

6

8

3

6

.

9

4

0

.

7

7

4

2

.

9

6

0

.

8

6

4

9

.

0

8

0

.

9

7

5

5

.

6

2

W

a

l

l

I

.

D

.

0

.

4

0

3

.

1

6

0

.

4

1

3

.

9

8

0

.

4

3

6

.

0

4

0

.

4

5

8

.

1

5

0

.

4

7

1

0

.

1

6

0

.

4

9

1

2

.

2

2

0

.

5

1

1

4

.

2

8

0

.

5

2

1

6

.

3

6

0

.

5

3

1

8

.

4

4

0

.

5

4

2

0

.

5

2

0

.

5

6

2

4

.

6

8

0

.

6

3

3

0

.

7

4

0

.

7

3

3

6

.

8

4

0

.

8

3

4

2

.

8

4

0

.

9

3

4

8

.

9

4

1

.

0

5

5

5

.

4

6

W

a

l

l

I

.

D

.

C

L

A

S

S

5

6

0

.

1

2

5

0

.

2

5

0

0

.

1

2

5

0

.

2

5

0

0

.

1

2

5

0

.

2

5

0

0

.

1

2

5

0

.

2

5

0

0

.

1

2

5

0

.

2

5

0

0

.

1

2

5

0

.

2

5

0

0

.

1

8

7

5

0

.

3

7

5

0

.

1

8

7

5

0

.

3

7

5

0

.

1

8

7

5

0

.

3

7

5

0

.

1

8

7

5

0

.

3

7

5

0

.

1

8

7

5

0

.

3

7

5

0

.

2

5

0

0

.

5

0

0

0

.

2

5

0

0

.

5

0

0

0

.

2

5

0

0

.

5

0

0

0

.

2

5

0

0

.

5

0

0

0

.

2

5

0

0

.

5

0

0

S

i

n

g

l

e

D

o

u

b

l

e

L

i

n

e

r

(

C

e

m

e

n

t

)

S

i

e

m

e

n

s

E

n

e

r

g

y

&

A

u

t

o

m

a

t

i

o

n

,

I

n

c

.

1

5

5

P

l

a

n

t

A

v

e

n

u

e

,

H

a

u

p

p

a

u

g

e

,

N

e

w

Y

o

r

k

1

1

7

8

8

-

3

8

0

1

T

e

l

.

+

1

(

6

3

1

)

2

3

1

-

3

6

0

0

T

o

l

l

F

r

e

e

.

+

1

(

8

0

0

)

2

7

5

-

8

4

7

9

F

a

x

.

+

1

(

6

3

1

)

2

3

1

-

3

3

3

4

W

e

b

:

w

w

w

.

s

e

a

.

s

i

e

m

e

n

s

.

c

o

m

/

i

a

E

-

m

a

i

l

:

i

n

f

o

.

u

l

t

r

a

s

o

n

i

c

f

l

o

w

@

s

i

e

m

e

n

s

.

c

o

m

C

L

A

S

S

A

P

i

p

e

S

i

z

e

3468

1

0

1

2

1

4

1

6

1

8

2

0

2

4

3

0

3

6

4

2

4

8

5

4

6

0

7

2

8

4

3

.

8

0

0

.

3

9

3

.

0

2

4

.

8

0

0

.

4

2

3

.

9

6

6

.

9

0

0

.

4

4

6

.

0

2

9

.

0

5

0

.

4

6

8

.

1

3

1

1

.

1

0

0

.

5

0

1

0

.

1

0

1

3

.

2

0

0

.

5

4

1

2

.

1

2

1

5

.

3

0

0

.

5

7

1

4

.

1

6

1

7

.

4

0

0

.

6

0

1

6

.

2

0

1

9

.

5

0

0

.

6

4

1

8

.

2

2

2

1

.

6

0

0

.

6

7

2

0

.

2

6

2

5

.

8

0

0

.

7

6

2

4

.

2

8

3

1

.

7

4

0

.

8

8

2

9

.

9

8

3

7

.

9

6

0

.

9

9

3

5

.

9

8

4

4

.

2

0

1

.

1

0

4

2

.

0

0

5

0

.

5

0

1

.

2

6

4

7

.

9

8

5

6

.

6

6

1

.

3

5

5

3

.

9

6

6

2

.

8

0

1

.

3

9

6

0

.

0

2

7

5

.

3

4

1

.

6

2

7

2

.

1

0

8

7

.

5

4

1

.

7

2

8

4

.

1

0

O

.

D

W

a

l

l

I

.

D

.

C

L

A

S

S

B

3

.

9

6

0

.

4

2

3

.

1

2

5

.

0

0

0

.

4

5

4

.

1

0

7

.

1

0

0

.

4

8

6

.

1

4

9

.

0

5

0

.

5

1

8

.

0

3

1

1

.

1

0

0

.

5

7

9

.

9

6

1

3

.

2

0

0

.

6

2

1

1

.

9

6

1

5

.

3

0

0

.

6

6

1

3

.

9

6

1

7

.

4

0

0

.

7

0

1

6

.

0

0

1

9

.

5

0

0

.

7

5

1

8

.

0

0

2

1

.

6

0

0

.

8

0

2

0

.

0

0

2

5

.

8

0

0

.

8

9

2

4

.

0

2

3

2

.

0

0

1

.

0

3

2

9

.

9

4

3

8

.

3

0

1

.

1

5

3

6

.

0

0

4

4

.

5

0

1

.

2

8

4

1

.

9

4

5

0

.

8

0

1

.

4

2

4

7

.

9

6

5

7

.

1

0

1

.

5

5

5

4

.

0

0

6

4

.

4

0

1

.

6

7

6

0

.

0

6

7

6

.

0

0

1

.

9

5

7

2

.

1

0

8

8

.

5

4

2

.

2

2

8

4

.

1

0

O

.

D

W

a

l

l

I

.

D

.

C

L

A

S

S

C

3

.

9

6

0

.

4

5

3

.

0

6

5

.

0

0

0

.

4

8

4

.

0

4

7

.

1

0

0

.

5

1

6

.

0

8

9

.

3

0

0

.

5

6

8

.

1

8

1

1

.

4

0

0

.

6

2

1

0

.

1

6

1

3

.

5

0

0

.

6

8

1

2

.

1

4

1

5

.

6

5

0

.

7

4

1

4

.

1

7

1

7

.

8

0

0

.

8

0

1

6

.

2

0

1

9

.

9

2

0

.

8

7

1

8

.

1

8

2

2

.

0

6

0

.

9

2

2

0

.

2

2

2

6

.

3

2

1

.

0

4

2

4

.

2

2

3

2

.

4

0

1

.

2

0

3

0

.

0

0

3

8

.

7

0

1

.

3

6

3

9

.

9

8

4

5

.

1

0

1

.

5

4

4

2

.

0

2

5

1

.

4

0

1

.

7

1

4

7

.

9

8

5

7

.

8

0

1

.

9

0

5

4

.

0

0

6

4

.

2

0

2

.

0

0

6

0

.

2

0

7

6

.

8

8

2

.

3

9

7

2

.

1

0

O

.

D

W

a

l

l

I

.

D

.

C

L

A

S

S

D

3

.

9

6

0

.

4

8

3

.

0

0

5

.

0

0

0

.

5

2

3

.

9

6

7

.

1

0

0

.

5

5

6

.

0

0

9

.

3

0

0

.

6

0

8

.

1

0

1

1

.

4

0

0

.

6

8

1

0

.

0

4

1

3

.

5

0

0

.

7

5

1

2

.

0

0

1

5

.

6

5

0

.

8

2

1

4

.

0

1

1

7

.

8

0

0

.

8

9

1

6

.

0

2

1

9

.

9

2

0

.

9

6

1

8

.

0

0

2

2

.

0

6

1

.

0

3

2

0

.

0

0

2

6

.

3

2

1

.

1

6

2

4

.

0

0

3

2

.

7

4

1

.

3

7

3

0

.

0

0

3

9

.

1

6

1

.

5

8

3

6

.

0

0

4

5

.

5

8

1

.

7

8

4

2

.

0

2

5

1

.

9

8

1

.

9

6

4

8

.

0

6

5

8

.

4

0

2

.

2

3

5

3

.

9

4

6

4

.

8

2

2

.

3

8

6

0

.

0

6

O

.

D

W

a

l

l

I

.

D

.

C

L

A

S

S

E

7

.

2

2

0

.

5

8

6

.

0

6

9

.

4

2

0

.

6

6

8

.

1

0

1

1

.

6

0

0

.

7

4

1

0

.

1

2

1

3

.

7

8

0

.

8

2

1

2

.

1

4

1

5

.

9

8

0

.

9

0

1

4

.

1

8

1

8

.

1

6

0

.

9

8

1

6

.

2

0

2

0

.

3

4

1

.

0

7

1

8

.

2

0

2

2

.

5

4

1

.

1

5

2

0

.

2

4

2

6

.

9

0

1

.

3

1

2

4

.

2

8

3

3

.

1

0

1

.

5

5

3

0

.

0

0

3

9

.

6

0

1

.

8

0

3