Escolar Documentos

Profissional Documentos

Cultura Documentos

Power Transmission: Components Used To Transmit Power: Gears, Belt, Clutch and Brakes

Enviado por

rip111176Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Power Transmission: Components Used To Transmit Power: Gears, Belt, Clutch and Brakes

Enviado por

rip111176Direitos autorais:

Formatos disponíveis

1

Power transmission

Components used to transmit power: gears, belt, clutch and brakes.

Gear

Objective:

Student must be able to force analysis, stress analysis using basic formula and AGMA (bending stress and surface stress)

Type of gear:

Spur gear only

Types of Gear a) Spur Gear

� �

Teeth is parallel to axis of rotation Can transmit power from one shaft to another parallel shaft

b)

Helical gear

� � � �

Teeth is inclined to the axis of rotation Smoother than spur Develop thrust load (helix angle) Can transmit power from one shaft to a parallel and non-parallel shaft

c)

Bevel gear

� �

Teeth on conical surfaces Transmit power between two intersecting shafts

d)

Worm gear � Transmit power between intersecting shafts two

Terminologies

A pair of gears can represented as 2 circles d1 = Nm d2 = Nm

where: N : number of teeth m : module note: mating gear must have same m

Module: is the ratio if diametral pitch and number of teeth m = d/N [mm] Face Width (F) : width of the tooth Addendum [a] : distance between top face of the tooth to pitch circle Dedendum [b] : distance between pitch diameter to bottom of the gear In the following : we only concentrates on full depth gear

Full depth tooth

When the offset occurs between pitch.� not full-depth tooth, which is called stub Undercut: resulted from number of tooth is less than the minimum number of tooth suggested. Results: higher stresses at the root of the tooth.

Backlash : gap between mating tooth. The gap can be used for lubrication

5 Contact Ratio: the number of tooth in contact during meshing. Roughly � spur gear (1.4 to 1.8 )

Pinion and Gear : pinion is driver and gear is driven

Gear Parameters

Metric Imperial Module m = d/N Diametral Pitch P= N/d (inverse to module)

One pair of gear must have the same module

Pressure Angle: 200, 22.5o, 250 Table 13-1: relationship between addendum (a) and dedundum (b) Table 13-2: Available pitch diametral and module.

Gear Train

V2 = V3

Known that

60 where : n : revolution / min it

V=

dn

d 2 n 2 = d 3 n 3

d 2 n2 = d 3 n3

Equation 1

For a pair of gear m2 = m3

d2 d3 = N2 N3

Equation 2

From Eq 1 and 2

d 2 N 2 n3 = = d 3 N 3 n2

Significance: � d increases N increase � d increases n reduces � to reduce rpm requires small pinion and larger gear and vice versa.

Gear Train (continued)

3 4

V2 = V3 and V3 = V4 Therefore V2 = V3 = V4

From previous formula:

N2 n3 = N3 n2 N2 n2 = N3 n3

Gear 2 and 3

n3 =

Gear 3 and 4

N2 n2 N3

N3 n3 N4

(1)

n4 =

Eq (1) in eq (2)

(2)

n4 =

nL =

N3 N2 n2 N4 N3

product of driving tooth numbers nF product of driven tooth numbers

where: nL : rotational speed of last gear (output) nF : rotational speed of first gear (input)

Train value

e=

product of driving tooth numbers product of driven tooth numbers

Planetary Gear

5 4 2 3

Gear 2: Sun gear Gear 3: Arm Gear 4: Planet Gear Gear 5: Ring Gear

Assumption Arm Fixed:

4 2 3

Train value

e=

N2 N 4 N5 N 4 N5 N6

3 MAGIC FORMULAE FOR FBD ANALYSIS ON GEAR

Torque

d T = Wt 2

[ Nm ]

Wt: tangential force

Speed

V =

dn

60

[m / s]

D: pitch diameter in [m] N: rotational speed [rpm]

Power

H = WtV

[ watts ]

10

Force Analysis (Free Body Diagram)

Input rpm direction: cw

To transfer power, T must exist. When the pinion rotates, tooth from gear against the movement � direction Wt32 must against the direction of rotation Wt32 = H / V T2 = Wt32. d2/2 Due to pressure angle, Wr32 (radial force) is generated Wr32 = Wt32 tan

11

On Gear 3,

Wt23 and Wr23 must in the opposite direction. To be statically analytical, T3 is against Wt23 T3 = Wt23. d3/2 Note: Wt23 can be calculated using Wt32= H/ V, please remember that all the parameters must be based on gear 3.

Discuss example 13-7

12

Example You are responsible to design a gear system for speed reducer. The speed reducer is a two stage reduction which each pinion has 18T (Gear 2 and 4 in Figure 1). One of the constraints is that the maximum allowable reduction is 10 at each stage. Based on this, answer the following questions. a. Suggest the two possible number of teeth for Gear 3 and 5 if the speed has to be reduced by 24 times. Note: if Gear 3 has X teeth and Gear 5 has Y teeth and vice versa, the answer is considered as one) Number of Tooth Gear 3 Gear 5 Combination 1 ________ ________ Combination 2 ________ ________ Assume gear 3 and 5 have 72 and 90 teeth respectively and comprises of m = 4 and 200 pressure angle gears. The motor is 8kW at 100 rpm clockwise. b. Calculate the rpm of the output shaft. c. Draw and calculate all the resultant forces on all of the gears. d. Based on the above calculation, discuss the relationship between torque and gear ratio.

18T 2 Syaf masukan dari motor

18T 4 Syaf Keluaran 3 5

Figure 1

13

Example The figure below shows a dual output power transmission system. A 8kW motor with 1000 rpm in clockwise direction is attached to shaft 1 at A. 40% of the power is delivered to shaft 2 using gear 2 and 4 and the remaining 60% of the power is delivered to shaft 3 via gear 3 and 5. All the gear module is 2 mm (m = 2mm) with pressure angle of 200. Based on this information, answer the following questions a) Draw the FBD for every gear and also calculate all the forces and torques if the speed of both output shafts have been reduced by 3. b) Calculate N5 if torque on shaft 2 and 3 is equal and N4 is 72.

14

Failure Types

Bending: resulted from bending stress. Wt act on the tooth Lewis formula and AGMA

Pitting:

resulted from surface stress Repetition of high contact stresses

Scoring:

resulted from insufficiency of lubrication

Bending Stresses

Wt = FmY

Basic Formula:

*take note that there are two formulae in pair in the textbook (imperial and metric)

Assumption Basic Formula Cantilever Beam Problem Ft is carried by one tooth only. However, dynamic effects are present when a pair of gear at moderate and high speed. ( KV)

' KV Wt = FmY

eq 14-8 pp719

Y: Lewis form factor Table 14-2 pp 718. (interpolation if it is required)

15

Dynamic Effect

' = KV

3.05 + V 3.05 6.1 + V 6.1

(cast iron, cast profile) (cut or milled profile)

' = KV

' KV =

3.56 + V 3.56

(hobbed or shaped profile)

16

K 'V =

5.56 + V 5.56

(finishing process on gears: shaved or ground profile)

SURFACE DURABILITY

Surface Stresses (compressive ve)

K W 1 1 2 C = CP V t + F cos r1 r 2

1

= pressure angle P = pinion G = gear Cp = elastic coefficient

2 1 CP = 2 2 1 P 1 G E + E G P

1

= Poisson Ration (Table A-5 ) E = Modulus of Elasticity (Table A-5)

Radius of curvature of the tooth profile

r1 = dp sin

2 d sin r2 = G 2

17

Example

A 19-TOOTH 300 Bhn HOBBED STEEL SPUR GEAR PINION TRANSMITS 15 Kw AT A PINION SPEED OF 360 rev/min TO A 77 TOOTH OF THE SAME MATERIAL GEAR. THE FACE WIDTH IS 75 mm, = 200 AND m = 6mm. a) USING LEWIS FORMULA CALCULATE THE STRESSES DUE TO BENDING AND THE CONTACT STRESSES? b) CALCULATE THE F.S OF THE CONTACT STRESSES AGAINST CONTACT STRESS ENDUCRANCE LIMIT (Sc)?

Você também pode gostar

- Turning Moment Diagram & FlywheelDocumento88 páginasTurning Moment Diagram & FlywheelAshishAgarwal100% (1)

- ENGR 301 - Assign3solnDocumento1 páginaENGR 301 - Assign3solnAPAinda não há avaliações

- Dynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionNo EverandDynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionAinda não há avaliações

- MECH 6541 Course Outline and Evaluation 2015Documento11 páginasMECH 6541 Course Outline and Evaluation 2015SrikantChamarthiAinda não há avaliações

- SHARIFI-EnGR 371 Summer 2016 Outline ModifiedDocumento5 páginasSHARIFI-EnGR 371 Summer 2016 Outline ModifiedBrunoAinda não há avaliações

- MECH 6491 Engineering Metrology and Measurement SystemsDocumento61 páginasMECH 6491 Engineering Metrology and Measurement SystemsSivashankar MurugesanAinda não há avaliações

- ENGR 371 Final Exam April 2010Documento3 páginasENGR 371 Final Exam April 2010amnesiannAinda não há avaliações

- ENGR 301 - Assign4solnDocumento5 páginasENGR 301 - Assign4solnAP100% (1)

- Engr 301Documento13 páginasEngr 301Sang MangAinda não há avaliações

- ENGR 371 GradesaversDocumento25 páginasENGR 371 Gradesaversasdfg0% (1)

- ENGR 371 Midterm February 2010Documento4 páginasENGR 371 Midterm February 2010amnesiannAinda não há avaliações

- 1722 Fyp-IiiDocumento84 páginas1722 Fyp-IiiHammad Iftikhar HanifAinda não há avaliações

- Assignment 7Documento2 páginasAssignment 7AlexAinda não há avaliações

- ENGR301 Midterm Winter 2013 SolutionsDocumento9 páginasENGR301 Midterm Winter 2013 SolutionsJonathan RuizAinda não há avaliações

- Montgomery SolutionsDocumento6 páginasMontgomery SolutionsRafael NajeraAinda não há avaliações

- ALL CNC Printouts PROGRAMS PRINTOUTDocumento26 páginasALL CNC Printouts PROGRAMS PRINTOUTGajananAinda não há avaliações

- Scatter DiagramsDocumento12 páginasScatter DiagramsSamir ChaudhariAinda não há avaliações

- M4 3 Synthetic Surface Modeling Bicubic Hermite PatchDocumento28 páginasM4 3 Synthetic Surface Modeling Bicubic Hermite PatchNANDULA GOUTHAM SAIAinda não há avaliações

- T15.Matrix and Vector AlgebraDocumento42 páginasT15.Matrix and Vector Algebraambida02Ainda não há avaliações

- Design of Machine ElementsDocumento5 páginasDesign of Machine ElementsjayadevakodiAinda não há avaliações

- UnitcircleprojectDocumento12 páginasUnitcircleprojectapi-261587850100% (1)

- Chapter Two 2. Manual NC Part ProgrammingDocumento33 páginasChapter Two 2. Manual NC Part ProgrammingMulugeta WoldeAinda não há avaliações

- Kinematics of Machinery ManualDocumento29 páginasKinematics of Machinery ManualShubham NaikAinda não há avaliações

- Cad Cam3 Unit NeelimaDocumento96 páginasCad Cam3 Unit Neelimasatish86Ainda não há avaliações

- Applied Multivariate Analysis (Multivariate Analysis) DR Amit Mitra Iit KanpurDocumento2 páginasApplied Multivariate Analysis (Multivariate Analysis) DR Amit Mitra Iit Kanpurwork0670% (1)

- HES3350 Machine Design Semester 1 2012 Assignment 1 Compound Reverted Gear Train Design PDFDocumento18 páginasHES3350 Machine Design Semester 1 2012 Assignment 1 Compound Reverted Gear Train Design PDFrisirarocksAinda não há avaliações

- ENSC3004 2011 Exam PDFDocumento4 páginasENSC3004 2011 Exam PDFMichael TangAinda não há avaliações

- Industrial Engineering: Sales and Demand ForecastingDocumento47 páginasIndustrial Engineering: Sales and Demand ForecastingKAMAL PATIAinda não há avaliações

- Computer Aided Design (CAD) : DR Janardhan VDocumento206 páginasComputer Aided Design (CAD) : DR Janardhan Vk pAinda não há avaliações

- MECH 453 Course Outline Winter 2017Documento2 páginasMECH 453 Course Outline Winter 2017rony16novAinda não há avaliações

- Practice - Questions - Doc Practice - QuestionsDocumento2 páginasPractice - Questions - Doc Practice - Questionsmanish_chaturvedi_6Ainda não há avaliações

- Kitchen Knife Mon130 Afwan ReportDocumento9 páginasKitchen Knife Mon130 Afwan ReportAfwan IrfanAinda não há avaliações

- Group Technology andDocumento66 páginasGroup Technology andNoormalita IrvianaAinda não há avaliações

- FANUC G Code of LatheDocumento25 páginasFANUC G Code of LatheHùng LêAinda não há avaliações

- Apt PDFDocumento45 páginasApt PDFJignesh Rohit0% (1)

- MEC713 ProjectManagement MidtermlExam 2013Documento8 páginasMEC713 ProjectManagement MidtermlExam 2013Fadi RonaldoAinda não há avaliações

- Boston Gear Helical GearsDocumento14 páginasBoston Gear Helical GearssandchiAinda não há avaliações

- Ch-11 NC CNC DNC FMS Automation and RoboticsDocumento191 páginasCh-11 NC CNC DNC FMS Automation and RoboticsPrateek BayalAinda não há avaliações

- P&S Unit - III (BEC)Documento33 páginasP&S Unit - III (BEC)anchapremAinda não há avaliações

- ME 31 Kinematics Sample Problems Velocity Analysis PDFDocumento60 páginasME 31 Kinematics Sample Problems Velocity Analysis PDFAmadeo ErebaraAinda não há avaliações

- BTEC NC - Further Mathematics For Technicians - Applied CalculusDocumento15 páginasBTEC NC - Further Mathematics For Technicians - Applied CalculusBrendan BurrAinda não há avaliações

- Design of Form ToolsDocumento2 páginasDesign of Form ToolsSunny GaekwadAinda não há avaliações

- 6 - Turbomachinery-Pumps Performance 2Documento31 páginas6 - Turbomachinery-Pumps Performance 2medo ElrefaeyAinda não há avaliações

- Chapter 1 - Process DiagramsDocumento36 páginasChapter 1 - Process Diagramsmrajim93Ainda não há avaliações

- Industrial EngineeringDocumento63 páginasIndustrial Engineeringgaurav503050Ainda não há avaliações

- First Order InstrumentDocumento11 páginasFirst Order InstrumentEr TikAinda não há avaliações

- CH 3 Fa2018Documento89 páginasCH 3 Fa2018Hassan AliAinda não há avaliações

- c07 Catia v5r15 Transformation FeaturesDocumento32 páginasc07 Catia v5r15 Transformation FeaturesNayefGhazaliAinda não há avaliações

- TrigonometryDocumento177 páginasTrigonometryjohn martinAinda não há avaliações

- ControlDocumento2 páginasControlAhmad AlmasriAinda não há avaliações

- Optimization of Process Parameters in Wire-EDM of AL6063-T6 Alloy Using Taguchi DOEDocumento12 páginasOptimization of Process Parameters in Wire-EDM of AL6063-T6 Alloy Using Taguchi DOEIJRASETPublicationsAinda não há avaliações

- ENGRDocumento36 páginasENGRjherryAinda não há avaliações

- Cad Imp Questions PDFDocumento5 páginasCad Imp Questions PDFjeroldscdAinda não há avaliações

- Me352 E1 Fa2009 SolDocumento21 páginasMe352 E1 Fa2009 SolSteve KrodaAinda não há avaliações

- Lathe ProgramDocumento6 páginasLathe ProgramAwoke TesfaAinda não há avaliações

- Ansys: Turbulence Modeling For Engineering FlowsDocumento25 páginasAnsys: Turbulence Modeling For Engineering Flowskristeen78100% (1)

- Short Question Bank CADDocumento3 páginasShort Question Bank CADnravin5Ainda não há avaliações

- Modern Control Sys-Lecture Vi PDFDocumento46 páginasModern Control Sys-Lecture Vi PDFMtanzania MtanzaniaAinda não há avaliações

- Statement Ledger PDFDocumento1 páginaStatement Ledger PDFrip111176Ainda não há avaliações

- Gemc 511687728136292 17092022Documento3 páginasGemc 511687728136292 17092022rip111176Ainda não há avaliações

- Gemc 511687729107385 20012022 PDFDocumento4 páginasGemc 511687729107385 20012022 PDFrip111176Ainda não há avaliações

- Gemc 511687737438095 25032022 PDFDocumento3 páginasGemc 511687737438095 25032022 PDFrip111176Ainda não há avaliações

- Gemc 511687710420082 19012022 PDFDocumento3 páginasGemc 511687710420082 19012022 PDFrip111176Ainda não há avaliações

- GEMC-511687720852142 Invoice PDFDocumento2 páginasGEMC-511687720852142 Invoice PDFrip111176Ainda não há avaliações

- Tutorial: Optimization Techniques 1Documento6 páginasTutorial: Optimization Techniques 1rip111176Ainda não há avaliações

- 6-Interest Payable by The TaxpayerDocumento13 páginas6-Interest Payable by The Taxpayerrip111176Ainda não há avaliações

- GeM Bidding 3656858 PDFDocumento4 páginasGeM Bidding 3656858 PDFrip111176Ainda não há avaliações

- AMD Tutorial ME CADCAM 2022-23Documento6 páginasAMD Tutorial ME CADCAM 2022-23rip111176Ainda não há avaliações

- Index For RPTDocumento1 páginaIndex For RPTrip111176Ainda não há avaliações

- Tutorial MD II 2015 5Documento1 páginaTutorial MD II 2015 5rip111176Ainda não há avaliações

- GeM Bidding 3152874 PDFDocumento4 páginasGeM Bidding 3152874 PDFrip111176Ainda não há avaliações

- OT Tutorials 3Documento1 páginaOT Tutorials 3rip111176Ainda não há avaliações

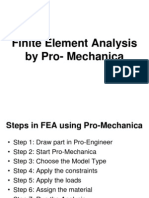

- ME SEM 2 CADCAM FEA Presentation MAY 2020 PDFDocumento1 páginaME SEM 2 CADCAM FEA Presentation MAY 2020 PDFrip111176Ainda não há avaliações

- FemDocumento12 páginasFemMiodrag OblakovicAinda não há avaliações

- OT Tutorials 6Documento1 páginaOT Tutorials 6rip111176Ainda não há avaliações

- ME SEM 2 CADCAM FEA OT Presentation MAY 2020Documento1 páginaME SEM 2 CADCAM FEA OT Presentation MAY 2020rip111176Ainda não há avaliações

- Finite Element 1Documento3 páginasFinite Element 1rip111176Ainda não há avaliações

- Finite Element 2 PDFDocumento5 páginasFinite Element 2 PDFrip111176Ainda não há avaliações

- Tutorial MD II 2015 3Documento1 páginaTutorial MD II 2015 3rip111176Ainda não há avaliações

- Tutorial MD II 2015 1Documento1 páginaTutorial MD II 2015 1rip111176Ainda não há avaliações

- Tutorial MD II 2015 4Documento1 páginaTutorial MD II 2015 4rip111176Ainda não há avaliações

- Finite Element 2 PDFDocumento5 páginasFinite Element 2 PDFrip111176Ainda não há avaliações

- ME SEM 2 CADCAM 3720821 OT Presentation MAY 2020Documento1 páginaME SEM 2 CADCAM 3720821 OT Presentation MAY 2020rip111176Ainda não há avaliações

- Turbine BladesDocumento37 páginasTurbine Bladeswsjouri2510Ainda não há avaliações

- Tutorial MD II 2015 2Documento1 páginaTutorial MD II 2015 2rip111176Ainda não há avaliações

- Subject: Machine Design Be Sem Vii Mechanical Tutorial:02 (Helical Gear)Documento1 páginaSubject: Machine Design Be Sem Vii Mechanical Tutorial:02 (Helical Gear)rip111176Ainda não há avaliações

- 77-9 Design of CranesDocumento10 páginas77-9 Design of Cranesrip111176Ainda não há avaliações

- Tutorial Design of Cranes 2017Documento2 páginasTutorial Design of Cranes 2017rip11117633% (3)

- Lerdge-Gcode List V3.0.5Documento108 páginasLerdge-Gcode List V3.0.5osman perez vidalAinda não há avaliações

- Given Values: Pressure Temperature Compressor Inlet 1.0325 Bar 300K Turbine Outlet 1.0325 Bar 815K Pressure Ratio 18.6Documento3 páginasGiven Values: Pressure Temperature Compressor Inlet 1.0325 Bar 300K Turbine Outlet 1.0325 Bar 815K Pressure Ratio 18.6Walter BircherAinda não há avaliações

- Digital Image ProcessingDocumento71 páginasDigital Image ProcessingPratibha SharmaAinda não há avaliações

- The Basics of Thread Rolling: Tools, Tips & Design ConsiderationsDocumento108 páginasThe Basics of Thread Rolling: Tools, Tips & Design ConsiderationsVictor ParvanAinda não há avaliações

- SmartPRO 5000U Plus ManualDocumento10 páginasSmartPRO 5000U Plus ManualMugiranezaAinda não há avaliações

- The Value Added by Electrodiagnostic Testing in The Diagnosis of Carpal Tunnel SyndromeDocumento7 páginasThe Value Added by Electrodiagnostic Testing in The Diagnosis of Carpal Tunnel SyndromeSRIJANAinda não há avaliações

- LoadRunner BasicsDocumento74 páginasLoadRunner BasicsmadhugangulaAinda não há avaliações

- Turbo-Pump Supply System For Liquid-Propellant Rocket EngineDocumento8 páginasTurbo-Pump Supply System For Liquid-Propellant Rocket EngineĐinh Quốc TríAinda não há avaliações

- Design Constraint ReportDocumento11 páginasDesign Constraint ReportCam MillerAinda não há avaliações

- Electrochemistry and Its Applications: © 2008 Brooks/Cole 1Documento65 páginasElectrochemistry and Its Applications: © 2008 Brooks/Cole 1Niel Karlo AtienzaAinda não há avaliações

- Wea Met Aws310 Brochure 210x280 B211290en C Low v2Documento4 páginasWea Met Aws310 Brochure 210x280 B211290en C Low v2Anonymous rpSGuQPAinda não há avaliações

- Calculations of The EFG Tensor in DTN Using GIPAW With CASTEP and QE SoftwareDocumento12 páginasCalculations of The EFG Tensor in DTN Using GIPAW With CASTEP and QE SoftwareAllen MAinda não há avaliações

- Vacuum TubeDocumento1 páginaVacuum Tubejose condoriAinda não há avaliações

- Aqa Byb1 W QP Jun07Documento12 páginasAqa Byb1 W QP Jun07李超然Ainda não há avaliações

- Сравнит. лингвистикаDocumento22 páginasСравнит. лингвистикаАнастасия ДобровольскаяAinda não há avaliações

- Parson Merton CritiqueDocumento9 páginasParson Merton CritiqueVishnu VarmaAinda não há avaliações

- Ee 494 ADocumento43 páginasEe 494 AGopinath B L NaiduAinda não há avaliações

- PNP Transistor OperationDocumento5 páginasPNP Transistor OperationmohanAinda não há avaliações

- 3013 Thule Atlantis 780Documento2 páginas3013 Thule Atlantis 780Duarte MartinsAinda não há avaliações

- 5000 KW Gearbox High Pinion Bearing Temperatures 1644227029Documento7 páginas5000 KW Gearbox High Pinion Bearing Temperatures 1644227029MC AAinda não há avaliações

- Paper I & 11 Answer All Questions: (E) Explain The Use of Correlation and Regression Studies in Busainess?Documento5 páginasPaper I & 11 Answer All Questions: (E) Explain The Use of Correlation and Regression Studies in Busainess?Suthaharan PerampalamAinda não há avaliações

- Sam W Hoke Torch PatentDocumento5 páginasSam W Hoke Torch PatentRichard.nlAinda não há avaliações

- PDFDocumento1 páginaPDFdhaktodesatyajitAinda não há avaliações

- Lab 3Documento8 páginasLab 3TOP 5 GHOSTAinda não há avaliações

- R134a HXWC Series Water Cooled Screw Flooded Chillers Cooling Capacity 200 To 740 Tons 703 To 2603 KW Products That Perform PDFDocumento16 páginasR134a HXWC Series Water Cooled Screw Flooded Chillers Cooling Capacity 200 To 740 Tons 703 To 2603 KW Products That Perform PDFmohamad chaudhariAinda não há avaliações

- How Torque Converters Work - HowStuffWorksDocumento7 páginasHow Torque Converters Work - HowStuffWorksKrishanu ModakAinda não há avaliações

- Experiment 3: Department of Civil Engineering, IIT DelhiDocumento2 páginasExperiment 3: Department of Civil Engineering, IIT DelhiSRAinda não há avaliações

- Industrial Organization (Theory and Practice) - 184-189Documento6 páginasIndustrial Organization (Theory and Practice) - 184-189kurniaAinda não há avaliações

- AristotleDocumento126 páginasAristotlenda_naumAinda não há avaliações

- Combined Gas Law Lab Report HJM ResearchDocumento5 páginasCombined Gas Law Lab Report HJM ResearchHelen100% (4)