Escolar Documentos

Profissional Documentos

Cultura Documentos

HDA-P Example #10

Enviado por

Thanit ThanadirekDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

HDA-P Example #10

Enviado por

Thanit ThanadirekDireitos autorais:

Formatos disponíveis

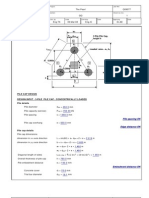

Design Example #10 Given: (4) Hilti M10 HDA-P undercut heavy-duty anchors subjected to a shear loading and

a tension loading as stated below. Objective: Analyze the connection for the given load situation.

Hilti HDA-P with Tension & Shear

Page 1 of 5

Dimensional Parameters: hef hef h s1 s2 ca1 ca2 ca3 d = 3.94 in. = 3.67 in. = 8 in. = 7 1/2 in. = 7 1/2 in. = 5 in. = 5 in. = 5 in. = 0.75 in.

Specifications / Assumptions: Normal weight concrete, fc = 4,000 psi Seismic design category (SDC) D High seismic & cracked concrete No supplementary reinforcing per ACI 318-05 Appendix D.1 => Condition B per ACI 318-05 Appendix D.4.4 (c)

If we assume that a brittle failure mode will control the design. In accordance with IBC 2006 Section 1908.1.16 there are two choices: D.3.3.5 Instead of D.3.3.4, the attachment that the anchor is connecting to the structure shall be designed so that the attachment will undergo ductile yielding at a load level corresponding to anchor forces no greater than the design strength of anchors specified in D.3.3.3, or the minimum design strength of the anchors shall be at least 2.5 times the factored forces transmitted by the attachment. All load factors are assumed to be taken from ACI 318-9.

For the purposes of this calculation, the loads shown are 2.5 times the factored loads.

Factored Tension Load = 10,000 lbf Factored Shear Load = 1,000 lbf (Toward edge along y-axis) Check 3-edge condition (ACI 318 Appendix D.5.2.3):

hef = 3.94in.

1.5 hef = 1.5 3.94 in. = 5.91in.

All edge distances < 5.91 in. Calculate modified hef = hef

c a,max smax 5 in. 7.5 in. hef ' = max 1.5 , 3 = max 1.5 , 3 = max(3.33 in.,2.5 in.) hef ' = 3.67 in.

Design Example #10

Hilti HDA-P with Tension & Shear ACI 318 Ref. D.5.1.2 Eq. (D-3)

Page 2 of 5 ESR Ref. Table 5 Table 5 Table 5 Section 4.1.2

Calculation per ACI 318-05 Appendix D and ICC-ES ESR-1546 Step 1. Check Minimums: Edge Distance, Anchor Spacing, and Member Thickness: cmin = 3 1/8 in. ca,min = 5 in. smin = 4 in. s = 7.5 in. hmin = 6 in. h = 8 in. Step 2. Calculate Steel Strength in Tension: ok. ok. ok.

Nsa = n A se futa

= 0.75 n=4 A se futa = 10,440 lb Nsa = n A se futa = 0.75 4 0.090 in 116,000 psi = 31 ,320 lb

2

Table 5

Step 3. Calculate Concrete Breakout Strength in Tension:

Ncbg =

A Nc ec ,N ed,N c ,N cp,N Nb A Nco

2 2

D.5.2.1 Eq. (D-5) D.5.2.1 Eq. (D-6) D.5.2.1 D.5.2.2 Eq. (D-7) D.5.2.4 D.5.2.5 Eq. (D-10)

Section 4.1.3

A Nco = 9 (h ef ) = 9 (3.33 in.) = 99 .8 in 2

Table 5 Table 5 -

ANc = (c a1 + s1 + c a3 ) (1.5 hef '+s2 + 1.5 hef ')

Nb = k c ,cr fc' (h ef )

1 .5

= (5 in. + 7.5 in. + 5 in.) (1.5 3.33 in. + 7.5 in. + 1.5 3.33 in.) = 306 in2

= 24 4,000 psi (3.33 in.)

1 .5

= 9,224 lb

ec,N = 1.0 ed,N = 1.0

c,N = 1.0

= 0.65 Ncbg =

(no eccentricity)

(assumed cracked concrete, kcr = 24)

D.5.2.6 D.5.2.7

cp,N = 1.0 (assumed cracked concrete, N/A for HDA anchors)

A Nc ec,N ed,N c,N cp,N Nb A Nco 306 in 1.0 1.0 1.0 1.0 9,224 lb = 18,398 lb 99.8 in2

2

D.5.2.1 Eq. (D-5)

Table 5

= 0.65

Step 4. Calculate Pullout Strength in Tension:

Npn,f ' c

f 'c = Np,cr 2,500 psi

f 'c 2,500 psi Np,cr = 8,992 lb

Section 4.1.4 Eq. (1)

Npn, f 'c = Np,cr

= 8,992 lb

4,000 psi = 11,374 lb 2,500 psi

Eq. (D-14h) Table 5

Design Example #10

Hilti HDA-P with Tension & Shear ACI 318 Ref.

Page 3 of 5 ESR Ref. Section 4.1.4 Table 5

Calculation per ACI 318-05 Appendix D and ICC-ES ESR-1546

= 0.65

n=4

-

Npn, f 'c = n Npn, f 'c = 0.65 4 11 ,374 lb = 29,572 lb

Step 5. Calculate Steel Strength in Shear:

Vsa = n Vseis

= 0.65 n=4 Vseis = 4,496 lb Vsa = n Vseis = 0.65 4 4,496 lb = 11 ,690 lb

Step 6. Calculate Concrete Breakout Strength in Shear:

D.6.1.2

Section 4.1.5

Section 4.1.11 Table 5

D.6.2.1 (b) Perpendicular Eq. (D-22) Section 4.1.6

Vcbg =

A Vc ec , V ed, V c, V Vb A Vco

Check 3-edge condition:

h smax 5 in. 8 in. 7.5 in. c ca1' = max a2 , , , , = max 3 1.5 1.5 1.5 1.5 3 = max(3.33 in., 5.33 in., 2.5 in.) = 5.33 in. > ca1 Use ca1 = 5.0 in.

A Vco = 4.5 (c a1' ) = 4.5 (5.0 in.) = 112 .5 in 2

2 2

D.6.2.4

Eq. (D-23) D.6.2.1

A Vc = (c a1 + s1 + c a3 ) (1.5 c a1 )

= (5 in. + 7.5 in. + 5 in.) (7.5 in.) = 131.25 in2

le = hef 8 d0 le Vb = 7 d 0

0.2

8 d0 = 6.0 in. d0 fc' (c a1 )

0.2 1.5

hef = 3.94 in.

(governs)

D.6.2.2 Eq. (D-24)

1.5

3.94 in. = 7 0.75 in.

0.75 in. 4,000 psi (5.0 in.)

= 5,973 lb

D.6.2.5 D.6.2.1 (c) Eq. (D-28) D.6.2.7 -

ec,V = 1.0

(there is no shear load eccentricity)

c a2,min 5 in. = 0 . 7 + 0 . 3 ed,V = 0.7 + 0.3 1.5 5.0 in. = 0.9 1.5 c ' a

c,V = 1.0

(cracked concrete with no supplementary reinforcement)

Design Example #10

Hilti HDA-P with Tension & Shear ACI 318 Ref.

Page 4 of 5 ESR Ref.

Calculation per ACI 318-05 Appendix D and ICC-ES ESR-1546

= 0.70 Vcbg = A Vc ec, V ed, V c, V Vcb A Vco 131.25 in 1.0 0.9 1.0 5,973 lb = 4,390 lb 112.5 in2

2

D.6.2.1 (c) Eq. (D-22)

Table 5

= 0.70

Step 7. Calculate Concrete Pry-out Strength in Shear:

D.6.3.1 (b) Eq. (D-30)

Vcpg = k cp Ncbg

hef ' = 3.33 in. > 2.5 in.

Ncbg =

Section 4.1.7

k cp = 2.0

D.6.3.1

A Nc ec ,N ed,N c ,N cp,N Nb A Nco 306 .25 in = 1.0 1.0 1.0 1.0 9,224 lb = 28,305 lb 112 .5 in2

2

D.5.2.1 Eq. (D-5)

= 0.70 Vcpg = k cp Ncbg = 0.70 2.0 28,305 lb = 39,627 lb

Step 8. Calculate Concrete Breakout Strength for Shear Parallel to Edge: D.6.3.1 (b) Eq. (D-30) D.6.2.1 (c) Parallel Eq. (D-22) Eq. (D-23) D.6.2.1 D.6.2.5 D.6.2.6 Eq. (D-28) D.6.2.7 Section 4.1.6 Section 4.1.7 Table 5

Vcbg

A = Vc ec,V ed,V c,V Vb A Vco

2 2

A Vco = 4.5 (c a1 ) = 4.5 (5 in.) = 113 in 2

A Vc = (1.5 c a,min + s2 + c a1 ) (1.5 c a,min )

= (7.5 in. + 7.5 in. + 5 in.) (7.5 in.) = 150 in2

ec,V = 1.0

c a2 5.0 in. = 0 . 7 + 0 . 3 ed, V = 0.7 + 0.3 1.5 5 in. = 0.90 1.5 c a1

c,V = 1.0

le = hef 8 d0 le Vb = 7 d 0

0.2

8 d0 = 6.0 in. d0 fc' (c a1 )

0.2 1.5

hef = 3.94 in.

(governs)

D.6.2.2 Eq. (D-24) -

3.94 in. = 7 0.75 in.

0.75 in. 4,000 psi (5 in.)

1.5

= 5,973 lb

Design Example #10

Hilti HDA-P with Tension & Shear ACI 318 Ref.

Page 5 of 5 ESR Ref.

Calculation per ACI 318-05 Appendix D and ICC-ES ESR-1546 Shear acts parallel to edge located 5 in. from anchors. Calculate Vcbg toward edge and multiply by 2.

Vcbg = 2

A Vc ec , V ed, V c, V Vb A Vco 150 in2 1.0 0.90 1.0 5,973 lb = 9,990lb 113 in2

D.6.2.1 (c) Parallel to edge Eq. (D-22) Table 5

= 2 0.70

Summary of Tension Strengths: Steel Strength in Tension Nsa = 31,320 lb Concrete Breakout Strength in Tension Ncbg = 18,398 lb Pullout Strength in Tension Npn,fc = 29,572 lb Summary of Shear Strengths: Steel Strength in Shear Vsa = 11,690 lb Concrete Breakout Strength in Shear Vcbg = 4,390 lb Concrete Breakout Strength in Shear Vcbg Parallel = 9,990 lb Pry-Out Strength in Shear Vcpg = 39,627 lb 0.75 Seismic Reduction per ACI 318 Appendix D.3.3.3 (SDC D): Concrete Breakout Strength in Tension 0.75 Ncbg = 13,798 lb Concrete Breakout Strength in Shear 0.75 Vcbg = 3,293 lb Interaction:

Controls

Controls

Nua = 10,000 lb Nn = 13,541lb Check : 0.2 Nn Nua 0.2 13,798 lb = 2,760 lb Vua = 1,000 lb Vn = 2,642 lb Check : 0.2 Vn Vua 0.2 3,293 lb = 659 lb

Check Interaction: D.7.1 D.7.2 -

Check Interaction

Check Interaction

Nua V + ua 1.2 Nn Vn 10,000 lb 1 ,000 lb + < 1 .2 13,798 lb 3,293 lb = 0.72 + 0.30 = 1.02 < 1.2 Use 5/3: = 0.585 + 0.137 = 0.72 < 1.0 ok ok

D.7.3 Eq. (D-31) Section 4.2.2 Eq. (6)

Important note: The sample calculations above reflect Hiltis understanding of the interaction between code requirements and ICC-ES ESR data. While every effort was made to verify they are correct, the calculations shall be reviewed by a licensed professional before being relied on.

Você também pode gostar

- Mathcad - Beam Capacity With A Prime S - Rev03Documento2 páginasMathcad - Beam Capacity With A Prime S - Rev03Travis C. Smith, P.E.Ainda não há avaliações

- Example Calculations: Example Calculation For A Single Strong-Bolt 2 Anchor Using SDDocumento2 páginasExample Calculations: Example Calculation For A Single Strong-Bolt 2 Anchor Using SDmordidomiAinda não há avaliações

- EMBEDMENT CALCULATIONDocumento5 páginasEMBEDMENT CALCULATIONMWKELIOLAAinda não há avaliações

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocumento29 páginasMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Mathcad - Partea 1Documento27 páginasMathcad - Partea 1Razvan BaiceanuAinda não há avaliações

- C1F1Documento9 páginasC1F1Hubert Jay Fedalino YubatAinda não há avaliações

- Mathcad - RC Pier DesignDocumento7 páginasMathcad - RC Pier Designlnt4Ainda não há avaliações

- Concrete Analysis and DesignDocumento99 páginasConcrete Analysis and DesignAdil Javed ChaudharyAinda não há avaliações

- Steel Column BeamDocumento6 páginasSteel Column Beamdharul khairAinda não há avaliações

- Elaborat Iz FundiranjaDocumento64 páginasElaborat Iz Fundiranjatis0125Ainda não há avaliações

- MAthcad Wall Calcs PDFDocumento4 páginasMAthcad Wall Calcs PDFManoj JaiswalAinda não há avaliações

- Ankeri SI JediniceDocumento30 páginasAnkeri SI Jedinicepperic13Ainda não há avaliações

- Shallow FoundationDocumento27 páginasShallow FoundationChristoper Dela CruzAinda não há avaliações

- Ec9 Ex61 Shear No StiffenersDocumento3 páginasEc9 Ex61 Shear No StiffenersimotalpAinda não há avaliações

- 10.1 Material Properties, Development, and Splice LengthsDocumento12 páginas10.1 Material Properties, Development, and Splice LengthsjoshuaAinda não há avaliações

- Slender Wall Byslender Wall DesignDocumento4 páginasSlender Wall Byslender Wall DesignDiquanAinda não há avaliações

- Time Saving Column Design by Is CodeDocumento10 páginasTime Saving Column Design by Is CodeNaveen RevannaAinda não há avaliações

- SEO-Optimized Beam Design CalculationDocumento169 páginasSEO-Optimized Beam Design CalculationabuzahrauAinda não há avaliações

- Pile Cap Design 1Documento6 páginasPile Cap Design 1kjpatel2100% (2)

- Shallow Foundations Design 1Documento9 páginasShallow Foundations Design 1kimkov119Ainda não há avaliações

- Design Reinforced Concrete Beam in ACI 318Documento7 páginasDesign Reinforced Concrete Beam in ACI 318lnt4Ainda não há avaliações

- Post-Tensioned Slab Design ExampleDocumento9 páginasPost-Tensioned Slab Design ExampleLaura ManolacheAinda não há avaliações

- Reinforced Concrete Design Solutions Manual 6th Edition ContentsDocumento63 páginasReinforced Concrete Design Solutions Manual 6th Edition ContentsSimasero Cero67% (3)

- Precast Prestressed Concrete Girder Bridge - Design ExampleDocumento37 páginasPrecast Prestressed Concrete Girder Bridge - Design Examplerammiris100% (1)

- FOUNDATION ANALYSISDocumento14 páginasFOUNDATION ANALYSISJuli NirwantoAinda não há avaliações

- PCA Rectangular - Tank Design ExampleDocumento15 páginasPCA Rectangular - Tank Design ExampleConrad Otieno100% (4)

- Single Footing Design - Telecomm, Transmission & Guyed Tower & Pole - TIA 222F & ACIDocumento12 páginasSingle Footing Design - Telecomm, Transmission & Guyed Tower & Pole - TIA 222F & ACIasad_naqvi100% (2)

- ACI-350 Concrete Beam Design 1.1Documento6 páginasACI-350 Concrete Beam Design 1.1nhulugalla33% (3)

- Anchorage To ConcreteDocumento10 páginasAnchorage To ConcretemakakkAinda não há avaliações

- Mathcad - InPEX Masela FLNG Korea-Batam (Calm)Documento5 páginasMathcad - InPEX Masela FLNG Korea-Batam (Calm)fahmyits100% (1)

- Pipeline Design-InstallationDocumento19 páginasPipeline Design-InstallationFaridah ZahraAinda não há avaliações

- Answers To ProblemsDocumento14 páginasAnswers To ProblemsMaria Laura PonceAinda não há avaliações

- Design of FootingsDocumento42 páginasDesign of Footingsxaekne91% (11)

- Design of Steel I-Section (BS5950)Documento6 páginasDesign of Steel I-Section (BS5950)Rachelle C. Abanes50% (4)

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportAinda não há avaliações

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesAinda não há avaliações

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionAinda não há avaliações

- Southern Marine Engineering Desk Reference: Second Edition Volume INo EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IAinda não há avaliações

- Process Intensification for Sustainable Energy ConversionNo EverandProcess Intensification for Sustainable Energy ConversionAinda não há avaliações

- Solving Partial Differential Equation Applications with PDE2DNo EverandSolving Partial Differential Equation Applications with PDE2DAinda não há avaliações

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsNo EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsNota: 5 de 5 estrelas5/5 (1)

- Analog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignNo EverandAnalog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignAinda não há avaliações

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationAinda não há avaliações

- Process Heat Transfer: Principles, Applications and Rules of ThumbNo EverandProcess Heat Transfer: Principles, Applications and Rules of ThumbNota: 4.5 de 5 estrelas4.5/5 (11)

- Instructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYNo EverandInstructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYAinda não há avaliações

- Solution Manual for an Introduction to Equilibrium ThermodynamicsNo EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsAinda não há avaliações

- Album of Dated Latin Inscriptions, Part I, Plates: Rome and the Neighborhood, Augustus to NervaNo EverandAlbum of Dated Latin Inscriptions, Part I, Plates: Rome and the Neighborhood, Augustus to NervaAinda não há avaliações

- The Fracture of Brittle Materials: Testing and AnalysisNo EverandThe Fracture of Brittle Materials: Testing and AnalysisAinda não há avaliações

- Album of Dated Latin Inscriptions, Part II, Plates: Rome and the Neighborhood, A.D. 100-199No EverandAlbum of Dated Latin Inscriptions, Part II, Plates: Rome and the Neighborhood, A.D. 100-199Ainda não há avaliações

- Electrochemical Processes in Biological SystemsNo EverandElectrochemical Processes in Biological SystemsAndrzej LewenstamAinda não há avaliações

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysAinda não há avaliações

- Testing PlanDocumento1 páginaTesting PlanThanit ThanadirekAinda não há avaliações

- Rebar Bending - GEM38Documento2 páginasRebar Bending - GEM38Thanit ThanadirekAinda não há avaliações

- How Do I Get To..Documento1 páginaHow Do I Get To..Thanit ThanadirekAinda não há avaliações

- Table of ContentDocumento3 páginasTable of ContentThanit ThanadirekAinda não há avaliações

- Building Inspection ManualDocumento162 páginasBuilding Inspection ManualPipim PogiAinda não há avaliações

- First Fix and Second Fix - Wikipedia, The Free EncyclopediaDocumento2 páginasFirst Fix and Second Fix - Wikipedia, The Free EncyclopediaThanit ThanadirekAinda não há avaliações

- S Structural Work: S1 Substructure S11 PilingDocumento12 páginasS Structural Work: S1 Substructure S11 PilingThanit ThanadirekAinda não há avaliações

- Manual For Precast Concrete Construction: by Ananda DevelopmentDocumento1 páginaManual For Precast Concrete Construction: by Ananda DevelopmentThanit ThanadirekAinda não há avaliações

- Cal Colum StrengtheningDocumento5 páginasCal Colum StrengtheningThanit ThanadirekAinda não há avaliações

- Table of Contents for Project Report on IDEO Wutthakat (S11Documento2 páginasTable of Contents for Project Report on IDEO Wutthakat (S11Thanit ThanadirekAinda não há avaliações

- FRPDocumento5 páginasFRPThanit ThanadirekAinda não há avaliações

- CoverDocumento2 páginasCoverThanit ThanadirekAinda não há avaliações

- Slab Deflections 2Documento3 páginasSlab Deflections 2Thanit ThanadirekAinda não há avaliações

- TC1Documento13 páginasTC1Thanit ThanadirekAinda não há avaliações

- VITSOE Dieter Rams SpeechDocumento4 páginasVITSOE Dieter Rams SpeechThanit ThanadirekAinda não há avaliações

- VG Extension PDFDocumento1 páginaVG Extension PDFThanit ThanadirekAinda não há avaliações

- VITSOE Dieter Rams SpeechDocumento4 páginasVITSOE Dieter Rams SpeechThanit ThanadirekAinda não há avaliações

- Wall BDocumento10 páginasWall BThanit ThanadirekAinda não há avaliações

- FRP Lamella ACI User ManualDocumento0 páginaFRP Lamella ACI User ManualThanit ThanadirekAinda não há avaliações

- Wall B2Documento10 páginasWall B2Thanit ThanadirekAinda não há avaliações

- STM Paper PDFDocumento73 páginasSTM Paper PDFAlrack sinner75% (4)

- Wall B2Documento10 páginasWall B2Thanit ThanadirekAinda não há avaliações

- BasfDocumento8 páginasBasfThanit ThanadirekAinda não há avaliações

- Beam - BS2toJ4 PDFDocumento1 páginaBeam - BS2toJ4 PDFThanit ThanadirekAinda não há avaliações

- JANUARY 2014: Sunday Monday Tuesday Wednesday Thursday Friday Saturday 1 2 3 4Documento4 páginasJANUARY 2014: Sunday Monday Tuesday Wednesday Thursday Friday Saturday 1 2 3 4Thanit ThanadirekAinda não há avaliações

- Tes 55Documento1 páginaTes 55Thanit ThanadirekAinda não há avaliações

- Queenax The Bridge X5 Gym in Vallentuna SwedenDocumento1 páginaQueenax The Bridge X5 Gym in Vallentuna SwedenThanit ThanadirekAinda não há avaliações

- Building AccessementDocumento12 páginasBuilding AccessementThanit ThanadirekAinda não há avaliações

- RAPT Installation Manual AmendmentDocumento16 páginasRAPT Installation Manual AmendmentbbwhaleAinda não há avaliações

- CE6302-Mechanics of SolidsDocumento15 páginasCE6302-Mechanics of Solidslalith kumarAinda não há avaliações

- Biaxial Bending (Beams in Both Axis) : Ce 514 - Steel DesignDocumento6 páginasBiaxial Bending (Beams in Both Axis) : Ce 514 - Steel DesignFrederick Perez IIAinda não há avaliações

- Excavacion PDFDocumento25 páginasExcavacion PDFLuis Alejandro Godoy OrdenesAinda não há avaliações

- 6 - Soil Data in Orcaflex-Y.T.kimDocumento9 páginas6 - Soil Data in Orcaflex-Y.T.kimYoungtae KimAinda não há avaliações

- Irc 22 2015Documento93 páginasIrc 22 2015rajpootsaurabhAinda não há avaliações

- Karbon Ve Cam KarşılaştırmaDocumento14 páginasKarbon Ve Cam KarşılaştırmaHasanmert KaymakAinda não há avaliações

- Understanding Vibration of Simple StructuresDocumento38 páginasUnderstanding Vibration of Simple StructuresMakaraSoyAinda não há avaliações

- Theories of Mechanical FailureDocumento11 páginasTheories of Mechanical FailureRavi PalaskarAinda não há avaliações

- Material Hardness Conversion TableDocumento3 páginasMaterial Hardness Conversion TableJessicalba LouAinda não há avaliações

- Blast Resistant DesignDocumento6 páginasBlast Resistant DesignKumaraavel ViswanathanAinda não há avaliações

- Earth Science PuzzleDocumento2 páginasEarth Science PuzzleSSha100% (2)

- Assignment 04Documento2 páginasAssignment 04Lucky JayswalAinda não há avaliações

- An Analysis of Three-Dimensional Ground Movements: The Thunder Bay TunnelDocumento17 páginasAn Analysis of Three-Dimensional Ground Movements: The Thunder Bay TunnelDidaBouchAinda não há avaliações

- Hooke's Law Explained: Force is Proportional to DisplacementDocumento2 páginasHooke's Law Explained: Force is Proportional to DisplacementStefan PalaghiaAinda não há avaliações

- Bridge Design Workshop with Eurocode Geotechnical StandardsDocumento38 páginasBridge Design Workshop with Eurocode Geotechnical StandardsFares ChammamAinda não há avaliações

- Machining Steel Data Sheet 1.0715Documento1 páginaMachining Steel Data Sheet 1.0715strangervinothAinda não há avaliações

- Effect Skin Pass Mill Parameter in Mechanical PropertiesDocumento10 páginasEffect Skin Pass Mill Parameter in Mechanical PropertiesErdi100% (1)

- Foundation Design - 5110-P-001ABC - Rev 0Documento11 páginasFoundation Design - 5110-P-001ABC - Rev 0Yatendra TyagiAinda não há avaliações

- Mechanics of Deformable Bodies Final ExamDocumento4 páginasMechanics of Deformable Bodies Final ExamMichael Mendez OfficialAinda não há avaliações

- Standard Test Method For Strain - Docx ASTM E606 E606MDocumento6 páginasStandard Test Method For Strain - Docx ASTM E606 E606MChusnadiAinda não há avaliações

- Crack Width Calculation for ColumnDocumento3 páginasCrack Width Calculation for ColumnNadira PervinAinda não há avaliações

- Analisis Stabilitas Lereng Dengan Perkuatan Soil Nailing Menggunakan Program KomputerDocumento7 páginasAnalisis Stabilitas Lereng Dengan Perkuatan Soil Nailing Menggunakan Program KomputerAULIA AGUSTINAAinda não há avaliações

- Excel Calculation For Column 5Documento17 páginasExcel Calculation For Column 5ariaAinda não há avaliações

- Sintap British Steel Bs-17Documento65 páginasSintap British Steel Bs-17Paul RuckAinda não há avaliações

- Engineering Properties of Marls PDFDocumento109 páginasEngineering Properties of Marls PDFSiwadol DejphumeeAinda não há avaliações

- Lecture 40 Som 13.05.2021Documento18 páginasLecture 40 Som 13.05.2021Dr. BIBIN CHIDAMBARANATHANAinda não há avaliações

- Atena TheoryDocumento330 páginasAtena Theorypassion777Ainda não há avaliações

- CTB2310 - Grondmechanica Tentamenbundel 2017-2018Documento105 páginasCTB2310 - Grondmechanica Tentamenbundel 2017-2018Pieter MeulendijksAinda não há avaliações

- Modeling Cracked Section Properties For Shear Wall and SlabDocumento2 páginasModeling Cracked Section Properties For Shear Wall and SlabSeifeldin Ali MarzoukAinda não há avaliações

- Concreto Pretensado-NAWY - Cap 7 PDFDocumento82 páginasConcreto Pretensado-NAWY - Cap 7 PDFCarlos Alberto Pacheco SierraAinda não há avaliações