Escolar Documentos

Profissional Documentos

Cultura Documentos

Wildeck MECH STRD Guide Spec

Enviado por

Bang AnuhDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Wildeck MECH STRD Guide Spec

Enviado por

Bang AnuhDireitos autorais:

Formatos disponíveis

1 OF 4 Guide Specification For

MECHANICAL / STRADDLE LIFT

GUIDE SPECIFICATIONS FOR ERTICAL RECIPROCATING CON E!ORS " RC# "MECHANICAL$ STRADDLE# PART % & GENERAL %'% RELATED (OR) A. The following sections contain preparatory requirements (by others), to recei e the !"# specifie$ in this section. 1. %i ision &' (#oncrete "einforcement(, pro i$es smooth an$ le el slab)pit to support loa$s in$icate$ by !"# manufacturer. *. %i ision 1+' (,lectrical(, pro i$e permanent power to operate the !"# through a loc-able fuse$ $isconnect bo. locate$ within ten feet of the !"# unit. S!STEM DESCRIPTION A. Furnish an$ install a !ertical "eciprocating #on eyor. 1. Type of !ertical #on eyor, /echanical 0tra$$le !.".#. !ertical tra el up to 1112 (actual must be specifie$). #apacity to 11,111 lbs. (actual must be specifie$). /ultiple le el operation (number of le els must be specifie$ if more than one). #arriage si3e to 112 . 112 (actual must be specifie$). REFERENCES A. A405)A0/, 6*1.1 7 (#urrent A$$ition) safety stan$ar$ for con eyor an$ relate$ equipment. 6. 4,# 7 (#urrent A$$ition) 4ational ,lectric #o$e. #. A0T/ A&+ 7 0tructural 0teel. %. A0T/ A&*8 9 :igh strength bolts for structural steel ;oints. ,. A<0 %1.1 7 0tructural <el$ing #o$e. -UALIT! ASSURANCE A. E.uip/ent0 shoul$ be $esigne$, installe$ an$ guar$e$ in accor$ance with "eferences 1.&. 6. Code Co/p1iance0 /anufacturer guarantees that shoul$ this equipment not be able to be use$ $ue to applicable Fe$eral, 0tate or =ocal #o$es, the equipment will be remo e$ an$ all money pai$ refun$e$, inclu$ing freight an$ installation. #. In2ta11er0 #ompany speciali3ing in performing the wor- of this section an$ appro e$ by the !"# equipment manufacturer.

%'*

%'+

%',

* OF 4 Guide Specification For

MECHANICAL / STRADDLE LIFT

%.

(arrant30

1.

*.

The supplier shall warrant the !"# materials to be free from manufacturing $efects beginning after completion of installation. a. 0tructural #omponents 7 Fi e years parts an$ labor. b. 4on70tructural #omponents 7 One year parts an$ >1 $ays labor. <arranty $oes not co er $amage cause$ by con$itions beyon$ the control of the supplier or installer? such as abuse, negligence or failure to operate or maintain properly.

%'4

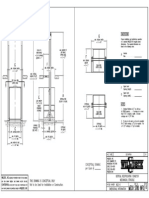

SU5MITTALS A. 0ubmit (&) brochures of manufacturer2s pro$uct $ata. 6. Appro6a1 Dra7in820 @ro i$e appro al $rawings $etailing specific application inclu$ing plan an$ ele ation iews with $imensional information, equipment specification an$ guar$ing requirements.

PART * & PRODUCTS

*'%

MANUFACTURERS A. A ailable /anufacturers' 0ub;ect to compliance with requirements, manufacturers offering pro$ucts that may be incorporate$ in the worinclu$e, but are not limite$ to the following' 1. (i1dec9$ Inc' (@.O. 6o. A>, <au-esha, <5 8&1AB). APPLICATION DATA A. LIFTING CAPACIT! poun$s. 6. CARRIAGE SI:E ( wi$e . ( long. The carriage will ha e a steel $ec- plate with rails on non7operating en$s an$ safety chains on operating en$s. The carriage shall be gui$e$ between two structural steel members, each a minimum of +( in wi$th an$ suitably $esigne$. #. LIFTING SPEED *A F@/ (nominal). %. ERTICAL RISE ft., in. RAISING AND LO(ERING of the carriage shall be pro i$e$ by lift chains an$ sproc-ets on a common shaft powere$ by a helical gear re$ucer assembly. UP(ARD/DO(N(ARD TRA EL of the carriage will begin by $epressing a control button, which acti ates the motor re$ucer in the proper $irection an$ releases the bra-e. As the shaft an$ sproc-ets rotate, the lift chains tra el up or $own mo ing the carriage until it trips the limit switch at the $esire$ floor le el. At this point the motor shuts7off an$

*'*

& OF 4 Guide Specification For

MECHANICAL / STRADDLE LIFT

,. F.

D.

:. 5. E.

F. =.

the bra-e engages. UNCONTROLLED DESCENT will be pre ente$ by $ual carriage safety cams attache$ to the lift chains. 5n the e ent a chain brea-s or goes slac-, the safety cams will loc- the carriage in place. ELECTRICAL CONTROL push7buttons an$ emergency stop switches will be pro i$e$ at each operating le el. These controls, as well as all limit switches on the lift an$ gates operate on 111)*4 olts to increase user safety. The step7$own transformer, re ersing motor starte$ an$ fiel$ wiring terminal bloc- is inclu$e$ in the main control panel. The control system will pro i$e? 4,#)C= /otor O erloa$ @rotection, A$;ustable /a.imum #apacity 0ensing, 5nrush 6ypass Timing, an$ /aintenance #ontrol. The control system will inclu$e a graphic operator interface an$ will pro i$e continuous system $iagnostics with an e ent history. The control panel must be manufacture$ to an$ labele$ C=781Aa. O ERLOAD/;AM PROTECTION will be of a force7limiting style so as to pro i$e ma.imum safety to operators, ma.imum cargo protection, an$ minimi3e wear7an$7tear of the equipment. @rotection to be pro i$e$ by a soli$7state $e ice that will $etect the power le el require$ to lift the empty, partial or fully loa$e$ carriage, an$ limit the lifting mechanisms power output to that le el. 0ensors that only $etect when full cargo capacity has been e.cee$e$ are not a$equate or acceptable for this application. CHAIN SENSING switches monitor the tension of the chain an$ will shut $own the unit in the e ent of a chain failure. FAIL&SAFE 5RA)ING is pro i$e$ by the spring set $isc bra-e which releases only when the motor is powere$7up. 5n the e ent of a power failure, the bra-e will automatically engage. GUARDING on all si$es of the !"#, which $o not coinci$e with soli$ walls, shall be by safety enclosures a minimum of A2 high, consisting of material which will re;ect a ball &)4( in $iameter. Access for loa$ing an$ unloa$ing shall be by gates which are electrically an$ mechanically interloc-e$ with carriage mo ement. The interloc- shall positi ely pre ent a gate from being opene$ unless the carriage is at the le el an$ shall also pre ent carriage mo ement if any gate is not fully close$ an$ loc-e$. RIDING the con eyor is forbi$$en an$ signs shall be furnishe$ with the unit so stating. These signs shall be poste$ at each point of access an$ each point of operation. FINISH on the lift, gates an$ enclosures shall be coate$ with one coat of manufacturer2s stan$ar$ paint' T7o < Part Po13uret=ane' #olor' <il$ec- Dray with "e$ carriage

*'+

FA5RICATION A. Fabrication of materials will comply with $imensions, profiles an$ gauges

4 OF 4 Guide Specification For

MECHANICAL / STRADDLE LIFT

(thic-ness) shown on the appro al $rawings an$, if not shown, will consist of the !"# manufacturer2s stan$ar$ pro$ucts. PART + & E>ECUTION +'% E>AMINATION A. ,.amine the construction an$ ser ice requirements of relate$ wor- by others for compliance with specifications in this an$ other sections. %o not procee$ with installation until unsatisfactory con$itions ha e been correcte$. PREPARATION A. #oor$ination' (Deneral #ontractor)Owner) to erify appro al $rawings prior to fabrication. Any obstructions not in$icate$ on the construction $rawings that may affect the $esign of the !"# shall be reporte$ to the manufacturer. INSTALLATION A. ,rection of the !"# an$ accessories shall be in accor$ance with the specifications, instructions containe$ in the erection manual an$ appro e$ $rawings. 6. 5nstaller to pro i$e manufacturer2s (5nstallation Operation an$ /aintenance /anual( to the en$ user upon completion of his scope of wor-. CLEANING F. A. #lean up all unuse$ materials an$ $ebris cause$ by the wor- of this section, -eeping the premises clean an$ neat at all times.

+'*

+'+

+',

!ertical =ift @ro$ucts /anufacture$ by (ILDEC)$ INC' @.O. 6o. A> <au-esha, <5 8&1AB A11)&*87+>&> (FAG) *+*)84>7&4++

Você também pode gostar

- Elementary English Book for Grade 5 StudentsDocumento19 páginasElementary English Book for Grade 5 StudentsYantii Kosdodol Srg67% (3)

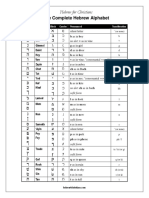

- Hebrew Alphabet ChartDocumento1 páginaHebrew Alphabet ChartBang AnuhAinda não há avaliações

- AlQuran Yang MengagumkanDocumento65 páginasAlQuran Yang Mengagumkanhanifan verdi100% (1)

- Video Formats GuideDocumento15 páginasVideo Formats GuideSivaprasad SrungarakaviAinda não há avaliações

- 068M017 - Jet Technologies (Indonesia) PN 2000S Plus+ist 90+ist 122 Ii2g...Documento19 páginas068M017 - Jet Technologies (Indonesia) PN 2000S Plus+ist 90+ist 122 Ii2g...Bang AnuhAinda não há avaliações

- Photoshop For Beginners Tastytuts PDFDocumento44 páginasPhotoshop For Beginners Tastytuts PDFHenizion100% (3)

- Multis Ep 3: Multi Purpose Extreme Pressure Lithium GreaseDocumento1 páginaMultis Ep 3: Multi Purpose Extreme Pressure Lithium GreaseSuyudi Surya WardayaAinda não há avaliações

- Train - Profibus - Siemens PDFDocumento28 páginasTrain - Profibus - Siemens PDFBang AnuhAinda não há avaliações

- Beginning Check List: 1. Water Pressure at Heat Exchanger Must Be in "Green Area" (1.5-2.5 Bar)Documento3 páginasBeginning Check List: 1. Water Pressure at Heat Exchanger Must Be in "Green Area" (1.5-2.5 Bar)Bang AnuhAinda não há avaliações

- Train - Profibus - Siemens PDFDocumento28 páginasTrain - Profibus - Siemens PDFBang AnuhAinda não há avaliações

- ABS UserManual PDFDocumento17 páginasABS UserManual PDFBang AnuhAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Blocked Site:: @ifalasteenDocumento1 páginaBlocked Site:: @ifalasteenBang AnuhAinda não há avaliações

- ITS Paper 19676 2107100039 Presentation3Documento8 páginasITS Paper 19676 2107100039 Presentation3Billy MoerdaniAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- LECTURE 1 - Fluid DynamicsDocumento8 páginasLECTURE 1 - Fluid DynamicsKiekie NuralamAinda não há avaliações

- Modifikasi Ink Pan ILSDocumento1 páginaModifikasi Ink Pan ILSBang AnuhAinda não há avaliações

- Cargill Plant Management TraineeDocumento1 páginaCargill Plant Management TraineeBang AnuhAinda não há avaliações

- Bakcuci 3dDocumento1 páginaBakcuci 3dBang AnuhAinda não há avaliações

- Mechanical Maintenance Coordinator Business Unit: COCOA Based: Surabaya, GresikDocumento3 páginasMechanical Maintenance Coordinator Business Unit: COCOA Based: Surabaya, GresikBang AnuhAinda não há avaliações

- Wildeck Mech STRDDocumento1 páginaWildeck Mech STRDBang AnuhAinda não há avaliações

- Utilities Supervisor Business Unit: COCOA Based: Surabaya, GresikDocumento2 páginasUtilities Supervisor Business Unit: COCOA Based: Surabaya, GresikBang AnuhAinda não há avaliações

- Meja Setting Tooling-ModelDocumento1 páginaMeja Setting Tooling-ModelBang AnuhAinda não há avaliações

- How Boilers WorkDocumento18 páginasHow Boilers Workhozipek5599100% (1)

- Filter Bak CuciDocumento1 páginaFilter Bak CuciBang AnuhAinda não há avaliações

- LECTURE 3 - Fluid DynamicsDocumento10 páginasLECTURE 3 - Fluid DynamicsBang AnuhAinda não há avaliações

- Bak Cuci 3d FullDocumento1 páginaBak Cuci 3d FullBang AnuhAinda não há avaliações

- LECTURE 2 - Fluid DynamicsDocumento13 páginasLECTURE 2 - Fluid DynamicsBang AnuhAinda não há avaliações

- LECTURE 1 - Fluid DynamicsDocumento8 páginasLECTURE 1 - Fluid DynamicsKiekie NuralamAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Lion Dam Gate Seals - INTLDocumento3 páginasLion Dam Gate Seals - INTLIoannis SanoudosAinda não há avaliações

- Ultra-Deepwater Semi-Submersible: General Description Storage CapacitiesDocumento2 páginasUltra-Deepwater Semi-Submersible: General Description Storage CapacitiesFrank CloseAinda não há avaliações

- Draft User Manual MISDocumento306 páginasDraft User Manual MISkhajuriaonlineAinda não há avaliações

- Bus Order SummaryDocumento3 páginasBus Order SummaryKhairul IdhamAinda não há avaliações

- STT041 and STT041.1 PDFDocumento59 páginasSTT041 and STT041.1 PDFHayrah Lawi100% (2)

- Pendola Suspendida MPK 450 1x150wDocumento3 páginasPendola Suspendida MPK 450 1x150wwilber ticonaAinda não há avaliações

- Li/FeS2 Battery Performance and ChemistryDocumento22 páginasLi/FeS2 Battery Performance and ChemistrypaulAinda não há avaliações

- Klem Et Al 2022 - Part 5 Rigor in Qualitative ResearchDocumento3 páginasKlem Et Al 2022 - Part 5 Rigor in Qualitative ResearchNora ElaAinda não há avaliações

- 2500 ManualDocumento196 páginas2500 Manualfede444Ainda não há avaliações

- Calculating Ampacity in Small-Gauge, Electrical Cables: Greig S. Latham, Member, IEEEDocumento4 páginasCalculating Ampacity in Small-Gauge, Electrical Cables: Greig S. Latham, Member, IEEEAlaa RamadanAinda não há avaliações

- 2016 MAEG 3040 SyllabusDocumento2 páginas2016 MAEG 3040 SyllabusJohnAinda não há avaliações

- Webpage Evaluation GuideDocumento1 páginaWebpage Evaluation Guideankit boxerAinda não há avaliações

- Literature Review of Job Satisfaction of TeachersDocumento7 páginasLiterature Review of Job Satisfaction of Teachersfeiaozukg100% (1)

- Lattice SeminarDocumento48 páginasLattice SeminarNaina JabbarAinda não há avaliações

- Wesleyan University-Philippines Graduate SchoolDocumento6 páginasWesleyan University-Philippines Graduate SchoolRachel Joy RosaleAinda não há avaliações

- 3rd Year MBBS Assessment in 3 BlocksDocumento5 páginas3rd Year MBBS Assessment in 3 BlocksEngecoon AcademyAinda não há avaliações

- Paper H3 - Mock Set 6 - MSchemeDocumento17 páginasPaper H3 - Mock Set 6 - MSchemeH Aslam100% (4)

- Positronic Industries Inc. FC4012D: SK2415 ECO B 23033 TK Yk Cole ECO C 52574 Cole CM ColeDocumento1 páginaPositronic Industries Inc. FC4012D: SK2415 ECO B 23033 TK Yk Cole ECO C 52574 Cole CM ColekamaveriyanAinda não há avaliações

- EZ-Phone (Hss Sip Ua) User's ManualDocumento17 páginasEZ-Phone (Hss Sip Ua) User's ManualVenkatrama Kaushik IyerAinda não há avaliações

- Sine and Cosine Functions WorksheetDocumento6 páginasSine and Cosine Functions WorksheetManya MAinda não há avaliações

- Founder-CEO Succession at Wily TechnologyDocumento12 páginasFounder-CEO Succession at Wily TechnologyMayank Saini100% (1)

- Arun GangwarDocumento7 páginasArun GangwarArun GangwarAinda não há avaliações

- Steps To Design A PCB Using OrcadDocumento3 páginasSteps To Design A PCB Using OrcadkannanvivekananthaAinda não há avaliações

- Safety and Security Manual For Safety Manager SCDocumento101 páginasSafety and Security Manual For Safety Manager SCk2tzgwmsc5Ainda não há avaliações

- Summary of FindingsDocumento3 páginasSummary of FindingsshairaAinda não há avaliações

- Manual de Usuario Hamilton Beach 40515R (Español - 28 Páginas)Documento3 páginasManual de Usuario Hamilton Beach 40515R (Español - 28 Páginas)yanelin escandelaAinda não há avaliações

- Global Economics 13th Edition by Carbaugh ISBN Solution ManualDocumento5 páginasGlobal Economics 13th Edition by Carbaugh ISBN Solution Manualdorothy100% (31)

- Build Ubuntu for Ultra-96 FPGA DevelopmentDocumento5 páginasBuild Ubuntu for Ultra-96 FPGA Developmentksajj0% (1)

- Math 362, Problem Set 5Documento4 páginasMath 362, Problem Set 5toancaoAinda não há avaliações

- Vehicle and Commercial Controls: Electrical Sector SolutionsDocumento197 páginasVehicle and Commercial Controls: Electrical Sector SolutionsVanderCastroAinda não há avaliações