Escolar Documentos

Profissional Documentos

Cultura Documentos

VT Notes

Enviado por

surya892Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

VT Notes

Enviado por

surya892Direitos autorais:

Formatos disponíveis

Crompton Greaves CVT Description

DESIGN AND CONSTRUCTION

Figure 1 shows the schematic view as well as the construction of a single stack CVT. Each CVT consists of a coupling capacitor (CC) which acts as a voltage divider and an Electro Magnetic Unit (EMU) which transforms the medium voltage to standard low voltage. Depending on the system voltage the CC can be a single or a multi stack unit. The CC and the EMU are individually hermetically sealed to ensure accurate performance and high reliability. Coupling Capacitor The Coupling Capacitor (CC) acts as a voltage divider and converts the system voltage to a medium voltage. The active part of the CC consists of a large number of oil impregnated paper (or paper and film) capacitor elements connected in series. Supercalendered capacitor tissue paper and pure aluminium foils are used to make the cap elements. The cap elements are stack pressed and held in insulating supports to ensure a stable capacitance even for large temperature variations. The electrical connections between the cap elements are designed for a natural frequency much above 600 Hz in order to avoid interference with carrier communication. The processed capacitor stack is assembled inside a porcelain insulator with corrosion resistant aluminium alloy end fittings. Brown glazed porcelain of shed profile as per IEC 815 is used. The insulators are cemented to aluminium alloy flanges for improved strength. Oil volume changes due to

temperature variations are compensated by a stainless steel bellow installed at the upper end of the CC. The unit is completely filled with degassed insulated oil under vacuum. The bellow is pressurised by inert gas (from the top surface) to maintain a positive oil pressure even in the case of large oil contraction. The CVT thus has very low PD levels even at low ambient temperatures. Electromagnetic Unit The Electromagnetic Unit (EMU) consists of a medium voltage transformer, compensating reactor, damping element and surge protection device. The unit is housed inside an aluminium tank which is filled with insulating oil leaving a gas cushion at the top in order to take care of changes in the oil volume due to fluctuations in the ambient temperature. An oil sight glass is mounted on the side wall of the tank. The CC unit is mounted on the EMU tank and the insulated earth terminal of the CC (marked as NHF in Fig. 1) is also accessible for connecting to power line carrier communication equipment. A spark gap across this terminal and earth serves as the surge protection device. The NHF terminal must always be connected to earth if the CVT is not connected to carrier equipment. The secondary terminal box is provided on the EMU tank. Secondary leadouts, NHF lead and earth leads are all terminated inside the secondary terminal box. The EMU is caliberated and adjusted at factory for all burden and accuracy requirements. No site adjustments or measurements

are neccessary. The EMU is given adequate surface treatment for corrosion protection for life long service.

MAINTENANCE

The product is self contained, maintenance free and requires no spares over its entire life span. We recommend regular and periodic checks as per pre-specified schedules (specified in the Instruction Manuals supplied with the CVTs).

FIG. 2 FIG. 3

C1 - HV Capacitance C2 - Intermediate Voltage Capacitor L - Compensating Reactor Tr - Intermediate Transformer Zd - Damping Device V - Varistor F - HRC Fuse / MCB Lk - Cable Link For Earthing f-g - Auxiliary Secondary Winding

OPTIONALS / ACCESSORIES

Terminal Connector (Aluminium/Bimetallic, NEMA or as per customer specs) Three element Carrier Protection Device(comprising Drain Coil, Lightning Arrester & Earth Switch) Oil Level Indicator (EMU) and Bellow Position Indicator (CC) Cable Glands Aluminium EMU tank

ABB Capacitor Voltage Transformer:

High Voltage Capacitor Voltage Transformers, type WN/WP/WS

ABB offers mixed dielectric type capacitor voltage transformers that cater to the dual application needs of measurement and carrier communication.

Main features

_ Hermetically

sealed with metallic bellows cushion on top _ EMU (electro magnetic unit) protection by spark gap across primary winding of intermediate PT _ Ratio error adjustment by compensating winding on PT primary winding, phase angle error adjustment by variable choke with adjustable air gap _ Intermediate capacitor tap connection through an epoxy bushing housed in the porcelain insulator and tank

ABB 3

protection against corrosion all ferrous parts and housing (tank) are hot dip galvanized _ Cost-effective design _ Dual application designed for measurement, protection and carrier communication _ High reliability robust design ensures excellent surge withstand level _ Low weight, compact and easy to install _ Ease of transportation shipped in easy-to-assemble parts _ It can be connected without danger at the end of unloaded line

_ High

Design and construction

The Capacitor Voltage Transformer type WN/WP/WS consists of a capacitive potential divider and an inductive medium voltage circuit. The inductive part is immersed in mineral oil and sealed inside a steel tank. As per the required rating, one, two or three capacitor units are mounted on the tank and used as capacitive potential divider(s). These consist of hermetically sealed capacitor stacks that are made of paper and PP film dielectric impregnated in transformer oil with a metal bellow.

Quality Assurance

The CVTs and CCs are designed to comply with IEC: 60186/ 60358 and IS: 3156. CVTs complying with ANSI/IEEE standards C57.13 or other standards can also be provided on request. ABBs state-of-the-art facility at Vadodara is ISO 9001 certified, which covers all aspects of production and testing to ensure the highest quality standards. The facility is also EHS

certified for environment and occupational health and safety management systems.

High Voltage Coupling Capacitors, type KN/KP

ABB offers mixed dielectric type coupling capacitors that cater to the needs of carrier communication.

Main features

_ Hermetically

sealed with metal bellows cushion on top _ Protection against corrosion all ferrous parts and bottom stand are hot dip galvanized _ Cost-effective due to optimal design _ High reliability robust design ensures excellent surge withstand level _ Low weight, compact and easy to install _ Ease of transportation shipped in easy-to-assemble parts

Technical data

Parameter Rated

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Boe NotesDocumento98 páginasBoe Notessurya892100% (3)

- Gis 420kv 1Documento16 páginasGis 420kv 1surya892Ainda não há avaliações

- Cahier Merlin-Gerin - Neutral Earthing in An Industrial HV NetworkDocumento12 páginasCahier Merlin-Gerin - Neutral Earthing in An Industrial HV NetworkGustavo AguayoAinda não há avaliações

- New Microsoft Office Word DocumentDocumento88 páginasNew Microsoft Office Word Documentsurya892Ainda não há avaliações

- Siemens Ebook ListDocumento3 páginasSiemens Ebook Listsurya892Ainda não há avaliações

- 7SRDocumento16 páginas7SRsurya892100% (1)

- I-11. Electromagnetic Forces and Mechanical Oscillations of The Stator End Winding of Turbo GeneratorsDocumento1 páginaI-11. Electromagnetic Forces and Mechanical Oscillations of The Stator End Winding of Turbo Generatorssurya892Ainda não há avaliações

- Diagnostic Tests To Improve PTR PerformanceDocumento10 páginasDiagnostic Tests To Improve PTR Performancejoydeep_d3232Ainda não há avaliações

- Introduction To Electrical Machines-I: - Abhiram.T AssistantprofDocumento59 páginasIntroduction To Electrical Machines-I: - Abhiram.T Assistantprofsurya892Ainda não há avaliações

- Power Factor Correction: Ch.V.Sesha Girirao Associate Professor EEE DepartmentDocumento33 páginasPower Factor Correction: Ch.V.Sesha Girirao Associate Professor EEE Departmentsurya892Ainda não há avaliações

- Rla DescriptiveDocumento22 páginasRla Descriptivesurya892Ainda não há avaliações

- Busbar RatingDocumento64 páginasBusbar RatingAbdulla Nashith100% (1)

- Circuit Breaker BrochureDocumento12 páginasCircuit Breaker Brochuresurya892Ainda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Preventive Maintenance PM-Freq (Q/H/Y) : - Check Points Checked Remarks Action Taken Status YES NODocumento1 páginaPreventive Maintenance PM-Freq (Q/H/Y) : - Check Points Checked Remarks Action Taken Status YES NOGnanavel GAinda não há avaliações

- Current Transformer - Part - IDocumento23 páginasCurrent Transformer - Part - IsrifaceAinda não há avaliações

- Harmonic Elimination in Three-Phase Voltage SourceDocumento9 páginasHarmonic Elimination in Three-Phase Voltage SourceDaniloAinda não há avaliações

- Template Manual Abb Ret 670 v1.1 Enu Tu2.22 v1.000Documento18 páginasTemplate Manual Abb Ret 670 v1.1 Enu Tu2.22 v1.000m_dh87129100% (1)

- User Guide and Technical Manual: Soundcraft Ddps-33 Ppower SsupplyDocumento16 páginasUser Guide and Technical Manual: Soundcraft Ddps-33 Ppower SsupplyMalay K GhoshAinda não há avaliações

- DB hrc800 e 9498-737-38613 PDFDocumento4 páginasDB hrc800 e 9498-737-38613 PDFpradeepchennai10_959Ainda não há avaliações

- Electrical Machines Lab ManualDocumento85 páginasElectrical Machines Lab ManualClause IandAinda não há avaliações

- DSD Lab Manual AitdDocumento31 páginasDSD Lab Manual Aitdprathameshbhat88Ainda não há avaliações

- Exp 1,2Documento4 páginasExp 1,2NischayAinda não há avaliações

- L16: Noise Performance of SSB & AM: (P&S Pp. 220-225 C&C 10.2)Documento9 páginasL16: Noise Performance of SSB & AM: (P&S Pp. 220-225 C&C 10.2)Hunter VerneAinda não há avaliações

- André-Marie Ampère Was: EncyclopédieDocumento5 páginasAndré-Marie Ampère Was: EncyclopédieAngela Monato de MesaAinda não há avaliações

- Gallien Krueger Mb150s 150e Service ManualDocumento21 páginasGallien Krueger Mb150s 150e Service Manualmichael brahemschaAinda não há avaliações

- Mech Eng TeDocumento9 páginasMech Eng TekarimAinda não há avaliações

- Checklist 5Documento3 páginasChecklist 5msmkhanAinda não há avaliações

- Ime Fs1570Documento82 páginasIme Fs1570Fet TransistörAinda não há avaliações

- Transductor GefranDocumento2 páginasTransductor GefranMarco Martinez SantiagoAinda não há avaliações

- 6gd27dfxfs SeriesDocumento35 páginas6gd27dfxfs SeriesFlorian LeordeanuAinda não há avaliações

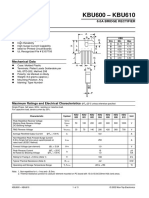

- KBU608Documento4 páginasKBU608José AdelinoAinda não há avaliações

- GTP - 150KVA-CU-11KV-433V-Pole Mounted-ExportDocumento3 páginasGTP - 150KVA-CU-11KV-433V-Pole Mounted-ExportAmir IbrahimAinda não há avaliações

- MG5248Documento4 páginasMG5248Royal Revolt 01Ainda não há avaliações

- Digital Panel Meters BDDocumento24 páginasDigital Panel Meters BDMuhammad Fajar Bhayangkara PAinda não há avaliações

- Conduct Loop TestDocumento19 páginasConduct Loop TestkoangyakAinda não há avaliações

- MFL49414507 M227WD-PZJDocumento41 páginasMFL49414507 M227WD-PZJmaxdornAinda não há avaliações

- Design and Development of Small Active and Passive Loop Antennas For Measurement of Shielding Effectiveness Per IEEE Std.299Documento5 páginasDesign and Development of Small Active and Passive Loop Antennas For Measurement of Shielding Effectiveness Per IEEE Std.299Andrea QuadriAinda não há avaliações

- 5827 Simulation Intro LTspiceDocumento13 páginas5827 Simulation Intro LTspiceChihiro SatoAinda não há avaliações

- Product Specifications Product Specifications: Cmax Cmax - Dm30 Dm30 - Cpusei53 Cpusei53Documento3 páginasProduct Specifications Product Specifications: Cmax Cmax - Dm30 Dm30 - Cpusei53 Cpusei53Fernando Cuestas RamirezAinda não há avaliações

- 3BDD010423R0201 A en S900 I O Digital I O Modules DO910 and DX910Documento48 páginas3BDD010423R0201 A en S900 I O Digital I O Modules DO910 and DX910ilke HANAinda não há avaliações

- dvs5500n DVD LG PDFDocumento11 páginasdvs5500n DVD LG PDFGerardo Mendez CamarilloAinda não há avaliações

- MV Capacitor and Voltage Divider DsDocumento4 páginasMV Capacitor and Voltage Divider DsCristiano BruschiniAinda não há avaliações

- 555 Timer (Important)Documento76 páginas555 Timer (Important)money_kandan2004Ainda não há avaliações