Escolar Documentos

Profissional Documentos

Cultura Documentos

48-Usmc Sae Mechanical Coupler Splice System

Enviado por

Antonio MorenoDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

48-Usmc Sae Mechanical Coupler Splice System

Enviado por

Antonio MorenoDireitos autorais:

Formatos disponíveis

LEGACY REPORT

Business/Regional Office # 5360 Workman Mill Road, Whittier, California 90601 # (562) 699-0543

Regional Office # 900 Montclair Road, Suite A, Birmingham, Alabama 35213 # (205) 599-9800

Regional Office # 4051 West Flossmoor Road, Country Club Hills, Illinois 60478 # (708) 799-2305

ICC Evaluation Service, Inc.

www.icc-es.org

Legacy report on the 1994 Uniform Building Code

ER-5216

Issued November 1, 1995

Copyright 2005

Page 1 of 5

ICC-ES legacy reports are not to be construed as representing aesthetics or any other attributes not specifically addressed, nor are they to be construed as

an endorsement of the subject of the report or a recommendation for its use. There is no warranty by ICC Evaluation Service, Inc., express or implied, as to

any finding or other matter in this report, or as to any product covered by the report.

DIVISION: 03CONCRETE

Section: 03210Reinforcing Steel

US/MC-SAE MECHANICAL COUPLER SPLICE SYSTEM

RICHMOND SCREW ANCHOR COMPANY

1202 AVENUE T

GRAND PRAIRIE, TEXAS 75050

1.0 SUBJECT

US/MC-SAE Mechanical Coupler Splice System.

2.0 DESCRIPTION

2.1 General:

The US/MC-SAE Mechanical Coupler Splice System

mechanically splices steel reinforcing bars (rebar) used in

reinforced concrete construction. The system butt splices

rebars of equal or different diameters. The couplers comply

as tension and compression mechanical connections in

accordance with Section 1912.14.3 of the code. Location of

tension splices must comply with Section 1912.14 and

1912.15 of the code. Four types of couplers are recognized:

Standard Splice, Transition Splice, Position Coupler Splice

and Welding Coupler Splice.

2.2 Materials:

2.2.1 Couplers: Couplers are manufactured from material

meeting ASTM A 108 material specifications and exceeding

ASTM A 615 Grade 60 strength requirements.

2.2.2 Rebar: Deformed reinforcing steel conforms to ASTM

A 615, Grade 60 specifications. Rebar sizes permitted to be

spliced with the coupler system are Nos. 7, 8, 9, 10 and 14.

2.3 Installation:

2.3.1 Standard Coupler Splice: The system consists of two

dowel-in rebars with standard threads and a US/MC coupler.

The coupler is fully threaded onto one rebar. The second bar

is butted to the end of the first bar and the coupler is then

reverse threaded onto the second bar. The bars are torqued

clockwise to a snug tight condition. See Figure 1 for details.

2.3.2 Position Coupler Splice: The system consists of two

dowel-in rebars with extended length threads, a US/MC

coupler, and two US/MC lock nuts. A lock nut and coupler is

fully threaded onto one bar. The second lock nut is threaded

onto the second bar to the position where the coupler will butt

the lock nut in its final position. The second bar is butted to

the end of the first bar and the coupler and first lock nut is

reverse threaded onto the second bar to the couplers final

position. The bars are rotated to the final position and the lock

nuts are torqued clockwise against the coupler to a snug tight

condition. See Figure 2 for details.

2.3.3 Transition Coupler Splice: The system consists of

two different diameter dowel-in rebars with standard length

threads and a US/MC welding coupler. The coupler is fully

threaded onto the smaller rebar. The larger bar is butted to

the end of the small bar and the coupler is reverse threaded

onto the larger bar. The bars are torqued clockwise together

to a snug tight fit. See Figure 3 for details.

2.3.4 Welding Coupler Splice: The system consists of a

dowel-in rebar with standard length threads and a US/MC

welding coupler. The coupler is positioned against the surface

to be attached and welded with approved welds specified by

the engineer of record. The dowel-in rebar is fully threaded

into the coupler and torqued snug tight. See Figure 4 for

details.

2.4 Special Inspection:

Coupler installation requires special inspection in accordance

with Section 1701 of the code. The special inspector verifies

that the coupler is identified and installed as described in this

report. Verification must include rebar embedment and the

bolt tightening pattern.

2.5 Identification:

Each coupler is stamped wit the rebar size. Each bundle,

pallet or skid of couplers has a shipping tag bearing the

company name of Richmond Screw Anchor Company,

product designation and size, production lot number and

installation instructions.

3.0 EVIDENCE SUBMITTED

Reports of static tensile and compressive load tests and

installation instructions.

4.0 FINDINGS

That the US/MC-SAE Mechanical Coupler Splice System

described in this report complies with the 1994 Uniform

Building Code, subject to the following conditions:

4.1 The splice locations shall comply with the code and

shall be detailed on plans approved by the building

official.

4.2 When a fire-resistive time period is required, the

concrete cover specified in Table 7-A of the code is

measured to the outside of the coupler where the

bars are acting in tension. In no case, however,

shall concrete cover be less than

3

/

4

inch.

Page 2 of 5 ER-5216

4.3 Special inspection in accordance with Section 1701

of the code and Section 2.4 of this report is required

during splicing.

This report is subject to re-examination in one year.

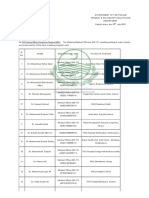

COUPLER DOWEL-IN

BAR SIZE THREAD SIZE O.D. (inches) Length (inches) A (inches) B (inches)

7 18 1

1

/

2

2

1

/

2

1 1

1

/

4

8 1

1

/

8

8 1

5

/

8

2

3

/

4

1

1

/

8

1

3

/

8

9 1

1

/

4

8 1

7

/

8

3 1

1

/

4

1

1

/

2

10 1

7

/

16

8 2

1

/

8

3

3

/

8

1

7

/

16

1

11

/

16

11 1

9

/

16

8 2

1

/

4

3

5

/

8

1

9

/

16

1

13

/

16

14 1

7

/

8

8 2

5

/

8

4

1

/

4

1

7

/

8

2

1

/

8

FIGURE 1STANDARD COUPLER SPLICE

Page 3 of 5 ER-5216

COUPLER DOWEL-IN LOCK NUT

BAR SIZE THREAD SIZE O.D. (inches) Length (inches) A (inches) B (inches) O.D. (inches) C (inches)

7 18 1

1

/

2

2

1

/

2

1 1

1

/

4

1

1

/

2

5

/

8

8 1

1

/

8

8 1

5

/

8

2

3

/

4

1

1

/

8

1

3

/

8

1

5

/

8

3

/

4

9 1

1

/

4

8 1

7

/

8

3 1

1

/

4

1

1

/

2

1

7

/

8

13

/

16

10 1

7

/

16

8 2

1

/

8

3

3

/

8

1

7

/

16

1

11

/

16

2

1

/

8

15

/

16

11 1

9

/

16

8 2

1

/

4

3

5

/

8

1

9

/

16

1

13

/

16

2

1

/

4

1

14 1

7

/

8

8 2

5

/

8

4

1

/

4

1

7

/

8

2

1

/

8

2

5

/

8

1

1

/

4

FIGURE 2POSITION COUPLER SPLICE

Page 4 of 5 ER-5216

SMALL DOWEL-IN TRANSITION COUPLER LARGE DOWEL-IN

Bar Size Thread Size A (inches) B (inches) O.D.

(inches)

Length

(inches)

Bar Size Thread Size A (inches) B (inches)

7 18 1 1

1

/

4

1

5

/

8

2

3

/

4

7 1

1

/

8

8 1

1

/

8

1

3

/

8

8 1

1

/

8

8 1

1

/

8

1

3

/

8

1

7

/

8

3 8 1

1

/

4

8 1

1

/

4

1

1

/

2

9 1

1

/

4

8 1

1

/

4

1

1

/

2

2

1

/

8

3

3

/

8

9 1

7

/

16

8 1

7

/

16

1

11

/

16

10 1

7

/

16

8 1

7

/

16

1

11

/

16

2

1

/

4

3

5

/

8

10 1

9

/

16

8 1

9

/

16

1

13

/

16

11 1

9

/

16

8 1

9

/

16

1

13

/

16

2

5

/

8

4

1

/

4

11 1

7

/

8

1

7

/

8

2

1

/

8

14 1

7

/

8

8 1

7

/

8

2

1

/

8

3

5

/

8

5

1

/

2

14 2

1

/

2

2

1

/

2

2

3

/

4

FIGURE 3TRANSITION COUPLER SPLICE

Page 5 of 5 ER-5216

WELDING COUPLER DOWEL-IN

BAR SIZE THREAD SIZE O.D. (inches) Length (inches) A (inches) B (inches)

7 18 1

1

/

2

1

3

/

8

1 1

1

/

4

8 1

1

/

8

8 1

5

/

8

1

1

/

2

1

1

/

8

1

3

/

8

9 1

1

/

4

8 1

7

/

8

1

5

/

8

1

1

/

4

1

1

/

2

10 1

7

/

16

8 2

1

/

8

1

13

/

16

1

7

/

16

1

11

/

16

11 1

9

/

16

8 2

1

/

4

1

15

/

16

1

9

/

16

1

13

/

16

14 1

7

/

8

8 2

5

/

8

2

1

/

4

1

7

/

8

2

1

/

8

FIGURE 4WELDING COUPLER SPLICE

Você também pode gostar

- The Jay I. Kislak Collection at The Library of CongressDocumento55 páginasThe Jay I. Kislak Collection at The Library of CongressAntonio Moreno100% (1)

- Cap Tulo I MIA VP UnlockedDocumento12 páginasCap Tulo I MIA VP UnlockedAntonio MorenoAinda não há avaliações

- Glyph GuideDocumento83 páginasGlyph GuideAntonio MorenoAinda não há avaliações

- Mayan Cosmology - Gods, Creation Myths and Religious BeliefsDocumento42 páginasMayan Cosmology - Gods, Creation Myths and Religious BeliefsAntonio Moreno100% (1)

- Reinforced Concrete Deep Beams - Prof. F.KDocumento299 páginasReinforced Concrete Deep Beams - Prof. F.Kward_civil036694100% (5)

- Rail SectionsDocumento32 páginasRail Sectionsdarkwing888100% (1)

- Aventuras de Sherlock HolmesDocumento181 páginasAventuras de Sherlock HolmesAntonio MorenoAinda não há avaliações

- An Ancient Megalith in Xalapa VeracruzDocumento7 páginasAn Ancient Megalith in Xalapa VeracruzAntonio MorenoAinda não há avaliações

- Taschen - 25er - Flyer - 2006 PDFDocumento28 páginasTaschen - 25er - Flyer - 2006 PDFAntonio MorenoAinda não há avaliações

- ΣΕΖΑΝDocumento166 páginasΣΕΖΑΝanimalismsAinda não há avaliações

- Impressionism: French The Era and SymbolismDocumento53 páginasImpressionism: French The Era and SymbolismAntonio MorenoAinda não há avaliações

- Concrete in Hot EnvironmentsDocumento272 páginasConcrete in Hot Environmentssplyc12100% (2)

- Ground Modification Methods VOLIDocumento394 páginasGround Modification Methods VOLIPeteris SkelsAinda não há avaliações

- TASCHEN's 25th Anniversary Program 2006Documento28 páginasTASCHEN's 25th Anniversary Program 2006Antonio MorenoAinda não há avaliações

- HuertosDocumento73 páginasHuertosAntonio MorenoAinda não há avaliações

- Shipping GlossaryDocumento12 páginasShipping GlossaryAnand Khisti.100% (5)

- The Structural Engineer's Response To Explosion DamageDocumento22 páginasThe Structural Engineer's Response To Explosion Damagenadeem2288Ainda não há avaliações

- Design and Construction of Rubble Mound BreakwatersDocumento15 páginasDesign and Construction of Rubble Mound BreakwatersManop MethaAinda não há avaliações

- Breakwaters Construction MethodsDocumento20 páginasBreakwaters Construction MethodsAmir Asyraf Suhaili100% (1)

- Pin Piles For Building FoundationsDocumento15 páginasPin Piles For Building FoundationsAntonio MorenoAinda não há avaliações

- MSR IpeDocumento1 páginaMSR IpeAntonio MorenoAinda não há avaliações

- 1995 Vandermeer ConceptualdesignDocumento48 páginas1995 Vandermeer ConceptualdesignKetakee SagdeoAinda não há avaliações

- Installation of Drilled Case MicropilesDocumento13 páginasInstallation of Drilled Case MicropilesAntonio MorenoAinda não há avaliações

- Dewatering For ConstructionDocumento14 páginasDewatering For ConstructionpabulumzengAinda não há avaliações

- POULOS DAVIS Pile Foundation Analysis and Design PDFDocumento410 páginasPOULOS DAVIS Pile Foundation Analysis and Design PDFSheril Chandrabose100% (7)

- Structural Details in ConcreteDocumento269 páginasStructural Details in Concretemarwannaseem100% (1)

- Diseño Sismico de Conec PDFDocumento174 páginasDiseño Sismico de Conec PDFAntonio MorenoAinda não há avaliações

- Compression MembersDocumento42 páginasCompression MembersAntonio MorenoAinda não há avaliações

- Connection Design PDFDocumento12 páginasConnection Design PDFAntonio MorenoAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- © 2020 Lippincott Advisor Nursing Care Plans For Medical Diagnoses - Coronavirus Disease 2019 (COVID 19) PDFDocumento7 páginas© 2020 Lippincott Advisor Nursing Care Plans For Medical Diagnoses - Coronavirus Disease 2019 (COVID 19) PDFVette Angelikka Dela CruzAinda não há avaliações

- 50hz Sine PWM Using Tms320f2812 DSPDocumento10 páginas50hz Sine PWM Using Tms320f2812 DSPsivananda11Ainda não há avaliações

- Effects of War On EconomyDocumento7 páginasEffects of War On Economyapi-3721555100% (1)

- 14 - Hydraulic Design of Urban Drainage Systems PDFDocumento45 páginas14 - Hydraulic Design of Urban Drainage Systems PDFDeprizon SyamsunurAinda não há avaliações

- Impression Techniques in Complete Denture Patients: A ReviewDocumento6 páginasImpression Techniques in Complete Denture Patients: A ReviewRoja AllampallyAinda não há avaliações

- The Collected Letters of Flann O'BrienDocumento640 páginasThe Collected Letters of Flann O'BrienSean MorrisAinda não há avaliações

- Chapter 04Documento3 páginasChapter 04gebreAinda não há avaliações

- Case Presentation - Bipolar Affective Disorder 2Documento73 páginasCase Presentation - Bipolar Affective Disorder 2Hemant's galaxy All is hereAinda não há avaliações

- Plumbing Arithmetic RefresherDocumento80 páginasPlumbing Arithmetic RefresherGigi AguasAinda não há avaliações

- Ohta, Honey Ren R. - Activity 7.2 (Reflection Agriculture and Religion)Documento5 páginasOhta, Honey Ren R. - Activity 7.2 (Reflection Agriculture and Religion)honey ohtaAinda não há avaliações

- Case Study, g6Documento62 páginasCase Study, g6julie pearl peliyoAinda não há avaliações

- 26th April 2021 ES Submission - CloudKitchens - ProfessorSriramDocumento16 páginas26th April 2021 ES Submission - CloudKitchens - ProfessorSriramSamarth LahotiAinda não há avaliações

- John PFTDocumento231 páginasJohn PFTAlexander Santiago ParelAinda não há avaliações

- Project Final Report: Crop BreedingDocumento16 páginasProject Final Report: Crop BreedingAniket PatilAinda não há avaliações

- Government of The Punjab Primary & Secondary Healthcare DepartmentDocumento3 páginasGovernment of The Punjab Primary & Secondary Healthcare DepartmentYasir GhafoorAinda não há avaliações

- ĐỀ CƯƠNG ANH 9 - CK2 (23-24)Documento7 páginasĐỀ CƯƠNG ANH 9 - CK2 (23-24)thuyhagl2710Ainda não há avaliações

- Capex Vs RescoDocumento1 páginaCapex Vs Rescosingla.nishant1245Ainda não há avaliações

- Divide Fractions by Fractions Lesson PlanDocumento12 páginasDivide Fractions by Fractions Lesson PlanEunice TrinidadAinda não há avaliações

- 37 Operational Emergency and Abnormal ProceduresDocumento40 páginas37 Operational Emergency and Abnormal ProceduresLucian Florin ZamfirAinda não há avaliações

- ROM Magazine V1i6Documento64 páginasROM Magazine V1i6Mao AriasAinda não há avaliações

- METRIC_ENGLISHDocumento14 páginasMETRIC_ENGLISHKehinde AdebayoAinda não há avaliações

- Course Handbook MSC Marketing Sept2022Documento58 páginasCourse Handbook MSC Marketing Sept2022Tauseef JamalAinda não há avaliações

- Past Paper Booklet - QPDocumento506 páginasPast Paper Booklet - QPMukeshAinda não há avaliações

- Corporate GovernanceDocumento35 páginasCorporate GovernanceshrikirajAinda não há avaliações

- Dwarf Boas of The Caribbean PDFDocumento5 páginasDwarf Boas of The Caribbean PDFJohn GamesbyAinda não há avaliações

- Exercise C: Cocurrent and Countercurrent FlowDocumento6 páginasExercise C: Cocurrent and Countercurrent FlowJuniorAinda não há avaliações

- The Top 10 Strategic Technology Trends For 2020: Tomas Huseby Executive PartnerDocumento31 páginasThe Top 10 Strategic Technology Trends For 2020: Tomas Huseby Executive PartnerCarlos Stuars Echeandia CastilloAinda não há avaliações

- 6.standard CostingDocumento11 páginas6.standard CostingInnocent escoAinda não há avaliações

- Surveying 2 Practical 3Documento15 páginasSurveying 2 Practical 3Huzefa AliAinda não há avaliações

- Book 7 More R-Controlled-VowelsDocumento180 páginasBook 7 More R-Controlled-VowelsPolly Mark100% (1)