Escolar Documentos

Profissional Documentos

Cultura Documentos

Lifting Lug Design Report

Enviado por

maniaxpdfDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Lifting Lug Design Report

Enviado por

maniaxpdfDireitos autorais:

Formatos disponíveis

1 2 3 4 5 6 7 8 9 10 11 12 13

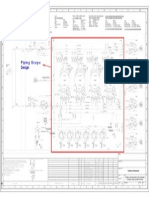

LIFTING LUG DESIGN & CALCULATION REPORT

14 15

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

Page 1 of 6

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

A. CHECK ON LUG STRENGTH (1) LUG DIMENSIONS

Material : SS400 Fy Fu = 235 MPa = 400 MPa

The geometric properties are as follow : e = 85 mm 20 mm

T1 = t =

D = w = 180 mm d = 60 mm

Check dimensional requirements using AISC 360-05 Specification Section D5.2

1.

be = =

2t + 16 mm 56 mm < > 1.33be 74 mm 2be + d 172 mm a 60 mm OK OK NOT OK (See our recommendation in the last page) 60 mm Controls

25 26

2.

27 28

60 mm > 3. w >

29 30 31 32 33 34 35 36 37 38 39 40 1 2 3

180 mm > 4. c >

60 mm >

(2) DESIGN LOAD Max. Load Impact Load Factor Design Load Number of lug used Design Load per Lug

4 5 6 7 8 9

W f

= =

11000 kg 2 22000 kg 4 5500 30

12 13

Wd = N =

Fv =

10

kg deg

14 15 16 17 18 19 20 21 22 23 24 25 26 27

=

11

Page 2 of 6

1 2 3 4 5 6 7 8 9 10 11 12 13 14

P = Fv/cos = Fh = P*sin =

6351 3175

kg kg

5 481

deg kg

H = Fv*tan =

Resultan force, R = R = =

SQRT (Fv2 + Fh2 + H2) 6369.1 kg 62459 N

(3) STRENGTH CHECK a) Tensile Rupture Calculate the available tensile rupture strength on the effective net area Pn = = Fu (2tbe) 896000 N (Spec. Eq. D5-1)

15 16 17 18

From AISC Specification Section D5.1, the available tensile rupture strength is : Pn , where t = 2.00 for ASD t Pn = 448000 N > 62459 N --> OK

19 20 21 22 23 24

b) Shear Rupture Asf = = Pn = = 2t(a + d/2) 3600 0.6FuAsf 864000 N mm2 (Spec. Eq. D5-2)

25 26 27 28

From AISC Specification Section D5.1, the available shear rupture strength is : Pn , where sf = 2.00 for ASD sf Pn = 432000 N > 62459 N --> OK

29 30 31 32

c) Bearing Apb = = Rn = = td 1200 1.8FyApb 507600 N mm2 (Spec. Eq. J7-1)

33 34

35 36 37 38 39 40 1 2 3 4

From AISC Specification Section J7, the available bearing strength is : Pn , where = 2.00 for ASD Pn =

5

253800 N

6 7 8

>

9

62459 N

10 11 12 13

--> OK

14 15 16 17 18 19 20 21 22 23 24 25 26 27

Page 3 of 6

1 2 3 4 5 6 7 8 9

d) Tensile Yielding Ag = = Pn = = wt 3600 FyAg 846000 N mm2 (Spec. Eq. D2-1)

From AISC Specification Section D2, the available tensile yielding strength is : Pn , where t = 1.67 for ASD t Pn = 506587 N > 62459 N --> OK

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 1 2 3

e) Flexural Yielding M = = Re 5309024 N.mm

From AISC Manual Table 17-27, the geometric properties are as follow : Sx = tw2 6 = Zx = 108000 mm3 tw2 4 = 162000 mm3

e-1 Calculate Nominal Flexural Strength, Mn Check limit from AISC Specification Section F11.1 Lbd < t2 38 < 0.08E Fy , where : Lb E = = 85 mm 199948 MPa

68 ,therefore, the yielding limit state applies

Mn = = 1.6My = = Mp = =

Mp FyZ < 1.6FySx 4E+07 N.mm FyZx 4E+07 N.mm < 1.6My

(Spec. Eq. F11-1)

4E+07 N.mm

--> OK

So, use Mn = Mp =

4E+07 N.mm

e-2 Lateral-Torsional Buckling (AISC Specification Section F11.2) As per previously calculated not apply.

4 5 6 7 8 9 10

Lbd < t

2

11 12

0.08E Fy

13 14

, therefore, the lateral torsional buckling limit state does

15

16

17

18

19

20

21

22

23

24

25

26

27

Page 4 of 6

1 2 3 4

From AISC Specification Section F1, the available flexural strength is : Mn , where b = 1.67 for ASD b Mn = 2E+07 N.mm > 5E+06 N.mm --> OK

5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

Conclusion : The available strength is governed by the bearing strength limit state.

(4) CHECK ON WELDMENT STRENGTH

Pa =

62459 N

a. The maximum fillet weld size that can be used notation per AISC Specification Section J2.2b Because the thickness material more than 6 mm, the maximum filled weld size : wfmax = = t - 2 mm 18 mm (Spec. J2.2b (b) )

While, from AISC Specification Table J2.4, the minimum size of fillet weld, based on a material thickness of 20 mm is 8 mm. (Spec. Table J2.4)

b. Length of Weld Required # The nominal weld strength per mm used = Rn = = = FnwAwe 0.6FEXXAwe 14 mm weld.

(Spec. Eq. J2-3, J2-4, J2-5) , where FEXX = 483 MPa

37 38 39 40 1 2 3 4

2866.7 N/mm

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Page 5 of 6

1 2 3 4 5 6 7 8

Pa , where = 2.00 for ASD Rn Min. Length of weld = 44 mm, but the actual length of weld (lw) = 300 mm of weld on each side.

# From AISC Specification Section J2.2b, for longtudinal filled weld used alone in end connections of flat-bar tension members, the length of each fillet weld shall be not less than the perpendicular distance between them. lw > w 180 mm --> OK

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

300 mm >

Conclusion : Weld size use 14 mm, and length of weld use 300 mm of weld on each side.

B. RECOMMENDATION To avoid not OK in the dimensional requirement (See page 2 row 27 in this report), We recommend to change the dimensional as the following:

105

210

26 27 28 29 30

D = w = 210 mm Check dimensional req. after updated D as per recommendation above:

1.

be = =

2t + 16 mm 56 mm < > 1.33be 74 mm 2be + d 172 mm a 75 mm OK OK OK 75 mm Controls

31 32

2.

33 34

75 mm > 3. w >

35 36 37 38 39 40 1 2 3

210 mm > 4. c >

75 mm >

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Page 6 of 6

Você também pode gostar

- Lifting Lug DesignDocumento6 páginasLifting Lug DesignmaniaxpdfAinda não há avaliações

- EN 2-2004 Ex002Documento4 páginasEN 2-2004 Ex002sertackcdgAinda não há avaliações

- C4.tension Member Compatibility ModeDocumento45 páginasC4.tension Member Compatibility ModejojomarbunAinda não há avaliações

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationAinda não há avaliações

- Cven3302 Assignment 1: Column Loading (For The Purpose of Spacegass)Documento11 páginasCven3302 Assignment 1: Column Loading (For The Purpose of Spacegass)fflegendsAinda não há avaliações

- Software Verification: TS 500-2000 Example 002Documento4 páginasSoftware Verification: TS 500-2000 Example 002sertackcdgAinda não há avaliações

- NTC 2008 Example 001Documento6 páginasNTC 2008 Example 001Anitha Hassan KabeerAinda não há avaliações

- Design of Steel StructuresDocumento179 páginasDesign of Steel StructuresneophymenAinda não há avaliações

- Wireless Power Transfer: Using Magnetic and Electric Resonance Coupling TechniquesNo EverandWireless Power Transfer: Using Magnetic and Electric Resonance Coupling TechniquesAinda não há avaliações

- Asd VS LRFDDocumento179 páginasAsd VS LRFDALONSO GOMEZAinda não há avaliações

- 607 HW-1 2016 SolutionDocumento18 páginas607 HW-1 2016 SolutionAMSA84Ainda não há avaliações

- Marine Electrical Practice: Marine Engineering SeriesNo EverandMarine Electrical Practice: Marine Engineering SeriesNota: 4 de 5 estrelas4/5 (8)

- NTC 2008 Example 002Documento14 páginasNTC 2008 Example 002Anitha Hassan KabeerAinda não há avaliações

- Dynamic Damage and FragmentationNo EverandDynamic Damage and FragmentationDavid Edward LambertAinda não há avaliações

- CSA S16 09 Example 001Documento7 páginasCSA S16 09 Example 001thanzawtun1981Ainda não há avaliações

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryAinda não há avaliações

- SAP2000 Software Verification for CSA S16-01 Beam ExampleDocumento7 páginasSAP2000 Software Verification for CSA S16-01 Beam ExampleBùi Văn HợpAinda não há avaliações

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysAinda não há avaliações

- CSA S16-09 Example 002Documento6 páginasCSA S16-09 Example 002Anitha Hassan KabeerAinda não há avaliações

- Solution Manual for 100 Genesys Design Examples: Second EditionNo EverandSolution Manual for 100 Genesys Design Examples: Second EditionAinda não há avaliações

- Singly Reinforced Concrete Beams AS3600Documento6 páginasSingly Reinforced Concrete Beams AS3600Preston WilliamAinda não há avaliações

- Aw-01-07 ColumnDocumento14 páginasAw-01-07 ColumnalexanderAinda não há avaliações

- CSA S16-09 steel frame design exampleDocumento6 páginasCSA S16-09 steel frame design exampleBùi Văn HợpAinda não há avaliações

- RCC13 Punching ShearDocumento10 páginasRCC13 Punching ShearMohammed RasheeduddinAinda não há avaliações

- TENSION MEMBER (Compatibility Mode)Documento44 páginasTENSION MEMBER (Compatibility Mode)ArThur BangunAinda não há avaliações

- BS-5950-90 Example 001Documento7 páginasBS-5950-90 Example 001Win ThanAinda não há avaliações

- Flyover FaislabadDocumento72 páginasFlyover Faislabadnespak06Ainda não há avaliações

- CISC 95 Example 002Documento6 páginasCISC 95 Example 002Bùi Văn HợpAinda não há avaliações

- Continuous Concrete Beam Design To Bs 81101997 Table 3.5Documento8 páginasContinuous Concrete Beam Design To Bs 81101997 Table 3.5sarv_kishoreAinda não há avaliações

- Stiffened Plate Buckling DNV-RP-C201 Rev02-December-2011Documento9 páginasStiffened Plate Buckling DNV-RP-C201 Rev02-December-2011Farid TataAinda não há avaliações

- All TutorialsDocumento37 páginasAll TutorialsSimphiweAinda não há avaliações

- Tutorial 7 - Connections - Part ADocumento28 páginasTutorial 7 - Connections - Part ACyrus HongAinda não há avaliações

- ETABS Software Verifies BS 5950-2000 Steel Frame ExampleDocumento5 páginasETABS Software Verifies BS 5950-2000 Steel Frame ExampleAnitha Hassan KabeerAinda não há avaliações

- Analysis and Design of One Way Slab with BeamsDocumento25 páginasAnalysis and Design of One Way Slab with Beamsklynchelle100% (4)

- Prestressed Beam Girder Floor Made of High Strength ConcreteDocumento18 páginasPrestressed Beam Girder Floor Made of High Strength ConcreteSebastian GusetuAinda não há avaliações

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocumento29 páginasMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Machine DesignDocumento76 páginasMachine DesignTerenz Calangi67% (3)

- PF2Documento4 páginasPF2nhulugallaAinda não há avaliações

- Mekanika Material Latihan Soal Untuk Jurusan Teknik FisikaDocumento17 páginasMekanika Material Latihan Soal Untuk Jurusan Teknik FisikaEsther Kezia SimanjuntakAinda não há avaliações

- WE Slabs Sep07Documento31 páginasWE Slabs Sep07Kristina OraAinda não há avaliações

- Structural design and analysis of a low-rise buildingDocumento42 páginasStructural design and analysis of a low-rise buildingMohammed SumerAinda não há avaliações

- Eurocode 2 Concrete Design GuideDocumento50 páginasEurocode 2 Concrete Design GuideanhkhoacgAinda não há avaliações

- AISC 360 05 Example 002Documento6 páginasAISC 360 05 Example 002thanzawtun1981Ainda não há avaliações

- BS 5950-2000 Example 001Documento5 páginasBS 5950-2000 Example 001Anitha Hassan KabeerAinda não há avaliações

- Splice Connection - Full CapacityDocumento14 páginasSplice Connection - Full Capacitykalpanaadhi75% (4)

- Plate Girder DesignDocumento8 páginasPlate Girder Designkalpanaadhi100% (1)

- Column Design Examples EBCSDocumento7 páginasColumn Design Examples EBCSMesfin Derbew89% (28)

- Lifting Sets Calculation - API RP 2ADocumento11 páginasLifting Sets Calculation - API RP 2AQuang-derer100% (28)

- Flexure in Beams: Reinforcement Ratio Limitations and GuidelinesDocumento16 páginasFlexure in Beams: Reinforcement Ratio Limitations and GuidelinesEngr SwapanAinda não há avaliações

- IS 800-2007 Example 003 PDFDocumento12 páginasIS 800-2007 Example 003 PDFwillowdoAinda não há avaliações

- Vežbe Br. 8 - Primeri: Specijalne Metalne Konstrukcije Aluminijum - Stabilnost - NastavakDocumento15 páginasVežbe Br. 8 - Primeri: Specijalne Metalne Konstrukcije Aluminijum - Stabilnost - NastavakDJordje JovanovicAinda não há avaliações

- Machine Design ProblemsDocumento10 páginasMachine Design ProblemsSiddharth ShekharAinda não há avaliações

- Bearing LayerDocumento1 páginaBearing LayermaniaxpdfAinda não há avaliações

- Deleted FileDocumento1 páginaDeleted FilemaniaxpdfAinda não há avaliações

- Equipment List for 40m Horizontal Conveyor with 4.2 Degree InclineDocumento1 páginaEquipment List for 40m Horizontal Conveyor with 4.2 Degree InclinemaniaxpdfAinda não há avaliações

- Meat Ball PDFDocumento1 páginaMeat Ball PDFmaniaxpdfAinda não há avaliações

- Data Name PlateDocumento1 páginaData Name PlatemaniaxpdfAinda não há avaliações

- Black Friday Ad 2010 Best Buy 49Documento12 páginasBlack Friday Ad 2010 Best Buy 49xler_rahulAinda não há avaliações

- PDF DuctDocumento2 páginasPDF DuctmaniaxpdfAinda não há avaliações

- Steel StructureDocumento1 páginaSteel StructuremaniaxpdfAinda não há avaliações

- Collar Eyebolts BS 4278: TABLE 1 1984 HW 410 Coarse ThreadsDocumento18 páginasCollar Eyebolts BS 4278: TABLE 1 1984 HW 410 Coarse ThreadssrwalkeAinda não há avaliações

- Time Optimization: Unit 1: Project Management Review and Project DevelopmentDocumento12 páginasTime Optimization: Unit 1: Project Management Review and Project DevelopmentmaniaxpdfAinda não há avaliações

- Lens Comp A Ti BileDocumento3 páginasLens Comp A Ti BilethedailycommuteAinda não há avaliações

- BOQ Coal Chute & Cold Air DuctDocumento1 páginaBOQ Coal Chute & Cold Air DuctmaniaxpdfAinda não há avaliações

- BOQ Coal Chute & Cold Air DuctDocumento1 páginaBOQ Coal Chute & Cold Air DuctmaniaxpdfAinda não há avaliações

- PJT 2018 013 PRF 001 Rev0Documento1 páginaPJT 2018 013 PRF 001 Rev0maniaxpdfAinda não há avaliações

- Deleted FileDocumento1 páginaDeleted FilemaniaxpdfAinda não há avaliações

- Daily ActivityDocumento1 páginaDaily ActivitymaniaxpdfAinda não há avaliações

- Browse For FolderDocumento2 páginasBrowse For FoldermaniaxpdfAinda não há avaliações

- L&P OldiestDocumento4 páginasL&P OldiestmaniaxpdfAinda não há avaliações

- Piping Scope DesignDocumento1 páginaPiping Scope DesignmaniaxpdfAinda não há avaliações

- Calculation Note For Removeable Side - Rev ADocumento28 páginasCalculation Note For Removeable Side - Rev AmaniaxpdfAinda não há avaliações

- Pipe Stress AnalysisDocumento3 páginasPipe Stress AnalysismaniaxpdfAinda não há avaliações

- Quotation - Pressure Vessel Mechanical Analysis - RevDocumento1 páginaQuotation - Pressure Vessel Mechanical Analysis - RevmaniaxpdfAinda não há avaliações

- Image Size Zoom Dimensi LCD Batery MemoryDocumento11 páginasImage Size Zoom Dimensi LCD Batery MemorymaniaxpdfAinda não há avaliações

- SEO-Optimized Calculation for Jig Insert Pipe Module DesignDocumento52 páginasSEO-Optimized Calculation for Jig Insert Pipe Module DesignmaniaxpdfAinda não há avaliações

- Penawaran - Tank of Terminal LPG BanyuwangiDocumento2 páginasPenawaran - Tank of Terminal LPG BanyuwangimaniaxpdfAinda não há avaliações

- Calculation Note Assesment Transmission Tower B74, B75, & L56 - Rev ADocumento8 páginasCalculation Note Assesment Transmission Tower B74, B75, & L56 - Rev AmaniaxpdfAinda não há avaliações

- Penawaran - FEA Base PlateDocumento1 páginaPenawaran - FEA Base PlatemaniaxpdfAinda não há avaliações

- Penawaran - Tank of Terminal LPG BanyuwangiDocumento2 páginasPenawaran - Tank of Terminal LPG BanyuwangimaniaxpdfAinda não há avaliações

- Penawaran - FEA Base PlateDocumento1 páginaPenawaran - FEA Base PlatemaniaxpdfAinda não há avaliações

- Data Sheet & DWGDocumento5 páginasData Sheet & DWGmaniaxpdfAinda não há avaliações

- Banas Dairy ETP Training ReportDocumento38 páginasBanas Dairy ETP Training ReportEagle eye0% (2)

- Part I-Final Report On Soil InvestigationDocumento16 páginasPart I-Final Report On Soil InvestigationmangjuhaiAinda não há avaliações

- Learning HotMetal Pro 6 - 132Documento332 páginasLearning HotMetal Pro 6 - 132Viên Tâm LangAinda não há avaliações

- Create A Gmail Account in Some Simple StepsDocumento9 páginasCreate A Gmail Account in Some Simple Stepsptjain02Ainda não há avaliações

- Supply Chain ManagementDocumento30 páginasSupply Chain ManagementSanchit SinghalAinda não há avaliações

- Management Pack Guide For Print Server 2012 R2Documento42 páginasManagement Pack Guide For Print Server 2012 R2Quang VoAinda não há avaliações

- Welding MapDocumento5 páginasWelding MapDjuangAinda não há avaliações

- Resume Ajeet KumarDocumento2 páginasResume Ajeet KumarEr Suraj KumarAinda não há avaliações

- Berry B Brey Part IDocumento49 páginasBerry B Brey Part Ikalpesh_chandakAinda não há avaliações

- Database Chapter 11 MCQs and True/FalseDocumento2 páginasDatabase Chapter 11 MCQs and True/FalseGauravAinda não há avaliações

- Milwaukee 4203 838a PB CatalogaciónDocumento2 páginasMilwaukee 4203 838a PB CatalogaciónJuan carlosAinda não há avaliações

- Iitk Syllabus PDFDocumento520 páginasIitk Syllabus PDFcombatps1Ainda não há avaliações

- Gary Mole and Glacial Energy FraudDocumento18 páginasGary Mole and Glacial Energy Fraudskyy22990% (1)

- SyllabusDocumento4 páginasSyllabusapi-105955784Ainda não há avaliações

- Well Control Kill Sheet (Low Angle Wells)Documento8 páginasWell Control Kill Sheet (Low Angle Wells)Tatita ValenciaAinda não há avaliações

- Supplier Quality Requirement Form (SSQRF) : Inspection NotificationDocumento1 páginaSupplier Quality Requirement Form (SSQRF) : Inspection Notificationsonnu151Ainda não há avaliações

- (Free Scores - Com) - Stumpf Werner Drive Blues en Mi Pour La Guitare 40562 PDFDocumento2 páginas(Free Scores - Com) - Stumpf Werner Drive Blues en Mi Pour La Guitare 40562 PDFAntonio FresiAinda não há avaliações

- ATOMIC GAMING Technical Tutorial 1 - Drawing Game Statistics From Diversity Multigame StatisticsDocumento4 páginasATOMIC GAMING Technical Tutorial 1 - Drawing Game Statistics From Diversity Multigame StatisticsmiltoncgAinda não há avaliações

- WitepsolDocumento21 páginasWitepsolAnastasius HendrianAinda não há avaliações

- Ieee Research Papers On Software Testing PDFDocumento5 páginasIeee Research Papers On Software Testing PDFfvgjcq6a100% (1)

- Philippine Architecture, Film Industry EvolutionDocumento4 páginasPhilippine Architecture, Film Industry EvolutionCharly Mint Atamosa IsraelAinda não há avaliações

- Dinsmore - Gantt ChartDocumento1 páginaDinsmore - Gantt Chartapi-592162739Ainda não há avaliações

- Econometrics Chapter 1 7 2d AgEc 1Documento89 páginasEconometrics Chapter 1 7 2d AgEc 1Neway AlemAinda não há avaliações

- CTS experiments comparisonDocumento2 páginasCTS experiments comparisonmanojkumarAinda não há avaliações

- Bob Duffy's 27 Years in Database Sector and Expertise in SQL Server, SSAS, and Data Platform ConsultingDocumento26 páginasBob Duffy's 27 Years in Database Sector and Expertise in SQL Server, SSAS, and Data Platform ConsultingbrusselarAinda não há avaliações

- RTL8316C GR RealtekDocumento93 páginasRTL8316C GR RealtekMaugrys CastilloAinda não há avaliações

- HI - 93703 Manual TurbidimetroDocumento13 páginasHI - 93703 Manual Turbidimetrojesica31Ainda não há avaliações

- Department Order No 05-92Documento3 páginasDepartment Order No 05-92NinaAinda não há avaliações

- Gps Anti Jammer Gpsdome - Effective Protection Against JammingDocumento2 páginasGps Anti Jammer Gpsdome - Effective Protection Against JammingCarlos VillegasAinda não há avaliações

- Chapter 3: Elements of Demand and SupplyDocumento19 páginasChapter 3: Elements of Demand and SupplySerrano EUAinda não há avaliações

- Coating and Drying Defects: Troubleshooting Operating ProblemsNo EverandCoating and Drying Defects: Troubleshooting Operating ProblemsNota: 5 de 5 estrelas5/5 (1)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeNo EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeNota: 4.5 de 5 estrelas4.5/5 (3)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeNo EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeNota: 5 de 5 estrelas5/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeNo EverandChemistry for Breakfast: The Amazing Science of Everyday LifeNota: 4.5 de 5 estrelas4.5/5 (14)

- The Periodic Table: A Very Short IntroductionNo EverandThe Periodic Table: A Very Short IntroductionNota: 4.5 de 5 estrelas4.5/5 (3)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsNo EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsNota: 4 de 5 estrelas4/5 (146)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableNo EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableNota: 3.5 de 5 estrelas3.5/5 (22)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilNo EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilNota: 5 de 5 estrelas5/5 (1)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeNo EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeNota: 4 de 5 estrelas4/5 (9)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksNo EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksNota: 5 de 5 estrelas5/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingNo EverandIt's Elemental: The Hidden Chemistry in EverythingNota: 4 de 5 estrelas4/5 (10)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolNo EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolAinda não há avaliações

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsNo EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsNota: 5 de 5 estrelas5/5 (3)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeNo EverandChemistry for Breakfast: The Amazing Science of Everyday LifeNota: 4.5 de 5 estrelas4.5/5 (90)

- Chemical Elements Pocket Guide: Detailed Summary of the Periodic TableNo EverandChemical Elements Pocket Guide: Detailed Summary of the Periodic TableAinda não há avaliações

- Napoleon's Buttons: 17 Molecules That Changed HistoryNo EverandNapoleon's Buttons: 17 Molecules That Changed HistoryNota: 4 de 5 estrelas4/5 (25)

- Guidelines for Asset Integrity ManagementNo EverandGuidelines for Asset Integrity ManagementNota: 5 de 5 estrelas5/5 (1)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeNo EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeNota: 4 de 5 estrelas4/5 (1)

- The History of Chemistry (Vol.1&2): Complete EditionNo EverandThe History of Chemistry (Vol.1&2): Complete EditionNota: 1 de 5 estrelas1/5 (1)

- The Long Hangover: Putin's New Russia and the Ghosts of the PastNo EverandThe Long Hangover: Putin's New Russia and the Ghosts of the PastNota: 4.5 de 5 estrelas4.5/5 (76)