Escolar Documentos

Profissional Documentos

Cultura Documentos

Production of Ethanol AS - Chemistry

Enviado por

williamack3611Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Production of Ethanol AS - Chemistry

Enviado por

williamack3611Direitos autorais:

Formatos disponíveis

Comparison of the production of ethanol by fermentation and the reaction of Ethene with steam

Fermentation of Carbohydrates

C6H12O6 2 CH3CH2OH + 2 CO2 C12H22O11 + H2O 4 CH3CH2OH + 4CO2

Reaction of Ethene with Steam

C2H4 + H2O CH3CH2OH

Fermentation only needs to be kept warm at say around 35C which obviously uses less energy As this is a natural process no different pressures are required so only the pressure of the normal atmosphere is required which means that no extra energy is required to form this pressure, only an air tight vessel is required in order to keep oxygen out which would react unwantedly producing carboxylic acids In this reaction to produce ethanol there is no catalyst required besides perhaps the addition of yeast Usually a starch - carbohydrate based crop such as maize, wheat, barley or potatoes. These contain complex carbohydrates and are therefore heated with malt which contains amylase and other enzymes which break down the carbohydrates into simpler sugars such as maltose. Yeast is then required to ferment the disaccharides to form ethanol The crops used are all renewable carbon neutral sources as any carbon produced by burning the produced ethanol was taken in by the plant during photosynthesis in the first place This process is discontinuous as the fermentation and crop growing both take longer periods of time and a yield is only obtained at the end of these phases so ethanol is not able to be constantly produced The reaction rate by fermentation is very slow with respect to the hydration of ethene meaning that to obtain larger yields larger facilities that must lie dormant for large periods of time as the mixture ferments are required Fermentation is a cheaper production mechanism of ethanol as high amounts

Carried out at 300C which means lots of energy is required to reach this temperature A pressure of 60 70 atmospheres is used as the higher pressure favors the product as there is only a single product with respect to the multiple reactants. Pressures higher than this are not used to prevent the formation of poly(ethene) A catalyst of phosphoric (V) acid absorbed onto a porous support such as silica gel is commonly used Ethene and water as gasses at 300C. The ethene is obtained from the fractional distillation and cracking of crude oil

The ethene is obtained from crude oil which is a non renewable source. Water is easily obtained and is in large supply as a renewable component This is a continuous process that can be adapted to produce the amount of ethanol required without much notice (providing the infrastructure is present) The relative reaction rate is very fast and so ethanol can be produced rapidly without delay

The hydration of ethene with steam to produce ethanol is a more costly

Comparison of the production of ethanol by fermentation and the reaction of Ethene with steam of energy are not required to sustain the reaction conditions that are used. Less manpower is required for this process however it takes a far longer time and so leaves great expanses of land unusable for long periods when it could be put to other economic benefit. operation as the reaction conditions require great deals of energy to allow the reaction to run its course at the stated levels. Additionally there are greater labour costs as more experienced and skilled workers are required to operate the machinery associated with this process The purity of fermented ethene with Ethanol produced in this way is pure if steam is far lower than that of hydrated the small amount of water and ethane ethene. This purity requires lots of is removed by fractional distillation refining and further processing in order to reach a desirable product of ethanol The yield from fermentation is far Around 5% of the reactants form lower than that of hydrating ethene ethanol on each passing over the and requires far more refining and catalyst but a total yield of around 95% distillation in order to achieve greater is achieved puritys The raw crops could be used as food Crude oil has many uses so the ethene stuffs and so by using them in the used in this production of ethanol could production of ethanol the amount of be seen as a waste of a resource that is available food is reduced which in a running out as it is possible to produce world that is already starved is a ethanol in different ways such as questionable decision fermentation As a farming process is the start to this This is an industrial process and so a process, farmers are required as well as full factory workforce is involved in its staff to orchestrate the fermentation production providing many jobs. process, the farming staff especially could be differently deployed to produce food for the starving world. This is therefore a batch process This farming fermentation production The factory site for this production of of ethanol requires a lot of land with ethanol does not take up much room respect to the amount of ethanol with respect to the amount of ethanol produced as the land is required to produced and so is geographically grow the crops to ferment. This land stable could be used to grow crops for food and so this process can be seen as a waste of land area

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Ode To Joy For 2 TrumpetsDocumento7 páginasOde To Joy For 2 Trumpetswilliamack3611Ainda não há avaliações

- Banjo Chord ChartDocumento2 páginasBanjo Chord ChartDANAAinda não há avaliações

- S y R Ia: History Effects of Sarin On Humans Synaptic InteractionDocumento1 páginaS y R Ia: History Effects of Sarin On Humans Synaptic Interactionwilliamack3611Ainda não há avaliações

- The TEM and SEM Electron Microscope A ComparisonDocumento1 páginaThe TEM and SEM Electron Microscope A Comparisonwilliamack3611Ainda não há avaliações

- Chords Banjo A ChordsDocumento1 páginaChords Banjo A Chordswilliamack3611Ainda não há avaliações

- Lesson 1Documento2 páginasLesson 1williamack3611Ainda não há avaliações

- Ocr GCSE Vocab List German Print 14 To EndDocumento52 páginasOcr GCSE Vocab List German Print 14 To Endwilliamack3611100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- NBM Guidelines New PDFDocumento38 páginasNBM Guidelines New PDFiit powaiAinda não há avaliações

- Street Food As A Gastronomic Tool in Turkey: December 2016Documento17 páginasStreet Food As A Gastronomic Tool in Turkey: December 2016Arda Yılmaz100% (1)

- DLL ENGLISH-4 Q3 W2 Write-DirectionsedumaymaylauramosDocumento9 páginasDLL ENGLISH-4 Q3 W2 Write-DirectionsedumaymaylauramosPantay ES (R IV-A - Rizal)Ainda não há avaliações

- Deap 116Documento10 páginasDeap 116Ringor L. SonnyAinda não há avaliações

- NSTP 2 - Disaster Management ProgramDocumento17 páginasNSTP 2 - Disaster Management ProgramMc Balabat Villaflores100% (1)

- 11 English Core Impqsection B Writing 02 PDFDocumento52 páginas11 English Core Impqsection B Writing 02 PDFgmuthu2000Ainda não há avaliações

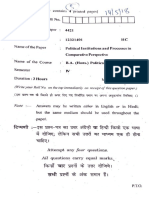

- B.A. (Hons.) Pol. Science 4th Semester-2018Documento8 páginasB.A. (Hons.) Pol. Science 4th Semester-2018Mohd AsifAinda não há avaliações

- Hare Masale Ki Chicken - Special Pakistani Dishes Urdu Recipes Pakistani Cooking, Chines, Italian Indian Food Cooking TipsDocumento2 páginasHare Masale Ki Chicken - Special Pakistani Dishes Urdu Recipes Pakistani Cooking, Chines, Italian Indian Food Cooking Tipsmsiddiq1975Ainda não há avaliações

- Industrial Relations and Labour Welfare NotesDocumento30 páginasIndustrial Relations and Labour Welfare Notesroadiesgeet100% (1)

- Peserta Kelas XiDocumento12 páginasPeserta Kelas XiHelmi Rachma FandiaAinda não há avaliações

- Food and BeverageDocumento2 páginasFood and BeveragePatrick MwangiAinda não há avaliações

- GROUP-2-Chapter-2 NewDocumento18 páginasGROUP-2-Chapter-2 NewClarissa MorteAinda não há avaliações

- Korean Busan Trip InternaryDocumento6 páginasKorean Busan Trip Internaryapi-437726628Ainda não há avaliações

- Basics From Gelato Messina by Nick Palumbo Cooked PDFDocumento11 páginasBasics From Gelato Messina by Nick Palumbo Cooked PDFalmeidavale50% (2)

- Today's DieticianDocumento68 páginasToday's DieticianPooja ManojAinda não há avaliações

- The Simple Past Tense - Regular VerbsDocumento3 páginasThe Simple Past Tense - Regular VerbsVandaAinda não há avaliações

- Answers To Quiz No.2Documento2 páginasAnswers To Quiz No.2Lary Lou VenturaAinda não há avaliações

- The Outsiders Comp Ques CH 3 and 4Documento4 páginasThe Outsiders Comp Ques CH 3 and 4api-522241483Ainda não há avaliações

- Okey &kekongDocumento12 páginasOkey &kekongIrom OkeyAinda não há avaliações

- Experiment 1 CHM260 PDFDocumento4 páginasExperiment 1 CHM260 PDFTifa IbrahimAinda não há avaliações

- EMP - Environmental Monitoring ProgramDocumento10 páginasEMP - Environmental Monitoring Programahmed nasserAinda não há avaliações

- Background ResearchDocumento5 páginasBackground ResearchJesús Balmaseda JalvoAinda não há avaliações

- Alcohol Dissertation TopicsDocumento4 páginasAlcohol Dissertation TopicsOnlinePaperWriterCanada100% (1)

- Golden Age Angkor: Architecture of CambodiaDocumento13 páginasGolden Age Angkor: Architecture of CambodiaTharin Arc IBsAinda não há avaliações

- Mindfullness TeenDocumento163 páginasMindfullness TeenCarla Barbosa Rocha100% (5)

- Past Continues TenseDocumento6 páginasPast Continues Tenseruby Javaid21Ainda não há avaliações

- Chocolate LasagnaDocumento1 páginaChocolate LasagnaLocksley Belicena AmernaAinda não há avaliações

- Cosmetic Product DevelopmentDocumento15 páginasCosmetic Product DevelopmentGizelle Mae Pasiol-MacayanAinda não há avaliações

- Kaluuuuuuuuu FinalllllllllllDocumento33 páginasKaluuuuuuuuu Finalllllllllllevzy fernanadoAinda não há avaliações

- 2020-11-12 Calvert County TimesDocumento24 páginas2020-11-12 Calvert County TimesSouthern Maryland OnlineAinda não há avaliações