Escolar Documentos

Profissional Documentos

Cultura Documentos

Barrenas Triconicas PDF

Enviado por

4s0m0z4Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Barrenas Triconicas PDF

Enviado por

4s0m0z4Direitos autorais:

Formatos disponíveis

TM

New Product Offerings -

ReedHycalog has a new line of products designed to meet demanding drilling challenges.

TuffCutter (TC) Tooth bits

Titan (T) Large Diameter Tooth and Insert Bits

Advanced manufacturing process enables 100% hardmetal coverage with optimized

tooth hardmetal for specific formations.

Bearing System

Increased load capacity journal bearing

Threaded retention system (8 1/2 and larger)

Silver plated floating thrust washer

HNBR radial seal

Cutting Structure

Patented powder metal forging technology with application specific

optimized hardmetal

Hydraulics

Mudpick

Precision Logarithmic Roller bearing technology combined with cutting structures

designed for demanding big hole drilling.

Bearing System

Precision Logarithmic Roller bearing

Fully encapsulated ball retention system

Silver plated floating thrust washer

HNBR radial seal

Cutting Structure

Patented MatchFit insert retention Insert bits

ArmorClad II hardmetal tooth bits

GageGuard

Hydraulics

Mudpick & Mudpick II

TuffDuty (TD) - Tooth and Insert Bits

Increased load-carrying capacity bearing with wear resistant inlay makes TD bits the

natural choice for high energy applications where superior durability is needed.

Bearing System

Increased load capacity journal bearing

Threaded retention system (8 1/2 and larger)

Silver plated floating bushing

Silver plated floating thrust washer

HNBR radial seal

Cutting Structure

Patented MatchFit insert retention

ArmorCladII hardmetal tooth bits

Increased gage protection

Hydraulics

Mudpick and Mudpick II

TuffDuty Directional (D) Tooth and Insert Bits

The same rugged TD bearing package for high energy applications combined

with cutting structure features developed specifically for directional applications.

Bearing System

Increased load capacity journal bearing

Threaded retention system (8 1/2 and larger)

Silver plated floating bushing

Silver plated floating thrust washer

HNBR radial seal

Cutting Structure

Patented MatchFit insert retention

GageGuard protection

Flare chisel inserts

Staggered row insert placement

Carburized cutter shell

ArmorClad II hardmetal tooth bits

Shirttail Features

Protruding round top inserts

Hydraulics

Mudpick and Mudpick II

TM

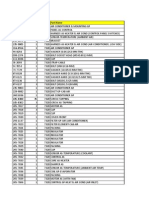

IADC Code Roller Cone Comparison Chart

Milled Tooth Bits

Soft formations

with low compression

strength and high

drillability

Y11

R1

GTX-1 SDS

T11, EMS11G

GTX-G1, MAX-GT1, MX-1

MSDSH, MSDSSH,

GGSSH+, MGSH+

R3

DGJ

XN3

V2J

XN4

L4H

XN5

GTX-3 MCG+

T13, EMS13G

GTX-G3, MAX-GT3, MX-3

XT1

SDGH, MSDGH

MGGH+,

XT3

SVH, MSVH

XT4

Security

Smith

XLX-1, GT-G1H,

GT-G1, STX-1, MX-1

STR-1

MFDSH, FDSH+, MFDSSH, FDS+2 XS1, XL1

FDSS+2, FGS+, FGS+2, FGSH+

FDSS+, FGSS+2, XR+, FGSSH+, FGXi

D13, TD13G, EHT13G, HP13G

MX-3

FDGH, MFDGH

XS3, XL3

HP21G

ATJ-G4

FVH

XS4, XL4

TD11, EHT11, HP11 GT-1

FDS

FDSS+

D11,EHT11G, SL11

TC10, TC11

EHT12, HP12

FDT

SL12

HP13

FDG

ATJ-4 FV

Hughes

ReedHycalog

Sealed Friction Bearing and Gauge Protection

Security

Smith

Hughes

ReedHycalog

Friction Bearing

Security

Smith

Hughes

ReedHycalog

Sealed Roller Bearing and Gauge Protection

Security

Smith

Hughes

Security

XN1

ReedHycalog

Smith

DSJ

Sealed Bearing

DTJ

Y13

Medium to medium-hard

formations with high

compressive strength

Hard semiabrasive or

abrasive formations

Hughes

Formations

ReedHycalog

Type

Series

Features

Standard Roller

DR5

R7

ATJ-G8

Soft formations with

low compressive

strength and high

drillability

Tungsten Carbide Insert Bits

Soft to medium

formations with high

compressive strength

Medium-hard

formations with high

compressive strength

T41, EMS41H

T42, EMS42H

GTX-00 ,GTX03,

MAXGT-00, MAXGT-03

MX-00, MX-03

GTX-03C

MGSO1, O1GMS,

XT00XT05

02MG, MGO2T,

MGO4,MGSO4, GO4

MGS05

XT06XT09

05GM, G05

XT10XT13

M10T, MGS10

MG10T

10GM, G10

TD41A, TD41H, TD41, EHP41, EHP41A

EHP41H, HP41A, HP41H

GT-00, GT-03, H-03, STR-03, MX-00

MX03

F02T

XS00XS05

XL00XL05

TD42H, EHP42H

STR-05C, HX-05C

05MF, F05, F07, MF05T, GF05

TD43A, TD43H, SL43H, TD43, EHP43

EHP43A, EHP43H, HP43

D43

10GF, 10MF, F1, F10T, F12T

MF10T, XR10T

XS06XS09

XL06XL09

XS10XS13

XL10XL13

D44, TD44H, TD44, EHP44, EHP44H

HP44, HP44H, HP44X

GT-09, STR-09, STX-09C

STX-09H, H-09, MX-09

MX-09H, MX-09CG

MX-11, MX-11H, MX-18C

GT-18, STR-18

H-18, H-18H, HX-18,

MX-18, MX-18H

GT-20, STR-20, STX-20

H-20, HX-20, MX-20,

MX-20H

T43, EMS43A

EMS43H

GTX-09, GTX-11H,

MAXGT-09, MX-09,

MX-11

T44, EMS44H

EMS44A

MAXGT-18, MX-18

M15T,15GM, G15

MGS18, G18

T51, EMS51A

EMS51H

GTX-20, GTX-20G

GTX-20H, MAXGT-20

MX-20

MA1SL, M20T

XT18XT23

MGS20

21GMS, 20GM, G20

T52

GTX-20C, MAXGT-20CG

MX-28G

XT24XT27

TD52, TD52A, TD52H, TD52I, TD52X

EHP52, HP52, HP52A, HP52X

T53, EMS53,

EMS53A

MX-30H, MAXGT-30

XT28XT33

TD53, TD53A, SL53A, SL53

EHP53A, EHP53, HP53, HP53A,HP53H

HP53X, HP53B, HP53JA, D53

T54

GTX-30C, MAXGT-30CG

XT34XT39

TD54A, TD54X, HP54, HP54A, HP54X

4JS

XT40XT45

EMS62

GTX-40C

5JS

47JS

XT46XT51

TD61, TD61A, SL61, SL61A, EHP61

EHP61A, HP61, HP61A, HP61H

TD62, TD62A, SL62, SL62A, HP62, HP62A

HP62H, HP63, HP64, HP62JA

M57S

XT52XT59

XT61XT69

EMS63

Hard semiabrasive

and abrasive formations

Extremely hard

and abrasive formations

XT14XT17

TD51A, TD51H, TD51X, SL51H

EHP51, EHP51A, EHP51H, HP51, HP51A

HP51H, HP51X, D51

F15, MF15, MF14TY

XS14XS17

15MF, FG15T, FGS15, 15GF, GF15 XL14XL17

XR15, GF18

F15H, F17, F2, F20T, MF2, MF20T

XS18XS23

MFS20T, 20MF, F25, MF25T, 25MF

XL18XL23

FG20T, FGS20, GF20, 20GF, 25GF,

XR20, XR25

GT-20C, GT-28, H-28, H-20C

HX-28, HX-28C , MX-20C

MX-28

L-30A, STR-30, STX-20, STX-35

GT-30, H-30, HX-30

MX-30, MX-30H

F26Y, F27, F27I, MF27

FGS26OD, 26GFD, XR20TY

XR25TY

F3, MF3, F3H, FG3H, F30T, 30MF

XR32TD, XR30

XS24XS27

XL24XL27

XL46XL51

XS28XS33

XL28XL33

GT-30C, STR-30C, STR-35C

STX-30C, H-30C, HR-38C

HR-30C, HR-35, MX-35C

STR-40, HR-40, HR-44

STX-40, M-40, MX-40G

XL-40A, STR-40C, STR-44C

STX-44C, HR-40C, HR-44C,

MX-40C, MX-44CH

F35, F37, MF37

XR30Y, 30MFDY

XS34XS39

XL34XL39

F4, F45H, F47, F47A, F4H, XR40

XS40XS45

XL40XL45

XS46XS51

XL46XL51

TD63, EHP63, HP63

XL-50A, STR-50, STX-50

HR-50, HR-55RG, HR-55

MX-50, MX-55

F57, MF57, XR50Y

XS52XS59

XL52XL59

TD64, TD64H, HP64, HP64A, HP64H

HR-60, HR-66

F59, F59Y, F65, F67, F67Y

XS61XS69

F47H, F5, MF5, XR40Y

XR45YDD, XR50

XT71XT75

IADC Code Example

HP53: IADC 537

5 = Series (soft to medium insert bit)

3 = Type

7 = Feature (HP bearing and gauge protection)

XS71XS75

XT77XT81

TD73, SL73, HP73

XT83XT89

TD74, SL74, HP74

XT91, XT93

TD81, HP81

STR-70, STX-70, HR-70

F7, XR68Y, XR70Y

HR-80, HR-88, STX-80, STR-80

F8, F80Y

XS91, XS93

F8SY

XS95, XS97

F9, F90Y, XR90Y

XS99

XS83XS89

XT95, XT97

XT99

TD83, SL83, EHP83, HP83

XS77XS81

HR-90, HR-99, STX-90, STR-90

Note: Bits shown are based on individual manufacturers published availabilty data. Comparisons may differ in particular drilling areas. Your ReedHycalog representative can provide specific data for your needs.

TM

Bit

Size

Roller Cone Availability Chart - Insert Bits

in. 334 378 418 412 458 434 512 57 8 6

[mm] [95.3] [98.4] [104.8] [114.3] [117.5] [120.6] [139.7] [149.2] [152.4]

618

[155.6]

614

[158.8]

612

[165.1]

634

77 8

[171.4] [200.0]

8 3 8 812

[212.7] [215.9]

834

[222.2]

912 97 8

[241.3] [250.8]

10 58 11 1158 12 1214

[269.9] [279.4] [295.3] [304.8] [311.2]

1312 1334 1412 1434 1512 16

[342.9] [349.2] [368.3] [374.6] [393.7] [406.4]

1712

17

[431.8] [444.5]

1812 20 22 24 26

[469.9] [508] [558.8] [609.6] [660.4]

SL53A SL53 SL51H SL51H SL53A SL51H SL53A SL51H SL43H, SL51H SL43H, SL51H SL43H, SL51H SL51H, SL53A SL51H

SL63

SL53A SL62 SL53A SL73 SL53 SL53, SL53A SL53, SL53A SL53, SL53A SL61, SL62A SL53

SL62

SL62

SL53A SL61, SL61A SL61A, SL62 SL61A, SL62A SL63, SL73 SL53A

SL63 SL83

SL62A, SL63

SL83

SL83

SL73, SL83

Sabre

TuffDuty

TD44, TD41H

TD51X, TD52, TD52A, TD52I

TD52X, TD53A, TD61A, TD62

TD44X, TD51H, TD64

TD43A, TD44H

TD51A, TD53

TD53A, TD61A

TD63, TD83

TD41H, TD51H

TD74

TD43, TD43A, TD44, TD44H

TD51A, TD51H, TD51X, TD52

TD52A, TD52I, TD52X, TD53

TD53A, TD54A, TD61, TD61A

TD62, TD62A, TD64, TD64H

TD74, TD81, TD83, TD63

TD41, TD41A

TD43A, TD53, TD53A

TD61, TD61A, TD51

TD51A, TD62A

TD44H,

TD61A, TD63

TD42H,

TD43H, TD44H

TD51, TD51A

TD51H, TD52H

TD53, TD53A

TD83

TuffDuty

Directional

D44, D51

D43, D51, D44

D44, D51, D53

D44, D51, D53

D44, D51

EHP

Series

EHP43H

EHP51H

HP Series

HP53A

HP63

HP43A,

HP44X, HP51A, HP51X,

HP52X, HP53, HP53H

HP61H, HP62

HP63, HP74, HP81

HP51H

HP53A

HP63

HP73

HP53A,

HP62A, HP63

HP73, HP74,

HP83

HP51X,

HP61A, HP62

HP64, HP74

HP83

HP41A,

HP64, HP74

HP83

EHP41H, EHP42H

EHP43H, EHP44H

EHP51H, EHP53

EHP53A

HP63 HP53 HP53A HP53A HP43A, HP43H

HP83 HP53H

HP61A HP51H

HP62

HP53A

HP61A

HP63, HP64

Titan

T43, T44, T51

EMS

EMS43H

EMS44H

EMS51H

Jet Air

JA53, JA62, HP53JA, HP62JA

Standard Pin 238 238 238

Connection

Optional Pin

Connection

278

278

278

312

312

312

312

312

312

312

412

T41, T42, T43

T41, T42

T44, T51

T43, T44

T51, T52

EMS51H EMS63 EMS51H EMS41H, EMS42H EMS44A EMS41H, EMS43A

EMS44H, EMS51A

EMS53A EMS43H, EMS44H

EMS53, EMS53A

EMS51A

EMS62

412

412

658

658

658

658

658

658

658

658

658

758

758

758

758

658

658

658

658

758

758

Explanation of ReedHycalog bit type suffixes

Diamond enhanced suffixes

EMS

EHT

EHP

HP

MHT

SL

T

TC

TD

D

Y

A, B, H, I, X

C

F

G

JA

K

KP

KPR

L

M

DI

DG

DH

DGH

DIH

DA

DN

DK

DKP

DL

DKPR

Motor Series bit with sealed roller bearing

Enhanced hardmetal tooth bit

Enhanced performance bit with Mudpick II hydraulics

Standard journal bearing tooth and insert bit

Motor tooth bit

Sabre Premium small diameter journal bearing

Titan Premium sealed roller bearing tooth and insert bit

TuffCutter premium tooth bit with journal bearing

TuffDuty journal bearing with Mudpick

TuffDuty Directional tooth and insert

Nonsealed roller bearing tooth bit

T41

T43

EMS43H

JA62, HP62JA

412

Explanation of ReedHycalog bit type designations prefix

T41 T41

T42

T43

EMS43H

T43, T44

T51, T53

Cutting structure variants that may differ by bit type

Center jet

High-velocity flame-blasted coating

Tungsten carbide heel pacs on steel tooth bits

Non-offset bit for air applications

Premium shirttail protection to reduce wear and protect the seal

Premium Khigher density of inserts

Raised premium shirttail protection

Steel pads with tungsten carbide inserts welded to the bit body

Mudpick II hydraulics

758

8 58 8 58

658 758

758

8 58

8 58

758

758

Diamond inner row inserts

Diamond gauge row inserts

Diamond heel row inserts

Diamond gauge and heel inserts

Diamond inner and heel row inserts

Diamond inner, gauge and heel row inserts

Diamond nose

Diamond shirttail protection

Diamond premium shirttail protection

Diamond lug pads

Diamond KPR

TM

Roller Cone Availability Chart - Tooth Bits

Bit

Size

in. 334

[mm] [95.3]

418 412 458 434 512 57 8 6

[104.8] [114.3] [117.5] [120.6] [139.7] [149.2] [152.4]

Sabre

SL12 SL12

618

[155.6]

614

[158.8]

612

[165.1]

634

77 8

[171.4] [200.0]

SL12

SL12

SL11, SL12 SL11,SL12

8 3 8 812

[212.7] [215.9]

834

[222.2]

912 97 8

[241.3] [250.8]

10 58 11 1158 12 1214

[269.9] [279.4] [295.3] [304.8] [311.2]

TuffDuty

TD11

TD11, TD13

TD11

TD11

TD11

TuffDuty

Directional

D11

D11

D11

D11

D11

TuffCutter

TC10, TC11

EHT Series

EHT11

EHT11

EHT11, EHT11G

HP Series

HP11, HP12, HP13G

HP11, HP12

HP13G

HP21G

HP11, HP12, HP13G

EHT11G EHT11, EHT11G

EHT11 EHT11 EHT13G

HP11, HP13G

HP11

1312 1334 1412 1434 1512 16

[342.9] [349.2] [368.3] [374.6] [393.7] [406.4]

HP13

HP11, HP12

HP13G, HP21G

T11

EMS11G

EMS

Y Series

Y11

278

278

312

312

312

312

312

Cutting Structure

Inner

Outer

Dull Characteristics

Location

IADC Dull Bit Grading

1

2

Inner cutting structure

(all inner rows)

Outer cutting structure

(gauge row only)

In columns 1 and 2, a linear scale from 0 to 8 is

used to describe the condition of the cutting

structure according to the following:

Steel tooth bits

A measure of lost tool height resulting from

abrasion and/or damage.

0 No loss of tooth height.

8 Total loss of tooth height.

Insert bits

A measure of total cutting structure reduction

resulting from lost, worn and/or broken inserts.

0 No lost, worn and/or broken inserts.

8 All inserts lost, worn and/or broken.

Fixed cutter bits

A measure of lost, worn and/or broken cutting

structure.

0 No lost, worn and/or cutting structure.

8 All of cutting structure Lost, worn and/or

broken.

312

312

412

412

412

658

412

658

658

Bearings/Seals

Gauge

Other Dull Characteristics

Reason Pulled

Dull characteristics

(Use only cutting structure related codes.)

Roller cone

N nose row

M middle row

G gauge row

A all rows

BC

broken cone

BF bond failure

BT broken teeth/cutters

BU balled up bit

CC cracked cone

CD cone dragged

CI cone Interference

CR cored

CT chipped teeth/cutters

ER erosion

FC flat crested wear

HC heat checking

JD junk damage

LC lost cone

LN lost nozzle

LT lost teeth/cutters

OC off-center wear

PB pinched bit

PN plugged nozzle/flow passage

RG rounded gauge

RO ring out

SD shirttail damage

SS self-sharpening wear

TR tracking

WO washed out bit

WT worn teeth/cutters

NO no dull characteristic

Show Cone number or numbers under location

Location

Fixed rutter

C cone

N nose

T taper

7

Cone no.

1

2

3

S shoulder

G gauge

A all areas

Bearings/seals

Nonsealed bearings

A linear scale estimating bearing

life used. (0 No life used, 8 All

life used, i.e., no bearing life

remaining.)

Sealed bearings

E seals effective

F seals failed

N not able to grade

X fixed cutter bit (bearingless)

Gauge measure in of an inch.

1 16

I In gauge

1 16 1 16 in. out of gauge

2 16 1 8 in. out of gauge

4 16 14 in. out of gauge

Other dull characteristic

Refer to column three codes.

Reason pulled or run terminated

BHA

DMF

DTF

DSF

DST

LOG

LIH

RIG

CM

CP

DP

FM

HP

HR

PP

PR

TD

TQ

TW

WC

change bottomhole assembly

downhole motor failure

downhole tool failure

downhole string failure

drill stem test

run logs

left in hole

rig repair

condition mud

core point

drill plug

formation change

hole problems

hours on bit

pump pressure

penetration rate

total depth/casing depth

torque

twist off

weather conditions

658

658

658

Jet Nozzle Flow Areas

278

1812 20 22 24 26

[469.9] [508] [558.8] [609.6] [660.4]

EHT11, EHT11G

Titan

Standard Pin 238 238 238

Connection

Optional Pin

Connection

1712

17

[431.8] [444.5]

658

Y11

EMS11G

Y11

658

658

T11, T13

T11, T13

EMS11G EMS11, EMS11G

EMS13G EMS13, EMS13G

EMS11G

EMS13G

Y11

T11

EMS11G

Y11

758

758

758

758

658

658

658

658

758

EMS11G

Y11 Y13

758

758

EMS11

EMS11G

Y11

8 58 8 58

658 758

T11

758

Y11, Y13

8 58

8 58

758

758

Nozzle

Size

(in. [mm])

Nozzle

Number

Flow Area

of One Nozzle

(in.2 [mm 2])

Flow Area

of Two Nozzles

(in.2 [mm 2])

Flow Area

of Three Nozzles

(in.2 [mm 2])

Flow Area

of Four Nozzles

(in.2 [mm 2])

7 32 [5.5]

0.0376 [24.3]

0.0752 [48.5]

0.1127 [72.9]

0.1503 [97.0]

14 [6.4]

0.0491 [31.7]

0.0982 [63.4]

0.1473 [95.0]

0.1963 [126.1]

9 32 [7.1]

0.0621 [40.1]

0.1242 [80.1]

0.1864 [120.2]

0.2485 [160.3]

5 16 [7.9]

10

0.0767 [49.5]

0.1534 [99.0]

0.2301 [148.4]

0.3068 [197.9]

11 32 [8.7]

11

0.0928 [59.5]

0.1856 [119.7]

0.2784 [179.6]

0.3712 [239.5]

3 8 [9.5]

12

0.1104 [71.2]

0.2209 [142.5]

0.3313 [213.7]

0.4418 [285.0]

13 32 [10.3]

13

0.1296 [83.6]

0.2592 [167.2]

0.3889 [250.9]

0.5185 [334.5]

7 16 [11.1]

14

0.1503 [97.0]

0.3007 [194.0]

0.4510 [291.0]

0.6013 [388.0]

15 32 [11.9]

15

0.1726 [111.4]

0.3451 [222.8]

0.5177 [334.2]

0.6903 [445.4]

1 2 [12.7]

16

0.1963 [126.6]

0.3927 [253.2]

0.5890 [379.8]

0.7854 [506.7]

9 16 [14.3]

18

0.2485 [160.3]

0.4970 [320.6]

0.7455 [481.0]

0.9940 [641.3]

5 8 [15.9]

20

0.3068 [197.9]

0.6136 [395.9]

0.9204 [593.8]

1.2272 [791.8]

11 16 [17.5]

22

0.3712 [239.5]

0.7424 [479.0]

1.1137 [718.5]

1.4849 [958.1]

3 4 [19.0]

24

0.4418 [285.0]

0.8836 [570.1]

1.3254 [855.0]

1.7672 [1140.2]

7 8 [22.2]

28

0.6013 [387.9]

1.2026 [775.9]

1.8040 [1163.7]

2.4053 [1551.9]

Bit Size

(in. [mm])

Recommended

Roller Cone

Makeup Torque

API Pin Size

(in. [mm])

Recommended Torque

(lbt-ft [Newton])

33 441 2 [95.2114.3]

23 8 [60.3]

3,0003,500 [4,0004,800]

45 85 [117.5127.0]

27 8 [73.0]

6,0007,000 [8,0009,500]

51 873 8 [136.5187.3]

31 2 [88.9

7,0009,000 [9,50012,000]

75 89 [193.7228.6]

41 2 [114.3]

12,00016,000 [16,00022,000]

91 226 [241.3660.4]

65 8 [168.3]

28,00032,000 [38,00043,000]

143 426 [374.6660.4]

75 8 [193.7]

34,00040,000 [46,00054,000]

Você também pode gostar

- Iadc Classification - ChartDocumento2 páginasIadc Classification - ChartNacer MezghicheAinda não há avaliações

- Iadc 2001 071801Documento3 páginasIadc 2001 071801jalalAinda não há avaliações

- 625245-A-S990-01 ChassisDocumento687 páginas625245-A-S990-01 Chassisdavidmaciasv007Ainda não há avaliações

- Mechanical Spare PartsDocumento19 páginasMechanical Spare Parts金杰尼Ainda não há avaliações

- Data Barang Project Stok Banyak (Stok Lama)Documento36 páginasData Barang Project Stok Banyak (Stok Lama)Marsel TimbulengAinda não há avaliações

- Shipping Spare Parts ListsDocumento17 páginasShipping Spare Parts Lists金杰尼Ainda não há avaliações

- Пазовые фрезы PDFDocumento72 páginasПазовые фрезы PDFstctoolAinda não há avaliações

- AT3600-6 (PDF Library)Documento2 páginasAT3600-6 (PDF Library)janusz malyAinda não há avaliações

- d6m 3wnDocumento10 páginasd6m 3wnJohanna FabianAinda não há avaliações

- TrioTTH 6203D Horizontal Screen Parts Manual SN 226 PDFDocumento23 páginasTrioTTH 6203D Horizontal Screen Parts Manual SN 226 PDFJoanMontillaAinda não há avaliações

- Ceratizit U DrillDocumento8 páginasCeratizit U DrillJitendra BagalAinda não há avaliações

- HDADocumento13 páginasHDAnetozxAinda não há avaliações

- 2012-2013 Specifications v010 enDocumento222 páginas2012-2013 Specifications v010 enMário CorreiaAinda não há avaliações

- FRD Product LineDocumento8 páginasFRD Product Linegiapy0000Ainda não há avaliações

- VAREL RC Comparison Chart Final 2012Documento2 páginasVAREL RC Comparison Chart Final 2012Baitaw WanwarangAinda não há avaliações

- 811 GUIDE Pump InterchangeabilityDocumento68 páginas811 GUIDE Pump Interchangeabilitykztro066100% (1)

- Short Block For CAT 320 D PDFDocumento5 páginasShort Block For CAT 320 D PDFerisunarkoAinda não há avaliações

- Blind Bolt Catalog Fy 02Documento54 páginasBlind Bolt Catalog Fy 02tangyuAinda não há avaliações

- Tube Installation Accessories: GT Serrating ToolsDocumento8 páginasTube Installation Accessories: GT Serrating ToolsMilad MAinda não há avaliações

- 320DDocumento225 páginas320DMohamed Bakheet100% (2)

- Especificacion API 5lDocumento44 páginasEspecificacion API 5ljpcc1986100% (1)

- Homelite Parts ListDocumento10 páginasHomelite Parts Listmecrea1Ainda não há avaliações

- Monthly Plan PS, Filter & Oil Minning FSP Juli 2022Documento150 páginasMonthly Plan PS, Filter & Oil Minning FSP Juli 2022irfanAinda não há avaliações

- 2022 OTR Catalog SinglepgDocumento24 páginas2022 OTR Catalog SinglepgJ. Enrique Monroy H.Ainda não há avaliações

- Implements: 112-7486 CIRCLE GPDocumento2 páginasImplements: 112-7486 CIRCLE GPHemerson MatosAinda não há avaliações

- Onsrud Catalog - Milling and Drilling ToolsDocumento40 páginasOnsrud Catalog - Milling and Drilling ToolsDaniel AustinAinda não há avaliações

- Industrial Tools For Fabrication and MaintenanceDocumento216 páginasIndustrial Tools For Fabrication and MaintenanceMohammedAinda não há avaliações

- D-Bucket ChainsDocumento45 páginasD-Bucket ChainsMuhammad Irvan FAinda não há avaliações

- Enerpac Hydratight Powergen CapabilitiesDocumento81 páginasEnerpac Hydratight Powergen CapabilitiesAhmed El TayebAinda não há avaliações

- Scule HidrauliceDocumento34 páginasScule HidraulicelucianbordeutAinda não há avaliações

- Classifier Classifier: 2007 Drill BitDocumento17 páginasClassifier Classifier: 2007 Drill BitIchalroz AudioDefectAinda não há avaliações

- 290-7232 Suspension Gp-Front: Entire GroupDocumento3 páginas290-7232 Suspension Gp-Front: Entire GroupLucio Junior Carbajal TorresAinda não há avaliações

- Manual de Partes 120HDocumento5 páginasManual de Partes 120HJose YatoAinda não há avaliações

- Parts Number Cylinder GP Ripper D7G2Documento3 páginasParts Number Cylinder GP Ripper D7G2Andri HermantoAinda não há avaliações

- Flo-Thru Trench Drain Systems: Industrial Civil MechanicalDocumento41 páginasFlo-Thru Trench Drain Systems: Industrial Civil MechanicalTantan AñesAinda não há avaliações

- FTM '12 HKD Push-In AnchorDocumento14 páginasFTM '12 HKD Push-In AnchorShankerAinda não há avaliações

- Uhing ManualDocumento28 páginasUhing Manualganon188Ainda não há avaliações

- Stat Prod Range enDocumento23 páginasStat Prod Range enhjyujyagghjafhgjhgafAinda não há avaliações

- Homelite Chain Saw Parts Manual For LX30 Bandit Chain Saw UT 10705 E PDFDocumento10 páginasHomelite Chain Saw Parts Manual For LX30 Bandit Chain Saw UT 10705 E PDFPanos RousetisAinda não há avaliações

- M5A78L-M PLUS-USB3 Devices ReportDocumento21 páginasM5A78L-M PLUS-USB3 Devices ReportDante MoretaAinda não há avaliações

- CXZ-MAN Supplies Diesel Engine Spare Parts and Marine Equipment To Ships - Welcome To Consult The PriceDocumento18 páginasCXZ-MAN Supplies Diesel Engine Spare Parts and Marine Equipment To Ships - Welcome To Consult The Pricexin zhangAinda não há avaliações

- Power Train: 296-6217 FINAL DRIVE GPDocumento6 páginasPower Train: 296-6217 FINAL DRIVE GPSidney RodriguesAinda não há avaliações

- Machinery Application 1A 1999Documento178 páginasMachinery Application 1A 1999elinpetAinda não há avaliações

- BX50PDocumento6 páginasBX50PAngel85Ainda não há avaliações

- Alberg Cutting Tool 2002 PDFDocumento28 páginasAlberg Cutting Tool 2002 PDFApichat1967Ainda não há avaliações

- TrioTTH 6203D Horizontal Screen Parts Manual (SN. 226)Documento23 páginasTrioTTH 6203D Horizontal Screen Parts Manual (SN. 226)pedrofalfan100% (2)

- Alto Products Corp 2010 CatalogueDocumento71 páginasAlto Products Corp 2010 CatalogueAshley CardwellAinda não há avaliações

- DSI Alwag-Systems DYWIDAG Cable Bolts For Mining en 01Documento8 páginasDSI Alwag-Systems DYWIDAG Cable Bolts For Mining en 01MarkusMakuAldoAinda não há avaliações

- KOSUN Centrifuge PDFDocumento6 páginasKOSUN Centrifuge PDFMEHDIAinda não há avaliações

- d8r Brake & Planetary DWJDocumento3 páginasd8r Brake & Planetary DWJKusuma JayaAinda não há avaliações

- Flygt Pump SealDocumento6 páginasFlygt Pump SealmazzingerzAinda não há avaliações

- 2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Documento6 páginas2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Difa LiuAinda não há avaliações

- Camshaft Kit Catalgue 2018Documento5 páginasCamshaft Kit Catalgue 2018sandyman68Ainda não há avaliações

- Tricone Rock Bit Comparison Chart - Milled ToothDocumento1 páginaTricone Rock Bit Comparison Chart - Milled Toothعلی محمودیAinda não há avaliações

- Catalogo GehaDocumento42 páginasCatalogo GehaSebastian Deossa RestrepoAinda não há avaliações

- MP513ENDocumento132 páginasMP513ENAnonymous H3I29yjAinda não há avaliações

- D9RDocumento127 páginasD9RMohamed BakheetAinda não há avaliações

- Practical Variable Speed Drives and Power ElectronicsNo EverandPractical Variable Speed Drives and Power ElectronicsNota: 5 de 5 estrelas5/5 (3)

- English WorkbookDocumento99 páginasEnglish WorkbookTrà MinhAinda não há avaliações

- (SPE 3474) Analysis & Prediction of Gas Well PerformanceDocumento10 páginas(SPE 3474) Analysis & Prediction of Gas Well Performance4s0m0z4Ainda não há avaliações

- AbrasiFRAC Stimulation Service (Schlumberger) PDFDocumento2 páginasAbrasiFRAC Stimulation Service (Schlumberger) PDF4s0m0z4Ainda não há avaliações

- AbrasiFRAC Stimulation Service (Schlumberger) PDFDocumento2 páginasAbrasiFRAC Stimulation Service (Schlumberger) PDF4s0m0z4Ainda não há avaliações

- A Rod Pumping System For California Lift RequirementsDocumento8 páginasA Rod Pumping System For California Lift Requirements4s0m0z4Ainda não há avaliações

- Thi Thu TNTHPT - Tieng Anh 12 - 136Documento5 páginasThi Thu TNTHPT - Tieng Anh 12 - 136Yến LinhAinda não há avaliações

- Certipur Certified Reference Material: Sodium Standard Solution 1000 MG/L NaDocumento1 páginaCertipur Certified Reference Material: Sodium Standard Solution 1000 MG/L NaJuan BenitezAinda não há avaliações

- Electrical Service Minimum RequirmentDocumento97 páginasElectrical Service Minimum RequirmentachniajosiAinda não há avaliações

- Title DefenseDocumento3 páginasTitle DefenseLiezl Sabado100% (1)

- Assignment On Training & Development Process of Uniliver BangladeshDocumento9 páginasAssignment On Training & Development Process of Uniliver BangladeshMohaiminul Islam50% (2)

- 3 Master Star 1 Super Star: Forged Steel Ball ValvesDocumento7 páginas3 Master Star 1 Super Star: Forged Steel Ball ValvesAhmed IbrahimAinda não há avaliações

- Experiment 13 Ultrafiltration UnitDocumento13 páginasExperiment 13 Ultrafiltration UnitKishen NaniAinda não há avaliações

- Assessment of Spinach Seedling Health Status and Chlorophyll Content by Multivariate Data Analysis and Multiple Linear Regression of Leaf Image FeaturesDocumento9 páginasAssessment of Spinach Seedling Health Status and Chlorophyll Content by Multivariate Data Analysis and Multiple Linear Regression of Leaf Image FeaturesYugal KumarAinda não há avaliações

- SAP TestingDocumento7 páginasSAP Testingpvpreddy67Ainda não há avaliações

- Practical FileDocumento108 páginasPractical FileRakesh KumarAinda não há avaliações

- 3838-Article Text-7786-1-10-20230403Documento8 páginas3838-Article Text-7786-1-10-20230403Ramona Elena SpiridonAinda não há avaliações

- Op Amps and Linear Integrated Circuits 4th Edition by Gayakwad Ramakant A Textbook PDF Download PDFDocumento1 páginaOp Amps and Linear Integrated Circuits 4th Edition by Gayakwad Ramakant A Textbook PDF Download PDFNiraj KapoleAinda não há avaliações

- Project 8 - Part 1 - ResumeDocumento2 páginasProject 8 - Part 1 - Resumeapi-275234784Ainda não há avaliações

- Access MISS ProxyDocumento7 páginasAccess MISS ProxyKorintus TedyAinda não há avaliações

- Defense MechanismsDocumento4 páginasDefense MechanismsTillu TilluAinda não há avaliações

- MgF2 SolGelDocumento8 páginasMgF2 SolGelumut bayAinda não há avaliações

- VisualizationDocumento4 páginasVisualizationspanglemaker3719349Ainda não há avaliações

- The Standard Model Theory - Kreon Papathanasiou - ph4884Documento30 páginasThe Standard Model Theory - Kreon Papathanasiou - ph4884Haigh RudeAinda não há avaliações

- Define-Phase Yellow BeltDocumento52 páginasDefine-Phase Yellow BeltBhadri NarayananAinda não há avaliações

- Excel Tips Tricks e-BookV1.1 PDFDocumento20 páginasExcel Tips Tricks e-BookV1.1 PDFSulabhAinda não há avaliações

- Chapter 2 Solutions - Power-Generation-OperationDocumento11 páginasChapter 2 Solutions - Power-Generation-OperationKleilson Chagas50% (4)

- Philosophical Warfare and The Shadow of IdeasDocumento5 páginasPhilosophical Warfare and The Shadow of IdeasDavid MetcalfeAinda não há avaliações

- Introduction EthicsDocumento26 páginasIntroduction EthicsLawrence MarquezAinda não há avaliações

- Daily ReportDocumento39 páginasDaily ReportLe TuanAinda não há avaliações

- 02.03.05.06.01 - Manage Sales Rebate AgreementDocumento11 páginas02.03.05.06.01 - Manage Sales Rebate AgreementVinoth100% (1)

- Ten Steps To An Amazing INFJ LifeDocumento15 páginasTen Steps To An Amazing INFJ LifeG. S.100% (5)

- Respons 910 Analyzer: Operator's ManualDocumento246 páginasRespons 910 Analyzer: Operator's ManualUmashankar LoganathanAinda não há avaliações

- How To Query Asham Tele Points (Telebirr)Documento13 páginasHow To Query Asham Tele Points (Telebirr)Fayisa ETAinda não há avaliações

- Implementation of Smart and Secure Gate Pass System Using QR CodeDocumento7 páginasImplementation of Smart and Secure Gate Pass System Using QR CodeResearch ParkAinda não há avaliações

- AWS Lecture NotesDocumento4 páginasAWS Lecture NotesAsad Bin Ala Qatari0% (1)