Escolar Documentos

Profissional Documentos

Cultura Documentos

Supply Chain Management at GCMMF: Submitted By, Deepa Raghu I MBA (2011-13) (14.02.12)

Enviado por

Rahul SttudTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Supply Chain Management at GCMMF: Submitted By, Deepa Raghu I MBA (2011-13) (14.02.12)

Enviado por

Rahul SttudDireitos autorais:

Formatos disponíveis

Supply Chain Management at GCMMF Submitted by, Deepa Raghu I MBA (2011-13) (14.02.

12)

INTRODUCTION: Amul (Anand Milk Union Limited) one of the most successful brands in India, was the brand name for the dairy products marketed by the Gujarat Co-operative Milk Marketing Federation (GCMMF). GCMMF collected 5.71 million liters of milk a day from vendors like Parmar. GCMMF with its range of products that included butter, cheese, milk powder, sweets, ice creams, and buttermilk, managed to successfully compete with multinationals like Unilevers subsidiary Hindustan Lever, and Nestl in the Indian market. It had also expanded globally to countries in the Middle East, Africa, and to the US. WHAT DOES GCMMF DO? GCMMF was owned by a chain of farmers who had formed a network of cooperative societies. Milk was collected from more than 2.4 million farmers in 11,615 villages twice a day, and tested, graded, and transported to the processing centers. GCMMFs products were marketed through 50 sales offices located across India to 4,000 stockists and 500,000 retail outlets. To combat the monopoly of Polson Dairy in Mumbai, the GCMMF was set up. The seeds of the cooperative movement, which helped turn India into the largest milk producer in the world by 2000. With the major success of the Kaira Union, similar unions were formed in various other districts of Gujarat. This was followed by setting up of new marketing agencies and plants.

PROBLEMS FACED BY AMUL: In the winter season milk collected by the cooperative exceeded the demand from the Mumbai government. This meant that once more the milk producers were forced to sell the surplus milk at lower prices to the middlemen. The solution to this problem lay in converting the surplus milk into other products with a longer shelf life. SUPPLY CHAIN MANAGEMENT: At the start of the GCMMFs supply chain the farmers supplied milk to the VCSs. The district unions processed the milk and took care of making the final product. In 2005, GCMMF had 12 district milk unions. The essential elements included milk production, procurement, transportation, processing, packaging and distribution of final products like butter, cheese, ice-cream, etc to the customers. The logistics of collecting 5.71 million liters of milk each day, processing them at 23 plants of 12 dairy unions, and sending them to more than 500,000 retailers was highly complicated. However, the coordination among producers and distributors ensured the smooth functioning of the supply chain. The structure of GCMMF guaranteed that the farmers interests would be given prime importance. It coordinated with different unions to decide on the product mix. PROCUREMENT: Activities at the village level comprised developing and servicing the VCSs, increasing milk collection, procuring milk, and transporting it to the chilling and processing units twice a day. The staff was responsible for feeding animals, collecting milk, payment, transportation for processing. The average milk procurement in the financial year 2004-05 was at 5.88 million kilograms per day, as against 5.11 million kilograms per day in the financial year 2003-04. More than 4,000 Automatic Milk Collection Units (AMCUS) were installed at the VCSs by 1996 to record information. The milk supplied to Mother Dairy was sold through bulk vending booth and rail milk tankers. PROCESSING: After the union received the milk, it was tested for quality, and it was sent for processing. If the milk was found to have high acidity, it was used to make

buttermilk. Raw milk was sent through a filter, clarifier and was pasteurized. The cream was separated, skimmed milk was obtained. According to demand, the unions packed a n d d i s t r i b u t e d the milk. The cream was marketed as Amul Fresh Cream. For manufacturing butter, the cream obtained from the milk was pasteurized and stored at 14 degrees centigrade for about eight hours. The cream was then sent through a balance tank and through a heat exchanger and churned where the temperature was maintained between 6-13 degrees centigrade. The butter grains were washed twice and treated under vacuum mainly to remove any residues of the buttermilk from the butter. To make table butter, salt, brine, and color were added to unsalted butter, blended, treated under vacuum and sent to a butter silo from which the butter was packed in chiplets. In order to produce one kilogram of butter, 13 liters of milk was required. To obtain baby food concentrate, the milk was vacuum evaporated, subjec t to spray and then vitamins, minerals, and sugar were added. GCMMF made cheese, which was totally vegetarian. Rennet was added to the milk to obtain curd which was sold under the name Masti Dahi. The curd was subjected to other processes like cheddaring and vacuumizing to obtain different varieties of cheeses. DISTRIBUTION: GCMMF coordinated with various unions to get a regular supply of milk and dairy products. The processed milk and dairy products were procured from district dairy unions and distributed through third party distributors and were closely monitored. Third party distribution depots, managed by exclusive GCMMF distributors, were used to distribute GCMMFs products. These distributors served the retail outlets all over the country. GCMMF ensured nationwide product availability. Hence, Amul ice-creams were made available through push carts, small shops, public call offices, chemists, restaurants and bakeries. Amul also set up its own brand of parlors called Utterly Delicious. CONCLUSION: The main objective of GCMMF was to market milk and dairy products and thus help in the economic development of the agriculturalists. After India became a part of WTO, there was greater pressure on the government to liberalize the milk sector. However, the Indian government tried to limit foreign competition by imposing high quality standards.

Você também pode gostar

- Mother Diary Industrial Visit ReportDocumento12 páginasMother Diary Industrial Visit ReportSahil Manchanda100% (2)

- Producing Cream on the Dairy Farm - A Collection of Articles on the Methods, Science and Equipment Used in Cream ProductionNo EverandProducing Cream on the Dairy Farm - A Collection of Articles on the Methods, Science and Equipment Used in Cream ProductionAinda não há avaliações

- Plant Visit To Mother DairyDocumento6 páginasPlant Visit To Mother DairyHimanshu GuptaAinda não há avaliações

- KMFFFDocumento8 páginasKMFFFShashi ReddyAinda não há avaliações

- How To Get Cream From Goats' Milk: Make Your Own Butter, Whipped Cream, Ice Cream, & MoreNo EverandHow To Get Cream From Goats' Milk: Make Your Own Butter, Whipped Cream, Ice Cream, & MoreAinda não há avaliações

- "A Comparative Study On of Amul India and Mother Dairy 2. Introduction & Review of LiteratureDocumento19 páginas"A Comparative Study On of Amul India and Mother Dairy 2. Introduction & Review of LiteratureNishant RatheeAinda não há avaliações

- Presented By: Yaswant Narayan Singh Presented To: SCCE ProfDocumento38 páginasPresented By: Yaswant Narayan Singh Presented To: SCCE ProfSunny SinhaAinda não há avaliações

- Amul SCMDocumento36 páginasAmul SCMSachin SharmaAinda não há avaliações

- Distrbution and PLCDocumento3 páginasDistrbution and PLCARUNIKA GUNJAALAinda não há avaliações

- Amul Supply Chain Management WriteupDocumento22 páginasAmul Supply Chain Management WriteupPalak AdwaniAinda não há avaliações

- Name LocationDocumento11 páginasName LocationVijay JBAinda não há avaliações

- Executive SummaryDocumento19 páginasExecutive SummaryKayzad MadanAinda não há avaliações

- Supply Chain ManagementDocumento4 páginasSupply Chain ManagementNaman MaheshwariAinda não há avaliações

- FMCG Sales DistributionDocumento8 páginasFMCG Sales DistributionRadhika ChhabraAinda não há avaliações

- Project Report On Industrial Visit To Amul: Submitted By, ARUNA LAMBHA (Roll No.45)Documento18 páginasProject Report On Industrial Visit To Amul: Submitted By, ARUNA LAMBHA (Roll No.45)Dimitry VegasAinda não há avaliações

- Nandini Milk-FinalDocumento19 páginasNandini Milk-Finalopalq100% (1)

- Amul 1Documento30 páginasAmul 1kishi0% (1)

- Amul External AnalysisDocumento14 páginasAmul External AnalysisGagan AulakhAinda não há avaliações

- Finnal Project of NeerajDocumento40 páginasFinnal Project of NeerajRam LalAinda não há avaliações

- Try Magic DesignDocumento18 páginasTry Magic Designrookieaadi17Ainda não há avaliações

- Amul LogisticsDocumento35 páginasAmul LogisticsAdil Akhtar Khan100% (1)

- AmulDocumento41 páginasAmulParag MaheshwariAinda não há avaliações

- AMULDocumento39 páginasAMULmohitAinda não há avaliações

- Velammal Engineering College Department of Science: Internship Report (Documento19 páginasVelammal Engineering College Department of Science: Internship Report (ramu rajakannu100% (2)

- AMUL-The Taste of India Born: 1946, Christened in 1955n 1955Documento14 páginasAMUL-The Taste of India Born: 1946, Christened in 1955n 1955faraz_alam_3Ainda não há avaliações

- Sales and Distribution Management of AmulDocumento45 páginasSales and Distribution Management of AmulPravesh Dhavale100% (2)

- Amul Marketing ProjectDocumento57 páginasAmul Marketing ProjectShivamSrivastava100% (1)

- Amul PresentationDocumento47 páginasAmul PresentationsrishtijiAinda não há avaliações

- Evolution of Marketing Strategy: Anuj SharmaDocumento25 páginasEvolution of Marketing Strategy: Anuj SharmaPreeti VatnaniAinda não há avaliações

- Annual Sustainability Report 2704Documento86 páginasAnnual Sustainability Report 2704Gaming with AyushAinda não há avaliações

- A Project Report On The Consumer Behaviour Towards Amul BeveragesDocumento36 páginasA Project Report On The Consumer Behaviour Towards Amul Beveragesadil khan0% (1)

- Milma Company Minor ProjectDocumento38 páginasMilma Company Minor ProjectGovind SAinda não há avaliações

- Presentation On Supply Chain Management of AMULDocumento38 páginasPresentation On Supply Chain Management of AMULChandan PahelwaniAinda não há avaliações

- Presentation On: Guided By: Manish Sir Presented By: Amit Sharma Gourav JainDocumento55 páginasPresentation On: Guided By: Manish Sir Presented By: Amit Sharma Gourav Jaincimr33Ainda não há avaliações

- Amul Model For MarketingDocumento22 páginasAmul Model For MarketingshalinpshahAinda não há avaliações

- Aavin Company ProjectDocumento10 páginasAavin Company ProjectDinesh Kumar100% (4)

- Comparative Analysis of Supply Chain of Amul & Mother Dairy AmulDocumento7 páginasComparative Analysis of Supply Chain of Amul & Mother Dairy Amulshashank jaiswalAinda não há avaliações

- Amul KoolmilkDocumento78 páginasAmul Koolmilkpraveenjonty100% (1)

- Kieni Dairy Brief Company Profile 2023Documento2 páginasKieni Dairy Brief Company Profile 2023Solomon MainaAinda não há avaliações

- Industry Profile of MilmaDocumento23 páginasIndustry Profile of MilmaDavid Le71% (14)

- "Amul's Supply Chain Management": Report OnDocumento6 páginas"Amul's Supply Chain Management": Report Onabhisekh dasAinda não há avaliações

- Supply Chain Management Group 1: Ruchika PGDM (Ma) PGMA1954 Term-IVDocumento7 páginasSupply Chain Management Group 1: Ruchika PGDM (Ma) PGMA1954 Term-IVRuchikaAinda não há avaliações

- Full Notes From Salem Aavin Diary WebsitesDocumento9 páginasFull Notes From Salem Aavin Diary WebsitesyuvanabhuvanAinda não há avaliações

- Amul - The Taste of IndiaDocumento16 páginasAmul - The Taste of IndiaBhavAinda não há avaliações

- AmulDocumento22 páginasAmulJinal ShahAinda não há avaliações

- The Country, Who Have Converted Dairying From A Subsidiary Occupation Into An IndustryDocumento17 páginasThe Country, Who Have Converted Dairying From A Subsidiary Occupation Into An IndustryMohan ManuAinda não há avaliações

- SCM of AmulDocumento26 páginasSCM of AmulbharathkrishnaimuAinda não há avaliações

- AMUL Taste of IndiaDocumento44 páginasAMUL Taste of Indialaxmikant-sharma-8109Ainda não há avaliações

- Amul FinalDocumento92 páginasAmul FinalVivek KumarAinda não há avaliações

- Lotus Dairy PresentationDocumento15 páginasLotus Dairy PresentationcoolpiyushAinda não há avaliações

- AavinDocumento34 páginasAavinyogesh v50% (2)

- I Ntroductio N & HistoryDocumento40 páginasI Ntroductio N & Historyavneeshpimr14367% (3)

- Chapt: 1.1. Product Evolution: 1.1.1.mother Dairy MilkDocumento9 páginasChapt: 1.1. Product Evolution: 1.1.1.mother Dairy MilkNehaCruiseAinda não há avaliações

- Hapter: Histo Amulsec Tofsuc CessDocumento46 páginasHapter: Histo Amulsec Tofsuc CessAmreen kousarAinda não há avaliações

- The Birth of AmulDocumento12 páginasThe Birth of AmulSunny AroraAinda não há avaliações

- Amul InsightDocumento13 páginasAmul InsightRohit Kumar AnchaliyaAinda não há avaliações

- Bhavna Aggarwal OE 3 January, 2012Documento14 páginasBhavna Aggarwal OE 3 January, 2012Onam GargAinda não há avaliações

- Highlights From Budget 2012Documento2 páginasHighlights From Budget 2012Rahul SttudAinda não há avaliações

- Pranav Haridas Executive Trainee - Sales PPL 20th Feb 2014Documento1 páginaPranav Haridas Executive Trainee - Sales PPL 20th Feb 2014Rahul SttudAinda não há avaliações

- AFM Assignment - FebinDocumento3 páginasAFM Assignment - FebinRahul SttudAinda não há avaliações

- Consumer Behaviour: Amrita Vishwa Vidyapeetham Amrita School of BusinessDocumento4 páginasConsumer Behaviour: Amrita Vishwa Vidyapeetham Amrita School of BusinessRahul SttudAinda não há avaliações

- Stratergic Management Case Study On StarbucksDocumento30 páginasStratergic Management Case Study On StarbucksRahul Sttud50% (2)

- HTC StoresDocumento2 páginasHTC StoresRahul SttudAinda não há avaliações

- Training and DevelopmentDocumento25 páginasTraining and DevelopmentRahul SttudAinda não há avaliações

- Concor TeaDocumento35 páginasConcor TeaRahul SttudAinda não há avaliações

- AFM AssignmentDocumento12 páginasAFM AssignmentRahul SttudAinda não há avaliações

- Debt MGTDocumento21 páginasDebt MGTRahul SttudAinda não há avaliações

- Nike 1Documento17 páginasNike 1Rahul SttudAinda não há avaliações

- Nike IncDocumento16 páginasNike IncRahul SttudAinda não há avaliações

- Case Presentation 1Documento16 páginasCase Presentation 1Rahul SttudAinda não há avaliações

- Case Study On India Cements Limited & CSKDocumento24 páginasCase Study On India Cements Limited & CSKRahul SttudAinda não há avaliações

- Deflation Spiral Group 3Documento16 páginasDeflation Spiral Group 3Rahul SttudAinda não há avaliações

- Financial Data For Bata HydroDocumento1 páginaFinancial Data For Bata HydroRahul SttudAinda não há avaliações

- Zero Debt Companies in 2013Documento9 páginasZero Debt Companies in 2013Rahul SttudAinda não há avaliações

- Zero Debt Companies in 2013Documento9 páginasZero Debt Companies in 2013Rahul SttudAinda não há avaliações

- Cyber Warfare: Presented ByDocumento14 páginasCyber Warfare: Presented ByRahul Sttud100% (1)

- Case Study On India Cements Limited & CSKDocumento24 páginasCase Study On India Cements Limited & CSKRahul SttudAinda não há avaliações

- Sales and Distribution ManagementDocumento6 páginasSales and Distribution ManagementRahul SttudAinda não há avaliações

- Submitted By: Arun Sen Arjun Anakha Keerthi Ashok Hima Lavanya Suraj T FebinDocumento21 páginasSubmitted By: Arun Sen Arjun Anakha Keerthi Ashok Hima Lavanya Suraj T FebinRahul SttudAinda não há avaliações

- Case Study-Analysis of Cigarette Ads: Group No-4Documento16 páginasCase Study-Analysis of Cigarette Ads: Group No-4Rahul SttudAinda não há avaliações

- Questionnaire: How Long You Work For This OrganisationDocumento4 páginasQuestionnaire: How Long You Work For This OrganisationRahul SttudAinda não há avaliações

- MR Final PPT IntelDocumento21 páginasMR Final PPT IntelRahul SttudAinda não há avaliações

- Coca Cola Group 2Documento28 páginasCoca Cola Group 2Rahul SttudAinda não há avaliações

- Questionnaire On FeasibilityDocumento4 páginasQuestionnaire On FeasibilityRahul SttudAinda não há avaliações

- Business-To-Business: EtymologyDocumento2 páginasBusiness-To-Business: EtymologyRahul SttudAinda não há avaliações

- Salesforce Job Oriented Training: About UsDocumento2 páginasSalesforce Job Oriented Training: About UsInjumamAinda não há avaliações

- Brand Guidelines-Toyota - BrandStdsGd - 10 - 6 - 11Documento15 páginasBrand Guidelines-Toyota - BrandStdsGd - 10 - 6 - 11Panit SaksripanitAinda não há avaliações

- Fair Trade in IndiaDocumento13 páginasFair Trade in IndiaLekshmy Surendran100% (1)

- BRU Café Design BriefDocumento5 páginasBRU Café Design BriefPriyanka Ganguly100% (2)

- 15 Strength 7 ElevenDocumento3 páginas15 Strength 7 ElevenPavitra ThinakaranAinda não há avaliações

- Interview Questions (TFK)Documento3 páginasInterview Questions (TFK)tgjhrtjAinda não há avaliações

- Market Oriented Value Enhancement - MOVEDocumento60 páginasMarket Oriented Value Enhancement - MOVEBest Practices FoundationAinda não há avaliações

- FedEx ConsolidatedDocumento10 páginasFedEx ConsolidatedPriyadarshini TyagiAinda não há avaliações

- Brewer Chapter 2 Alt ProbDocumento6 páginasBrewer Chapter 2 Alt ProbAtif RehmanAinda não há avaliações

- Chapter 1 Introduction To Global Marketing: Warren J. KeeganDocumento21 páginasChapter 1 Introduction To Global Marketing: Warren J. Keeganrameshmba100% (2)

- Management Accounting CVP AnalysisDocumento29 páginasManagement Accounting CVP AnalysisJanani RamanandAinda não há avaliações

- Moondogs Final PaperDocumento38 páginasMoondogs Final Paperapi-273224146Ainda não há avaliações

- JMC324 Assignment - Final PDFDocumento5 páginasJMC324 Assignment - Final PDFPatience OmondiAinda não há avaliações

- Life Insurance Policy-A Case Study Project at Bajaj AllianzDocumento35 páginasLife Insurance Policy-A Case Study Project at Bajaj AllianzrupalAinda não há avaliações

- Output and CostsDocumento59 páginasOutput and CostsMohammad Raihanul HasanAinda não há avaliações

- Part 4Documento24 páginasPart 4Nibras Uddin NibirAinda não há avaliações

- Senior Sales Executive: Job DescriptionDocumento2 páginasSenior Sales Executive: Job DescriptionAspire SuccessAinda não há avaliações

- The Marketing Advantages of Strong BrandsDocumento26 páginasThe Marketing Advantages of Strong BrandsMadir MustaffaAinda não há avaliações

- Sales Promotion Proposal PPTDocumento31 páginasSales Promotion Proposal PPTArnold Gernadius LuttaAinda não há avaliações

- Group6 Newell Company SM2Documento1 páginaGroup6 Newell Company SM2Anoop SlathiaAinda não há avaliações

- My BusinessDocumento12 páginasMy BusinessAshley earl MalabanaAinda não há avaliações

- Chapter 1 and 2 Long EssayDocumento2 páginasChapter 1 and 2 Long EssayAtim TimAinda não há avaliações

- Project Report ON: "Event Management As A Strategic Marketing Tool - The Launch of A Product"Documento57 páginasProject Report ON: "Event Management As A Strategic Marketing Tool - The Launch of A Product"Madhurima MitraAinda não há avaliações

- Iim Kozhikode: An Innovative Mask (Biokare Masks) For Skin Care Conscious IndividualsDocumento12 páginasIim Kozhikode: An Innovative Mask (Biokare Masks) For Skin Care Conscious IndividualsNik SatAinda não há avaliações

- Chopra & Meindl - ForecastingDocumento22 páginasChopra & Meindl - ForecastingjayakumargjAinda não há avaliações

- Private School Business PlanDocumento16 páginasPrivate School Business Planmaranatha rallosAinda não há avaliações

- StraMa-PreFinals-with ANSWER KEYDocumento6 páginasStraMa-PreFinals-with ANSWER KEYFRANCESAinda não há avaliações

- Airbnb Strategy AnalysisDocumento11 páginasAirbnb Strategy AnalysisThư Mabư88% (8)

- Seafood Case StudyDocumento5 páginasSeafood Case StudyPrashant AggarwalAinda não há avaliações

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldNo EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldNota: 3.5 de 5 estrelas3.5/5 (5)

- Authentic Mexican: Regional Cooking from the Heart of MexicoNo EverandAuthentic Mexican: Regional Cooking from the Heart of MexicoAinda não há avaliações

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookNo EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookNota: 3.5 de 5 estrelas3.5/5 (2)

- Mostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyNo EverandMostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyNota: 4 de 5 estrelas4/5 (11)

- Pati's Mexican Table: The Secrets of Real Mexican Home CookingNo EverandPati's Mexican Table: The Secrets of Real Mexican Home CookingNota: 4 de 5 estrelas4/5 (9)

- The Obesity Code: Unlocking the Secrets of Weight LossNo EverandThe Obesity Code: Unlocking the Secrets of Weight LossNota: 4 de 5 estrelas4/5 (6)

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterNo EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterNota: 3.5 de 5 estrelas3.5/5 (487)

- Instant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayNo EverandInstant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayNota: 4 de 5 estrelas4/5 (4)

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingNo EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingNota: 4 de 5 estrelas4/5 (3)

- Chicano Eats: Recipes from My Mexican-American KitchenNo EverandChicano Eats: Recipes from My Mexican-American KitchenAinda não há avaliações

- Not That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsNo EverandNot That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsAinda não há avaliações

- Surprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideNo EverandSurprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideNota: 4 de 5 estrelas4/5 (6)

- Saved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayNo EverandSaved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayNota: 4 de 5 estrelas4/5 (10)

- Eating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyNo EverandEating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyNota: 4 de 5 estrelas4/5 (1)

- Binging with Babish: 100 Recipes Recreated from Your Favorite Movies and TV ShowsNo EverandBinging with Babish: 100 Recipes Recreated from Your Favorite Movies and TV ShowsAinda não há avaliações

- Poilâne: The Secrets of the World-Famous Bread BakeryNo EverandPoilâne: The Secrets of the World-Famous Bread BakeryAinda não há avaliações

- The Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingNo EverandThe Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingAinda não há avaliações

- Eat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthNo EverandEat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthNota: 2 de 5 estrelas2/5 (1)

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomNo EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomNota: 4 de 5 estrelas4/5 (1)

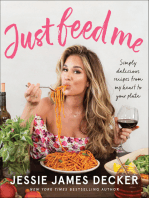

- Just Feed Me: Simply Delicious Recipes from My Heart to Your PlateNo EverandJust Feed Me: Simply Delicious Recipes from My Heart to Your PlateNota: 2 de 5 estrelas2/5 (1)

- Keto Friendly Recipes: Easy Keto For Busy PeopleNo EverandKeto Friendly Recipes: Easy Keto For Busy PeopleNota: 3.5 de 5 estrelas3.5/5 (2)

- The Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoNo EverandThe Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoAinda não há avaliações

- Heirloom Kitchen: Heritage Recipes & Family Stories from the Tables of Immigrant WomenNo EverandHeirloom Kitchen: Heritage Recipes & Family Stories from the Tables of Immigrant WomenNota: 4.5 de 5 estrelas4.5/5 (3)