Escolar Documentos

Profissional Documentos

Cultura Documentos

Above Ground Piping Wall Thickness Calculations

Enviado por

Farid TataDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Above Ground Piping Wall Thickness Calculations

Enviado por

Farid TataDireitos autorais:

Formatos disponíveis

PTT PUBLIC

COMPANY LIMITED

RATCHABURI WORLD COGENERATION

COMPANY LIMITED

GAS PIPELINE AND GAS METERING AND REGULATING STATION PROJECT

DOCUMENT NO.:

ED-P-1102.21-4012-001

REVISION: A

DOCUMENT TITLE:

ABOVE GROUND PIPING WALL THICKNESS CALCULATION

20-Oct-11

Issued for Approval

JJ

PP

NS

REV.

DATE

DESCRIPTION

BY

CHK

APP

Doc. No. ED-P-1102.21-4012-001

ABOVE GROUND PIPING WALL THICKNESS

CALCULATION

Rev.B

Page 3 of 10

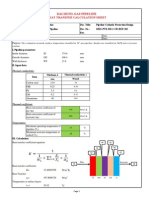

Calculation Cover Sheet

Project Title:

Client:

Calc Title:

Gas Pipeline and Gas Metering and Regulating Station Project

Ratchaburi World Cogeneration Company Limited

Above Ground Piping Wall Thickness Calculation

Calculation Objective

To determine the minimum required wall thickness for piping in the following ANSI Class 150,300,600

Services:

1) Natural gas metering station piping - Piping to ASME B31.8.

2) Vent piping at the MLV and scraper stations on the main transmission gas pipeline - Piping to ASME

B31.8.

Calculation Method

For piping to ASME B31.8 : Clause 841.1 is used

Assumptions

1) Pipe assumed to be straight section.

2) Manufacturing allowance for ASME B31.8 piping as shown on the calculation sheets.

3) Corrosion allowance is 1.6mm for specification D61, D31 , D11, L11 and G11

4) Pipe is assumed to be seamless for DN15 to DN300.

5) Pipe assumed to be ERW for pipe greater than DN350.

References

ASME B31.8

ASME B31.4

ASTM A106

ASTM A333

ASTM A53

API5L-B,X42,X65

Specification for piping material class

Conclusions

See specified schedules on calculation sheets

Piping Wall Thicknesses to ASME B31.8 (D61)

Design Clause:

ASME B31.8 : Clause 841.1

Design Variables

Pipe Material

API 5L Gr.X65

Design Pressure

8.618

Pipe Grade

Mpa

1,250 Psig

Mpa

65,009 Psig

10

Pipe SMYS

448.100

Location Class

Design Factor

0.4

Pipe Specification

16

Longitudinal Joint Factor

Temperature

49

Temp. Derating Factor

1.000

Corrosion Allowance

CA

1.60

deg C

mm.

0.063 inch.

Nominal

Diameter

Nominal

Diameter

Outer

Diameter

Outer

Diameter

Nominal

WT

Nominal

WT

(DN)

DN15

(inch.)

0.5

(mm.)

21.3

(inch.)

0.840

(inch.)

0.083

DN20

0.75

26.7

1.050

DN25

33.4

DN40

1.5

DN50

Selected

Schedule

Pipe

Material

(mm.)

2.113

Selected Wall

Thickness

(inch.)

XS

0.147

API 5L Gr.X65

Nominal

WT

(mm.)

3.73

0.088

2.241

XS

0.154

API 5L Gr.X65

3.91

1.315

0.095

2.403

XS

0.179

API 5L Gr.X65

4.55

48.3

1.902

0.109

2.761

XS

0.200

API 5L Gr.X65

5.08

60.3

2.374

0.120

3.050

XS

0.218

API 5L Gr.X65

5.54

DN80

88.9

3.500

0.147

3.737

XS

0.300

API 5L Gr.X65

7.62

DN100

114.3

4.500

0.171

4.348

XS

0.337

API 5L Gr.X65

8.56

DN150

168.3

6.626

0.222

5.646

XS

0.432

API 5L Gr.X65

10.97

DN200

219.1

8.626

0.270

6.867

XS

0.500

API 5L Gr.X65

12.70

DN250

10

273.1

10.75

0.321

8.165

80

0.593

API 5L Gr.X65

15.06

DN300

12

323.9

12.75

0.370

9.387

0.438

API 5L Gr.X65

11.13

DN350

14

355.6

14.00

0.400

10.149

80

0.750

API 5L Gr.X65

19.05

15.880

Piping Wall Thicknesses to ASME B31.8 (D61)

Design Clause:

ASME B31.8 : Clause 841.1

Design Variables

Pipe Material

API 5L Gr.B, A106 Gr.B

Design Pressure

8.618

Pipe Grade

Mpa

1,250 Psig

Mpa

35,007 Psig

Pipe SMYS

241.300

Location Class

Design Factor

0.4

Pipe Specification

16

Longitudinal Joint Factor

Temperature

49

Temp. Derating Factor

1.000

Corrosion Allowance

CA

1.60

deg C

mm.

0.063 inch.

Nominal

Diameter

Nominal

Diameter

Outer

Diameter

Outer

Diameter

Nominal

WT

Nominal

WT

(DN)

DN15

(inch.)

0.5

(mm.)

21.3

(inch.)

0.840

(inch.)

0.100

DN20

0.75

26.7

1.050

DN25

33.4

DN40

1.5

DN50

Selected

Schedule

(mm.)

2.553

Selected Wall

Thickness

(inch.)

XS

0.147

Nominal

WT

(mm.)

3.73

0.110

2.791

XS

0.154

3.91

1.315

0.122

3.091

XS

0.179

4.55

48.3

1.902

0.148

3.756

XS

0.200

5.08

60.3

2.374

0.169

4.292

XS

0.218

5.54

DN80

88.9

3.500

0.219

5.569

XS

0.300

7.62

DN100

114.3

4.500

0.264

6.703

XS

0.337

8.56

DN150

168.3

6.626

0.359

9.114

XS

0.432

10.97

DN200

219.1

8.626

0.448

11.381

XS

0.500

12.70

DN250

10

273.1

10.75

0.543

13.792

80

0.593

15.06

DN300

12

323.9

12.75

0.632

16.060

80

0.687

17.45

DN350

14

355.6

14.00

0.688

17.475

80

0.750

19.05

DN400

16

406.4

16.00

0.777

19.743

80

0.843

21.412

15.880

Doc. No. ED-P-1102.21-4012-001

ABOVE GROUND PIPING WALL THICKNESS

CALCULATION

Rev.A

Page 6 of 12

Pipeline Wall Thicknesses to ASME B31.8 (D61)

Design Clause:

15.880

15.880

15.880

ASME B31.8 : Clause 841.1

Design Variables

15.880

Design Pressure

8.618

Pipe Grade

Mpa

1,250 Psig

Mpa

65,009 Psig

15.880

15.880

10

Pipe SMYS

448.100

Location Class

Design Factor

Pipe Specification

Longitudinal Joint Factor

15.880

15.880

0.4

15.880

17

15.880

15.880

Temperature

49

15.880

deg C

15.880

Temp. Derating Factor

1.000

Manufacturing Tolerance

12.50

of Seclected wall thickness (as per Table 9 of API 5L)

15.880

Corrosion Allowance

CA

1.60

mm.

15.880

0.063 inch.

15.880

Nominal

Diameter

Nominal

Diameter

Outer

Diameter

Outer

Diameter

Nominal

WT

Nominal

WT

(DN)

DN250

(inch.)

10

(mm.)

273.1

(inch.)

10.75

(inch.)

0.362

DN300

12

323.9

12.75

DN350

14

355.6

DN400

16

DN450

DN500

Selected

Schedule

Pipe

Material

(mm.)

9.186

Selected Wall

Thickness

(inch.)

60

0.500

API 5L Gr.X65

Nominal

WT

(mm.)

12.70

0.416

10.560

60

0.562

API 5L Gr.X65

14.27

14.00

0.450

11.417

60

0.593

API 5L Gr.X65

15.06

406.4

16.00

0.504

12.791

40

0.500

API 5L Gr.X65

12.70

18

457.0

18.0

0.557

14.160

40

0.562

API 5L Gr.X65

14.27

20

508.0

20.00

0.612

15.539

40

0.594

API 5L Gr.X65

15.09

0.625

API 5L - X65

15.880

DN1100

44

1117.6

44.00

1.261

32.026

DN1150

46

1168.4

46.00

1.315

33.400

DN1200

48

1219.2

48.00

1.369

34.774

DN1300

52

1321

52.01

1.477

37.527

DN1400

56

1422

55.98

1.585

40.259

DN1500

60

1524

60.00

1.694

43.017

DN1600

64

1626

64.02

1.802

45.776

DN1700

68

1727

67.99

1.910

48.507

Piping Wall Thicknesses to ASME B31.8 (L61)

Design Clause:

15.880

15.880

15.880

ASME B31.8 : Clause 841.1

Design Variables

15.880

Pipe Material

A333 Gr.6

Design Pressure

8.618

Pipe Grade

Mpa

15.880

1,250 Psig

15.880

14

Pipe SMYS

241.300

Location Class

Design Factor

Pipe Specification

Longitudinal Joint Factor

Mpa

15.880

35,007 Psig

15.880

0.4

15.880

17

15.880

15.880

Temperature

49

Temp. Derating Factor

1.000

Corrosion Allowance

CA

1.60

15.880

deg C

15.880

mm.

15.880

0.063 inch.

15.880

Nominal

Diameter

Nominal

Diameter

Outer

Diameter

Outer

Diameter

Nominal

WT

Nominal

WT

(DN)

DN15

(inch.)

0.5

(mm.)

21.3

(inch.)

0.840

(inch.)

0.100

DN20

0.75

26.7

1.050

DN25

33.4

DN40

1.5

DN50

Selected

Schedule

(mm.)

2.553

Selected Wall

Thickness

(inch.)

80

0.147

Nominal

WT

(mm.)

3.73

0.110

2.791

80

0.154

3.91

1.315

0.122

3.091

80

0.179

4.55

48.3

1.902

0.148

3.756

80

0.200

5.08

60.3

2.374

0.169

4.292

80

0.218

5.54

DN80

88.9

3.500

0.219

5.569

80

0.300

7.62

DN100

114.3

4.500

0.264

6.703

80

0.337

8.56

DN150

168.3

6.626

0.359

9.114

80

0.432

10.97

DN200

8

10

219.1

8.626

0.448

11.381

80

273.1

10.75

0.543

13.792

80

0.500

0.593

12.70

DN250

DN300

12

323.9

12.75

0.632

16.060

80

0.687

17.45

DN350

14

355.6

14.00

0.688

17.475

80

0.750

19.05

0.625

15.880

15.06

Piping Wall Thicknesses to ASME B31.8 (D31)

.

Design Clause:

ASME B31.8 : Clause 841.1

Design Variables

Pipe Material

API 5L Gr.B, A106 Gr.B

Design Pressure

4.964

Pipe Grade

Mpa

720

psig

Mpa

35007

psi

0.063

inch.

Pipe SMYS

241.3

Location Class

Design Factor

0.4

Pipe Specification

4

1

Longitudinal Joint Factor E

49

Temperature

Temp. Derating Factor

1.000

Corrosion Allowance

CA

1.60

deg C

mm.

Nominal

Diameter

Nominal

Diameter

Outer

Diameter

Outer

Diameter

(DN)

DN15

(inch)

0.5

(mm)

21.3

(inch)

0.84

(inch)

0.085

(mm)

2.149

80

0.147

3.73

DN20

0.75

26.7

1.05

0.090

2.286

80

0.154

3.91

DN25

33.4

1.31

0.097

2.459

80

0.179

4.55

DN40

1.5

48.3

1.90

0.112

2.842

80

0.200

5.08

DN50

60.3

2.37

0.124

3.151

40

0.154

3.91

DN80

88.9

3.50

0.153

3.886

40

0.216

5.49

DN100

114.3

4.50

0.179

4.539

40

0.237

6.02

DN150

168.3

6.63

0.233

5.928

40

0.280

7.11

DN200

219.1

8.63

0.285

7.234

40

0.322

8.18

DN250

10

273.1

10.75

0.339

8.623

40

0.365

9.27

DN300

12

323.9

12.75

0.391

9.929

XS

0.500

12.70

DN350

14

355.6

14.00

0.423

10.744

XS

0.500

12.70

Nominal WT Nominal WT

Selected

Schedule

Selected

Nominal

Wall

WT (mm.)

thick.(Inch)

Piping Wall Thicknesses to ASME B31.8 (D11)

.

Design Clause:

ASME B31.8 : Clause 841.1

Design Variables

Pipe Material

API 5L Gr.B, A106 Gr.B

Design Pressure

1.896

Pipe Grade

Mpa

275

psig

Mpa

35007

psi

0.063

inch.

Pipe SMYS

241.3

Location Class

Design Factor

0.4

Pipe Specification

16

1

Longitudinal Joint Factor E

55

Temperature

Temp. Derating Factor

1.000

Corrosion Allowance

CA

1.60

deg C

mm.

Nominal

Diameter

Nominal

Diameter

Outer

Diameter

Outer

Diameter

(DN)

DN15

(inch)

0.5

(mm)

21.3

(inch)

0.84

(inch)

0.071

(mm)

1.810

XS

0.147

3.73

DN20

0.75

26.7

1.05

0.073

1.862

XS

0.154

3.91

DN25

33.4

1.31

0.076

1.928

XS

0.179

4.55

DN40

1.5

48.3

1.90

0.082

2.074

XS

0.200

5.08

DN50

60.3

2.37

0.086

2.192

XS

0.218

5.54

DN80

88.9

3.50

0.097

2.473

STD

0.216

5.49

DN100

114.3

4.50

0.107

2.723

STD

0.237

6.02

DN150

168.3

6.63

0.128

3.253

STD

0.280

7.11

DN200

219.1

8.63

0.148

3.752

STD

0.322

8.18

DN250

10

273.1

10.75

0.169

4.282

STD

0.365

9.27

DN300

12

323.9

12.75

0.188

4.781

STD

0.375

9.53

DN350

14

355.6

14.00

0.200

5.093

STD

0.375

9.53

Nominal WT Nominal WT

Selected

Schedule

Selected

Nominal

Wall

WT (mm.)

thick.(Inch)

Piping Wall Thicknesses to ASME B31.8 (L11)

.

Design Clause:

ASME B31.8 : Clause 841.1

Design Variables

Pipe Material

A333 Gr.6

Design Pressure

1.896

Pipe Grade

Mpa

275

psig

Mpa

35007

psi

14

Pipe SMYS

241.3

Location Class

Design Factor

0.4

Pipe Specification

9

1

Longitudinal Joint Factor E

65.5

Temperature

deg C

1.000

Manufacturing Tolerance %

12.50

of Seclected wall thickness (as per Table 9 of API 5L)

Corrosion Allowance

1.60

mm.

Temp. Derating Factor

CA

0.063

inch.

Nominal

Diameter

Nominal

Diameter

Outer

Diameter

Outer

Diameter

(DN)

DN15

(inch)

0.5

(mm)

21.3

(inch)

0.84

(inch)

0.080

(mm)

2.036

80

0.147

3.73

DN20

0.75

26.7

1.05

0.082

2.095

80

0.154

3.91

DN25

33.4

1.31

0.085

2.169

80

0.179

4.55

DN40

1.5

48.3

1.90

0.092

2.334

80

0.200

5.08

DN50

60.3

2.37

0.097

2.466

80

0.218

5.54

DN80

88.9

3.50

0.110

2.782

STD

0.216

5.49

DN100

114.3

4.50

0.121

3.063

STD

0.237

6.02

DN150

168.3

6.63

0.144

3.660

STD

0.280

7.11

DN200

219.1

8.63

0.166

4.221

STD

0.322

8.18

DN250

10

273.1

10.75

0.190

4.818

STD

0.365

9.27

DN300

12

323.9

12.75

0.212

5.379

STD

0.375

9.53

DN350

14

355.6

14.00

0.226

5.729

STD

0.375

9.53

Nominal WT Nominal WT

Selected

Schedule

Selected

Nominal

Wall

WT (mm.)

thick.(Inch)

Você também pode gostar

- Essar Pump Data 208810Documento9 páginasEssar Pump Data 208810Rakhee SinhaAinda não há avaliações

- Piping Material Specification Pipe Class: A1ADocumento8 páginasPiping Material Specification Pipe Class: A1AShreesh SharmaAinda não há avaliações

- Friction FactorDocumento6 páginasFriction Factorrajeshsapkota123Ainda não há avaliações

- Thermoplastic Ancillary Fittings of Nominal Sizes 110 and 160 For Below Ground Gravity Drainage and SewerageDocumento16 páginasThermoplastic Ancillary Fittings of Nominal Sizes 110 and 160 For Below Ground Gravity Drainage and SewerageAsira UdayakanthaAinda não há avaliações

- 2012 Comprehensive StudyDocumento13 páginas2012 Comprehensive Studymdalt9180Ainda não há avaliações

- Thrust Block DesignxlsDocumento8 páginasThrust Block DesignxlsRuben Dario Posada BAinda não há avaliações

- HIC Failure Investigation ReportDocumento25 páginasHIC Failure Investigation Reportravindra_jivaniAinda não há avaliações

- MR For Non Slamming Check ValveDocumento5 páginasMR For Non Slamming Check ValveAlvin SmithAinda não há avaliações

- Domestic Gas MetersDocumento3 páginasDomestic Gas MetersSrinivas VenkatramanAinda não há avaliações

- HPCL Mundra-Delhi P/L PRJ Mundra - Delhi 16/71: Piping Material Specification 6544-00-16-71-SP-02 Rev 0Documento7 páginasHPCL Mundra-Delhi P/L PRJ Mundra - Delhi 16/71: Piping Material Specification 6544-00-16-71-SP-02 Rev 0Gaurav TripathiAinda não há avaliações

- Is 15105 2002Documento62 páginasIs 15105 2002Srinivas100% (2)

- Project Study For Seismic Engineering For Chemical and Petrochemical PlantDocumento182 páginasProject Study For Seismic Engineering For Chemical and Petrochemical PlantchublackAinda não há avaliações

- PNGRB Regulations General Concepts Followed Up in CGDsDocumento59 páginasPNGRB Regulations General Concepts Followed Up in CGDsYogesh SainiAinda não há avaliações

- Calculating Flow Rate and Velocity Using Colebrook-White FormulaDocumento3 páginasCalculating Flow Rate and Velocity Using Colebrook-White FormulaSuryantoro Wono NarodoAinda não há avaliações

- BS 476-31.1 1983 PDFDocumento15 páginasBS 476-31.1 1983 PDFAdrian DorhatAinda não há avaliações

- 72957d3bb1659d7c77dbf6b6c550abeeDocumento41 páginas72957d3bb1659d7c77dbf6b6c550abeerasheedillikkalAinda não há avaliações

- IS 10987 (1992) - Above & Under Ground Tanks For SolventsDocumento17 páginasIS 10987 (1992) - Above & Under Ground Tanks For SolventsNishith100% (1)

- ASHRAE 62.1 2010+errata-2010Documento59 páginasASHRAE 62.1 2010+errata-2010Vishal Mohite100% (1)

- Gas Schematic: Boilers B2, B3, B4 Gas MeterDocumento5 páginasGas Schematic: Boilers B2, B3, B4 Gas MeterMario B. DaluAinda não há avaliações

- Estimation of Errors in Gas MetersDocumento59 páginasEstimation of Errors in Gas MetersMinhaj UllahAinda não há avaliações

- Basic Engineering & Site DataDocumento13 páginasBasic Engineering & Site DataBalasubramanianAinda não há avaliações

- Pipeline Surge Analysis DetailsDocumento1 páginaPipeline Surge Analysis DetailsGelorawan AditAinda não há avaliações

- Pipeline Heat Transfer CalculationDocumento2 páginasPipeline Heat Transfer CalculationErica MartinAinda não há avaliações

- Design partition plate for refinery distillation columnDocumento5 páginasDesign partition plate for refinery distillation columnpippo2378793Ainda não há avaliações

- Design Sheet As Per ASME 31.8 2012 For 12inch TeeDocumento3 páginasDesign Sheet As Per ASME 31.8 2012 For 12inch TeechethanAinda não há avaliações

- Natural Gas EmissionDocumento8 páginasNatural Gas EmissionvisutsiAinda não há avaliações

- Indian Standard: Code of Practice For Plastics Pipe Work For Potable Water SuppliesDocumento18 páginasIndian Standard: Code of Practice For Plastics Pipe Work For Potable Water SuppliesRosa JoseAinda não há avaliações

- Is 6044 1-2013Documento17 páginasIs 6044 1-2013tapas bera0% (1)

- PS HVAC Design Project Planning PDFDocumento2 páginasPS HVAC Design Project Planning PDFXozanAinda não há avaliações

- Civil Spec Part-ADocumento118 páginasCivil Spec Part-AAnonymous nwByj9LAinda não há avaliações

- Filter ManualDocumento53 páginasFilter ManualHazem DiabAinda não há avaliações

- AHRI - Guide Refrige ColourDocumento9 páginasAHRI - Guide Refrige Coloursenthilarasu5Ainda não há avaliações

- Is 6044 1 2000Documento13 páginasIs 6044 1 2000Subhradeb PramanikAinda não há avaliações

- Dev Energy - GASIFIERDocumento33 páginasDev Energy - GASIFIERvinay1999Ainda não há avaliações

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Documento1 páginaPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadAinda não há avaliações

- HAZOP Study for LNG Storage, Regasification and Dispensing FacilityDocumento185 páginasHAZOP Study for LNG Storage, Regasification and Dispensing Facilitytirth barot100% (2)

- Electirc Arc Welding e 04-02-2009Documento26 páginasElectirc Arc Welding e 04-02-2009RamziAhmedAinda não há avaliações

- Procedure For Welder QualificationDocumento28 páginasProcedure For Welder Qualificationjagannath100% (1)

- FF Plan Submission Guide-Rev3Documento7 páginasFF Plan Submission Guide-Rev3FaseeshAinda não há avaliações

- Ultrasonic Examination ReportDocumento2 páginasUltrasonic Examination ReportShyam Sundar GayenAinda não há avaliações

- Water Quality Regulations 2021 Edition 5Documento67 páginasWater Quality Regulations 2021 Edition 5Samer KhaledAinda não há avaliações

- Sand-Trap LouversDocumento5 páginasSand-Trap LouversAyaEzzAinda não há avaliações

- Piping Design CalculationDocumento1 páginaPiping Design CalculationAnkur Gupta100% (2)

- Preliminary tunnel fire ventilation calculations for XXX Tunnel projectDocumento6 páginasPreliminary tunnel fire ventilation calculations for XXX Tunnel projectakat zkyAinda não há avaliações

- Bs 29692Documento25 páginasBs 29692maguenhoyosAinda não há avaliações

- BS2655-8 1971Documento20 páginasBS2655-8 1971Liquor LiamAinda não há avaliações

- 3LPE 1d44a0 PDFDocumento33 páginas3LPE 1d44a0 PDFHotnCrispy CrispyAinda não há avaliações

- Composite Construction Works For CNG Station at Kovvur, West Godavari District, A.PDocumento209 páginasComposite Construction Works For CNG Station at Kovvur, West Godavari District, A.Pvinay1999Ainda não há avaliações

- ARI Standard 370-2001Documento17 páginasARI Standard 370-2001Niong DavidAinda não há avaliações

- ARI Standard 210 240Documento124 páginasARI Standard 210 240rag2604756437Ainda não há avaliações

- Conversion table for fuel types and their energy values in SCM of natural gasDocumento4 páginasConversion table for fuel types and their energy values in SCM of natural gasUJJWALAinda não há avaliações

- Calculate The Wall Thickness of Ammonia Storage TankDocumento4 páginasCalculate The Wall Thickness of Ammonia Storage Tankmamansetiawan87100% (1)

- Indian Standard On Fire Safety Equipments PDFDocumento31 páginasIndian Standard On Fire Safety Equipments PDFShubham RoyAinda não há avaliações

- Mahanagar Gas Annual Report 2016-17Documento172 páginasMahanagar Gas Annual Report 2016-17Prateek PatraAinda não há avaliações

- LTS 6 TableOfContents PDFDocumento29 páginasLTS 6 TableOfContents PDFTAHAAinda não há avaliações

- Above Ground Piping Wall Thickness CalculationsDocumento7 páginasAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- 094135-PI-MTO-001 - BOM For Piping & Valve - Rev.1Documento80 páginas094135-PI-MTO-001 - BOM For Piping & Valve - Rev.1thongAinda não há avaliações

- Liquid Pitch and Pitch Fume Piping SpecificationDocumento3 páginasLiquid Pitch and Pitch Fume Piping SpecificationAnonymous FoHj39G8CAinda não há avaliações

- Anderson Separator: Fuel Gas Skid General Arrangment - 250 PsigDocumento2 páginasAnderson Separator: Fuel Gas Skid General Arrangment - 250 PsigJhonny Rincones100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceNo EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceNota: 5 de 5 estrelas5/5 (1)

- Hydrogen Generation from Electrolysis Trade StudyDocumento17 páginasHydrogen Generation from Electrolysis Trade StudyFarid TataAinda não há avaliações

- IRENA Hydrogen From Renewable Power 2018 PDFDocumento52 páginasIRENA Hydrogen From Renewable Power 2018 PDFDilip100% (1)

- TN7-Galvanic Corrosion Rev Aug 2010Documento4 páginasTN7-Galvanic Corrosion Rev Aug 2010Poncho RmzAinda não há avaliações

- Stainless Steel Is A Promising Electrode Material For Anodes of Microbial Fuel CellsDocumento9 páginasStainless Steel Is A Promising Electrode Material For Anodes of Microbial Fuel CellsFarid TataAinda não há avaliações

- Non-Precious Electrodes For Practical Alkaline - Materials-12-01336Documento17 páginasNon-Precious Electrodes For Practical Alkaline - Materials-12-01336Farid TataAinda não há avaliações

- Naturel Resources H 2 El RCT RodesDocumento8 páginasNaturel Resources H 2 El RCT RodesFarid TataAinda não há avaliações

- Naturel Resources H 2 El RCT RodesDocumento8 páginasNaturel Resources H 2 El RCT RodesFarid TataAinda não há avaliações

- 2018 HP ElectrolyzerDocumento6 páginas2018 HP ElectrolyzerFarid TataAinda não há avaliações

- Stainless Steel Is A Promising Electrode Material For Anodes of Microbial Fuel CellsDocumento9 páginasStainless Steel Is A Promising Electrode Material For Anodes of Microbial Fuel CellsFarid TataAinda não há avaliações

- ME1112 Engineers Guide To Corrosion Causes Protection and ControlDocumento162 páginasME1112 Engineers Guide To Corrosion Causes Protection and ControlFarid TataAinda não há avaliações

- Hydrogen Compatibility Handbook - I S For Stainless Steels 017051Documento155 páginasHydrogen Compatibility Handbook - I S For Stainless Steels 017051Farid TataAinda não há avaliações

- A Systematic Study On Electrolytic Production of Hydrogen Gas by Using Graphite As ElectrodeDocumento5 páginasA Systematic Study On Electrolytic Production of Hydrogen Gas by Using Graphite As ElectrodeZahra AlifiaAinda não há avaliações

- ME1112 Engineers Guide To Corrosion Causes Protection and ControlDocumento162 páginasME1112 Engineers Guide To Corrosion Causes Protection and ControlFarid TataAinda não há avaliações

- Non-Precious Electrodes For Practical Alkaline - Materials-12-01336Documento17 páginasNon-Precious Electrodes For Practical Alkaline - Materials-12-01336Farid TataAinda não há avaliações

- Hydrogen Compatibility Handbook - I S For Stainless Steels 017051Documento155 páginasHydrogen Compatibility Handbook - I S For Stainless Steels 017051Farid TataAinda não há avaliações

- TN7-Galvanic Corrosion Rev Aug 2010Documento4 páginasTN7-Galvanic Corrosion Rev Aug 2010Poncho RmzAinda não há avaliações

- Bricolage Pour Tous - MenuiserieDocumento69 páginasBricolage Pour Tous - MenuiserieFarid TataAinda não há avaliações

- A Systematic Study On Electrolytic Production of Hydrogen Gas by Using Graphite As ElectrodeDocumento5 páginasA Systematic Study On Electrolytic Production of Hydrogen Gas by Using Graphite As ElectrodeZahra AlifiaAinda não há avaliações

- Progressing Cavity Pumps - Oil Well Production Artificial Lift 2nd Ed (2013) PDFDocumento227 páginasProgressing Cavity Pumps - Oil Well Production Artificial Lift 2nd Ed (2013) PDFFarid Tata100% (2)

- Petroleum Refining V.1 - Crude Oil, Petroleum Products, Process Flowsheets (1995) PDFDocumento492 páginasPetroleum Refining V.1 - Crude Oil, Petroleum Products, Process Flowsheets (1995) PDFFarid TataAinda não há avaliações

- Ansys Releasenotes KS278-RNDocumento21 páginasAnsys Releasenotes KS278-RNFarid TataAinda não há avaliações

- ANSYS Shell 63 HelpDocumento10 páginasANSYS Shell 63 HelpFarid TataAinda não há avaliações

- Woodcraft AlalloyDocumento11 páginasWoodcraft AlalloyAmal Al-abriAinda não há avaliações

- Nonlinear Buckling WebDocumento21 páginasNonlinear Buckling WebEl Youbi MohammedAinda não há avaliações

- Ansys Capabilities 16.0 PDFDocumento10 páginasAnsys Capabilities 16.0 PDFFarid TataAinda não há avaliações

- Chicago Pipe Stress Analysis Different Tools Different ResultsDocumento27 páginasChicago Pipe Stress Analysis Different Tools Different ResultsFarid Tata100% (1)

- A Dream Machine: Risk, in Full Bloom Can Pot Ease Addiction?Documento4 páginasA Dream Machine: Risk, in Full Bloom Can Pot Ease Addiction?Farid TataAinda não há avaliações

- PTFE Flat Gasket WS 7553 FD01 2009 04 enDocumento1 páginaPTFE Flat Gasket WS 7553 FD01 2009 04 enFarid TataAinda não há avaliações

- Woodcraft AlalloyDocumento11 páginasWoodcraft AlalloyAmal Al-abriAinda não há avaliações

- Failure Analysis of Thermowell Weldment CrackingDocumento12 páginasFailure Analysis of Thermowell Weldment CrackingFarid TataAinda não há avaliações

- 2023-RegisterBook Version 202212Documento95 páginas2023-RegisterBook Version 202212Moin AltafAinda não há avaliações

- CS5371 Theory of Computation: Lecture 1: Mathematics Review I (Basic Terminology)Documento23 páginasCS5371 Theory of Computation: Lecture 1: Mathematics Review I (Basic Terminology)Kamal WaliaAinda não há avaliações

- Ultra-Low-Power Wireless Systems - Energy-Efficient Radios For The Internet of Things PDFDocumento11 páginasUltra-Low-Power Wireless Systems - Energy-Efficient Radios For The Internet of Things PDFnhatvpAinda não há avaliações

- Total Quality Management (TQM) ToolsDocumento7 páginasTotal Quality Management (TQM) ToolsLaks_AsgAinda não há avaliações

- Lecture - 12 - Project EvaluationDocumento68 páginasLecture - 12 - Project EvaluationEngr. Md. Ashraful AlamAinda não há avaliações

- SousVide Supreme Chef - PCV-00100Documento2 páginasSousVide Supreme Chef - PCV-00100Nena OchoaAinda não há avaliações

- NeurophysiologyDocumento364 páginasNeurophysiologyTaimoor Ul HassanAinda não há avaliações

- ST RDDocumento2 páginasST RDBalteshwar SinghAinda não há avaliações

- Sejarah Unsur Kimia Bumi PDFDocumento449 páginasSejarah Unsur Kimia Bumi PDFJon WheelerAinda não há avaliações

- Blockchain Technology For Cloud Storage - A Systematic Literature ReviewDocumento33 páginasBlockchain Technology For Cloud Storage - A Systematic Literature ReviewNgocAinda não há avaliações

- Diebold ManualDocumento2 páginasDiebold Manualjoseperezlopes069Ainda não há avaliações

- Wilo Fire Fighting BrochureDocumento20 páginasWilo Fire Fighting BrochureAkhmad Darmaji DjamhuriAinda não há avaliações

- Liquefaction AnalysisDocumento16 páginasLiquefaction AnalysisKristi Engineering Services Pvt. Ltd.Ainda não há avaliações

- QST HamClockDocumento3 páginasQST HamClockCPC PHCAinda não há avaliações

- METAL CLUSTER COMPLEXESDocumento13 páginasMETAL CLUSTER COMPLEXESKeybateAinda não há avaliações

- Powtech Pt100 ManualDocumento112 páginasPowtech Pt100 ManualNisar AhmedAinda não há avaliações

- Green Building Store MVHR Brochure-File032484Documento9 páginasGreen Building Store MVHR Brochure-File032484Anthi ValavaniAinda não há avaliações

- Maths Comparison Summary ReportDocumento274 páginasMaths Comparison Summary ReportShahrukh MunirAinda não há avaliações

- Understand The Standardization Protocol For Iot Understand The Concepts of Web of Things. Understand The Concepts of Cloud of Things With Understand The Basic Concepts of Aspect OrientedDocumento2 páginasUnderstand The Standardization Protocol For Iot Understand The Concepts of Web of Things. Understand The Concepts of Cloud of Things With Understand The Basic Concepts of Aspect OrientedShanthi GanesanAinda não há avaliações

- Lee Et Al-1998-AIChE JournalDocumento10 páginasLee Et Al-1998-AIChE JournalNoUrElhOdaAinda não há avaliações

- 10.8 Special Polar GraphsDocumento16 páginas10.8 Special Polar GraphsIlias NihaAinda não há avaliações

- HistoryDocumento87 páginasHistoryMatthew MathewsAinda não há avaliações

- Leica CME ManualDocumento24 páginasLeica CME ManualMaria DapkeviciusAinda não há avaliações

- Brushless DC Motor Control Using PLCDocumento6 páginasBrushless DC Motor Control Using PLCvuluyen6688Ainda não há avaliações

- Laminar Flow Reactor ProblemDocumento6 páginasLaminar Flow Reactor ProblemAileen Banua Añonuevo100% (1)

- Final Physics GCSE-EOU AssessmentDocumento4 páginasFinal Physics GCSE-EOU AssessmentBehram QureshiAinda não há avaliações

- The Windows Process Journey v6 0 Aug2023 1691726739Documento53 páginasThe Windows Process Journey v6 0 Aug2023 1691726739blakboukiAinda não há avaliações

- Astm D2899Documento6 páginasAstm D2899btwilliAinda não há avaliações

- StudenttextDocumento15 páginasStudenttextapi-195130729Ainda não há avaliações

- Cessna 172Documento4 páginasCessna 172James DeatoAinda não há avaliações