Escolar Documentos

Profissional Documentos

Cultura Documentos

Dual-Fuel ARTEMIS CaseStud e

Enviado por

torjaniceDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Dual-Fuel ARTEMIS CaseStud e

Enviado por

torjaniceDireitos autorais:

Formatos disponíveis

www. hei nzmann.

com

ARTEMIS

www. hei nzmann. com/dual - f uel - management

Worldwide Case Studies

Dual Fuel

Control Solutions

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company PonPower BV

Country The Netherlands

Commissioning 2005

Engine

Type CAT 3516B

Manufacturing 1981

Speed 1500 rpm

Nominal output 1600 kW

el

Application Genset

Dual Fuel System Configuration

(ARTEMIS)

E-ELS 80

Knocking monitoring

Gas positioner controller

Background

An alternative to keep rentable operation of diesel

engines is the fuel flexibility. Dual fuel enables the

final customer to save money by purchasing the

fuel with best price in the market.

Dual Fuel Operation

Pilot fuel Diesel 550 kW

Gas fuel LNG 1050 kW

Output 35 % / 65 % 600 kW

el

Valve overlapping < 30 crank shaft

Gas Venturi 2 x GM 200

Gas pressure 85 mbar

Case Study:

Gas Mixer Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company DESA

Country Iran

Commissioning September 2011

Engine

Type D87

Manufacturing 2011

Speed 1500 rpm

Nominal output 1000 kW

el

Application Multiple

Dual Fuel System Configuration

(ARTEMIS V)

Misfire detection

Knocking monitoring

Magnetic valve controller for gas valves

Magnetic valve controller for diesel injectors

Background

In Iran the diesel price is more expensive as natural

gas. Also, diesel availability is sometimes limited.

Therefore, developing engines with fuel flexibility is

essential.

Dual Fuel Operation

Pilot fuel Diesel 500 kW

Gas fuel NG 500 kW

Output 50 % / 50 % 1000 kW

el

Valve overlapping 120 crank shaft

Gas properties 4 bar, 250 m/h

Case Study:

Gas Port Injection and Common Rail Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company Sanandaj Power Plant

Country Iran

Commissioning September 2011

Engine

Type Mirrlees K9 Major

Manufacturing 1981

Speed 500 rpm

Nominal output 3300 kW

el

Application Genset (base load)

Dual Fuel System Configuration

(ARTEMIS V)

Misfire detection

Knocking monitoring

Magnetic valve controller

Diesel digital controller

Load share module

Background

Sanandaj Power Plant provides 30 MW electricity

to the city with British diesel gensets. However,

the diesel price is more than twice as expensive

as natural gas. Given the high engine utilisation,

the payback period after dual fuel retrofitting the

engine to dual fuel, is in a couple of months.

Dual Fuel Operation

Pilot fuel Diesel 850 kW

Gas fuel NG 1550 kW

Output 35 % / 65 % 2400 kW

el

Valve overlapping 110 crank shaft

Gas injection valve MEGASOL 200

Gas properties 4 bar, 700 m/h

Case Study:

Gas Port Injection and Electrical Diesel Governor Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company Hagalis AG

Country Germany

Commissioning December 2011

Engine

Type MAN D2842 V12

Manufacturing 2007

Speed 1500 rpm

Nominal output 400 kW

el

Application Genset (base load)

Dual Fuel System Configuration

(ARTEMIS III)

Knocking monitoring

Gas positioner controller

Background

The subventions for the palm oil have been

eliminated by the German government. The

operation diesel engines driven with palm oil are

therefore not rentable anymore. An alternative to

keep rentable operation of the generator sets is to

use natural gas or biogas. As a pilot project, one

diesel engine has been successfully converted to

dual fuel.

Dual Fuel Operation

Pilot fuel Diesel 120 kW

Gas fuel H-NG 280 kW

Output 30 % / 70 % 400 kW

el

Valve overlapping approx. 30 crank shaft

Gas mixer 2 x GM 140

Gas properties 50 mbar, 75 m/h

Case Study:

Gas Mixer Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company Kerman Cement Inc.

Country Iran

Commissioning 2007

Engine

Type Mirrlees K8 Major

Manufacturing 1980

Speed 600 rpm

Nominal output 3000 kW

el

Application Genset (base load)

Dual Fuel System Configuration

(ARTEMIS V)

Knocking monitoring

Magnetic valve controller

Diesel digital controller

Load share module

Background

The power plant of Kerman Cement provides

electricity to the factory processes. However, the

diesel price is twice expensive as natural gas. Given

the high engine utilisation, the payback period after

dual fuel retrofitting is in a fraction of a year.

Dual Fuel Operation

Pilot fuel Diesel 500 kW

Gas fuel NG 1900 kW

Output 20 % / 80 % 2400 kW

el

Valve overlapping 120 crank shaft

Gas injection valve MEGASOL 200

Gas properties 3 bar, 600 m/h

Case Study:

Gas Port Injection and Electrical Diesel Actuator Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company Aluminium Pars Inc.

Country Iran

Commissioning 2008

Engine

Type 3 x Mirrlees K9 Major

Manufacturing 1980

Speed 500 rpm

Nominal output 3300 kW

el

Application Genset (peak saving)

Dual Fuel System Configuration

(ARTEMIS V)

Knocking monitoring

Magnetic valve controller 01

Diesel digital controller PRIAMOS

Load share module

Background

The power plant of Aluminium Pars provides

electricity to the factory processes. Here the diesel

price is more expensive than natural gas. Given the

engine utilisation, the payback period after dual fuel

retrofitting the engine with a dual fuel system is

achieved in a couple of months.

Dual Fuel Operation

Pilot fuel Diesel 726 kW

Gas fuel NG 1320 kW

Output 33 % / 66 % 2200 kW

el

Valve overlapping 120 crank shaft

Gas injection valve MEGASOL 425

Gas properties 3 bar, 600 m/h

Case Study:

Gas Port Injection and Electrical Diesel Actuator Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company Onsite Power Pvt. Ltd.

Country India

Commissioning April 2010

Engine

Type GREAVES TBD4 V12

Manufacturing 2007

Speed 1500 rpm

Nominal output 500 kW

el

Application Genset (base load)

Dual Fuel System Configuration

(ARTEMIS III)

Gas mixer 100

LES GT 25

Background

New natural gas pipe lines have been installed in

some regions of India. Given the low gas price, the

retrofitting of fast engines is attractive.

Dual Fuel Operation

Pilot fuel Diesel 120 kW

Gas fuel H-NG 280 kW

Output 30 % / 70 % 400 kW

el

Valve overlapping < 30 crank shaft

Gas mixer 2 x GM 100

Gas properties 50 mbar

Case Study:

Gas Mixer Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company Maschinenbau

Halberstadt GmbH

Country Germany

Commissioning 1991-1999

Engine

Type 12 x VDG 48/ 42

Manufacturing 1991-1999

Speed 500 rpm

Nominal output 2823 kW

el

Application Genset (base load)

Dual Fuel System Configuration

(ARTEMIS I)

PRIAMOS

StG 64 diesel

StG 10 Ruhrgas

Background

The engine operation with gas minimises the

electricity generation costs. The engine heat is used

as well.

Dual Fuel Operation

Pilot fuel Diesel 2681 kW

Gas fuel H-NG 141 kW

Output 5 % / 95 % 2823 kW

el

Valve overlapping < 100 crank shaft

Gas injection valve MEGASOL 200

Gas properties 4 bar

Case Study:

Gas Port Injection Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company Wrtsil NSD

Country Cairo, Egypt

Commissioning July 1998

Engine

Type 15 x 16 V CR 26GD

Manufacturing 2000-2005

Speed 750 rpm

Nominal output 2300 kW

el

Application Genset (CHP)

Dual Fuel System Configuration

(ARTEMIS I/II)

Actuator StG 16 + StG 6

DC 16.1-04

LMG

Background

In this plant the engines are running with natural

gas to generate electric power for the power station.

Other engines are located in a sewage treatment

plant and running with sewage gas.

Case Study:

Gas Mixer and Electronic Diesel Governor Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company Anglo Belgian Corp. nv

Country Belgium, Brugge

Commissioning 1995

Engine

Type 8 x ABC 6 DXD

Manufacturing 1991-1999

Speed 750 rpm

Nominal output 550 kW

el

Application Genset (CHP)

Location De Reese

Dual Fuel System Configuration

(ARTEMIS I/II)

StG16

DC 04 (PRIAMOS)

Background

Given the low gas price, the retrofitting of fast

engines is attractive. The gen-set is running with

biogas and is connected to the mains and can work

also in island mode. Other application is marine

propulsion.

Dual Fuel Operation

Pilot fuel Diesel 120 kW

Gas fuel Biogas 280 kW

Output 30 % / 70 % 400 kW

el

Valve overlapping < 10 crank shaft

Gas Misher GM 300

Gas properties 50 mbar

Case Study:

Gas Mixer Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company Isfahan Cement Co.

Country Iran

Commissioning October 2011

Engine

Type MAN 8 L52/ 55 ADG

Manufacturing 1980

Speed 428 rpm

Nominal output 3200 kW

el

Application Genset (base load)

Dual Fuel System Configuration

(ARTEMIS V)

Misfire detection

Knocking monitoring

Magnetic valve controller

Diesel digital controller

Load share module

Background

The diesel availability in the region is limited.

Trucks must deliver diesel daily, transporting it long

distances. Nevertheless a pipeline is installed to

the Isfahan Cement factory ovens (for the cement

production process); gas supply can also be used

for the power generation.

Dual Fuel Operation

Pilot fuel Diesel 650 kW

Gas fuel NG 1550 kW

Output 30 % / 70 % 2200 kW

el

Valve overlapping 115 crank shaft

Gas injection valve MEGASOL 200

Gas properties 4 bar, 700 m/h

Case Study:

Gas Port Injection and Electrical Diesel Actuator Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company Jinan Diesel Engine

Co., Ltd.

Country China

Commissioning 2011

Engine

Type 6L190

Speed 1000 rpm

Nominal output 400 kW

el

Application propulsion

Dual Fuel System Configuration

(ARTEMIS)

DC 6 + StG 6-02, diesel control

DC 6 + StG 2040, gas control

Dual fuel control panel with the PLC engine

monitor system

Background

Nowadays the atmospheric pollution of the city

beside Changjiang river is turning worse and

worse. The price of diesel is turning higher and

higher as well. The government and ship owners

are taking action and want to use the dual fuel

engine to minimise the environmental problems.

HEINZMANN has implemented the first dual

fuel propulsion application for the inland river

in China. The government will install gas supply

stations along the Changjiang River to support this

application.

Case Study:

Gas Mixer Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company Dongying ShengLi

Country China

Commissioning 2011

Engine

Type 12V190

Speed 1000 rpm

Nominal output 800 kW

el

Application Oil rig

Dual Fuel System Configuration

(ARTEMIS)

DC 6 + StG 2040 DP, diesel control

DC 6 + StG 6-02, gas control

Background

The diesel price is higher and higher. With the dual

fuel system our costumers can save some money.

Case Study:

Gas Mixer Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company Ningbo Zhongce

Country China

Commissioning 2011

Engine

Type 6L300

Speed 500 rpm

Nominal output 1100 kW

el

Application Generator set

Dual Fuel System Configuration

(ARTEMIS)

MVC 03 + MEGASOL 200, gas control

KC 01, knocking control

Background

Zhongce possess about 100 gensets in Nigeria.

The purpose is to modify the engines to dual fuel

to save diesel fuel. HEINZMANN China has tested

one engine in 2011. In the test bench higher diesel

replacement are being investigated.

Case Study:

Gas Port Injection Technology

ARTEMIS Dual Fuel Control Solutions

Jrg Hess

Gas Engine Management & Dual Fuel Solutions

Heinzmann GmbH & Co. KG

Am Haselbach 1

79677 Schnau, Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www. hei nzmann. com

Customer

Company LVNeng Diesel

Country China

Commissioning 2011

Engine

Type WP6C122-15

Speed 1500 rpm

Nominal output 90 kW

el

Application Marine genset

Dual Fuel System Configuration

(ARTEMIS)

DC 6 + StG 2010, gas control

GM 100, gas mixer

Background

This engine is used as a genset on the Changjiang

River ship dual fuel project. Each ship has two

6L190 dual fuel propulsion engines and two

WR6C122-15 dual fuel genset engines.

Case Study:

Gas Mixer Technology

C

D

_

D

u

a

l

F

u

e

l

_

0

0

1

_

1

2

_

0

6

_

e

_

1

_

2

0

1

2

Manufacturing plants

Subsidiaries

Dealers and agents

Am Haselbach 1

D-79677 Schnau

Germany

Phone: +49 7673 8208 - 0

Fax: +49 7673 8208 - 188

Email: info@heinzmann.de

www.heinzmann.com

HEINZMANN - clean engine technology

www. hei nzmann. com

Worldwide Case Studies

Você também pode gostar

- WartsilaDocumento55 páginasWartsiladavinci engineeringAinda não há avaliações

- Project Guide C25 33 Propulsion EnginesDocumento138 páginasProject Guide C25 33 Propulsion EnginesJose RamonAinda não há avaliações

- ERS M22 PC4 FerryDocumento2 páginasERS M22 PC4 FerryouakgoodAinda não há avaliações

- Technical Specification: (Engine, Alternator, Engine Auxiliaries)Documento30 páginasTechnical Specification: (Engine, Alternator, Engine Auxiliaries)Shihab AhmedAinda não há avaliações

- Hydac-Components and Systems For Agricultural MachineryDocumento36 páginasHydac-Components and Systems For Agricultural MachineryLuciano MathierAinda não há avaliações

- 2011 Engine Tech Review MWMDocumento2 páginas2011 Engine Tech Review MWMGrietekeAinda não há avaliações

- Aksa Global Rental Power CatalogueDocumento24 páginasAksa Global Rental Power CatalogueThato Merapelo PuleAinda não há avaliações

- Green Power International (P) LTD.: Selection Chart For Natural Gas Based GensetsDocumento1 páginaGreen Power International (P) LTD.: Selection Chart For Natural Gas Based GensetssanitermAinda não há avaliações

- Catalogopistones PDFDocumento91 páginasCatalogopistones PDFrenatoAinda não há avaliações

- Rolls Royce TUG LNG - 2012Documento72 páginasRolls Royce TUG LNG - 2012Maurizio BernasconiAinda não há avaliações

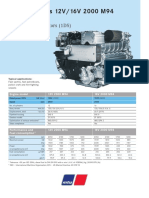

- Mtu 12v&16v2000m93Documento2 páginasMtu 12v&16v2000m93vaibhavdabhade5Ainda não há avaliações

- محطات إنتاج الطاقة الكهربائية في السودانDocumento6 páginasمحطات إنتاج الطاقة الكهربائية في السودانTruuth SeekerAinda não há avaliações

- MarelliMotori A4C 180 L4Documento48 páginasMarelliMotori A4C 180 L4superspif100% (1)

- 190 e Cr302 en Servomotors-For-steam-turbinesDocumento10 páginas190 e Cr302 en Servomotors-For-steam-turbinesscribdkhatnAinda não há avaliações

- GOLTENS InService2014Documento20 páginasGOLTENS InService2014Alchemist_JVCAinda não há avaliações

- 14cyl For RTA96CDocumento2 páginas14cyl For RTA96Cmarko4096Ainda não há avaliações

- ID FLX Lite 1 3 OperatorGuide ComapDocumento19 páginasID FLX Lite 1 3 OperatorGuide ComapMahesh MirajkarAinda não há avaliações

- Cogeneration Unit Technical DataDocumento7 páginasCogeneration Unit Technical DataElias RizkAinda não há avaliações

- Mtu 12v&16v2000m94Documento2 páginasMtu 12v&16v2000m94ozakyus50% (2)

- LG Chiller Reference SitesDocumento21 páginasLG Chiller Reference Sitesalexandra sunAinda não há avaliações

- ASCO Miniature Valve Products (AV017R5)Documento96 páginasASCO Miniature Valve Products (AV017R5)vasudeva yasasAinda não há avaliações

- Corporate Profile: GasgenDocumento44 páginasCorporate Profile: GasgenAhmad SolichinAinda não há avaliações

- DB S60 1DS GB 3231171 112010 PDFDocumento2 páginasDB S60 1DS GB 3231171 112010 PDFjhonmarcAinda não há avaliações

- For C & I and Mining Applications EPA Tier 4 Certification: Diesel Engine 12V 1600Documento2 páginasFor C & I and Mining Applications EPA Tier 4 Certification: Diesel Engine 12V 1600Megat Rambai SrAinda não há avaliações

- Scansteering CatDocumento16 páginasScansteering CatosamaAinda não há avaliações

- Lec 3 Hydrolic Actuators and MotorsDocumento68 páginasLec 3 Hydrolic Actuators and MotorsSayed ShafeiAinda não há avaliações

- LV Generator Catalogue - Standard Marine EN LR 201205 PDFDocumento30 páginasLV Generator Catalogue - Standard Marine EN LR 201205 PDFPutra Kusuma HarditoAinda não há avaliações

- 12V 4000 M73/M73L Diesel Engines: For Fast Vessels With High Load Factors (1B)Documento3 páginas12V 4000 M73/M73L Diesel Engines: For Fast Vessels With High Load Factors (1B)derfgthAinda não há avaliações

- Lucas Alternator CatalogueDocumento189 páginasLucas Alternator CatalogueNeftali RosalesAinda não há avaliações

- ZF Minicommand User Manual PDFDocumento30 páginasZF Minicommand User Manual PDFAlexander Varela100% (1)

- Safety Concept - Dual Fuel EnginesDocumento100 páginasSafety Concept - Dual Fuel EnginesLucas Manuel CamueiraAinda não há avaliações

- Alternator Dynamo Components 2023 2025Documento564 páginasAlternator Dynamo Components 2023 2025Асен ВасилевAinda não há avaliações

- Himsen H46 60VDocumento4 páginasHimsen H46 60VairtupasAinda não há avaliações

- OE Brochure NPP 2 14 Lay ESDocumento12 páginasOE Brochure NPP 2 14 Lay ESguichen wangAinda não há avaliações

- Faraz Ahmed C.VDocumento3 páginasFaraz Ahmed C.Vfaraz24Ainda não há avaliações

- MBH Conversion References - Deutz-MWM TBD 6M 628Documento1 páginaMBH Conversion References - Deutz-MWM TBD 6M 628Marbun Benny100% (1)

- World of Industrial Applications Brochure 2011-02 CPCEIDAPDocumento44 páginasWorld of Industrial Applications Brochure 2011-02 CPCEIDAPMarcelo Palacios SantanaAinda não há avaliações

- Bergen Engines Roadshow Poland 2013Documento44 páginasBergen Engines Roadshow Poland 2013Sylvek91Ainda não há avaliações

- Zelda Welding Machine CatalogDocumento72 páginasZelda Welding Machine CatalogJuan Manuel Suarez OreAinda não há avaliações

- JCB Broadcrown Generator BrochureDocumento28 páginasJCB Broadcrown Generator BrochureRachmat ZakariailyasAinda não há avaliações

- AVK MTU Diesel Generators 715-3300kVADocumento2 páginasAVK MTU Diesel Generators 715-3300kVA5ofyAinda não há avaliações

- PagesDocumento72 páginasPagesAngel NajarroAinda não há avaliações

- Belt-Coupled Motor Generator SetDocumento173 páginasBelt-Coupled Motor Generator Setcustro_mohaleAinda não há avaliações

- MTU Datasheet s4000px3 Constant SpeedDocumento2 páginasMTU Datasheet s4000px3 Constant SpeedKrish100% (1)

- KTA19 G4 Generator Specsheet PDFDocumento2 páginasKTA19 G4 Generator Specsheet PDFstrato1977Ainda não há avaliações

- PGW32Documento104 páginasPGW32Hasan Syaiful IAinda não há avaliações

- Axial-Fan Transformers enDocumento36 páginasAxial-Fan Transformers enEko SusantoAinda não há avaliações

- Propulsion Solutions For Large High Speed VesselsDocumento29 páginasPropulsion Solutions For Large High Speed VesselshaujesAinda não há avaliações

- Brousre HyundaiDocumento27 páginasBrousre HyundaiKristyadi Daripada PaidiAinda não há avaliações

- Compact CHP Units 40-400 kW for Efficient EnergyDocumento6 páginasCompact CHP Units 40-400 kW for Efficient EnergysilvercristiAinda não há avaliações

- Wip May2013Documento56 páginasWip May2013Orlando BarriosAinda não há avaliações

- Bergen KV G42 enDocumento2 páginasBergen KV G42 ennanocycleAinda não há avaliações

- R.W. Fernstrum & CompanyDocumento7 páginasR.W. Fernstrum & CompanystrtsAinda não há avaliações

- Catalogo Genalt English EmailDocumento33 páginasCatalogo Genalt English EmailKhaleel Qatanani100% (1)

- CMD Diesel EnginesDocumento27 páginasCMD Diesel EnginesceeyesmeAinda não há avaliações

- Installation Instructions: WarningDocumento35 páginasInstallation Instructions: WarningwcuevasmAinda não há avaliações

- 2-Jan Kollmus-Siemens Carbon Capture Technologies - Successful Technology Development From Pilot Scale To Application in Mega Plant ScaleDocumento39 páginas2-Jan Kollmus-Siemens Carbon Capture Technologies - Successful Technology Development From Pilot Scale To Application in Mega Plant ScaleIsmar AdrianAinda não há avaliações

- MWM Company PresentationDocumento27 páginasMWM Company PresentationsdiamanAinda não há avaliações

- Sgt-600 GT Mechdrive enDocumento4 páginasSgt-600 GT Mechdrive enRoozbeh PAinda não há avaliações

- SGT 750Documento24 páginasSGT 750andmar2011Ainda não há avaliações

- Qsk60 - Service ScheduleDocumento1 páginaQsk60 - Service ScheduletorjaniceAinda não há avaliações

- Engine Interface ModuleDocumento3 páginasEngine Interface Moduletorjanice89% (46)

- Battery Cross RefDocumento130 páginasBattery Cross ReftorjaniceAinda não há avaliações

- Perkins Light SetDocumento1 páginaPerkins Light SettorjaniceAinda não há avaliações

- 1300 Series PerkinsDocumento1 página1300 Series Perkinstorjanice80% (5)

- MEP UNIT Service ScheduleDocumento2 páginasMEP UNIT Service ScheduletorjaniceAinda não há avaliações

- QuickGuide MicrometersDocumento4 páginasQuickGuide MicrometerstorjaniceAinda não há avaliações

- SopananrithamDocumento4 páginasSopananrithamtorjaniceAinda não há avaliações

- Vcaliper How ToDocumento2 páginasVcaliper How TotorjaniceAinda não há avaliações

- Amperage ChartDocumento1 páginaAmperage ChartWage KarsanaAinda não há avaliações

- Sdmo Telys 1 Control Panel ManualDocumento40 páginasSdmo Telys 1 Control Panel ManualAlberto Celleri Bravo86% (28)

- Laser Printer: Reliable, High-Quality Black and White Laser OutputDocumento2 páginasLaser Printer: Reliable, High-Quality Black and White Laser OutputtorjaniceAinda não há avaliações

- CAN DictionaryDocumento2 páginasCAN DictionarytorjaniceAinda não há avaliações

- VolvoDocumento2 páginasVolvotorjaniceAinda não há avaliações

- Fuel - Consumption - Chart - Standard Diesel EngineDocumento1 páginaFuel - Consumption - Chart - Standard Diesel EngineCaptIsqanAinda não há avaliações

- Remote AnnunciatorsDocumento2 páginasRemote AnnunciatorstorjaniceAinda não há avaliações

- MEP UNIT 250 Service ScheduleDocumento3 páginasMEP UNIT 250 Service ScheduletorjaniceAinda não há avaliações

- Exide Fitment Guide2010Documento72 páginasExide Fitment Guide2010torjaniceAinda não há avaliações

- SwitchgearDocumento32 páginasSwitchgearistenicAinda não há avaliações

- Power Generation Service ChecklistDocumento1 páginaPower Generation Service ChecklisttorjaniceAinda não há avaliações

- Automatic Transfer SwitchesDocumento4 páginasAutomatic Transfer Switchestorjanice100% (1)

- EIG H LV SwitchgearDocumento28 páginasEIG H LV SwitchgeartorjaniceAinda não há avaliações

- 1000 Series PerkinsDocumento1 página1000 Series PerkinstorjaniceAinda não há avaliações

- VolvoDocumento2 páginasVolvotorjaniceAinda não há avaliações

- 1000 Series PerkinsDocumento1 página1000 Series PerkinstorjaniceAinda não há avaliações

- Anuroop Switchgear Company Price ListDocumento2 páginasAnuroop Switchgear Company Price ListtorjaniceAinda não há avaliações

- ESP Pricelist May 2013Documento80 páginasESP Pricelist May 2013torjaniceAinda não há avaliações

- ABB SwitchDocumento6 páginasABB SwitchtorjaniceAinda não há avaliações

- Amperage ChartDocumento1 páginaAmperage ChartWage KarsanaAinda não há avaliações

- 06s Rr310303 Thermal Engineering IIDocumento9 páginas06s Rr310303 Thermal Engineering IIandhracollegesAinda não há avaliações

- Marine Engines and PropulsionDocumento192 páginasMarine Engines and PropulsionAmba Shanker100% (1)

- NSP16NDocumento825 páginasNSP16Nalex100% (1)

- Carburetor Instruction Sheet MODELS 4165 & 4175: Read This FirstDocumento6 páginasCarburetor Instruction Sheet MODELS 4165 & 4175: Read This FirstAlfonso JaureguiAinda não há avaliações

- Piaggio X7 EVO 125 I.E. (En)Documento333 páginasPiaggio X7 EVO 125 I.E. (En)Manualles50% (2)

- ReFlex Wiring Diagram - 02-10-2021Documento5 páginasReFlex Wiring Diagram - 02-10-2021sachtdeAinda não há avaliações

- ET 796 Gas Turbine Jet Engine Gunt 261 PDF 1 en GBDocumento3 páginasET 796 Gas Turbine Jet Engine Gunt 261 PDF 1 en GBAli AbushhiwaAinda não há avaliações

- JAC - Hfc4da12cDocumento104 páginasJAC - Hfc4da12cLaibern JppdAinda não há avaliações

- Piston Motor (Hydrostatic) : SpecificationsDocumento4 páginasPiston Motor (Hydrostatic) : SpecificationsRajan MullappillyAinda não há avaliações

- G-35 SD Parts Manual PDFDocumento6 páginasG-35 SD Parts Manual PDFyuanAinda não há avaliações

- 3 Axis Modern TrailerDocumento24 páginas3 Axis Modern TrailerRATHANAinda não há avaliações

- 825 Series Product Overview & General DataDocumento30 páginas825 Series Product Overview & General Datamauricio cañonAinda não há avaliações

- Lubrication System: To IndexDocumento13 páginasLubrication System: To IndexzeroAinda não há avaliações

- GP1200R Service ManualDocumento245 páginasGP1200R Service ManualCZJake100% (4)

- 2008 Ford F-150 5.4L Electric Wiring DiagramsDocumento61 páginas2008 Ford F-150 5.4L Electric Wiring Diagramskamaleon dorado100% (2)

- enDocumento2 páginasenZobeida RizoAinda não há avaliações

- Yamaha 4AC 5C ManualDocumento54 páginasYamaha 4AC 5C ManualLionel le Moal50% (2)

- Holsetpartnumbers 2008Documento1 páginaHolsetpartnumbers 2008Marielis ContrerasAinda não há avaliações

- Something ConfidentialDocumento107 páginasSomething ConfidentialBhagyesh DokeAinda não há avaliações

- MGS2500B - Brochures (Standby Duty)Documento4 páginasMGS2500B - Brochures (Standby Duty)outfit49 besteverAinda não há avaliações

- Komatsu - Program Ecm Tidak SesuaiDocumento79 páginasKomatsu - Program Ecm Tidak Sesuaihendra mmAinda não há avaliações

- 1993 Engines Eurovan - 2.5L 5-CylinderDocumento20 páginas1993 Engines Eurovan - 2.5L 5-Cylinderfrancesco pavanAinda não há avaliações

- PowerKit 6M26 Series Diesel Engine SpecsDocumento2 páginasPowerKit 6M26 Series Diesel Engine SpecsDuc Thao VuAinda não há avaliações

- Glossary of Sae and ToyotaDocumento3 páginasGlossary of Sae and Toyotamike chenAinda não há avaliações

- Subaru Select MonitorDocumento6 páginasSubaru Select MonitorCristian Yarasca Cayro100% (1)

- Induction Motors Stiff ShaftDocumento2 páginasInduction Motors Stiff ShaftJuan Jose AraqueAinda não há avaliações

- Iseki Th4295 4335 4365 Parts ManualDocumento20 páginasIseki Th4295 4335 4365 Parts Manualscott100% (54)

- m102 Service ManualDocumento304 páginasm102 Service ManualAlejandroPáramoFandiño60% (5)

- TCS-PTG Savings With Extra PowerDocumento12 páginasTCS-PTG Savings With Extra Powermieszko9888100% (1)

- Terex AWP Fuel Consumption Data for Diesel and Spark Ignition EnginesDocumento2 páginasTerex AWP Fuel Consumption Data for Diesel and Spark Ignition EnginesRie ReiAinda não há avaliações