Escolar Documentos

Profissional Documentos

Cultura Documentos

E - Valvulas KTM

Enviado por

jplutodTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

E - Valvulas KTM

Enviado por

jplutodDireitos autorais:

Formatos disponíveis

KTM Ball Valves

Overview

Flow Control

2

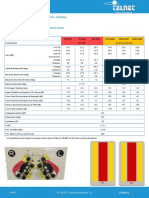

Model Number E0100/E0800 EB100/EB800 E03100/E03800 E3900/E3200

Type Split Body Split Body 3-Way, 2 Seats 3-Way, 4 Seats

Floating Ball Floating Ball Floating Ball Floating Ball

Bi-directional Bi-directional L Port L Port

RF Flanged Ends RF Flanged Ends RF Flanged Ends T Port

Trunnion available RF Flanged Ends

Trunnion available

Bore Full and Reduced Full Full and Reduced Full and Reduced

Pressure ANSI 150 lb ANSI 150 lb ANSI 150 lb ANSI 150 lb

Class ANSI 300 lb ANSI 300 lb ANSI 300 lb ANSI 300 lb

ANSI 600 lb

Size

1

/2 to 8 (Full)

1

/2 to 8 (Full) 1

1

/2 to 8 (Full) 1

1

/2 to 4 (Full)

Range 3 to 10 (Reduced) 6 to 10 (Reduced) 6 to 8 (Reduced) 6 to 8 (Full and Reduced)

10 to 12 (Trunnion) 10 to 12 (Trunnion)

Body Carbon Steel Carbon Steel Carbon Steel Carbon Steel

Material 316 SS 316 SS 316 SS 316 SS

304 SS 304 SS Special Alloys

Alloy 20 Alloy 20

Monel

Monel

Special Alloys Special Alloys

Trim 316 SS 316 SS 316 SS 316 SS

Options 304 SS 304 SS Monel

Monel

Monel

Monel

Hastelloy

C Hastelloy

C

Alloy 20 Alloy 20 Special Alloys Special Alloys

Hastelloy

C Hastelloy

C

Special Alloys Special Alloys

Maximum

Working 285 psi/720 psi 285 psi/720 psi 285 psi/720 psi/1440 psi 285 psi/720 psi

Pressure

Temperature -20F up to 500F -320F up to 932F -150F up to 932F -20F up to 500F

Range

Seat Options E E, K, F, M, T E, G, K, T (F) T, G

Features Anti-static Electricity Anti-static Electricity Anti-static Electricity Anti-static Electricity

Blow-out Proof Stem Blow-out Proof Stem Blow-out Proof Stem Blow-out Proof Stem

Cavity Relief Cavity Relief Cavity Relief Cavity Relief

Fire-Safe Cold-flow Resistance Seat Fugitive Emission Control Fugitive Emission Control

Fugitive Emission Control Device Fire-Safe Device Device

Locking Device Fugitive Emission Control Device Locking Device Locking Device

Positive Flow Stem Indicator ISO Integral Mounting Flange Positive Flow Stem Indicator Positive Flow Stem Indicator

Positive Shut-off Locking Device Positive Shut-off Positive Shut-off

NACE MR01.75 Positive Flow Stem Indicator NACE MR01.75 NACE MR01.75

Positive Shut-off

NACE MR01.75

Omni I Omni II Three-Way

3

EB800R EB100/E0800 EB100 E01200

One-Piece Body Split Body Split Body Split Body

Floating Ball Floating Ball Floating Trunnion

Bi-directional Bi-directional Uni-directional Bi-directional

RF Flanged Ends RF Flanged Ends RF Flanged Ends RF Flanged Ends

Class 5 Seat Leakage Class 5 Seat Leakage

Reduced Full and Reduced Full Full

ANSI 150 lb ANSI 150 lb ANSI 150 lb ANSI 150 lb

ANSI 300 lb ANSI 300 lb ANSI 300 lb ANSI 300 lb

ANSI 600 lb ANSI 600 lb ANSI 600 lb

1

/2 to 8

1

/2 to 8 (Full 150/300)

1

/2 to 8 (150/300) 1

1

/2 to 4 (Full)

3 to 10 (Reduced 150/300)

1

/2 to 2 (600) 6 to 8 (Full and Reduced)

1

/2 to 4 (Full 600) 10 to 12 (Trunnion)

Carbon Steel Carbon Steel Carbon Steel Carbon Steel

316 SS 316 SS 316 SS 316 SS

Special Alloys Special Alloys

316 SS 316 SS/329 SS 316 SS/329 SS 316 SS

Monel

Monel

Monel

Monel

Hastelloy

C Hastelloy

C Hastelloy

C Hastelloy

C

Special Alloys Special Alloys Special Alloys Special Alloys

285 psi/720 psi 285 psi/720 psi/1440 psi 285 psi/720 psi/1440 psi 285 psi/720 psi/1440 psi

-20F up to 500F -50F up to 932F -20F up to 932F -20F up to 932F

E F M M

Anti-static Electricity Anti-static Electricity Anti-static Electricity Anti-static Electricity

Blow-out Proof Stem Blow-out Proof Stem Blow-out Proof Stem Blow-out Proof Stem

Cavity Relief Cavity Relief Cavity Relief Cavity Relief

Fire-Safe Fire-Safe Fire-Safe Fire-Safe

Fugitive Emission Control Device Fugitive Emission Control Device Fugitive Emission Control Device Fugitive Emission Control

Integral Mounting Flange Locking Device Locking Device Device

Locking Device Positive Flow Stem Indicator Positive Flow Stem Indicator Positive Flow Stem Indicator

Positive Flow Stem Indicator Positive Shut-off

Positive Shut-off NACE MR01.75

NACE MR01.75

Unibody

Hi-Temp Two-Way

Gratite

Metal Seated

Trunnion Floating

4

E01200/E08200 E0100/E01100 and E0800/E08100 W0400/W0600 WA Series

Split Body Split Body Split Body One-Piecee Body

Trunnion Trunnion and Floating Ball Trunnion Trunnion

Bi-directional Bi-directional Uni-directional Uni-directional

RF/RTJ/BW RF/RTJ/BW RF Flanged Ends RF Flanged Ends/Wafer Ends

Class II, IV Seat Leakage Class 5 Seat Leakage

Full and Reduced Full and Reduced Reduced

ANSI 150 lb ANSI 150 lb ANSI 150 lb ANSI 150 lb

ANSI 300 lb ANSI 300 lb ANSI 300 lb ANSI 300 lb

ANSI 600 lb ANSI 400 lb

ANSI 900 lb ANSI 600 lb

ANSI 1500 lb ANSI 900 lb

ANSI 1500 lb

ANSI 2500 lb

2 to 36 (150/300)

1

/2 to 4 (600, Floating) 1 to 20 1 to 8

2 to 28 (600) 2 to 28 (600)

1

1

/2 to 24 (900/1500)

1

/2 to 1 (900/1500, Floating)

1

1

/2 to 24 (900/1500)

1

/2 to 8 (2500)

2 to 36 (150/300)

Carbon Steel Carbon Steel Carbon Steel 316 SS

316 SS 316 SS 316 SS

316 SS Carbon Steel 316 SS Laminated 316 SS

ENP 316 SS Stellite #6 Thick Seat

HCR ENP

HCR

285 psi/720 psi 285 psi/720 psi/1440 psi

285 psi/720 psi/1440 psi 275 psi/720 psi

1440 psi/2220 psi/3600 psi 2220 psi/3600 psi/6000 psi

-20F up to 300F -20F up to 300F -20F up to 482F -20F up to 500F

H H M

Anti-static Electricity Anti-static Electricity Cavity Relief Cavity Relief

Block and Bleed Block and Bleed Locking Device Fugitive Emission Control

Blow-out Proof Stem Blow-out Proof Stem Positive Flow Stem Indicator Device

Cavity Relief Cavity Relief NACE MR01.75 ISO Integral Mounting Flange

Fire-Safe Fire-Safe Locking Device

Fugitive Emission Control Device Fugitive Emission Control Device Positive Flow Stem Indicator

Positive Flow Stem Indicator Positive Flow Stem Indicator NACE MR01.75

Positive Shut-off Positive Shut-off

NACE MR01.75 NACE MR01.75

Process Trunnion

Production Floating

and Trunnion

Single-V Dual-V

5

KTM manufactures the most complete line of

quality ball valves, and can provide the exact

ball valves and actuators to meet the most

demanding application requirements.

Experience and Reputation

During KTMs 60 years of valve

manufacturing experience, we have

developed a reputation for high quality,

dependable valves and outstanding service

for our customers.

Totally Integrated Manufacturing

Facility

You can count on KTM ball valves for lasting,

dependable service. Each valve is precision

manufactured from foundry casting to final

assembly. By controlling every component of

manufacturing, we maintain total quality

control.

Dependable Quality Products and

Performance

In addition, unique design features add to the

life and performance of our valves such as an

incredibly high degree of accuracy that is

machined into every ball a sphericity of

0.0008 and 4RMS finish specifications

that are unsurpassed anywhere!

Quality Assurance (ISO 9001)

KTM now complies fully with the global ISO

9001 quality system requirements, the first

major ball valve manufacturer to do so.

Process and Quality Control

(S.P.Q.C.)

KTM has been committed to Statistical

Process Quality Control. Products are

manufactured utilizing S.P.Q.C. as a powerful

tool for producing quality products.

Advantages

The most complete line of ball valves in

either a manual or an automated mode of

operation.

Standard, off-the-shelf, special and custom-

made valves.

Mill Test Reports (MTRs) available on all

valves.

Material traceability

Continuing source guarantees

Product warranties

Strategically located sales, service and

distribution centers provide rapid delivery,

service and repair.

Qualified service and engineering support

Special options and testings are

available on application

Options

Stem Extension

Body Coating

Double Block & Bleed

Tests

Chlorine Service

Oxygen Service

Vacuum Service

Liquid Penetrant

Magnetic Particle

Ultra-Sonic

X-ray

KTM Ball Valves

KTM Ball Valves are manufactured in strict

accordance with worldwide industry standards.

ANSI Title

B16.5 Steel pipe flanges and flanged fittings

B16.10 Face-to-Face and End-to-End dimensions

B16.34 Valves Flanged, threaded and welded end

B16.25 Butt-welding ends

FCI 70-2 Control valve seat leakage

API Title

6D Pipeline valve specifications

598 Valve inspection and test

607 Fire Test for soft-seated valves (Fourth Edition) and EXES 3-14-1-2A

RP6F Fire Test for valves

6FA Fire Test for valves

608 Metal ball valves flanged and butt-welding ends

MSS Title

SP-6 Standard finishes for contact faces of pipe flanges and connecting-end

flanges of valves and fittings

SP-25 Standard marking system for valves, fittings, flanges and unions

SP-55 Quality standard for steel castings for valves, flanges and fittings (Visual method)

SP-61 Pressure testing of steel valves

SP-72 Ball valves with flanged or butt-welding ends for general services

NACE Title

MR-01-75 Sulfide stress-cracking resistant metallic materials for oilfield equipment

BS Title

5351 Steel ball valve for the petroleum, petrochemical and allied industries

5146 Inspection and testing

Approvals, Acceptances and

Listings

American National Standards Institute

(ANSI)

American Bureau of Shipping (ABS)

American Petroleum Institute (API)

Bureau Veritas

International Organization for

Standardization (ISO)

Oil Companies Material Association (OCMA)

Lloyds Register of Shipping

National Association of Corrosion Engineers

(Nance)

Chlorine Institute (CI)

Manufacturers Standardization Society

(MSS)

British Standards Institute (BSI)

Provincial Boiler Inspection Department

(Canada)

Japan Industrial Standards (JIS)

Deutsche Institut Fr Normung (DIN)

TV Rheinland Register (West German

Inspection Organization)

Details on additional acceptance of KTM

products with other organizations are

available upon request.

KTMMC-0505 / Printed in USA / 5M / 0407

Tyco Valves & Controls

Tyco Flow Control (TFC) provides the information herein in good faith but makes no representation as to its

comprehensiveness or accuracy. This data sheet is intended only as a guide to TFC products and services.

Individuals using this data sheet must exercise their independent judgment in evaluating product selection

and determining product appropriateness for their particular purpose and system requirements. TFC

MAKES NO REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING

WITHOUT LIMITATION ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE WITH RESPECT TO THE INFORMATION SET FORTH HEREIN OR THE PRODUCT(S) TO

WHICH THE INFORMATION REFERS. ACCORDINGLY, TFC WILL NOT BE RESPONSIBLE FOR

DAMAGES (OF ANY KIND OR NATURE, INCLUDING INCIDENTAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES) RESULTING FROM THE USE OF OR RELIANCE UPON THIS INFORMATION. Patents and

Patents Pending in the U.S. and foreign countries. Tyco reserves the right to change product designs and

specifications without notice.

Tyco Valves & Controls incorporates many market-leading

brand names in the manufacture of valves, actuators and

control systems, including...

Anderson Greenwood - Pressure relief valves

Anderson Greenwood Instrumentation - Hand valves, gauge

valves, manifolds

AVID - Position, control and network monitors, electro-

pneumatic and smart positioners

Biffi - Gas, electric and pneumatic quarter-turn and

multi-turn actuators

Cash Valve - Pressure relief valves, control valves and

pressure regulators

Clarkson - Slurry valves

Crosby - Pressure relief valves

Descote - Globe valves for hazardous fluids

Dewrance - Parallel slide gate valves

FCT - Split body trunnion mounted ball valves

Fasani - Gate, globe and check valves

Gimpel - Steam valves

Gulf - Double-door wafer check

Hancock - Forged steel gate, globe and check

Hovap - Hygienic valves

Intervalve - High pressure isolation gate, globe and check

valves

Keystone - Resilient seated and high-performance

butterfly valves

KTM - Ball valves

Kunkle - Safety and relief valves

L&M Valve - Polymer lined knife gate valves

MCF - Three-piece ball valves

Morin - Spring return and double acting quarter-turn actuators

Narvik - Desuperheaters, sight gauges, sample valves

Neotecha - Lined butterfly and ball valves and sampling

devices

Penberthy - Liquid level monitoring

Prince - Wafer swing check

Raimondi - Gate, globe, check and ball valves

Rovalve - Special application knife gate and custom designed

valves

Sapag - Safety valves

Sempell - Valves for high pressure, high temperature and

critical media

Valvtron - Severe service ball valves

Vanessa - Zero leakage, critical service valves

Varec - Vapor control

Yarway - Valves, instruments and steam traps

www.tycovalves.com

With sales and distribution operations in strategic locations

throughout the world, Tyco Valves and Controls is a global,

single-source supplier of innovative flow control solutions.

Tyco Valves & Controls

Sales, Service and Distribution Centers

Eastern Region

Philadelphia, Pennsylvania

Phone: 610-296-2000 Fax: 610-296-8038

Atlanta, Georgia

Phone: 770-326-5654 Fax: 770-326-2989

Gulf Coast Region

Pasadena, Texas

Phone: 832-261-2400 Fax: 281-291-8801

Baton Rouge, Louisiana

Phone: 225-751-9000 Fax: 225-751-0130

Western Region

Seattle, Washington

Phone: 425-398-2000 Fax: 425-398-2001

Denver, Colorado

Phone: 303-343-0425 Fax: 303-343-0930

Anaheim, California

Phone: 714-575-9201 Fax: 714-575-9206

Midwest Region

Chicago, Illinois

Phone: 630-343-3333 Fax: 630-343-3334

St. Louis, Missouri

Phone: 314-428-3888 Fax: 314-428-9829

Canada

Calgary, Alberta

Phone: 403-250-9888 Fax: 403-291-5659

Edmonton, Alberta

Phone: 780-461-2228 Fax: 780-461-6242

Burlington, Ontario

Phone: 905-319-3406 Fax: 905-319-3529

Montreal, Quebec

Phone: 450-978-6640 Fax: 450-978-6641

Você também pode gostar

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNota: 4.5 de 5 estrelas4.5/5 (10)

- OneSteel Valve Product CatalogueDocumento40 páginasOneSteel Valve Product CatalogueEr Pupone de Naza100% (1)

- KTMMC 0550 UsDocumento84 páginasKTMMC 0550 UsmaungmaunglattAinda não há avaliações

- A - General Bray InternationalDocumento16 páginasA - General Bray InternationalNestor QuevedoAinda não há avaliações

- Fisher Globe Valve Selection GuideDocumento12 páginasFisher Globe Valve Selection GuideAmiroucheBenlakehalAinda não há avaliações

- Needle ValvesDocumento18 páginasNeedle ValvesPablo RodriguezAinda não há avaliações

- Public Media PDF PDF BALLDocumento64 páginasPublic Media PDF PDF BALLCarlos LópezAinda não há avaliações

- App B Piping Specifications PDFDocumento4 páginasApp B Piping Specifications PDFirawan_epAinda não há avaliações

- 3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2Documento16 páginas3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2zampacaanasAinda não há avaliações

- Ball ValveDocumento12 páginasBall ValveIdabaAinda não há avaliações

- PFQDocumento9 páginasPFQVictorSanchezAinda não há avaliações

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocumento8 páginasTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4Ainda não há avaliações

- The Process Control, The Control of Your WorldDocumento8 páginasThe Process Control, The Control of Your WorldChristian Van MensidorAinda não há avaliações

- Fainger Leser Catalogue' 11Documento68 páginasFainger Leser Catalogue' 11rudrakrAinda não há avaliações

- Valves - PresentationDocumento119 páginasValves - Presentationkrahul100% (15)

- CVH Series PDFDocumento9 páginasCVH Series PDFhendrabudimanAinda não há avaliações

- BakerSPD Choke Tech Handbook 5-9-06 PDFDocumento14 páginasBakerSPD Choke Tech Handbook 5-9-06 PDFCassielAlexzylalas LiambaAinda não há avaliações

- DeZURIK Valve Selection GuideDocumento18 páginasDeZURIK Valve Selection GuideJosé Manuel GonzálezAinda não há avaliações

- Linkmet Brochure May2022 - LrfaDocumento8 páginasLinkmet Brochure May2022 - LrfaHidzir ShamsudinAinda não há avaliações

- 10 00 1 (Valve Selection Guide)Documento18 páginas10 00 1 (Valve Selection Guide)Zahid MehmoodAinda não há avaliações

- SG - Product CatalogueDocumento12 páginasSG - Product CatalogueManish JhaAinda não há avaliações

- UCM Ball ValvesDocumento22 páginasUCM Ball ValvesBalakrishna BisoyiAinda não há avaliações

- Ball Valve KnowledgeDocumento40 páginasBall Valve KnowledgeMeanRat100% (1)

- 274 Regulator Technical BulletinDocumento11 páginas274 Regulator Technical BulletinJonathan S. R.Ainda não há avaliações

- DPCVDocumento4 páginasDPCVjamil voraAinda não há avaliações

- Flanged Standard Bore Ball Valves: ANSI CLASS 150 & 300Documento8 páginasFlanged Standard Bore Ball Valves: ANSI CLASS 150 & 300marpadanAinda não há avaliações

- Made in Italy - EuropeDocumento8 páginasMade in Italy - EuropeenenickAinda não há avaliações

- Flow ServeDocumento8 páginasFlow ServeSagarKBLAinda não há avaliações

- Ham-Let Astava Line of ManifoldsDocumento24 páginasHam-Let Astava Line of ManifoldsjcestupinanAinda não há avaliações

- Vintrol Ball ValveDocumento8 páginasVintrol Ball ValvechadAinda não há avaliações

- APV Plug Valve CatalogueDocumento40 páginasAPV Plug Valve CatalogueVeerapandianAinda não há avaliações

- Literature Force Floating Ball Valve CatalogDocumento16 páginasLiterature Force Floating Ball Valve CatalogJohn Néstor Ramirez CalderónAinda não há avaliações

- Trunnion Ball ValveDocumento16 páginasTrunnion Ball ValveDavid ZhuangAinda não há avaliações

- Swing Check ValveDocumento6 páginasSwing Check ValveAsemota OghoghoAinda não há avaliações

- Metal Seated Ball ValvesDocumento14 páginasMetal Seated Ball ValvesUday GokhaleAinda não há avaliações

- L&T GateGlobe&CheckValves-API 600Documento31 páginasL&T GateGlobe&CheckValves-API 600vsvineesh100% (1)

- SFS Products BrochureDocumento14 páginasSFS Products BrochureJoshuaAinda não há avaliações

- Series 805YD Specification SheetDocumento2 páginasSeries 805YD Specification SheetFEBCOAinda não há avaliações

- Dezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bDocumento24 páginasDezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bjasonlaiymAinda não há avaliações

- Aquestia OCV TERMINALDocumento12 páginasAquestia OCV TERMINALSony Nd AshaAinda não há avaliações

- Valve Selection GuideDocumento20 páginasValve Selection GuideGagandeep SinghAinda não há avaliações

- 240 AC Models - Platypus PowerDocumento7 páginas240 AC Models - Platypus Powerrabei romulusAinda não há avaliações

- A 02 1064Documento4 páginasA 02 1064Marliton SalinasAinda não há avaliações

- KTMMC 0550 Us PDFDocumento84 páginasKTMMC 0550 Us PDFThirukkumaranBalasubramanianAinda não há avaliações

- Metro Enterprise: Quality Solution To Flow ControlDocumento7 páginasMetro Enterprise: Quality Solution To Flow Controlak47ichiAinda não há avaliações

- Double Block Bleed TOSVDocumento8 páginasDouble Block Bleed TOSVplanet123Ainda não há avaliações

- Raceland CatalogDocumento52 páginasRaceland CatalogAntonis Georgiadis100% (1)

- Product Brochure Kunkle Safety Relief Valves Product Overview Kunkle Valve en en 5198290Documento12 páginasProduct Brochure Kunkle Safety Relief Valves Product Overview Kunkle Valve en en 5198290Vilas m ChinkeAinda não há avaliações

- Jas-Anz: ISO 9001: 2008 CertifiedDocumento12 páginasJas-Anz: ISO 9001: 2008 CertifiedshambhoiAinda não há avaliações

- Wescol SS-N-10-2GDocumento12 páginasWescol SS-N-10-2Gpuccio78Ainda não há avaliações

- ValvesDocumento24 páginasValvesaaa100% (1)

- L&T Pipeline Ball ValvesDocumento24 páginasL&T Pipeline Ball Valvesjamil vora100% (1)

- Inside Sales For Valves Part 3Documento6 páginasInside Sales For Valves Part 3niket honnalliAinda não há avaliações

- Enflow Floating BallvalvesDocumento8 páginasEnflow Floating Ballvalvesa100acomAinda não há avaliações

- How To Get High Quality Weldoflange or NipoflangeDocumento7 páginasHow To Get High Quality Weldoflange or NipoflangeYaneYangAinda não há avaliações

- Fisher Globe ValveDocumento16 páginasFisher Globe ValvePhornlert WanaAinda não há avaliações

- Catalogo Tecnico Stud WeldingDocumento68 páginasCatalogo Tecnico Stud Weldingalexfc81Ainda não há avaliações

- Ductile Iron FPF SPN Metric BRO-089sm 19Documento1 páginaDuctile Iron FPF SPN Metric BRO-089sm 19jplutodAinda não há avaliações

- Ductile Iron FPF SPN Metric BRO-089sm 22Documento1 páginaDuctile Iron FPF SPN Metric BRO-089sm 22jplutodAinda não há avaliações

- Ductile Iron FPF SPN Metric BRO-089sm 18Documento1 páginaDuctile Iron FPF SPN Metric BRO-089sm 18jplutodAinda não há avaliações

- Type 646 Electro-PneumaticDocumento6 páginasType 646 Electro-PneumaticjplutodAinda não há avaliações

- Camflex II Parts Supplement 1Documento1 páginaCamflex II Parts Supplement 1jplutodAinda não há avaliações

- Camflex II Parts Supplement 2Documento1 páginaCamflex II Parts Supplement 2jplutodAinda não há avaliações

- Medidor de Gas - Smith MeterTM Turbine Meters FMCDocumento5 páginasMedidor de Gas - Smith MeterTM Turbine Meters FMCjplutodAinda não há avaliações

- Table 3.1 Continued: (Continued On Next Page)Documento1 páginaTable 3.1 Continued: (Continued On Next Page)jplutodAinda não há avaliações

- Magnetrol Switch Level ORS-300Documento2 páginasMagnetrol Switch Level ORS-300jplutodAinda não há avaliações

- Pipe Chart 1 Pul PDFDocumento1 páginaPipe Chart 1 Pul PDFjplutodAinda não há avaliações

- Table 3-1 Continued: Single Random Double Random Cut LengthsDocumento1 páginaTable 3-1 Continued: Single Random Double Random Cut LengthsjplutodAinda não há avaliações

- Isa 12.12.01Documento48 páginasIsa 12.12.01jplutodAinda não há avaliações

- Valvula Bola Menor PDFDocumento2 páginasValvula Bola Menor PDFjplutodAinda não há avaliações

- Hygrophil F 5673 ManualDocumento66 páginasHygrophil F 5673 ManualjplutodAinda não há avaliações

- Rotomixx: Cost Effective and Reliable Total Stainless Batch MixersDocumento2 páginasRotomixx: Cost Effective and Reliable Total Stainless Batch MixersYusuf DabhiyaAinda não há avaliações

- Automation TestingDocumento20 páginasAutomation TestingmaryamAinda não há avaliações

- Datasheet For ATC2603C V2.1Documento141 páginasDatasheet For ATC2603C V2.1Ha Long ThangAinda não há avaliações

- AN296220 Bootstrap SupplyDocumento4 páginasAN296220 Bootstrap Supplya9841140155Ainda não há avaliações

- Installation Procedure For Version 4.2.12.00 - Release 4.2Documento54 páginasInstallation Procedure For Version 4.2.12.00 - Release 4.2Talhaoui ZakariaAinda não há avaliações

- The Product & UX Design Roadmap 2023Documento16 páginasThe Product & UX Design Roadmap 2023shreya kaleAinda não há avaliações

- 9814663735Documento367 páginas9814663735scribdermanAinda não há avaliações

- Proteza Oticon More Minirite R Instructions For UseDocumento49 páginasProteza Oticon More Minirite R Instructions For UseOvidiu PascuAinda não há avaliações

- ATM200 Actuators PDFDocumento8 páginasATM200 Actuators PDFMiguel ComprésAinda não há avaliações

- GK500 ManualDocumento14 páginasGK500 ManualDox BachmidAinda não há avaliações

- Install Flutter in WindowsDocumento10 páginasInstall Flutter in WindowsazharAinda não há avaliações

- Icjecapu 09Documento7 páginasIcjecapu 09meghanamavuru30Ainda não há avaliações

- LO 2. Use FOS Tools, Equipment, and ParaphernaliaDocumento5 páginasLO 2. Use FOS Tools, Equipment, and ParaphernaliaReymond SumayloAinda não há avaliações

- An Essay On Software Testing For Quality AssuranceDocumento9 páginasAn Essay On Software Testing For Quality AssurancekualitatemAinda não há avaliações

- Analox Sensor Technology LTD PDFDocumento2 páginasAnalox Sensor Technology LTD PDFefren.ramirez.arias9488Ainda não há avaliações

- Manual Generador MagravDocumento6 páginasManual Generador MagravacuonautAinda não há avaliações

- Accenture Managed Services Future Process Led TransformationDocumento12 páginasAccenture Managed Services Future Process Led TransformationYusuf KusumaAinda não há avaliações

- ZTE ZXSDR R8882 Product DescriptionDocumento23 páginasZTE ZXSDR R8882 Product Descriptionrdmiguel_198360% (1)

- JBT Exp-310 Brochure 0313cDocumento2 páginasJBT Exp-310 Brochure 0313cCiprian OprescuAinda não há avaliações

- Nguyenvanthinh BKC13107 N01Documento35 páginasNguyenvanthinh BKC13107 N01Văn thinh NguyenAinda não há avaliações

- DEFA 800 Serie Installations ManualDocumento20 páginasDEFA 800 Serie Installations ManualWendy Mon De ValderramaAinda não há avaliações

- DS ANT TNA352A33rDocumento3 páginasDS ANT TNA352A33rEdelAinda não há avaliações

- Flyback Using Microcontroller AN2122 MicrochipDocumento70 páginasFlyback Using Microcontroller AN2122 MicrochipCarlos Zevallos100% (1)

- WS500 Getting Started PDFDocumento23 páginasWS500 Getting Started PDFkhalid100% (1)

- Aastha ConsultingDocumento4 páginasAastha Consultinghkzn groupAinda não há avaliações

- 441 1105 1 PBDocumento6 páginas441 1105 1 PBblackraidenAinda não há avaliações

- 2010 NEXIQ Catalog PDFDocumento12 páginas2010 NEXIQ Catalog PDFJose Antonio Tano Cisneros100% (1)

- Specsheet 3516 1825 kVA PrimeDocumento6 páginasSpecsheet 3516 1825 kVA PrimeYusman EkaAinda não há avaliações

- Power Supply Unit (PCA-N3060-PSU)Documento2 páginasPower Supply Unit (PCA-N3060-PSU)RommelEusuyaAinda não há avaliações

- Maintenance Engineering (Che-405) : DR Sikander Rafiq Assoc. ProfessorDocumento37 páginasMaintenance Engineering (Che-405) : DR Sikander Rafiq Assoc. ProfessorHajra AamirAinda não há avaliações