Escolar Documentos

Profissional Documentos

Cultura Documentos

AVK Valve

Enviado por

mih4iTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

AVK Valve

Enviado por

mih4iDireitos autorais:

Formatos disponíveis

AVK SWING CHECK VALVE, PN 10/16

41/60

003

Swing check valve with free shaft end, for water and sewage to max. 70 C, designed according to DIN/EN, Face to face according to EN 558 table 2 basic series 48. Standard flange drilling to EN1092-2 (ISO 7005-2) Hydraulic test according to EN12050-4. Approved according to LGA regulations.

Resilient seated with full bore. Body and bonnet of GJS-500-7 (GGG-50). Hinge of stainless steel AISI 316 in DN 50-200 and GGG-50 in DN 250-300. Disc with steel insert fully vulcanized with EDPM rubber. The disc and hinge are assembled on a shaft of stainless steel AISI 430F fitted in the bonnet. Bonnet gasket of EPDM rubber in a groove between body and bonnet. Epoxy coating to DIN 30677-2 and GSK guidelines - internally and externally.

Accessories:

Lever and weight AVK series 41/23, lever and spring AVK series 41/32, valve guard kit AVK series 41/50, combi-flanges AVK series 05, flange adaptors AVK series 603 and 623.

For further details see section "Technical Information". The designs, materials, and specifications shown are subject to change without notice due to the continuous development of our product programme. 2010-02-23 07:02 CET

COPYRIGHTAVK GROUP A/S 2010 / AVK INTERNATIONAL A/S

AVK SWING CHECK VALVE, PN 10/16

1 2 3 4 5 6 7

41/60

8

003

9

10

10

Low head loss

The full bore minimizes pressure loss and allows maximum utilisation of the pump capacity. The disc is designed with a steel insert fully vulcanized with EPDM rubber. It provides a drop tight closure and due Hto the light weight it requires a minimum of force to open/close.

Easy maintenance and long life

Disassembly of the valve can be performed without removing the valve from the pipe system by unscrewing the bonnet bolts and removing the bonnet assembly including hinge and disc. In case of damage the necessary spare parts can be changed before reassembly. The valve is easy to handle due to its low weight. The hinge is designed with double keyways and is tightened around the shaft with bolts to eliminate play and thus preventing wear of the components. The resilient seated disc features optimum corrosion resistance. L

11

12

13

14

15

Component11 list12

1. Washer 2. Nylon spacer 3. Bolt 4. Disc 5. Washer 6. Hexagon bolt 7. Hinge 8. Bonnet 9. Bonnet gasket 10. Body 11. O-ring 12. O-ring 13. Bushing 14. Pin 15. Shaft

13

14

15

W1

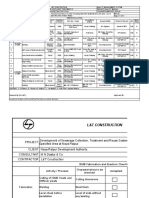

Reference nos. and dimensions

AVK ref. nos.

41-050-60018 41-065-60018 41-080-60018 41-100-60018 41-125-60018 41-150-60018 41-200-60008 41-200-60018 41-250-60008 41-250-60018 41-300-60008 41-300-60018

W1

DN mm

PN drilling

L mm

H mm

W1 mm

Theoretical weight kg

50 65 80 100 125 150 200 200 250 250 300 300

10/16 10/16 10/16 10/16 10/16 10/16 10 16 10 16 10 16

200 216 260 300 350 400 500 500 600 600 700 700

110 140 140 150 195 195 230 230 270 270 300 300

160 160 160 175 220 220 240 240 415 415 415 415

13 17 20 26 40 51 83 83 183 183 231 231

Você também pode gostar

- Avk Knife Gate Valve, PN 10, CTC 702/10Documento2 páginasAvk Knife Gate Valve, PN 10, CTC 702/10AVK_PHAinda não há avaliações

- MIV Product OverviewDocumento13 páginasMIV Product OverviewAmir_skorpionAinda não há avaliações

- Crane - Series.rs Center LineDocumento23 páginasCrane - Series.rs Center LinenedwestAinda não há avaliações

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryAinda não há avaliações

- W4.9 Ozkan Seal On Disc Butterfly Valve PDFDocumento8 páginasW4.9 Ozkan Seal On Disc Butterfly Valve PDFmanmohansingh1999Ainda não há avaliações

- Technical Bulletin: Valtek Mark One Control ValvesDocumento20 páginasTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzAinda não há avaliações

- Eko4000-4100 WebDocumento4 páginasEko4000-4100 WebSubramanian SaravananAinda não há avaliações

- Butterfly ValveDocumento14 páginasButterfly ValveSingSareblakKanaManahAinda não há avaliações

- BallValues PDFDocumento12 páginasBallValues PDFDevdatt WaghuleAinda não há avaliações

- 854 00-001 AVK015 Eng v1-0Documento3 páginas854 00-001 AVK015 Eng v1-0Jeff Tingin MarceloAinda não há avaliações

- Flowserve Vlatb001Documento20 páginasFlowserve Vlatb001Selva KumarAinda não há avaliações

- Delvalcataloguemay 3006Documento4 páginasDelvalcataloguemay 3006Balu VedhachalamAinda não há avaliações

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocumento20 páginasBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelAinda não há avaliações

- Check Valves With Tilting DiscDocumento2 páginasCheck Valves With Tilting DiscSamir RawalAinda não há avaliações

- Aloyco Stainess Steel ValvesDocumento26 páginasAloyco Stainess Steel Valvescristi_molins100% (1)

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesDocumento20 páginasFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraAinda não há avaliações

- Neojv 0040 enDocumento0 páginaNeojv 0040 enLuis GuevaraAinda não há avaliações

- Cat. No. 2111 2002: Flanged Gate Valve With Soft SealDocumento9 páginasCat. No. 2111 2002: Flanged Gate Valve With Soft SealzaidAinda não há avaliações

- Flow Divertor Ball Valve DN20 - DN32 - DN50: DescriptionDocumento3 páginasFlow Divertor Ball Valve DN20 - DN32 - DN50: Description윤병택Ainda não há avaliações

- Crane Katalog-RS AngDocumento29 páginasCrane Katalog-RS AngNNAinda não há avaliações

- AVK Pneumatic Gate Valves BrochureDocumento2 páginasAVK Pneumatic Gate Valves BrochureCuong Nguyen ChiAinda não há avaliações

- Iso 9001 CertifiedDocumento4 páginasIso 9001 CertifiedLuis R. Salas SotoAinda não há avaliações

- Y-Pattern Globe Valves PDFDocumento11 páginasY-Pattern Globe Valves PDFcristhianAinda não há avaliações

- Mueller Resilient Wedge Gate Valves: For Reliable Performance and Long Service Life-Certified To NSF 61Documento4 páginasMueller Resilient Wedge Gate Valves: For Reliable Performance and Long Service Life-Certified To NSF 61gad30Ainda não há avaliações

- KVC 01Documento35 páginasKVC 01hamidreza_m85Ainda não há avaliações

- Epoxy Resin BushingDocumento12 páginasEpoxy Resin BushingSURJIT SINGHAinda não há avaliações

- Valves Reference PDFDocumento35 páginasValves Reference PDFJulio RodriguezAinda não há avaliações

- Fisher v150Documento16 páginasFisher v150Doug LambAinda não há avaliações

- AVKDocumento2 páginasAVKpiscesguy78Ainda não há avaliações

- Full Lift Spring Loaded Open PDFDocumento4 páginasFull Lift Spring Loaded Open PDFVenkatespatange RaoAinda não há avaliações

- SAPAG Butterfly ValvesDocumento22 páginasSAPAG Butterfly ValvespawelzakAinda não há avaliações

- Catalogue Uk PDFDocumento2 páginasCatalogue Uk PDFramjee prasad jaiswalAinda não há avaliações

- AVK Valvula Borboleta Com Flanges Iso5752 Concentric A Corpo Longo Serie 7542Documento2 páginasAVK Valvula Borboleta Com Flanges Iso5752 Concentric A Corpo Longo Serie 7542PkKhakeAinda não há avaliações

- Series 30-31 Butterfly ValveDocumento6 páginasSeries 30-31 Butterfly ValveJercy SanchezAinda não há avaliações

- 11422Documento10 páginas11422balajivangaruAinda não há avaliações

- L&T Aquaseal Butterfly Check ValvesDocumento24 páginasL&T Aquaseal Butterfly Check ValvesSohail PathanAinda não há avaliações

- Asco Solenoid SpecificationsDocumento2 páginasAsco Solenoid SpecificationsPrathamesh GangalAinda não há avaliações

- NS PDFDocumento5 páginasNS PDFTarunPatraAinda não há avaliações

- ASCO Info Filter Canada PDFDocumento8 páginasASCO Info Filter Canada PDFdicicaAinda não há avaliações

- 100G - 2100G ClavalDocumento2 páginas100G - 2100G Clavale1901bAinda não há avaliações

- ATS Catalog BV0102Documento12 páginasATS Catalog BV0102Jaehun YuAinda não há avaliações

- Econ Gate ValvesDocumento22 páginasEcon Gate ValvesRiyas Udheen100% (1)

- IOM Ball Valve Top EntryDocumento8 páginasIOM Ball Valve Top Entrytoader56Ainda não há avaliações

- VALVULA DE SOLENOIDE HS7 BulletinDocumento4 páginasVALVULA DE SOLENOIDE HS7 BulletinJoséMarcanoAinda não há avaliações

- Valve0114 PDFDocumento14 páginasValve0114 PDFbinhjukiAinda não há avaliações

- Valvula Guilhotina D2GDocumento4 páginasValvula Guilhotina D2Gkrlos_SW2009Ainda não há avaliações

- Apv Delta Sv1Documento20 páginasApv Delta Sv1VLASTARAinda não há avaliações

- Brochure - Ex TENDDocumento4 páginasBrochure - Ex TENDBilly ZununAinda não há avaliações

- PressureDocumento84 páginasPressureHangloque GabanoAinda não há avaliações

- Howell Bunger Valve 05. HBGR - Text New CoverDocumento4 páginasHowell Bunger Valve 05. HBGR - Text New CovermuazeemKAinda não há avaliações

- Valvulas de Control FisherDocumento16 páginasValvulas de Control FisherAnonymous GKTRypAinda não há avaliações

- Sapag JHP Valves Jun04 enDocumento18 páginasSapag JHP Valves Jun04 enanwar01Ainda não há avaliações

- NW FlangeDocumento11 páginasNW FlangeStanley PeterAinda não há avaliações

- ValvesDocumento6 páginasValvesstevegazeleyAinda não há avaliações

- Butterfly Valve, Grooved End, Globe, Model GLR300GDocumento9 páginasButterfly Valve, Grooved End, Globe, Model GLR300Grahu2260Ainda não há avaliações

- Magnetrol ThermatelDocumento12 páginasMagnetrol Thermatelmih4iAinda não há avaliações

- Perceptron Helixevo CutSheet Rev.B EmailDocumento2 páginasPerceptron Helixevo CutSheet Rev.B Emailmih4iAinda não há avaliações

- Short Paths-Optimal Results: On-Site Analysers For Ammonium and PhosphateDocumento8 páginasShort Paths-Optimal Results: On-Site Analysers For Ammonium and Phosphatemih4iAinda não há avaliações

- 00a - Photo Lesson Rule of ThirdsDocumento19 páginas00a - Photo Lesson Rule of Thirdsmih4iAinda não há avaliações

- 00a - Photo Lesson Rule of ThirdsDocumento19 páginas00a - Photo Lesson Rule of Thirdsmih4iAinda não há avaliações

- NatGeo GuideToPhotographyDocumento15 páginasNatGeo GuideToPhotographyAna@PetreAinda não há avaliações

- AerzenDocumento20 páginasAerzenmih4iAinda não há avaliações

- Axis Blowers TechnicaldataDocumento22 páginasAxis Blowers Technicaldatamih4iAinda não há avaliações

- Piesa Trecere Etansa Prin BetonDocumento2 páginasPiesa Trecere Etansa Prin Betonmih4iAinda não há avaliações

- Date Tehnice Rwg-Iwg - TD RWG Ewg Poti enDocumento3 páginasDate Tehnice Rwg-Iwg - TD RWG Ewg Poti enmih4iAinda não há avaliações

- Lagerschuh: Edelstahl W.1.4404 / AISI 316 (V4)Documento1 páginaLagerschuh: Edelstahl W.1.4404 / AISI 316 (V4)mih4iAinda não há avaliações

- Everest Fall Prospectus FinalDocumento17 páginasEverest Fall Prospectus Finalmih4iAinda não há avaliações

- AN-ISE SC: Combination Sensor For Ammonium and Nitrate: Data SheetDocumento4 páginasAN-ISE SC: Combination Sensor For Ammonium and Nitrate: Data SheetprannoyAinda não há avaliações

- Compresor EinhellDocumento1 páginaCompresor Einhellmih4iAinda não há avaliações

- How To Read MTF CurvesDocumento33 páginasHow To Read MTF CurvesDaffyAinda não há avaliações

- Pompe Manuale Si ElectriceDocumento54 páginasPompe Manuale Si Electricemih4iAinda não há avaliações

- Lowara PumpDocumento84 páginasLowara Pumpmih4iAinda não há avaliações

- 1074 PDF TocDocumento8 páginas1074 PDF Tocmih4iAinda não há avaliações

- 1074 PDF C02Documento116 páginas1074 PDF C02mih4iAinda não há avaliações

- 1074 PDF C04Documento82 páginas1074 PDF C04mih4iAinda não há avaliações

- 2012 BrochureDocumento4 páginas2012 BrochureKino Tel LokAinda não há avaliações

- Rodamientos SKFDocumento1.380 páginasRodamientos SKFSebastian Lobos OpitzAinda não há avaliações

- Table Cold Steel Products 2013Documento41 páginasTable Cold Steel Products 2013Daniel BoldeanuAinda não há avaliações

- Pompa Manuala de Transfer JP 04Documento4 páginasPompa Manuala de Transfer JP 04mih4iAinda não há avaliações

- MagFlux Flow MeterDocumento16 páginasMagFlux Flow Metermih4iAinda não há avaliações

- EN 1092-1-Flange PDFDocumento18 páginasEN 1092-1-Flange PDFSimona Adriana100% (1)

- Dresing AltitudeDocumento530 páginasDresing Altitudemih4iAinda não há avaliações

- Moon PhotoDocumento38 páginasMoon Photomih4iAinda não há avaliações

- Coliere Norma GbsDocumento5 páginasColiere Norma Gbsmih4iAinda não há avaliações

- European Construction Sector Observatory: Country Profile MaltaDocumento40 páginasEuropean Construction Sector Observatory: Country Profile MaltaRainbootAinda não há avaliações

- Fake News Infographics by SlidesgoDocumento33 páginasFake News Infographics by SlidesgoluanavicunhaAinda não há avaliações

- 1.co - Deb4113 - Industrial ManagementDocumento10 páginas1.co - Deb4113 - Industrial ManagementrohaizadAinda não há avaliações

- 160kW SOFT STARTER - TAP HOLE 1Documento20 páginas160kW SOFT STARTER - TAP HOLE 1Ankit Uttam0% (1)

- Term Paper Inorganic PolymersDocumento24 páginasTerm Paper Inorganic PolymersCasey Karua0% (1)

- EZ Water Calculator 3.0.2Documento4 páginasEZ Water Calculator 3.0.2adriano70Ainda não há avaliações

- Guided-Discovery Learning Strategy and Senior School Students Performance in Mathematics in Ejigbo, NigeriaDocumento9 páginasGuided-Discovery Learning Strategy and Senior School Students Performance in Mathematics in Ejigbo, NigeriaAlexander DeckerAinda não há avaliações

- Coal Bottom Ash As Sand Replacement in ConcreteDocumento9 páginasCoal Bottom Ash As Sand Replacement in ConcretexxqAinda não há avaliações

- Duo Interpretation Class PresentationDocumento31 páginasDuo Interpretation Class PresentationPlanetSparkAinda não há avaliações

- Sainik School Balachadi: Name-Class - Roll No - Subject - House - Assigned byDocumento10 páginasSainik School Balachadi: Name-Class - Roll No - Subject - House - Assigned byPagalAinda não há avaliações

- Paper 1 AnalysisDocumento2 páginasPaper 1 AnalysisNamanAinda não há avaliações

- Cambridge IGCSE: CHEMISTRY 0620/42Documento12 páginasCambridge IGCSE: CHEMISTRY 0620/42Khairun nissaAinda não há avaliações

- Generalized Class of Sakaguchi Functions in Conic Region: Saritha. G. P, Fuad. S. Al Sarari, S. LathaDocumento5 páginasGeneralized Class of Sakaguchi Functions in Conic Region: Saritha. G. P, Fuad. S. Al Sarari, S. LathaerpublicationAinda não há avaliações

- Ethical Conflicts in Psychology PDF DownloadDocumento2 páginasEthical Conflicts in Psychology PDF DownloadAvory0% (2)

- A 138Documento1 páginaA 138pooja g pAinda não há avaliações

- Gujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalDocumento18 páginasGujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalABCDAinda não há avaliações

- A Case On Marketing Strategy of Xiaomi IndiaDocumento39 páginasA Case On Marketing Strategy of Xiaomi IndiaSoumyajeet Rout0% (1)

- Notice: Premerger Notification Waiting Periods Early TerminationsDocumento5 páginasNotice: Premerger Notification Waiting Periods Early TerminationsJustia.comAinda não há avaliações

- On Animal Language in The Medieval Classification of Signs PDFDocumento24 páginasOn Animal Language in The Medieval Classification of Signs PDFDearNoodlesAinda não há avaliações

- G1000 Us 1014 PDFDocumento820 páginasG1000 Us 1014 PDFLuís Miguel RomãoAinda não há avaliações

- Vieworks DR Panel BrochureDocumento8 páginasVieworks DR Panel Brochuretito goodAinda não há avaliações

- Reflection in Sexually Transmitted DiseaseDocumento1 páginaReflection in Sexually Transmitted Diseasewenna janeAinda não há avaliações

- Second Conditional Conversation QuestionsDocumento2 páginasSecond Conditional Conversation QuestionsEdith Salomé PinosAinda não há avaliações

- Impact of Government Policies and EthicsDocumento24 páginasImpact of Government Policies and EthicsGunveen AbrolAinda não há avaliações

- Lalit Resume-2023-LatestDocumento2 páginasLalit Resume-2023-LatestDrew LadlowAinda não há avaliações

- Ismb ItpDocumento3 páginasIsmb ItpKumar AbhishekAinda não há avaliações

- Acetylcysteine 200mg (Siran, Reolin)Documento5 páginasAcetylcysteine 200mg (Siran, Reolin)ddandan_2Ainda não há avaliações

- Community Architecture Concept PDFDocumento11 páginasCommunity Architecture Concept PDFdeanAinda não há avaliações

- IQAc 04-05Documento10 páginasIQAc 04-05ymcacollegewebsiteAinda não há avaliações

- At The Origins of Music AnalysisDocumento228 páginasAt The Origins of Music Analysismmmahod100% (1)

- House Rules: How to Decorate for Every Home, Style, and BudgetNo EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetAinda não há avaliações

- Crochet Impkins: Over a million possible combinations! Yes, really!No EverandCrochet Impkins: Over a million possible combinations! Yes, really!Nota: 4.5 de 5 estrelas4.5/5 (10)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsNo EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsNota: 4.5 de 5 estrelas4.5/5 (2)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiNo EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiNota: 4 de 5 estrelas4/5 (3)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiNo Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiNota: 5 de 5 estrelas5/5 (2)

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchNo EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchNota: 5 de 5 estrelas5/5 (1)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastNo EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastNota: 5 de 5 estrelas5/5 (1)

- The Martha Manual: How to Do (Almost) EverythingNo EverandThe Martha Manual: How to Do (Almost) EverythingNota: 4 de 5 estrelas4/5 (11)

- Dream Sewing Spaces: Design & Organization for Spaces Large & SmallNo EverandDream Sewing Spaces: Design & Organization for Spaces Large & SmallNota: 4 de 5 estrelas4/5 (24)

- Timeless Textured Baby Crochet: 20 heirloom crochet patterns for babies and toddlersNo EverandTimeless Textured Baby Crochet: 20 heirloom crochet patterns for babies and toddlersAinda não há avaliações

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestNo EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestNota: 5 de 5 estrelas5/5 (2)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeNo EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeNota: 5 de 5 estrelas5/5 (1)

- Tunisian Crochet for Beginners: Step-by-step Instructions, plus 5 Patterns!No EverandTunisian Crochet for Beginners: Step-by-step Instructions, plus 5 Patterns!Nota: 5 de 5 estrelas5/5 (3)

- Friends: The One with the Crochet: The Official Crochet Pattern BookNo EverandFriends: The One with the Crochet: The Official Crochet Pattern BookNota: 5 de 5 estrelas5/5 (1)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)No EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Ainda não há avaliações

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsNo EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsNota: 4.5 de 5 estrelas4.5/5 (10)

- Crochet Collage Garden: 100 patterns for crochet flowers, plants and petalsNo EverandCrochet Collage Garden: 100 patterns for crochet flowers, plants and petalsNota: 5 de 5 estrelas5/5 (1)

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreNo EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreNota: 5 de 5 estrelas5/5 (5)

- Too Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreNo EverandToo Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreNota: 5 de 5 estrelas5/5 (2)

- Knit Soxx for Everyone: 25 Colorful Sock Patterns for the Whole FamilyNo EverandKnit Soxx for Everyone: 25 Colorful Sock Patterns for the Whole FamilyNota: 4.5 de 5 estrelas4.5/5 (2)

- Crochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysNo EverandCrochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysNota: 4.5 de 5 estrelas4.5/5 (7)

- Colorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsNo EverandColorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsAinda não há avaliações

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNo EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesAinda não há avaliações

- Jane Austen Embroidery: Authentic embroidery projects for modern stitchersNo EverandJane Austen Embroidery: Authentic embroidery projects for modern stitchersNota: 4 de 5 estrelas4/5 (3)

- Two Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!No EverandTwo Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!Nota: 3 de 5 estrelas3/5 (2)

- Crochet Lace: Techniques, Patterns, and ProjectsNo EverandCrochet Lace: Techniques, Patterns, and ProjectsNota: 3.5 de 5 estrelas3.5/5 (3)

- The Knotting & Braiding Bible: The Complete Guide to Creative Knotting including Kumihimo, Macramé, and PlaitingNo EverandThe Knotting & Braiding Bible: The Complete Guide to Creative Knotting including Kumihimo, Macramé, and PlaitingNota: 4.5 de 5 estrelas4.5/5 (5)