Escolar Documentos

Profissional Documentos

Cultura Documentos

API 571 Damage Mechanism Affecting Fixed Refining Equipments

Enviado por

Kmt_AeDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

API 571 Damage Mechanism Affecting Fixed Refining Equipments

Enviado por

Kmt_AeDireitos autorais:

Formatos disponíveis

PETROSYNC

Synchronize Your Petroleum Skills

A lot of Case Studies, Practical Things and Exercises !

Damage Mechanisms Affecting Fixed Refining Equipments

Sculpt Your Skills to Detect, Evaluate, and Prevent Various Degradations and Damages Inflicted on Equipment !

API 571

7th July 2014 - 9th July 2014, Bangkok, Thailand

Petrosync Distinguished Instructor Uday B. Kale (M. Eng. Mechanical)

Technical Director KUB Quality Services

SUMMARY OF PROFESSIONAL ACHIEVEMENT

API 580 Risk Based Inspection Supplementary Certification API 510 & 570 Authorized Inspector AWS Certified Welding Inspector CSWIP 3.1 Authorized Welding Inspector ACCP Professional Level III (ASNT) ASNT NDT Level III BS EN 473 Level III

PARTIAL CLIENT LIST

The Middle East: Qatar Petroleum, QAFAC, ADCO, ADGAS, ADMA, GASCO, Banagas, Technip (Bahrain), Equate Petrochemicals Company, Al Jubail Fertilizer Company, TUV Akadamie Middle East (UAE, Saudi Arabia and Qatar) Africa: BP - GUPCO (Egypt), Inspection and Test Nigeria Ltd India & Asia: Oil India Limited, Tata, Dacon Inspection Ltd Europe: Rosen Europe (The Netherlands)

Course Objectives

Understanding of the various degradations and damages inflicted on equipment in Refinery Service Knowledge of how to detect, evaluate, and prevent degradations and damages of Refinery Equipment Advanced information in preventive as well as predictive maintenance of equipment Different forms of degradations and various mechanisms and related environmental factors. Factors contributing the damage, the correct monitoring & inspection of damage, prevention/mitigation of damage mechanisms.

Specially Designed for

Plant inspection engineers and managers, Inspection personnel, plant operating engineers Maintenance engineers and technicians and people involved in trouble shooting of plant operations. will have immense benefit from this course in terms of identifying, understanding, prevention and mitigation of corrosion mechanisms and related damages of refinery equipment.

Supported by

API 571 - Damage Mechanisms Affecting Fixed Refining Equipments 7th - 9th July 2014, Bangkok, Thailand Course Overview

This 3 days training course is designed to give a detailed discussion on the required API 571 document containing Practical information and guidance on damage mechanisms that can affect process equipment, assistance regarding the type and extent of damage, and How this knowledge can be applied to the selection of effective inspection methods to detect size and characterize damage. API 571 is means for imparting knowledge to the participants with damage mechanisms which are important when implementing the API Inspection Codes (API 510, API 570, API 653) and in conducting risk based inspection per API 580 and API 581. Refineries and chemical plants contain many different processing units, each having its own combination of aggressive process streams and temperature/pressure conditions. This course helps the participants to understand easily the various degradations and damages inflicted on equipments and how to detect, evaluate, and prevent them.

Course Agenda

Introduction to Damage Mechanisms Types of Damages- Thinning, Cracking, Metallurgical, Mechanical damages Common damage mechanisms encountered in Refining Industry Brittle Fracture Thermal Fatigue Erosion/Erosion Corrosion Mechanical Fatigue Atmospheric Corrosion Corrosion Under Insulation (CUI) Cooling Water Corrosion Boiler Water Condensate Corrosion Sulfidation Chloride Stress Corrosion Cracking (ClSCC) Corrosion Fatigue Caustic Stress Corrosion Cracking (Caustic Embrittlement) Wet H2S Damage (Blistering/HIC/SOHIC/SCC) High Temperature Hydrogen Attack (HTHA) Temper Embrittlement Microbiologically Induced Corrosion (MIC) Soil Corrosion Sulfuric Acid Corrosion Amine Corrosion High Temp H2/H2S Corrosion Hydrofuoric (HF) Acid Corrosion Other Damage Mechanisms in Refining Industry Inspection, Prevention and Mitigation Mock Examination and Feed back

API 571 - Damage Mechanisms Affecting Fixed Refining Equipments 7th - 9th July 2014, Bangkok, Thailand

Petrosync Distinguished Instructor

INSTRUCTOR

Uday B. Kale (M. Eng. Mechanical)

Technical Director KUB Quality Services

SUMMARY OF PROFESSIONAL ACHIEVEMENT

API 510 & 570 Authorized Piping Inspector AWS Certified Welding Inspector CSWIP 3.1 Authorized Welding Inspector ACCP Professional Level III (ASNT) ASNT NDT Level III BS EN 473 Level III API 580 Risk Based Inspection Supplementary Certification API 510 Authorized Pressure Vessel Inspector API 580 Risk Based Inspection Supplementary Certification API 653 Authorized Aboveground Storage Tank Inspector

PARTIAL CLIENT /PROJECT LIST

Qatar Petroleum BP - GUPCO (Egypt) Oil India Limited ADCO (Abu Dhabi) ADGAS (Abu Dhabi) ADMA (Abu Dhabi) GASCO (Abu Dhabi) QAFAC Rosen Europe (The Netherlands) Banagas (Bahrain) TATA (India) Al Jubail Fertilizer Company Technip (Bahrain) Equate Petrochemicals (Kuwait) TUV Akadamie Middle East (UAE, Saudi Arabia and Qatar) Inspection and Test Nigeria Ltd Dacon Inspection Ltd HBJ pipeline up-gradation projects

Uday B. Kale is an API570 authorized piping inspector. Currently

he is the technical director of M/s KUB Quality Services. He has involved in inspection, welding and NDT projects in the Middle East, Africa and India for over 15 years on offshore production platform and petrochemical refineries. Mr. Uday is very well-versed in international Codes and Standards. He performed and led the shutdown teams in performing NDE, internal and external inspection of equipments in central processing plant, ammonia plant, FCCU, SRU, SWS and amine treating units for Code stamp facilities of ADCO, Qatar Petroleum, Oil India, QAFAC, Banagas, Al Jubail Fertilizer Company. He was the appointed plant inspector for BP (GUPCO) in asset integrity management, who took charge of 9 offshore production complex, 75 Satellites and Onshore process units involving Close Visual Inspection of piping, equipments, NDT co-ordination, Baseline and Corrosion Monitoring. Furthermore, as an Inspector in GASCO OAG pipeline project, he conducted and witnessed Ultrasonic Examination of first 50 production weld joints of pipeline done by PWT (Pipe Welding Technology, GMAW).

With his extensive involvement in various projects, Mr. Uday is also an enthusiastic and knowledgeable mentor, who has been a faculty in training, examination, qualification and certification of API 510 & 570, ASME B31.3, API653, welding and NDT in the Middle East, Africa and Asia. He is a charted engineer with a Masters in Mechanical Engineering.

API 571 - Damage Mechanisms Affecting Fixed Refining Equipments 7th - 9th July 2014, Bangkok, Thailand

INVESTMENT PACKAGES

Please checklist the package that you are attending!

Investment Package Deadline Course Fee SGD $ 2,250 SGD $ 2,050

10% discounts for group of 3 registering from the same organization at the same time

PROGRAMME CONSULTANT

Name : Cay Aagen Email : registration@petrosync.com Phone : +65 6415 4500 Fax : +65 6826 4322

Standard Price Early Bird Offer Group Discount

(3 or more Delegates)

4th Jul 2014 7th Jun 2014 4th Jul 2014

TERMS AND CONDITIONS

DISCLAIMER

Please note that trainers and topics were confirmed at the time of publishing; however, PetroSync may necessitate substitutions, alterations or cancellations of the trainers or topics. As such, PetroSync reserves the right to change or cancel any part of its published programme due to unforeseen circumstances. Any substitutions or alterations will be updated on our web page as soon as possible.

Group Discount is based on Standard Price * To enjoy the promotion & discount offer, payment must be made before deadline * For 7 or more delegates, please inquire for more attractive package. * Prices include lunches, refreshments and materials. Promotion & discount cannot be combined with other promotional offers. * Important: Please note that registration without payment will incur a SGD 200 administration fee.

DELEGATES DETAILS

1st Delegate Name

DATA PROTECTION

Mr Mrs Ms Dr Others

Direct Line Number: Job Title: Head of Department:

2nd Delegate Name

Email: Department:

The information you provide will be safeguarded by PetroSync that may be used to keep you informed of relevant products and services. As an international group we may transfer your data on a global basis for the purpose indicated above. If you do not want us to share your information with other reputable companies, please tick this box

CANCELLATION POLICY

Mr Email: Department: Mrs Ms Dr Others

Direct Line Number: Job Title: Head of Department:

3rd Delegate Name

You may substitute delegates at any time as long as reasonable advance notice is given to PetroSync. For any cancellation received in writing not less than fourteen (14) working days prior to the training course, you will receive a credit voucher worth total transaction with less a SGD 200 administration fee and any related bank or credit card charges. Delegates who cancel less than fourteen (14) working days of the training course, or who do not attend the course, are liable to pay the full course fee and no refunds will be granted. In the event that PetroSync cancels or postpones an event for any reason and that the delegate is unable or unwilling to attend in on the rescheduled date, you will receive a credit voucher for 100% of the contract fee paid. You may use this credit voucher for another PetroSync to be mutually agreed with PetroSync, which must occur within a year from the date of postponement. PetroSync is not responsible for any loss or damage as a result of the cancellation policy. PetroSync will assume no liability whatsoever in the event this event is cancelled, rescheduled or postponed due to any Act of God, fire, act of government or state, war, civil commotion, insurrection, embargo, industrial action, or any other reason beyond management control.

Mr Email: Department:

Mrs

Ms

Dr

Others

Direct Line Number: Job Title: Head of Department:

INVOICE DETAILS

Attention Invoice to: ______________________________________________________________________________ Direct Line Number: ______________________________ Fax: _____________________________________________ Company:____________________________________________ Industry : __________________________________ Address: _______________________________________________________Postcode: _________________________ Country: ________________________Email: __________________________________________________________

Please note: Fax Email Web - Indicate if you have already registered by Phone - If you have not received an acknowledgement before the training, please call us to confirm your booking.

PAYMENT METHODS

By Credit Card : Please debit my credit card: Card Number: Visa MasterCard AMEX Security Code: Expiry Date:

CERTIFICATE OF ATTENDANCE

70% attendance is required for PetroSync's Certificate of Attendance.

DETAILS

Please accept our apologies for mail or email that is incorrectly addressed. Please email us at registration@petrosync.com and inform us of any incorrect details. We will amend them accordingly.

Name printed on card: _____________________________________________________________________ By Direct Transfer : Please quote invoice number(s) on remittance advice PetroSync LLP Bank details: Account Name: PetroSync LLP Bank Number: 7144 Branch Code: 013 Account No: 13-1-005531-6 Name of Correspondent Bank : Standard Chartered Bank, 6 Battery Road, Singapore 049909 SWIFT Code of Correspondent Bank: SCBLSGSGXXX All bank charges to be borne by payer. Please ensure that PetroSync LLP receives the full invoiced amount.

CHARGES & FEE(s)

- For Payment by Direct TelegraphicTransfer, client has to bear both local and oversea bank charges. - For credit card payment, there is additional 4% credit card processsing fee.

Course Confirmation

I agree to PetroSyncs terms & conditions,payment terms and cancellation policy.

:

Authorized Signature

____________________________________________________________________________

PAYMENT TERMS : Payment is due in full at the time of registration. Full payment is mandatory for event attendance.

Você também pode gostar

- Pinnacle 571 Training FlyerDocumento2 páginasPinnacle 571 Training FlyerDennis Arley SanchezAinda não há avaliações

- Industrial Plant Inspection GuideDocumento5 páginasIndustrial Plant Inspection GuideMohamedAinda não há avaliações

- Mechanical FatigueDocumento6 páginasMechanical FatigueRamyMoustafaAinda não há avaliações

- Surface Profile Measurement by Replica Tape SSPC-SP10-Nace 2-Near - WhiteDocumento5 páginasSurface Profile Measurement by Replica Tape SSPC-SP10-Nace 2-Near - WhiteClyde CoopperAinda não há avaliações

- ApiDocumento4 páginasApiMahmoud Alwasif100% (1)

- API 570 Exam Prep TrainingDocumento3 páginasAPI 570 Exam Prep Trainingalouis100% (1)

- Imprimir API 571Documento88 páginasImprimir API 571ismael archila100% (1)

- PDF Api 570 Awareness Coursepdf DDDocumento23 páginasPDF Api 570 Awareness Coursepdf DDkareemAinda não há avaliações

- Interzone 4954 Antifungal Coating Test ReportDocumento10 páginasInterzone 4954 Antifungal Coating Test Reportsteffy182100% (1)

- API 571 Exam InfoDocumento1 páginaAPI 571 Exam InfoSathiyaseelan Sakthi ShanmugamAinda não há avaliações

- CORROSION QUIZ - InG - Painting and CoatingDocumento3 páginasCORROSION QUIZ - InG - Painting and CoatingErik Alfiandy100% (1)

- API 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical Industries PDFDocumento1 páginaAPI 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical Industries PDFAzhar Ahmad100% (1)

- Pew 105.04 (P)Documento174 páginasPew 105.04 (P)Raj BindasAinda não há avaliações

- (PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduDocumento4 páginas(PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduKumar R100% (1)

- API571 - NEW APP - Effective 2011 - CompletedDocumento12 páginasAPI571 - NEW APP - Effective 2011 - Completedtong2jeAinda não há avaliações

- Corrosion and Cathodic Protection in PipelinesDocumento3 páginasCorrosion and Cathodic Protection in PipelinesPavan_yoyoAinda não há avaliações

- API 571 Study NoteDocumento1 páginaAPI 571 Study Notebmkale100% (1)

- General Damage Mechanisms and Corrosion Failure ModesDocumento6 páginasGeneral Damage Mechanisms and Corrosion Failure ModesShrikant Moje100% (1)

- Electrochemical Corrosion Theory ExplainedDocumento1 páginaElectrochemical Corrosion Theory Explainedget5rajesh100% (1)

- API 570 Study PlanDocumento2 páginasAPI 570 Study PlanShaalan Ali100% (1)

- Salt ContaminationDocumento8 páginasSalt Contaminationabdayub100% (1)

- API 571-Damage Mechanism (October 4-7-2010)Documento4 páginasAPI 571-Damage Mechanism (October 4-7-2010)ananda_27Ainda não há avaliações

- Damage MechanismDocumento4 páginasDamage MechanismJomon MathewAinda não há avaliações

- API 571 Part 3Documento20 páginasAPI 571 Part 3Bashu Poudel100% (2)

- API-510 Pressure Vessel Inspector Preparatory Training Program Final Exam - (Close Book)Documento3 páginasAPI-510 Pressure Vessel Inspector Preparatory Training Program Final Exam - (Close Book)Ali AhmedAinda não há avaliações

- API 571 Test Registration Applicant's Name: Exam ID #Documento2 páginasAPI 571 Test Registration Applicant's Name: Exam ID #Ali AhmedAinda não há avaliações

- API 510 vessel inspection standardsDocumento2 páginasAPI 510 vessel inspection standardsHemaAinda não há avaliações

- 17 Multiple Choice Questions: No Answer GivenDocumento5 páginas17 Multiple Choice Questions: No Answer GivenAnonymous Q4YUvRAinda não há avaliações

- Assessment 1 API 570Documento5 páginasAssessment 1 API 570Mohamed ZainAinda não há avaliações

- Mechanical Insulation - Types and MaterialsDocumento9 páginasMechanical Insulation - Types and Materialssowman tungAinda não há avaliações

- Boost Your API-570 Piping Inspectors Exam ScoreDocumento6 páginasBoost Your API-570 Piping Inspectors Exam Scorejaire esparzaAinda não há avaliações

- Standard For AWS Certification of Welding InspectorsDocumento24 páginasStandard For AWS Certification of Welding InspectorsFrancisco Eduardo SouzaAinda não há avaliações

- API RP 571 corrosion questionsDocumento5 páginasAPI RP 571 corrosion questionsأحمد صبحى100% (1)

- API 510 Final Answer Closed Book1Documento1 páginaAPI 510 Final Answer Closed Book1Nsidibe Michael EtimAinda não há avaliações

- CBT QuestionsDocumento17 páginasCBT QuestionsNaseer Ahmed SokhalAinda não há avaliações

- 9 Multiple Choice Questions: No Answer GivenDocumento3 páginas9 Multiple Choice Questions: No Answer GivenAnonymous Q4YUvRAinda não há avaliações

- API 571 Damage Mechanisms MasterclassDocumento6 páginasAPI 571 Damage Mechanisms MasterclassRahim A Ahmad100% (1)

- A Brief Synopsis ofDocumento54 páginasA Brief Synopsis ofNO ONEAinda não há avaliações

- Bgas PaintingDocumento1 páginaBgas Paintingnabeelcool17Ainda não há avaliações

- Cswip Div 9 03 General Inspector 4th Edition Jan 2008Documento12 páginasCswip Div 9 03 General Inspector 4th Edition Jan 2008obinnaAinda não há avaliações

- API 571 DemoDocumento14 páginasAPI 571 Demophan hoang diep100% (1)

- Self-Study On API RP 571 - Damage MechanismDocumento84 páginasSelf-Study On API RP 571 - Damage Mechanismrosli2503100% (2)

- Toaz - Info Coating Interview Question PRDocumento1 páginaToaz - Info Coating Interview Question PRMurugan Irusappan100% (1)

- Daily Points To Recall (Day 5) : Professional Training and ConsultationDocumento3 páginasDaily Points To Recall (Day 5) : Professional Training and Consultationraobabar21Ainda não há avaliações

- API 570 - Mockup CB - Paper 2Documento16 páginasAPI 570 - Mockup CB - Paper 2Shanawas Abdul Razak100% (1)

- API 510 Data Sheets - QuizletDocumento1 páginaAPI 510 Data Sheets - Quizletads_1203Ainda não há avaliações

- Asset Intelligence Report: A Primer On Corrosion Under Insulation (CUI)Documento5 páginasAsset Intelligence Report: A Primer On Corrosion Under Insulation (CUI)dzamir203Ainda não há avaliações

- API 571 damage mechanisms refining petrochemicalDocumento3 páginasAPI 571 damage mechanisms refining petrochemicalMahmoud Elmahdy100% (1)

- API 510 - Day 1: G T Technical & Management Institute PVT - LTD.Documento109 páginasAPI 510 - Day 1: G T Technical & Management Institute PVT - LTD.fathiAinda não há avaliações

- Examen de Evaluación API 571Documento18 páginasExamen de Evaluación API 571berray2007100% (2)

- Some Grades of Carbon Steel and 0.5mo SteelsDocumento27 páginasSome Grades of Carbon Steel and 0.5mo SteelsNidharshan Selvaraj RAinda não há avaliações

- WCMJT Painting Inspection Grade 3/2 CourseDocumento71 páginasWCMJT Painting Inspection Grade 3/2 CourseAhmedA.HassanAinda não há avaliações

- Corrosion Management Issue151Documento32 páginasCorrosion Management Issue151Issam Mokrani100% (1)

- Introduction To API 571Documento13 páginasIntroduction To API 571M. Nasikhun WahidinAinda não há avaliações

- API 570 - Daily Exam 5C API-571-577 Questions - PSJDocumento4 páginasAPI 570 - Daily Exam 5C API-571-577 Questions - PSJKrishna Moorthy50% (2)

- Industrial radiography A Complete Guide - 2019 EditionNo EverandIndustrial radiography A Complete Guide - 2019 EditionAinda não há avaliações

- Painting Inspector: Passbooks Study GuideNo EverandPainting Inspector: Passbooks Study GuideAinda não há avaliações

- API 580 & API 581 - PetroSyncDocumento5 páginasAPI 580 & API 581 - PetroSyncAbdullah DinsuhaimiAinda não há avaliações

- Risk Based Inspection Professional: Certification Preparation ProgramDocumento6 páginasRisk Based Inspection Professional: Certification Preparation ProgramMuhammad HannanAinda não há avaliações

- API 510 Inspector CourseDocumento6 páginasAPI 510 Inspector CourseKmt_AeAinda não há avaliações

- Pipe Stess Static and Dynamic AnalysisDocumento5 páginasPipe Stess Static and Dynamic AnalysisKmt_AeAinda não há avaliações

- World Class ShutdownDocumento6 páginasWorld Class ShutdownKmt_AeAinda não há avaliações

- Heat Exchanger Fouling Mitigation TechnologyDocumento5 páginasHeat Exchanger Fouling Mitigation TechnologyKmt_AeAinda não há avaliações

- ASME VIII Pressure Vessel MasterclassDocumento6 páginasASME VIII Pressure Vessel MasterclassKmt_AeAinda não há avaliações

- Catalog 2001Documento10 páginasCatalog 2001Kmt_AeAinda não há avaliações

- API 579 Fitness For ServiceDocumento5 páginasAPI 579 Fitness For ServiceKmt_Ae100% (1)

- Pressure ReliefDocumento207 páginasPressure ReliefAH100% (1)

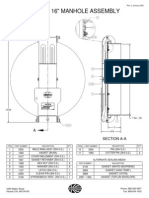

- Ld3310 16" Manhole Assembly: Rev. 0, January 2003Documento1 páginaLd3310 16" Manhole Assembly: Rev. 0, January 2003Kmt_AeAinda não há avaliações

- Aerosol Adhesives LitDocumento18 páginasAerosol Adhesives LitKmt_AeAinda não há avaliações

- API 653 - Storage Tank Inspector Certification Examination Preparatory CourseDocumento5 páginasAPI 653 - Storage Tank Inspector Certification Examination Preparatory CourseKmt_AeAinda não há avaliações

- Corrosion Control in E&PDocumento7 páginasCorrosion Control in E&PKmt_AeAinda não há avaliações

- Corrosion Control in Refining IndustryDocumento8 páginasCorrosion Control in Refining IndustryKmt_Ae0% (1)

- API 653 - Storage Tank Inspector Certification Examination Preparatory CourseDocumento5 páginasAPI 653 - Storage Tank Inspector Certification Examination Preparatory CourseKmt_AeAinda não há avaliações

- API 580 and 581risk Based InspectionDocumento5 páginasAPI 580 and 581risk Based InspectionKmt_Ae100% (1)

- API 510 Inspector CourseDocumento6 páginasAPI 510 Inspector CourseKmt_AeAinda não há avaliações

- API 570 Piping InspectorDocumento6 páginasAPI 570 Piping InspectorBuddharaju KiranAinda não há avaliações

- Acoustic and Flow Induced VibrationDocumento5 páginasAcoustic and Flow Induced VibrationKmt_AeAinda não há avaliações

- API 579 Fitness For ServiceDocumento5 páginasAPI 579 Fitness For ServiceKmt_Ae100% (1)

- Tema & HtriDocumento5 páginasTema & HtriKmt_AeAinda não há avaliações

- Heat Exchanger Fouling Mitigation TechnologyDocumento5 páginasHeat Exchanger Fouling Mitigation TechnologyKmt_AeAinda não há avaliações

- z4 Coupe Roadster CatalogueDocumento19 páginasz4 Coupe Roadster CatalogueKmt_AeAinda não há avaliações

- Aboveground Storage Tank Design Masterclass (M'Sia) - LynnDocumento5 páginasAboveground Storage Tank Design Masterclass (M'Sia) - LynnKmt_AeAinda não há avaliações

- z4 Coupe Roadster CatalogueDocumento19 páginasz4 Coupe Roadster CatalogueKmt_AeAinda não há avaliações

- Advanced Pressure Vessels and Other Pressure EquipmentsDocumento6 páginasAdvanced Pressure Vessels and Other Pressure EquipmentsKmt_AeAinda não há avaliações

- z4 Coupe Roadster DatasheetDocumento8 páginasz4 Coupe Roadster DatasheetStephenAinda não há avaliações

- x3 DatasheetDocumento7 páginasx3 DatasheetKmt_AeAinda não há avaliações

- FC Catalogue PDFDocumento36 páginasFC Catalogue PDFIndra FandyAinda não há avaliações

- x5 DatasheetDocumento7 páginasx5 DatasheetKmt_AeAinda não há avaliações

- x5 CatalogueDocumento18 páginasx5 CatalogueKmt_AeAinda não há avaliações

- Seife Progress TrackerDocumento4 páginasSeife Progress TrackerngilaAinda não há avaliações

- UCPB Violated Truth in Lending Act in Loan to SpousesDocumento4 páginasUCPB Violated Truth in Lending Act in Loan to SpousesMark Xavier Overhaul LibardoAinda não há avaliações

- Medtech LawsDocumento19 páginasMedtech LawsJon Nicole DublinAinda não há avaliações

- Time Value of Money - TheoryDocumento7 páginasTime Value of Money - TheoryNahidul Islam IUAinda não há avaliações

- FinTech BoguraDocumento22 páginasFinTech BoguraMeraj TalukderAinda não há avaliações

- Courtroom Etiquette and ProcedureDocumento3 páginasCourtroom Etiquette and ProcedureVineethSundarAinda não há avaliações

- Su Xiaomi's spring arrives in unexpected formDocumento4 páginasSu Xiaomi's spring arrives in unexpected formDonald BuchwalterAinda não há avaliações

- Payment of Bonus Form A B C and DDocumento13 páginasPayment of Bonus Form A B C and DAmarjeet singhAinda não há avaliações

- IiuyiuDocumento2 páginasIiuyiuLudriderm ChapStickAinda não há avaliações

- Purpose and Types of Construction EstimatesDocumento10 páginasPurpose and Types of Construction EstimatesAisha MalikAinda não há avaliações

- Airport Solutions Brochure Web 20170303Documento6 páginasAirport Solutions Brochure Web 20170303zhreniAinda não há avaliações

- 1 292583745 Bill For Current Month 1Documento2 páginas1 292583745 Bill For Current Month 1Shrotriya AnamikaAinda não há avaliações

- Principles of Administrative TheoryDocumento261 páginasPrinciples of Administrative TheoryZabihullahRasidAinda não há avaliações

- The Indian Navy - Inet (Officers)Documento3 páginasThe Indian Navy - Inet (Officers)ANKIT KUMARAinda não há avaliações

- ePass for Essential Travel Between Andhra Pradesh and OdishaDocumento1 páginaePass for Essential Travel Between Andhra Pradesh and OdishaganeshAinda não há avaliações

- Employee Separation Types and ReasonsDocumento39 páginasEmployee Separation Types and ReasonsHarsh GargAinda não há avaliações

- Controlled Chaos in Joseph Heller's Catch-22Documento5 páginasControlled Chaos in Joseph Heller's Catch-22OliverAinda não há avaliações

- Vdkte: LA-9869P Schematic REV 1.0Documento52 páginasVdkte: LA-9869P Schematic REV 1.0Analia Madeled Tovar JimenezAinda não há avaliações

- Agreement For Consulting Services Template SampleDocumento6 páginasAgreement For Consulting Services Template SampleLegal ZebraAinda não há avaliações

- Life Member ListDocumento487 páginasLife Member Listpuiritii airAinda não há avaliações

- Intermediate Algebra For College Students 7th Edition Blitzer Test BankDocumento19 páginasIntermediate Algebra For College Students 7th Edition Blitzer Test Bankdireful.trunnionmnwf5100% (30)

- Hue University Faculty Labor ContractDocumento3 páginasHue University Faculty Labor ContractĐặng Như ThànhAinda não há avaliações

- STAFF SELECTION COMMISSION (SSC) - Department of Personnel & TrainingDocumento3 páginasSTAFF SELECTION COMMISSION (SSC) - Department of Personnel & TrainingAmit SinsinwarAinda não há avaliações

- 721-1002-000 Ad 0Documento124 páginas721-1002-000 Ad 0rashmi mAinda não há avaliações

- SAS HB 06 Weapons ID ch1 PDFDocumento20 páginasSAS HB 06 Weapons ID ch1 PDFChris EfstathiouAinda não há avaliações

- PSEA Self Assessment Form - 2024 02 02 102327 - YjloDocumento2 páginasPSEA Self Assessment Form - 2024 02 02 102327 - Yjlokenedy nuwaherezaAinda não há avaliações

- Entrance English Test for Graduate Management StudiesDocumento6 páginasEntrance English Test for Graduate Management StudiesPhương Linh TrươngAinda não há avaliações

- MODULE 3 LeadershipDocumento25 páginasMODULE 3 LeadershipCid PonienteAinda não há avaliações

- RA MEWP 0003 Dec 2011Documento3 páginasRA MEWP 0003 Dec 2011Anup George Thomas100% (1)

- Pure TheoryDocumento3 páginasPure TheoryAshima MishraAinda não há avaliações