Escolar Documentos

Profissional Documentos

Cultura Documentos

Perfil Encaixe 104x81x1.5

Enviado por

Marcos AmorimDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Perfil Encaixe 104x81x1.5

Enviado por

Marcos AmorimDireitos autorais:

Formatos disponíveis

Generic shape

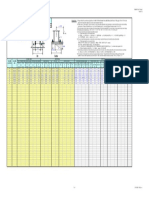

AXIAL TENSION Design tension resistance: Nt,Rd = 97.2 kN

Generic shape RESISTANCE OF CROSS-SECTION - AXIAL TENSION [5.2]

Increased yield strength, due to cold working: fya = 289.76 MPa [3.1.2] Gross area of the cross-section: Ag = 369 mm2 Design tension resistance: Nt,Rd = 97.18 kN WARNING: check the net-section resistance from 8.4 for the appropriate type of mechanical fastener

Generic shape RESISTANCE OF CROSS-SECTION - AXIAL COMPRESSION Yield strength: fyb = 280.00 MPa Effective area of the cross-section: Aeff = 252 mm2 Design compression resistance: Nc,Rd = 64.27 kN WARNING: the centroid of the effective section does not coincide to the centroid of the gross section (eNz=-12.1 mm; eNy= -4.7 mm). Check the section for bending and compression. EVALUATION OF THE EFFECTIVE CROSS-SECTION: Element 1 outstand element, supported at end 2 geometrical data: bP = 74.12 mm t = 1.50 mm bP/t = 49.41 end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 254.55 MPa end 2 - sigma = 254.55 MPa coefficients: k sigma = 0.4300 lambdaP = 2.8947 lambdaP red = 2.8947 rho = 0.3192 beff = 23.66 mm Element 2 doubly supported element geometrical data: bP = 48.74 mm t = 1.50 mm bP/t = 32.50 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 254.55 MPa end 2 - sigma = 254.55 MPa coefficients: k sigma = 4.0000 lambdaP = 0.6241 lambdaP red = 0.6241 rho = 1.0000 the element is fully effective Element 3 doubly supported element geometrical data: bP = 22.49 mm t = 1.50 mm bP/t = 15.00 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 254.55 MPa end 2 - sigma = 254.55 MPa coefficients: k sigma = 4.0000 lambdaP = 0.2880 lambdaP red = 0.2880 rho = 1.0000 the element is fully effective Element 4 doubly supported element geometrical data: bP = 50.24 mm t = 1.50 mm bP/t = 33.50 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 254.55 MPa end 2 - sigma = 254.55 MPa coefficients: k sigma = 4.0000 lambdaP = 0.6433 lambdaP red = 0.6433 rho = 1.0000 the element is fully effective Element 5 outstand element, supported at end 1 geometrical data: bP = 49.87 mm t = 1.50 mm bP/t = 33.25 end 1 - fr = 2.12 mm axial stresses: end 1 - sigma = 254.55 MPa end 2 - sigma = 254.55 MPa coefficients: k sigma = 0.4300 lambdaP = 1.9476 lambdaP red = 1.9476 rho = 0.4554 beff = 22.71 mm [5.3]

Generic shape RESISTANCE OF CROSS-SECTION - BENDING MOMENT bending plane x-y; positive [5.4]

Increased yield strength, due to cold working: fya = 289.76 MPa [3.1.2] Gross elastic section modulus: Wel = 3.8522 e03 mm3 Design moment resistance: Mc,Rd = 1.01 kNm WARNING - check the effect of shear lag according to 5.4.3, when relevant EVALUATION OF THE EFFECTIVE CROSS-SECTION: Element 1 outstand element, supported at end 2 geometrical data: bP = 74.12 mm t = 1.50 mm bP/t = 49.41 end 2 - fr = 2.12 mm axial stresses: end 1 - sigma =-254.55 MPa end 2 - sigma = 132.73 MPa coefficients: k sigma = 23.8000 lambdaP = 0.3891 lambdaP red = 0.2928 rho = 1.0000 the element is fully effective Element 2 doubly supported element geometrical data: bP = 48.74 mm t = 1.50 mm bP/t = 32.50 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 148.87 MPa end 2 - sigma = 148.87 MPa coefficients: k sigma = 4.0000 lambdaP = 0.6241 lambdaP red = 0.4773 rho = 1.0000 the element is fully effective Element 3 doubly supported element geometrical data: bP = 22.49 mm t = 1.50 mm bP/t = 15.00 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 132.73 MPa end 2 - sigma = 34.57 MPa coefficients: k sigma = 6.7735 lambdaP = 0.2213 lambdaP red = 0.1665 rho = 1.0000 the element is fully effective Element 4 doubly supported element geometrical data: bP = 50.24 mm t = 1.50 mm bP/t = 33.50 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 18.43 MPa end 2 - sigma = 18.43 MPa coefficients: k sigma = 4.0000 lambdaP = 0.6433 lambdaP red = 0.1731 rho = 1.0000 the element is fully effective Element 5 outstand element, supported at end 1 geometrical data: bP = 49.87 mm t = 1.50 mm bP/t = 33.25 end 1 - fr = 2.12 mm axial stresses: end 1 - sigma = 2.29 MPa end 2 - sigma =-254.55 MPa coefficients: k sigma = 23.8000 lambdaP = 0.2618 lambdaP red = 0.0607 rho = 1.0000 the element is fully effective RESISTANCE OF CROSS-SECTION - BENDING MOMENT bending plane x-y; negative Yield strength: Effective section modulus: Design moment resistance: fyb = 280.00 MPa Weff = 9.2206 e02 mm3 Mc,Rd = -0.23 kNm [5.4]

WARNING - check the effect of shear lag according to 5.4.3, when relevant EVALUATION OF THE EFFECTIVE CROSS-SECTION: Element 1 outstand element, supported at end 2 geometrical data: bP = 74.12 mm t = 1.50 mm bP/t = 49.41 end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 254.55 MPa end 2 - sigma = -63.39 MPa coefficients: k sigma = 0.6357 lambdaP = 2.3807 lambdaP red = 2.3807 rho = 0.3812 beff = 21.98 mm Element 2 doubly supported element the element is in tension, fully effective Element 3 doubly supported element

geometrical data: bP = 22.49 mm t = 1.50 mm bP/t = 15.00 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = -63.39 MPa end 2 - sigma = 17.20 MPa coefficients: k sigma = 83.5013 lambdaP = 0.0630 lambdaP red = 0.0204 rho = 1.0000 the element is fully effective Element 4 doubly supported element geometrical data: bP = 50.24 mm t = 1.50 mm bP/t = 33.50 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 30.45 MPa end 2 - sigma = 30.45 MPa coefficients: k sigma = 4.0000 lambdaP = 0.6433 lambdaP red = 0.2225 rho = 1.0000 the element is fully effective Element 5 outstand element, supported at end 1 geometrical data: bP = 49.87 mm t = 1.50 mm bP/t = 33.25 end 1 - fr = 2.12 mm axial stresses: end 1 - sigma = 43.70 MPa end 2 - sigma = 254.55 MPa coefficients: k sigma = 0.5430 lambdaP = 1.7333 lambdaP red = 1.7333 rho = 0.5037 beff = 25.12 mm

Generic shape RESISTANCE OF CROSS-SECTION - BENDING MOMENT bending plane x-z; positive Yield strength: Effective section modulus: Design moment resistance: fyb = 280.00 MPa Weff = 7.2307 e03 mm3 Mc,Rd = 1.84 kNm [5.4]

WARNING - check the effect of shear lag according to 5.4.3, when relevant EVALUATION OF THE EFFECTIVE CROSS-SECTION: Element 1 outstand element, supported at end 2 the element is in tension, fully effective Element 2 doubly supported element geometrical data: bP = 48.74 mm t = 1.50 mm bP/t = 32.50 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma =-143.85 MPa end 2 - sigma = 32.99 MPa coefficients: k sigma = 95.6000 lambdaP = 0.1277 lambdaP red = 0.0515 rho = 1.0000 the element is fully effective Element 3 doubly supported element geometrical data: bP = 22.49 mm t = 1.50 mm bP/t = 15.00 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 44.91 MPa end 2 - sigma = 44.91 MPa coefficients: k sigma = 4.0000 lambdaP = 0.2880 lambdaP red = 0.1210 rho = 1.0000 the element is fully effective Element 4 doubly supported element geometrical data: bP = 50.24 mm t = 1.50 mm bP/t = 33.50 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 56.84 MPa end 2 - sigma = 239.64 MPa coefficients: k sigma = 6.5859 lambdaP = 0.5014 lambdaP red = 0.4950 rho = 1.0000 the element is fully effective Element 5 outstand element, supported at end 1 geometrical data: bP = 49.87 mm t = 1.50 mm bP/t = 33.25 end 1 - fr = 2.12 mm axial stresses: end 1 - sigma = 251.56 MPa end 2 - sigma = 251.56 MPa coefficients: k sigma = 0.4300 lambdaP = 1.9476 lambdaP red = 1.9362 rho = 0.4593

beff = 22.91 mm RESISTANCE OF CROSS-SECTION - BENDING MOMENT bending plane x-z; negative Yield strength: Effective section modulus: Design moment resistance: fyb = 280.00 MPa Weff = 6.9153 e03 mm3 Mc,Rd = -1.76 kNm [5.4]

WARNING - check the effect of shear lag according to 5.4.3, when relevant EVALUATION OF THE EFFECTIVE CROSS-SECTION: Element 1 outstand element, supported at end 2 geometrical data: bP = 74.12 mm t = 1.50 mm bP/t = 49.41 end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 251.29 MPa end 2 - sigma = 251.29 MPa coefficients: k sigma = 0.4300 lambdaP = 2.8947 lambdaP red = 2.8761 rho = 0.3225 beff = 23.91 mm Element 2 doubly supported element geometrical data: bP = 48.74 mm t = 1.50 mm bP/t = 32.50 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 238.29 MPa end 2 - sigma = 45.38 MPa coefficients: k sigma = 6.8554 lambdaP = 0.4767 lambdaP red = 0.4701 rho = 1.0000 the element is fully effective Element 3 doubly supported element geometrical data: bP = 22.49 mm t = 1.50 mm bP/t = 15.00 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 32.37 MPa end 2 - sigma = 32.37 MPa coefficients: k sigma = 4.0000 lambdaP = 0.2880 lambdaP red = 0.1027 rho = 1.0000 the element is fully effective Element 4 doubly supported element geometrical data: bP = 50.24 mm t = 1.50 mm bP/t = 33.50 end 1 - fr = 2.12 mm end 2 - fr = 2.12 mm axial stresses: end 1 - sigma = 19.36 MPa end 2 - sigma =-180.05 MPa coefficients: k sigma = 95.6000 lambdaP = 0.1316 lambdaP red = 0.0441 rho = 1.0000 the element is fully effective Element 5 outstand element, supported at end 1 the element is in tension, fully effective

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Catálogo Siding HardiePlankDocumento6 páginasCatálogo Siding HardiePlankMarcos AmorimAinda não há avaliações

- Bridge Strudl - Manual: Proper IesDocumento30 páginasBridge Strudl - Manual: Proper IesAbera DeressaAinda não há avaliações

- Up Mir B Council TP 10 Storm WaterDocumento249 páginasUp Mir B Council TP 10 Storm WaterMarcos AmorimAinda não há avaliações

- PurlinsDocumento11 páginasPurlinsdanokrayAinda não há avaliações

- Wind Energy in JordanDocumento4 páginasWind Energy in JordanAnas MomaniAinda não há avaliações

- Bouwfolder Sadef 2012 Eng-Spread LR PDFDocumento55 páginasBouwfolder Sadef 2012 Eng-Spread LR PDFMarcos AmorimAinda não há avaliações

- Alignment MajorstatioDocumento3 páginasAlignment MajorstatioMarcos AmorimAinda não há avaliações

- Cathodic Protection PDFDocumento24 páginasCathodic Protection PDFJorge Luis Clavijo Iturri50% (2)

- GaticUKFullTechnicalBrochure December2013 (3.8mb)Documento35 páginasGaticUKFullTechnicalBrochure December2013 (3.8mb)Marcos AmorimAinda não há avaliações

- Solution For Water Tanks Techno ProtectionDocumento10 páginasSolution For Water Tanks Techno ProtectionMarcos AmorimAinda não há avaliações

- Cathodic Protection: The BasicsDocumento8 páginasCathodic Protection: The BasicsbookbumAinda não há avaliações

- UK TechnBroschDocumento52 páginasUK TechnBroschMarcos AmorimAinda não há avaliações

- Corrosion TheoryDocumento10 páginasCorrosion Theory7amada11100% (1)

- ... Energy: Igus Solutions For Renewable Energy: Solar and Wind EnergyDocumento7 páginas... Energy: Igus Solutions For Renewable Energy: Solar and Wind EnergyMarcos AmorimAinda não há avaliações

- File11 PTDocumento2 páginasFile11 PTMarcos AmorimAinda não há avaliações

- MA Freifeld 03 - 2008 (En)Documento20 páginasMA Freifeld 03 - 2008 (En)Marcos AmorimAinda não há avaliações

- Autocad Civil 3D General Discussion: Search This BoardDocumento3 páginasAutocad Civil 3D General Discussion: Search This BoardMarcos AmorimAinda não há avaliações

- UK TechnBroschDocumento52 páginasUK TechnBroschMarcos AmorimAinda não há avaliações

- Kalzip - Fixing Manual: Corus BausystemeDocumento56 páginasKalzip - Fixing Manual: Corus BausystemeMarcos AmorimAinda não há avaliações

- 5 Inch Monocrystalline SF 160mDocumento2 páginas5 Inch Monocrystalline SF 160mMarcos AmorimAinda não há avaliações

- Ficha Fachadas Paineis Hairisol1025CDocumento1 páginaFicha Fachadas Paineis Hairisol1025CMarcos AmorimAinda não há avaliações

- SANHIA210Documento2 páginasSANHIA210Marcos AmorimAinda não há avaliações

- Section 2Documento6 páginasSection 2Marcos AmorimAinda não há avaliações

- HIP 215NKHA6 DatasheetDocumento2 páginasHIP 215NKHA6 DatasheetMarcos AmorimAinda não há avaliações

- Kalzip Alupluszinc: Zinc Patinated Aluminium Profiled SheetsDocumento8 páginasKalzip Alupluszinc: Zinc Patinated Aluminium Profiled SheetsMarcos AmorimAinda não há avaliações

- UK Kliptec400Documento2 páginasUK Kliptec400Marcos AmorimAinda não há avaliações

- Kalzip - Fixing Manual: Corus BausystemeDocumento56 páginasKalzip - Fixing Manual: Corus BausystemeMarcos AmorimAinda não há avaliações

- UK-Kalzip Facade System TechnicalDocumento32 páginasUK-Kalzip Facade System TechnicalMarcos AmorimAinda não há avaliações

- Kalzip Sets StandardsDocumento32 páginasKalzip Sets StandardsClef GonadanAinda não há avaliações

- UK-Kalzip Insulation 040Documento2 páginasUK-Kalzip Insulation 040Marcos AmorimAinda não há avaliações

- Design Guide 11 Welded Beam To Column Moment ConnectionsDocumento8 páginasDesign Guide 11 Welded Beam To Column Moment ConnectionsVeerabhadrayya KatapurmathAinda não há avaliações

- Steel Design ExamDocumento37 páginasSteel Design ExamEugene CardamaAinda não há avaliações

- Analysis and Design of Shell Foundation Is 9456 1980 ProvisionDocumento6 páginasAnalysis and Design of Shell Foundation Is 9456 1980 ProvisionAhmed salahAinda não há avaliações

- Pure BendingDocumento4 páginasPure BendingSanthoshRockzzAinda não há avaliações

- CH 02 Cotter Knuckle JointDocumento39 páginasCH 02 Cotter Knuckle JointDifferent wayAinda não há avaliações

- Application of Hyperstatic Reaction Method For Designing of Tunnel Permanent Lining, Part I: 2D Numerical ModellingDocumento11 páginasApplication of Hyperstatic Reaction Method For Designing of Tunnel Permanent Lining, Part I: 2D Numerical ModellingIngrid Irreño PalomoAinda não há avaliações

- Lifting Lug DesignDocumento17 páginasLifting Lug Designguravdr100% (2)

- CIVN3001-FINAL REPORT ... MDocumento20 páginasCIVN3001-FINAL REPORT ... MThabiso MotalingoaneAinda não há avaliações

- Civil Engineering Syllabus Sem III Mumbai UniversityDocumento77 páginasCivil Engineering Syllabus Sem III Mumbai UniversityRahul patilAinda não há avaliações

- Week 12 - Prestressed Concrete - Part 2Documento35 páginasWeek 12 - Prestressed Concrete - Part 2adit guptaAinda não há avaliações

- Glasgow College of Nautical StudiesDocumento3 páginasGlasgow College of Nautical StudiesnoczviviAinda não há avaliações

- Design of TEE Sections in BendingDocumento3 páginasDesign of TEE Sections in BendingJimmyAinda não há avaliações

- Donikian Et Al (2012) 3D Ssi Analysis of Cut and Cover Tunnel Doyle Drive SF, CaDocumento10 páginasDonikian Et Al (2012) 3D Ssi Analysis of Cut and Cover Tunnel Doyle Drive SF, CaYuamar BasarahAinda não há avaliações

- 10.5 Eccentrically Loaded Columns: Axial Load and BendingDocumento20 páginas10.5 Eccentrically Loaded Columns: Axial Load and BendingAnthony ManigoAinda não há avaliações

- Dynamic Bending Response of CFRP Thin Walled Square Beams Filled With Aluminium HoneycombDocumento10 páginasDynamic Bending Response of CFRP Thin Walled Square Beams Filled With Aluminium HoneycombIeva MisiūnaitėAinda não há avaliações

- Design 2Documento29 páginasDesign 2cielo_cetd3670Ainda não há avaliações

- Theory of Simple Bending - Full1Documento62 páginasTheory of Simple Bending - Full1Rahul KasaudhanAinda não há avaliações

- Vlasov Computation of Prismatic SHellsDocumento53 páginasVlasov Computation of Prismatic SHellsMaliOdKužineAinda não há avaliações

- Chapter 8 - Combined LoadingDocumento38 páginasChapter 8 - Combined LoadingzamspaceklAinda não há avaliações

- Draw The SFD BMDDocumento12 páginasDraw The SFD BMDAshok PradhanAinda não há avaliações

- Steel Column Base Plate AnalysisDocumento1 páginaSteel Column Base Plate AnalysisVega DesAinda não há avaliações

- B TechDocumento38 páginasB TechZaid HadiAinda não há avaliações

- Dr.S.Arul Mary, Associate Professor, Department of Civil Thiagarajar College of Engg., Madurai-15Documento68 páginasDr.S.Arul Mary, Associate Professor, Department of Civil Thiagarajar College of Engg., Madurai-15nupurAinda não há avaliações

- Report by Yosef BerieDocumento65 páginasReport by Yosef Beriealem bayableAinda não há avaliações

- Static Pile Load Test ManualDocumento57 páginasStatic Pile Load Test Manualphamminhquang100% (1)

- BES7 MT3B Mechanics of Deformable Bodies SyllabusDocumento5 páginasBES7 MT3B Mechanics of Deformable Bodies SyllabusSTEPHEN VILLARUZAinda não há avaliações

- MA4702 Ch-1 Introduction WBDocumento39 páginasMA4702 Ch-1 Introduction WBWong Tian HaoAinda não há avaliações

- SkyCiv Beam - Hand Calculations Vv4qGwROUWk3NJ6yARlkk2SYHocMr4oFDocumento12 páginasSkyCiv Beam - Hand Calculations Vv4qGwROUWk3NJ6yARlkk2SYHocMr4oFsamAinda não há avaliações

- Design of Machine Elements 4Documento115 páginasDesign of Machine Elements 4Dr. Aung Ko Latt100% (1)