Escolar Documentos

Profissional Documentos

Cultura Documentos

VVT-i (Variable Valve Timing-Intelligent) System: General

Enviado por

sadiksnmTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

VVT-i (Variable Valve Timing-Intelligent) System: General

Enviado por

sadiksnmDireitos autorais:

Formatos disponíveis

38

ENGINE 1ZZ-FE ENGINE

6. VVT-i (Variable Valve Timing-intelligent) System

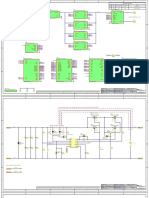

General This system controls the intake camshaft valve timing so as to obtain balance between the engine output, fuel consumption and emission control performance. The actual intake side valve timing is feed back by means of the camshaft position sensor for constant control to the target valve timing.

Camshaft Position Sensor

Engine Coolant Temp. Sensor

Throttle Position Sensor

ECM

Camshaft Timing Oil Control Valve

Mass Air Flow Meter

Crankshaft Position Sensor

169EG35

ECM Crankshaft Position Sensor Mass Air Flow Meter Feed Back Throttle Position Sensor Duty Control

Engine Coolant Temp. Sensor

Camshaft Timing Oil Control Valve

Target Valve Timing

Correction Actual Valve Timing

Camshaft Position Sensor Vehicle Speed Signal

172CR07

ENGINE 1ZZ-FE ENGINE Construction 1) VVT-i Controller

39

This controller consists of the housing driven from the timing chain and the vane coupled with the intake camshaft. The oil pressure sent from the advance or retard side path at the intake camshaft causes rotation in the VVT-i controller vane circumferential direction to vary the intake valve timing continuously. When the engine is stopped, the intake camshaft will be in the most retarded state to ensure startability. When hydraulic pressure is not applied to the VVT-i controller immediately after the engine has been started, the lock pin locks the movement of the VVT-i controller to prevent a knocking noise.

Lock Pin

Vane (Fixed on Intake Camshaft) Intake Camshaft

Housing Oil Pressure At a Stop In Operation

169EG36

Lock Pin

2) Camshaft Timing Oil Control Valve To VVT-i To VVT-i The camshaft timing oil control valve controls the Controller Controller spool valve position in accordance with the duty (Advance Side) (Retard Side) control from the ECM thus allocating the hydraulic pressure that is applied to the VVT-i controller to the advance and the retard side. When the en- Sleeve Spool Valve gine is stopped, the camshaft timing oil control valve is in the most retarded state.

Connector

Drain Drain Oil Pressure Spring Coil Plunger

165EG34

40 Operation

ENGINE 1ZZ-FE ENGINE

D The camshaft timing oil control valve selects the path to the VVT-i controller according to the advance, retard or hold signal from the ECM. The VVT-i controller rotates the intake camshaft in the timing advance or retard position or holds it according to the position where the oil pressure is applied. Operation Vane Camshaft Timing Oil Control Valve Drive Signal Advance Signal When the camshaft timing oil control valve is positioned as illustration by the advance signal from the ECM, the resultant oil pressure is applied to the timing advance side vane chamber to rotate the camshaft in the timing advance direction.

157EG35

Description

Advance

Rotating Direction

VVT-i Controller Housing

ECM

Duty Ratio Oil Pressure

178EG15

Retard Signal When the camshaft timing oil control valve is positioned as illustration by the retard signal from the ECM, the resultant oil pressure is applied to the timing retard side vane chamber to rotate the camshaft in the timing retard direction.

Retard

Rotating Direction

ECM Duty Ratio Oil Pressure

178EG16 157EG36

Hold Signal

ECM

Duty Ratio Oil Pressure

178EG17 157EG37

The ECM calculates the target timing angle according to the traveling state to perform control as described above. After setting at the target timing, the valve timing is held by keeping the camshaft timing oil control valve in the neutral position unless the traveling state changes. This adjusts the valve timing at the desired target position and prevents the engine oil from running out when it is unnecessary.

Hold

ENGINE 1ZZ-FE ENGINE

41

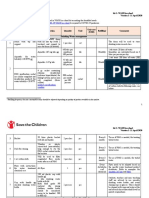

D In proportion to the engine speed, intake air volume, throttle position and water temperature, the ECM calculates an optimal valve timing under each driving condition and control the camshaft timing oil control valve. In addition, ECM uses signal from the camshaft position sensor and the crankshaft position sensor to detect the actual valve timing, thus performing feed back control to achieve the target valve timing. " Operation During Various Driving Condition (Conceptual Diagram) A Full Load Performance

Range 4 Engine Load

Range 5

Range 3 Range 1, 2

Engine Speed Operation State Range Valve Timing TDC Objective

162EG46

Effect

Latest timing

During Idling

EX

IN

Minimizing overlap to reduce blow back to the intake side

Stabilized idling rpm Better fuel economy

BDC

178EG18

To retard side

At Light Load

EX

IN

Decreasing overlap to eliminate blow back to the intake side

Ensured engine stability

178EG19

To advance side

At Medium load

EX

IN

Increasing overlap to increase internal EGR for pumping loss elimination

Better fuel economy Improved emission control

178EG20

42 Operation State Range

ENGINE 1ZZ-FE ENGINE Valve Timing

TDC

Objective

Effect

In Low to Medium Speed Range with Heavy Load

EX

IN

To advance

Advancing the intake valve close timing for volumetric efficiency improvement

Improved torque in low to medium speed range

BDC side178EG21

In High Speed Range with Heavy Load

EX

To retard side

IN

Retarding the intake valve close timing for volumetric efficiency improvement

Improved output

178EG22

Latest timing

At Low Temperatures

EX

IN

Minimizing overlap to prevent blow back to the intake side for reduction of fuel increase at low temperatures, and stabilizing the idling rpm for decreasing fast idle rotation

Stabilized fast idle rpm Better fuel economy

178EG23

Latest timing

Upon Starting/ Stopping the Engine

EX IN

Minimizing overlap to minimize blow back to the intake side

Improved startability

178EG24

Você também pode gostar

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SAinda não há avaliações

- 1gr Fe VvtisystemDocumento4 páginas1gr Fe VvtisystemGepenx AriesAinda não há avaliações

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAinda não há avaliações

- VVT Sensor PDFDocumento4 páginasVVT Sensor PDFDoDuyBac100% (1)

- VVT-i (Variable Valve Timing-Intelligent) SystemDocumento4 páginasVVT-i (Variable Valve Timing-Intelligent) SystemJorge Armando VelázquezAinda não há avaliações

- Essex Terraplane Six 1933 Owner's Manual of InformationNo EverandEssex Terraplane Six 1933 Owner's Manual of InformationAinda não há avaliações

- 1MZ-FE Engine Control SystemRX300 99Documento11 páginas1MZ-FE Engine Control SystemRX300 99Jose Calle100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementAinda não há avaliações

- Miscellaneous Information On AutomotiveDocumento6 páginasMiscellaneous Information On AutomotiveShashank ChheniyaAinda não há avaliações

- 1zzVS2zz 6Documento16 páginas1zzVS2zz 6Ofi de Mo100% (1)

- VVT (Variable Valve Timing)Documento26 páginasVVT (Variable Valve Timing)PramodPradhan100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAinda não há avaliações

- Variable Valve TimingDocumento3 páginasVariable Valve Timingsandesh ganigaAinda não há avaliações

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationAinda não há avaliações

- K41A - CVT - General InfoDocumento60 páginasK41A - CVT - General Infoesquisof86% (7)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesNo EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesNota: 1 de 5 estrelas1/5 (2)

- 2.3.2 GT DetailsDocumento40 páginas2.3.2 GT DetailsSarah Cohen100% (3)

- 2ZZGE Engine - Part of ManualDocumento46 páginas2ZZGE Engine - Part of ManualDavide Faelli100% (2)

- 04 D155 EngineDocumento32 páginas04 D155 Engineghitacrainic100% (5)

- Motorcycle, Solo (Harley-Davidson Model WLA)No EverandMotorcycle, Solo (Harley-Davidson Model WLA)Ainda não há avaliações

- B737-Powerplant Systems SummaryDocumento16 páginasB737-Powerplant Systems SummaryOB ChavasAinda não há avaliações

- Gaseous Fuel SystemDocumento5 páginasGaseous Fuel Systemchdeepak96Ainda não há avaliações

- SSP 327 - Audi Engines - Chain Drives - Part 2Documento47 páginasSSP 327 - Audi Engines - Chain Drives - Part 2McGiver990100% (2)

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)No EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)Ainda não há avaliações

- Fuel SystemDocumento99 páginasFuel SystemPaulus Saing100% (5)

- Variable Valve Timing Intelligent SystemDocumento17 páginasVariable Valve Timing Intelligent Systemmantusubudhi100% (8)

- 4transmission System ENGLISG-G9180Documento44 páginas4transmission System ENGLISG-G9180George Jhonson100% (6)

- 3Gr-Fse Fuel: GeneralDocumento14 páginas3Gr-Fse Fuel: Generalservice_007100% (1)

- Weber Injection-Ignition SystemDocumento27 páginasWeber Injection-Ignition SystemjohnvandurenAinda não há avaliações

- 10 Automatic Transaxle SystemDocumento35 páginas10 Automatic Transaxle SystemYun ZhenAinda não há avaliações

- VW Digifant ManualDocumento43 páginasVW Digifant ManualChris Rimmer100% (6)

- Garrett Turbocharger CatalogDocumento12 páginasGarrett Turbocharger Cataloghamiti100% (2)

- Sistema de Control de EmisionesDocumento45 páginasSistema de Control de EmisionesDavid ParariAinda não há avaliações

- MAN B&W Fuel PumpDocumento8 páginasMAN B&W Fuel PumpNick Konor100% (2)

- Injectors and Fuel Lines - OverviewDocumento17 páginasInjectors and Fuel Lines - Overviewjose_saugo2601100% (1)

- TFE 731 Chap 79Documento24 páginasTFE 731 Chap 79Egor8550% (2)

- Engine Control LS600HLDocumento66 páginasEngine Control LS600HLnang32Ainda não há avaliações

- Embraer145 EngineDocumento61 páginasEmbraer145 EngineTaksi100% (2)

- Tr7-8fi ManualDocumento82 páginasTr7-8fi ManualClint CooperAinda não há avaliações

- Self-Study Programme 246 - Variable Valve TimingDocumento30 páginasSelf-Study Programme 246 - Variable Valve TimingTombalicious100% (1)

- Variable Valve Timing In.7215890.powerpointDocumento7 páginasVariable Valve Timing In.7215890.powerpointAKSHAY SAinda não há avaliações

- Engine PerformanceDocumento1.301 páginasEngine PerformanceAlexis Yureni Rodriguez Rojas100% (1)

- 5brake System Englisg-G9165Documento28 páginas5brake System Englisg-G9165George Jhonson90% (10)

- 6b m3 c3Documento10 páginas6b m3 c3herysyam100% (1)

- GT Various Systems (G)Documento62 páginasGT Various Systems (G)shtiwari2002100% (2)

- 6284 2 05 PDFDocumento7 páginas6284 2 05 PDFnpsAinda não há avaliações

- TFE 731 Chap 73Documento34 páginasTFE 731 Chap 73Egor85100% (2)

- Diesel Injection Pump COVEC-FDocumento36 páginasDiesel Injection Pump COVEC-FPorras Edwin71% (7)

- حساسات الكراون PDFDocumento15 páginasحساسات الكراون PDFMarranAinda não há avaliações

- 2 Variable Valve TimingDocumento30 páginas2 Variable Valve TimingAlex Mariei100% (1)

- Cfm56-3 Systems Training ManualsDocumento187 páginasCfm56-3 Systems Training Manualsnono92100% (13)

- Engine Control System DiagramDocumento8 páginasEngine Control System DiagramGowher QadriAinda não há avaliações

- Exterior View of The GearboxDocumento14 páginasExterior View of The GearboxCYRIL100% (2)

- Ansys CFX Student User ManualDocumento64 páginasAnsys CFX Student User Manualvdnsit100% (1)

- Chapter 2Documento10 páginasChapter 2anil.gelra5140Ainda não há avaliações

- IES CONV Mechanical Engineering 1985Documento8 páginasIES CONV Mechanical Engineering 1985coolpawan10Ainda não há avaliações

- Hï Íßæçütè & ( Ëmîst Ü Sœæþ 1: SakshiDocumento4 páginasHï Íßæçütè & ( Ëmîst Ü Sœæþ 1: SakshisadiksnmAinda não há avaliações

- Toby Lai ThesisDocumento300 páginasToby Lai ThesissadiksnmAinda não há avaliações

- Chapter 5Documento11 páginasChapter 5anil.gelra5140Ainda não há avaliações

- EML5526 Finite Element Analysis: Basic InformationDocumento2 páginasEML5526 Finite Element Analysis: Basic InformationsadiksnmAinda não há avaliações

- 1st Week Insight (4th Jan To 10th Jan) of 2016Documento6 páginas1st Week Insight (4th Jan To 10th Jan) of 2016sadiksnmAinda não há avaliações

- 1st Week Q&A (4th Jan To 10th Jan)Documento24 páginas1st Week Q&A (4th Jan To 10th Jan)sadiksnmAinda não há avaliações

- NITI-Aayog For SSC and BankDocumento4 páginasNITI-Aayog For SSC and BankShan ReddyAinda não há avaliações

- Current Affairs 2016 Telugu Bit Bank Download 4 PDFDocumento3 páginasCurrent Affairs 2016 Telugu Bit Bank Download 4 PDFsadiksnmAinda não há avaliações

- Sample Questions PDFDocumento4 páginasSample Questions PDFsadiksnmAinda não há avaliações

- 1st Week Main Events (4th Jan To 10th Jan)Documento16 páginas1st Week Main Events (4th Jan To 10th Jan)sadiksnmAinda não há avaliações

- Scheme Pm1Documento9 páginasScheme Pm1manpreetsingh3458417Ainda não há avaliações

- AfmDocumento3 páginasAfmsadiksnmAinda não há avaliações

- Chapter 1Documento8 páginasChapter 1alexandraanastasiaAinda não há avaliações

- Dinamica Newton EulerDocumento16 páginasDinamica Newton EulerPaul Alvarez HerreraAinda não há avaliações

- CHPT 3 PDFDocumento137 páginasCHPT 3 PDFKevin Dwi PrasetioAinda não há avaliações

- Kalman Notes 001Documento11 páginasKalman Notes 001sadiksnmAinda não há avaliações

- Design of Steel StructuresDocumento26 páginasDesign of Steel StructuresMfon UdoitaAinda não há avaliações

- PTDocumento2 páginasPTsadiksnmAinda não há avaliações

- 2006 PDFDocumento1 página2006 PDFsadiksnmAinda não há avaliações

- 2017 2Documento3 páginas2017 2sadiksnmAinda não há avaliações

- Handbook of Robotics Chapter 1: KinematicsDocumento31 páginasHandbook of Robotics Chapter 1: KinematicssadiksnmAinda não há avaliações

- PLM 20dec17Documento18 páginasPLM 20dec17sadiksnmAinda não há avaliações

- Sample QuestionsDocumento4 páginasSample QuestionssadiksnmAinda não há avaliações

- N N=Ln (1+E) =Ln (1+0.35) =0.30 Kϵ K=775 MpaDocumento1 páginaN N=Ln (1+E) =Ln (1+0.35) =0.30 Kϵ K=775 MpasadiksnmAinda não há avaliações

- 8Documento23 páginas8sadiksnmAinda não há avaliações

- In This Section You Will Learn The FollowingDocumento13 páginasIn This Section You Will Learn The FollowingsadiksnmAinda não há avaliações

- Application of PLC in Computer Numerical Control Machine: Shuqin XuDocumento5 páginasApplication of PLC in Computer Numerical Control Machine: Shuqin XusadiksnmAinda não há avaliações

- China Ve01 With Tda93xx An17821 Stv9302a La78040 Ka5q0765-SmDocumento40 páginasChina Ve01 With Tda93xx An17821 Stv9302a La78040 Ka5q0765-SmAmadou Fall100% (1)

- Resources and Courses: Moocs (Massive Open Online Courses)Documento8 páginasResources and Courses: Moocs (Massive Open Online Courses)Jump SkillAinda não há avaliações

- SKF LGMT-2 Data SheetDocumento2 páginasSKF LGMT-2 Data SheetRahul SharmaAinda não há avaliações

- Hoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFDocumento2 páginasHoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFMarco Antonio Gutierrez PulchaAinda não há avaliações

- Scheme Bidirectional DC-DC ConverterDocumento16 páginasScheme Bidirectional DC-DC ConverterNguyễn Quang KhoaAinda não há avaliações

- ProAim InstructionsDocumento1 páginaProAim Instructionsfeli24arias06Ainda não há avaliações

- SCHEDULE OF FEES - FinalDocumento1 páginaSCHEDULE OF FEES - FinalAbhishek SunaAinda não há avaliações

- SWOT AnalysisDocumento6 páginasSWOT AnalysisSSPK_92Ainda não há avaliações

- Fast Binary Counters and Compressors Generated by Sorting NetworkDocumento11 páginasFast Binary Counters and Compressors Generated by Sorting Networkpsathishkumar1232544Ainda não há avaliações

- To Syed Ubed - For UpdationDocumento1 páginaTo Syed Ubed - For Updationshrikanth5singhAinda não há avaliações

- Software Hackathon Problem StatementsDocumento2 páginasSoftware Hackathon Problem StatementsLinusNelson100% (2)

- Qualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Documento23 páginasQualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Saqlain Siddiquie100% (1)

- Vocabulary Practice Unit 8Documento4 páginasVocabulary Practice Unit 8José PizarroAinda não há avaliações

- Harga H2H Pula-Paket Data - Saldo EWallet v31012022Documento10 páginasHarga H2H Pula-Paket Data - Saldo EWallet v31012022lala cemiAinda não há avaliações

- ACC403 Week 10 Assignment Rebecca MillerDocumento7 páginasACC403 Week 10 Assignment Rebecca MillerRebecca Miller HorneAinda não há avaliações

- Catalog enDocumento292 páginasCatalog enSella KumarAinda não há avaliações

- SEBI Circular Dated 22.08.2011 (Cirmirsd162011)Documento3 páginasSEBI Circular Dated 22.08.2011 (Cirmirsd162011)anantAinda não há avaliações

- Adjectives With Cork English TeacherDocumento19 páginasAdjectives With Cork English TeacherAlisa PichkoAinda não há avaliações

- Reading TPO 49 Used June 17 To 20 10am To 12pm Small Group Tutoring1Documento27 páginasReading TPO 49 Used June 17 To 20 10am To 12pm Small Group Tutoring1shehla khanAinda não há avaliações

- Gujarat Technological UniversityDocumento2 páginasGujarat Technological UniversityBhavesh PatelAinda não há avaliações

- Deshidratador Serie MDQDocumento4 páginasDeshidratador Serie MDQDAIROAinda não há avaliações

- Kit 2: Essential COVID-19 WASH in SchoolDocumento8 páginasKit 2: Essential COVID-19 WASH in SchooltamanimoAinda não há avaliações

- QuestionDocumento7 páginasQuestionNgọc LuânAinda não há avaliações

- Planas V Comelec - FinalDocumento2 páginasPlanas V Comelec - FinalEdwino Nudo Barbosa Jr.100% (1)

- CW February 2013Documento60 páginasCW February 2013Clint FosterAinda não há avaliações

- จัดตารางสอบกลางภาคภาคต้น53Documento332 páginasจัดตารางสอบกลางภาคภาคต้น53Yuwarath SuktrakoonAinda não há avaliações

- The Voice of The Villages - December 2014Documento48 páginasThe Voice of The Villages - December 2014The Gayton Group of ParishesAinda não há avaliações

- Computer Vision and Action Recognition A Guide For Image Processing and Computer Vision Community For Action UnderstandingDocumento228 páginasComputer Vision and Action Recognition A Guide For Image Processing and Computer Vision Community For Action UnderstandingWilfredo MolinaAinda não há avaliações

- Unit List MUZAFFARPUR - Feb 18 PDFDocumento28 páginasUnit List MUZAFFARPUR - Feb 18 PDFPawan Kumar100% (1)

- Pediatric Skills For OT Assistants 3rd Ed.Documento645 páginasPediatric Skills For OT Assistants 3rd Ed.Patrice Escobar100% (1)