Escolar Documentos

Profissional Documentos

Cultura Documentos

Three Phase Winding Technology

Enviado por

nir205Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Three Phase Winding Technology

Enviado por

nir205Direitos autorais:

Formatos disponíveis

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/1

3.

3.

Three phase winding technology

Three phase winding technology

Source:

VATech Hydro,

Austria

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/2

Single layer winding

Example:

Three-phase, 12-pole machine with q = 3

coils per pole and phase:

Total slot number: Q = m

.

2p

.

q = 3

.

12

.

3 = 108

North- and south pole are generated by ONE

coil group per phase.

Per slot only one coil side is placed.

Coils manufactured as:

a) Coils with identical coil span: W =

p

b) Concentric coils

Problem with single layer windings:

Crossing of coils in winding overhang part, as

all coils are lying in the same plane. Thus some

coils must be bent upward in winding overhang

region (2

nd

plane).

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/3

Example: Single layer winding with short and long coils

Unrolled winding system

gives winding scheme: her

four-pole machine: 2p = 4,

m = 3, q =2, Q = 24

Winding manufactured with

concentric coils.

Long coils: Winding over-

hang part of coils is longer;

so these coils may be bent

upwards !

Each phase has one pole pair

with short and one pole pair

with long coils ! So resistance

per phase is equal, but minimum of

4 poles required !

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/4

Stator three phase single-layer winding of induction machine

Source:

ELIN EBG Motors,

Austria

Round

wire coils

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/5

Two-layer winding

Coils with equal span

Two-layer winding: Per slot TWO

coil sides are placed one above the

other.

North- and south pole are generated

by two coil groups.

Direction of current flow in N- and

S-pole coils opposite !

Changing of current flow direction

by reversal connector.

Bigger machine ratings typically

above 500 kW: Profiled coil con-

ductors (rectangular cross section),

round wire with smaller machines !

Example: For 4-pole machine we need

four coil groups per phase !

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/6

Winding overhang of two-layer winding

a) Two form wound coils before being put into the stator slots: Due to S-shape in

winding overhang part of coils there are NO crossing points of the coils.

b) Form wound coil with profiled conductor, placed in stator slot, with left coil side in

lower and right coil side in upper layer. Manufacturing much more expensive than

with round wire single-layer winding, therefore used usually only in bigger machines:

e.g.high voltage machines up to 30 kV (High voltage: U > 1000 V (rms)!).

a) b)

Winding overhang

Coil side

slot

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/7

High voltage form wound stator coil with several

turns N

c

for two-layer winding

Source:

VATech Hydro,

Austria

Winding overhang

coil side, inserted in slot

coil terminals

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/8

Pitching (chording) of coils W <

p

With Two-layer windings: pitching of coils is possible !

Pitching = Shortening of coil span W , counted in number S of slot pitches

q m

Y

q m

S q m

W

Q

p p

=

S : integer number

Benefit of pitching: Shape of field curve fits better to ideal sinusoidal shape.

Example: Four-pole machine: Data: m = 3, Q = 24, q = 2:

Pitching is possible for S < mq = 3

.

2 = 6: S = 1, 2, 3, 4, 5.

e. g.: S = 1, hence pitching is W/

p

= 5/6.

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/9

Example: Pitched Two-layer winding

Four pole machine, m = 3, Q = 24, q = 2: Pitching W/

p

= 5/6.

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/10

Inserting form-wound two-layer winding in

induction generator stator

Source:

Winergy

Germany

Stator iron

stack

coil ends

Winding

overhang

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/11

Inserting form-wound two-layer winding in stator

slots

Source:

ABB, Switzerland

Stator iron

stack

slots

Winding

overhang

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/12

Stator three phase two-layer winding of induction generator

Source:

Winergy

Germany

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/13

Rotor three phase two-layer winding of slip ring

induction generator

Source:

Winergy

Germany

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/14

Inserting of impregnated form wound coils in the stator slots

of a synchronous hydro generator with high pole count

Source:

VATech Hydro,

Austria

Ventilation

duct

Tooth

Slot

Massive

iron

clamping

finger

Pressing

plate

1

st

layer

2

nd

layer

winding

overhang

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/15

Series and parallel connection of coil groups

Series and parallel connection of coil groups to get one winding phase

Example : Eight-pole machine:

Two-layer winding: 8 coil groups, which may be connected as follows:

a = 1: Series connection of all 8 coil groups

a = 2: 4 coil groups in series, then paralleling the two series sections

a = 4: 2 coil groups in series,then paralleling the four series sections

a = 8: All 8 coil groups are connected in parallel

Single-layer winding: 4 coil groups, which may be connected as follows:

a = 1: Series connection of all 4 coil groups

a = 2: 2 coil groups in series, then paralleling the two series sections

a = 4: All 4 coil groups are connected in parallel

Resulting number of turns per phase N:

Single-layer winding Two-layer winding

Example: 2p = 4, q = 2, eleven turns per coil (N

c

= 11), series connection of all

coil groups: a = 1: number of turns per phase: N = 4

.

2

.

11/1 = 88

a

pqN

N

c

=

a

pqN

N

c

2

=

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/16

Variants of cooling of winding and iron stack

Heat flow

density

(W/cm

2

)

Indirect air-

cooled stator

winding

Stator iron

stack packets

Directly air-cooled

rotor pole winding

Air/hydrogen water

Directly cooled hollow conductors

For

comparison:

Heat transfer

of flat -iron

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/17

Rated voltage U

n

of stator winding increases with increasing

apparent power S

n

to limit rated current I

n

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/18

Welded stator housing of synchronous hydro generator

Source:

VATech Hydro,

Austria

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/19

Stacking of stator iron sheets of synchronous hydro generator

Source:

VATech Hydro,

Austria

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/20

Pressing of laminated stator iron core with hydraulic

cylinders

Source:

VATech Hydro,

Austria

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/21

Insulation of high voltage stator winding (one

turn = stator bar) with insulation robot

Source:

VATech Hydro,

Austria

Big generators:

Only one turn per coil.

Coil is split into 2

halves = 2 bars.

Here visible: Insulating

one bar for a 2-pole

turbine generator with

glass-fibre band with

mica layer for high

voltage insulation.

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/22

Insulation of high voltage stator winding (one

turn = stator bar) with insulation robot

Source:

VATech Hydro,

Austria

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/23

Resin impregnated coils are heated in the oven

to dry and harden the insulation

Source:

VATech Hydro,

Austria

DARMSTADT

UNIVERSITY OF

TECHNOLOGY

Dept. of Electrical Energy Conversion

Prof. A. Binder

3/24

High voltage stator winding of synchronous hydro

generator - Pressing of winding bars in the slots

Source:

VATech Hydro,

Austria

Você também pode gostar

- AC Motors Winding DiagramDocumento40 páginasAC Motors Winding Diagrampepa6781% (31)

- Week3 Dc-Generator 1Documento32 páginasWeek3 Dc-Generator 1Heart Louise MalonesAinda não há avaliações

- Design of DC Machines ConstructionDocumento42 páginasDesign of DC Machines ConstructionSatya Sudhakar RasamsettiAinda não há avaliações

- A New 4 - 6 Pole-Changing Double Layer Winding For Three Phase Electrical MachinesDocumento7 páginasA New 4 - 6 Pole-Changing Double Layer Winding For Three Phase Electrical MachineszdrahalAinda não há avaliações

- 1337700609.8991chap - 6 Synchronous GeneratorsDocumento33 páginas1337700609.8991chap - 6 Synchronous GeneratorsRoel MoralezAinda não há avaliações

- Unit 3 Ee336Documento30 páginasUnit 3 Ee336Satya Sudhakar RasamsettiAinda não há avaliações

- EM-II HANDOUT Reg 2107Documento50 páginasEM-II HANDOUT Reg 2107karthikeyan249Ainda não há avaliações

- Chapter 4 - Synchronous MachineDocumento53 páginasChapter 4 - Synchronous MachinethuraiyaAinda não há avaliações

- Alternating Current GeneratorsDocumento28 páginasAlternating Current GeneratorsLouise UmaliAinda não há avaliações

- EMD U2 - Study MaterialDocumento7 páginasEMD U2 - Study MaterialSUJITHA NAinda não há avaliações

- AC Windings StudentsDocumento17 páginasAC Windings StudentsSisira JayamannaAinda não há avaliações

- Unit 4 Three Phase Induction Motor Design - Part 1Documento31 páginasUnit 4 Three Phase Induction Motor Design - Part 1Prema ElizabethAinda não há avaliações

- AlternatorDocumento27 páginasAlternatorseikh_aiAinda não há avaliações

- Induction Motor Notes LVBDocumento14 páginasInduction Motor Notes LVBlvb123Ainda não há avaliações

- TransformersDocumento31 páginasTransformersEhsan Elahi BashirAinda não há avaliações

- 4 and 6 Pole MotorDocumento6 páginas4 and 6 Pole Motorarajamani78100% (1)

- Problems - Chapter 4 1 PDFDocumento7 páginasProblems - Chapter 4 1 PDFjohn romel mojicaAinda não há avaliações

- DC Machine DesignDocumento25 páginasDC Machine DesignJatin PradhanAinda não há avaliações

- Design of DC MachinesDocumento60 páginasDesign of DC Machinesmanu eAinda não há avaliações

- Ee8002 - Dem - Question Bank - Unit2Documento3 páginasEe8002 - Dem - Question Bank - Unit2DEVIAinda não há avaliações

- Determine Different Parameters and Design of DC MachineDocumento31 páginasDetermine Different Parameters and Design of DC Machinechandan kumarAinda não há avaliações

- Electrical SystemDocumento42 páginasElectrical SystemSamiha Maysoon NooriaAinda não há avaliações

- Analysis of Brushless Three-Phase Synchronous Generator Without ExciterDocumento10 páginasAnalysis of Brushless Three-Phase Synchronous Generator Without ExciterJuan Andres Rojas SerranoAinda não há avaliações

- Armature Windings 2Documento22 páginasArmature Windings 2Ero RosalAinda não há avaliações

- L-13 (DK) (Pe) ( (Ee) Nptel)Documento108 páginasL-13 (DK) (Pe) ( (Ee) Nptel)Akshaya HariharanAinda não há avaliações

- 1 Permanent Magnet GeneratorDocumento6 páginas1 Permanent Magnet GeneratorGanti KameshAinda não há avaliações

- Alternators PDFDocumento57 páginasAlternators PDFChanning Tatum100% (5)

- DC MotorDocumento53 páginasDC MotorK04Anoushka TripathiAinda não há avaliações

- DC MachineDocumento3 páginasDC MachineKantharaj ChinnappaAinda não há avaliações

- DC Generator Armature Windings)Documento23 páginasDC Generator Armature Windings)zeshankhan4321_50832Ainda não há avaliações

- Dr. Ambedkar Institute of Technology, Bangalore - 560056Documento6 páginasDr. Ambedkar Institute of Technology, Bangalore - 5600561DA19EE004 AMBUJ KUMAR MISHRAAinda não há avaliações

- DC MachinesDocumento42 páginasDC Machineseee2014.rvsAinda não há avaliações

- AlternatorsDocumento43 páginasAlternatorsPauline SilvaAinda não há avaliações

- Three Phase Synchronous MachinesDocumento45 páginasThree Phase Synchronous MachinesAndrew Lapthorn100% (3)

- Electric Machines: Faculty of Engineering Tanta UniversityDocumento33 páginasElectric Machines: Faculty of Engineering Tanta UniversityMUuhammed FikiAinda não há avaliações

- Question Bank 2Documento11 páginasQuestion Bank 2IppiAinda não há avaliações

- Electrical Machine - Ga - 1Documento8 páginasElectrical Machine - Ga - 1rahulmeenameenarahul26Ainda não há avaliações

- EE301 AC Rotating Machines Lecture NoteDocumento194 páginasEE301 AC Rotating Machines Lecture NoteAnkit AadarshAinda não há avaliações

- 18) DC Machinary FundamentalsDocumento7 páginas18) DC Machinary FundamentalsAhmad SaadehAinda não há avaliações

- Basic Operation and Constructional Features of A DC Machine AreDocumento28 páginasBasic Operation and Constructional Features of A DC Machine AreBrijesh PrasadAinda não há avaliações

- GeneratorDocumento38 páginasGeneratorKhaledAhmedAinda não há avaliações

- Lecture Objectives: Working Principle of Alternator OR Synchronous Generator StatorDocumento5 páginasLecture Objectives: Working Principle of Alternator OR Synchronous Generator StatorZ_JahangeerAinda não há avaliações

- Unit 2 BEEDocumento27 páginasUnit 2 BEEgnancy subha gAinda não há avaliações

- DC Machine FundamentalsDocumento13 páginasDC Machine FundamentalsJamesDelmanAinda não há avaliações

- Ten Part-Winding Arrangements in Sample 4-Pole Induction MotorDocumento6 páginasTen Part-Winding Arrangements in Sample 4-Pole Induction MotorJunaid AhmadAinda não há avaliações

- 3D MSC/EMAS Simulation of A Three Phase Power Transformer by Means of Anisotropic Material PropertiesDocumento11 páginas3D MSC/EMAS Simulation of A Three Phase Power Transformer by Means of Anisotropic Material PropertiesConstantin DorinelAinda não há avaliações

- UNIT 7 AlternatorsDocumento8 páginasUNIT 7 AlternatorsPadmavathi ShenoyAinda não há avaliações

- Differential Forms on Electromagnetic NetworksNo EverandDifferential Forms on Electromagnetic NetworksNota: 4 de 5 estrelas4/5 (1)

- Dynamos and Electric Motors - How to Make and Run ThemNo EverandDynamos and Electric Motors - How to Make and Run ThemNota: 5 de 5 estrelas5/5 (2)

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsAinda não há avaliações

- Electrical Engineering Principles for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionNo EverandElectrical Engineering Principles for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionNota: 3 de 5 estrelas3/5 (4)

- Symmetrical Components: The Commonwealth and International Library: Applied Electricity and Electronics DivisionNo EverandSymmetrical Components: The Commonwealth and International Library: Applied Electricity and Electronics DivisionNota: 4 de 5 estrelas4/5 (2)

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNota: 4.5 de 5 estrelas4.5/5 (2)

- Electricity in Fish Research and Management: Theory and PracticeNo EverandElectricity in Fish Research and Management: Theory and PracticeAinda não há avaliações

- Solution Manual for 100 Genesys Design Examples: Second EditionNo EverandSolution Manual for 100 Genesys Design Examples: Second EditionAinda não há avaliações

- Electrical Analogues of Pin-Jointed Systems: International Series of Monographs on Electronics and InstrumentationNo EverandElectrical Analogues of Pin-Jointed Systems: International Series of Monographs on Electronics and InstrumentationAinda não há avaliações

- A New System of Alternating Current Motors and TransformersNo EverandA New System of Alternating Current Motors and TransformersNota: 1 de 5 estrelas1/5 (1)

- A New System of Alternating Current Motors and Transformers and Other EssaysNo EverandA New System of Alternating Current Motors and Transformers and Other EssaysNota: 5 de 5 estrelas5/5 (1)

- 02 Travel Card PDFDocumento1 página02 Travel Card PDFnir205Ainda não há avaliações

- RTDs Arrangement 50WT23E-138Documento1 páginaRTDs Arrangement 50WT23E-138nir205Ainda não há avaliações

- ICICI Travel Card Card No. Valid From Valid Thru CVV PINDocumento1 páginaICICI Travel Card Card No. Valid From Valid Thru CVV PINnir205Ainda não há avaliações

- Welcome: Tax & Investment Planning SeminarDocumento31 páginasWelcome: Tax & Investment Planning Seminarnir205Ainda não há avaliações

- Point of ViewDocumento2 páginasPoint of Viewnir205Ainda não há avaliações

- Condition Assessment Study On Stator Bars, After 40 Years of OperationDocumento4 páginasCondition Assessment Study On Stator Bars, After 40 Years of Operationnir205Ainda não há avaliações

- High Voltage Testing of Hydro Generator Stators Using Partial Core TransformersDocumento22 páginasHigh Voltage Testing of Hydro Generator Stators Using Partial Core Transformersnir205Ainda não há avaliações

- Isp321 2X PDFDocumento3 páginasIsp321 2X PDFBoroDragovicAinda não há avaliações

- Smart Office Automation SystemDocumento6 páginasSmart Office Automation SystemInternational Journal of Application or Innovation in Engineering & Management100% (1)

- Leonova Diamond TD Sheet 2Documento10 páginasLeonova Diamond TD Sheet 2Ahmed Mohamed HassanAinda não há avaliações

- Raid NotesDocumento10 páginasRaid NotesSrinivas GollanapalliAinda não há avaliações

- Service & Installation Rules 2017Documento149 páginasService & Installation Rules 2017Khay SaadAinda não há avaliações

- Jonnala 2016Documento8 páginasJonnala 2016sanjay sAinda não há avaliações

- 3D Holographic Projection TechniqueDocumento26 páginas3D Holographic Projection TechniqueGagan Shrivastava0% (1)

- WEG Guia de Instalacao pws5610 Quick Guide English PDFDocumento1 páginaWEG Guia de Instalacao pws5610 Quick Guide English PDFÁgó AttilaAinda não há avaliações

- MK 201 ADocumento4 páginasMK 201 AAli AhmadAinda não há avaliações

- Synopsis SamsungDocumento12 páginasSynopsis SamsungShivam ThakurAinda não há avaliações

- HJKHJHDocumento15 páginasHJKHJHibrargaddar123Ainda não há avaliações

- Samsung AC Servo System 2009 4Documento40 páginasSamsung AC Servo System 2009 4Frank M C100% (1)

- Seaga Od24 Instruction ManualDocumento42 páginasSeaga Od24 Instruction ManualMarco MolinaAinda não há avaliações

- Isow7741 q1Documento59 páginasIsow7741 q1gwegawAinda não há avaliações

- Intro To Operating SystemDocumento38 páginasIntro To Operating Systemmarc johansenAinda não há avaliações

- Service Manual T24PE EN 30251845A - 06192015Documento54 páginasService Manual T24PE EN 30251845A - 06192015DaniloSripAinda não há avaliações

- Chapter 09 Particle AcceleratorsDocumento32 páginasChapter 09 Particle AcceleratorsSukhmander SinghAinda não há avaliações

- Whites MXT: The Detector I Use Is A Whites MXT (Or As I Call It My "Wee Noisy!")Documento17 páginasWhites MXT: The Detector I Use Is A Whites MXT (Or As I Call It My "Wee Noisy!")corinne mills100% (2)

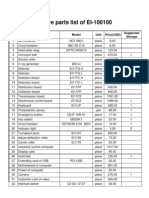

- Ei 100100Documento2 páginasEi 100100Tabassum BanuAinda não há avaliações

- SpaceTrack 4000 CaprockDocumento2 páginasSpaceTrack 4000 CaprockVanessa ChingAinda não há avaliações

- Sharp Mx-c300w Service ManualDocumento297 páginasSharp Mx-c300w Service ManualJavo IkeAinda não há avaliações

- 2822 HDocumento3 páginas2822 HKrank101Ainda não há avaliações

- UCPDocumento0 páginaUCPcontact_egypt2Ainda não há avaliações

- C Pen 3.5 Product SheetDocumento1 páginaC Pen 3.5 Product Sheetjaggy286Ainda não há avaliações

- Fonte 12v Bivolt TNY278PNDocumento37 páginasFonte 12v Bivolt TNY278PNRodolfo Arantes GonçalvesAinda não há avaliações

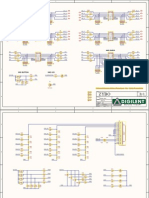

- PG 3 ZYBO - SCHDocumento13 páginasPG 3 ZYBO - SCHanuptonemeAinda não há avaliações

- Quiescent Current DrainDocumento5 páginasQuiescent Current DrainCmj LennonAinda não há avaliações

- MECH261 Control Principles: Tutorial #3Documento27 páginasMECH261 Control Principles: Tutorial #3Krushnasamy SuramaniyanAinda não há avaliações

- Irodov - Problems in Atomic and Nuclear PhysicsDocumento132 páginasIrodov - Problems in Atomic and Nuclear Physicsyomanshivi100% (2)