Escolar Documentos

Profissional Documentos

Cultura Documentos

FHP 500

Enviado por

DANIZACHDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

FHP 500

Enviado por

DANIZACHDireitos autorais:

Formatos disponíveis

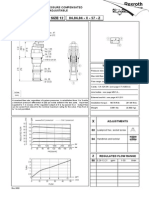

IN-LINE FILTER

FHP 500

SERIES

Maximum working pressure 420 bar

Fl ow r at e t o 700 l / mi n

Preliminary

2

CTC FHP B 0104 UK

Bypass Valve

Cast Iron Head

Electrical Indicator

Seals

Filter element

Steel Bowl

Visual Indicator

Visual - Electrical Indicator

The FHP 500 filter are designed for high pressure line

applications and are suitable for in-line installation.

Continued research and development on both the filter

bodies and the filter elements has resulted in a product

line with excellent pressure drop characteristics combi-

ned with a high filtration efficiency. The transverse

bypass valve is a standard feature with this range of pro-

duct. (Non bypass for servo applications is also availa-

ble).

A complete line of pressure differential visual and electri-

cal indicators are available with this series of filters.

FHP 500 filter are available with Reverse Flow Valve.

FHP 500 filter within this range are suitable for flow rates

to 750 l/min.

FHP 500 are specifically designed for industrial and

power pack applications.

Internal check valve option

This series of filters can be supplied with an internal

check valve. The valve eliminates the need for an exter-

nally fitted valve. Installing this valve, will prevent exces-

sive fluid loss when changing elements and reduce air

entrapment within the system. Refer to page 4 for speci-

fication.

FHP

500

Filter Symbol

without bypass

Filter Symbol

with bypass

Filter Symbol

with Check Valve

Filter Symbol

with by-pass &

Check Valve

Check Valve

Check Valve

Filter Symbol

with Reverse

Flow

R.F.

4

For application with kinematic viscositys other than 30

mm

2

/s - see below

Y factor for the pressure drop of the individual

filter elements

Sizing Example

Q = 550 l/min

V

2

= 46 mm

2

/s

Pmax = 350 bar

Filtration = 16 um absolute

p Total max = 1,5 bar (recommendation)

pc = 0,53 bar

pe = 0,0009950 x 550 x ( 46/30 ) = 0,84 bar

p Total = 0,53 + 0,84 = 1,37 bar

Filter selected

FHP 500 length 3 with A16 filter element

Filter Selection

Filter assembly sizing example

p Total

pc Filter housing

pe Filter element

Y Factor

Q l/min = Flow rate

V1 = Reference viscosity 30 mm

2

/s

V2 = Working viscosity in mm

2

/s

p Total = pc + pe

pe = Y x Q x ( V2/V1 )

FHP

SERIES

1,50

1,00

0,50

0,00

0 150 300 450 600 750

p

b

a

r

Flow rate l/min

15,0

10,0

5,00

0,00

0 150 300 450 600 750

p

b

a

r

Flow rate l/min

General - Filter selection

For a quick reference guide, refer to page 5

Filter assembly pressure drop:

p Total = p filter housing + p filter element

Housing pressure drop:

The p is proportional to the fluid density.

Filter element pressure drop:

The p is proportional to the kinematic viscosity.

The pressure drop data of the filter elements reported

in this brochure were obtained using mineral oil fluid

@ a kinematic viscosity of 30 mm

2

/s.

Technical data

The curves were obtained using a mineral oil with a

density of 0,86 kg/dm

3

according to ISO 3968.

The p is proportional to the fluid density.

Housing pressure drop

Bowl

Lengths

Y

Factor

Filter Element

S series

0,0039971

0,0049994

0,0024270

0,0021250

0,0016008

-

0,0033200

0,0023225

0,0016500

0,0014650

0,0012575

-

-

0,0012533

0,0023800

0,0018400

0,0008933

0,0010990

-

0,0008966

0,0019530

0,0014538

0,0007132

0,0008100

Filter

element

A03

A06

A10

M25

A03

A06

A25

A16

A25

M25

A03

A16

A10

A06

A10

A16

M25

A25

Y

Factor

Filter Element

N series

A03

A06

A10

A16

M25

A25

0,0008333

0,0003333

0,0009950

0,0049400

0,0038571

0,0023000

0,0020000

0,0015000

0,0011333

0,0008480

0,0032300

0,0022500

0,0015000

0,0013900

0,0017400

0,0011750

0,0005480

0,0022800

0,0006833

0,0002933

0,0007900

0,0008333

0,0013538

0,0018300

-

0,0007503

0,0013321

0,0011976

0,0004731

0,0006532

A03

A06

A10

A16

M25

A25

0,0004461

0,0001645

0,0006000

0,0006503

0,0010760

0,0012121

1

2

3

4

5

HP 500 - Technical data

Bypass pressure drop

with check Valve & Rev. Flow

1 1/2 port

2 port

3

Techni cal data

Filter body (Material)

Head: Cast iron

Bowl: Steel

By-pass valve : Brass

Reverse Flow : Steel

Check Valve : Steel

Pressure filter body

Working pressure: 420 bar (42 MPa)

Test pressure: 630 bar (63 MPa)

Burst pressure: 1250 bar (125 MPa)

Fatigue test: 1.000.000 cycles

with pressure impulses from 0 to 350 bar (35 MPa)

Working Temperature

from -25C to + 110C

Bypass valve

Bypass valve setting - 6 bar 10%

Other pressure settings available.

Filter elements - Collapse pressure

Microfibre elements N series: 20 bar

Microfibre elements S series: 210 bar

Inox Square wire mesh M series: 20 bar

Filtration outside - inside.

Seals

Standard Buna-N A series

Viton optional V series

Compatibility with fluids

Body, compatible for use with:

Mineral oil according to ISO 2943 - water-based emul

sions-synthetic fluids - water- glycol.

Filter elements, compatible for use with mineral oil

according to ISO 2943, synthetic fluids, water-based

emulsions and water-glycol.

For other fluids, please consult our sales network

organisation.

Seals in Nitrile (Buna-N) A series, compatible with:

Mineral oil according to ISO 2943 - water-based emul

sions-water- glycol.

Seals in Viton V series, compatible with:

Synthetic fluids type HS-HFDR-HFDS-HFDU

Weights ( Kg. )

Lengths 1 2 3 4 5

FHP 500 20,5 22,5 28,5 31,5 42,5

Port connections

See page x

MP filter elements, conform to the following

ISO standard:

ISO 2941 - Verification of collapse/burst resistence.

ISO 2942 - Verification of fabrication integrity and

determination of the first bubble point.

ISO 2943 - Verification of material Compatibility with fluids.

ISO 3723 - Method for end load test.

ISO 3724 - Verification of flow fatigue characteristics.

ISO 3968 - Evaluation of pressure drop versus flow

characteristics.

ISO 4572 - Multi-pass method for evaluating filtration

performance.

Filtering area

Electrical

N p 20 bar

S p 210 bar

M p 20 bar

3030 4900 6500

Filter element

type

1 2 3

9800

4

13000

13000

5

10800 4000

3030

2500

9800

7900 5400

4900 6500

Values in cm

2

(A)

5

5

5

0,5

0,25

(A)

5

5

3

0,03

0,03

(V)

Vca 125 (

)

Vca 250 (

)

Vcc 30 (

=

)

Vcc 125 (

=

)

Vcc 250 (

=

)

inductive load

Resistive load Supply voltage

50/60 Hz

K - E - N Series

Connector

DIN 43650

Electrical

connection

E - N Series

N.C.

N.O.

2

1

3

1

2

3

FHP

SERIES

Electrical

connection

K Series

2

3

1

0

N.C.

N.A.

Filter selection-quick reference guide

The following filter sizing recommendations are based on

using a mineral oil fluid @ 30 mm

2/s

(Csts) with a maxi-

mum filter assembly (housing & filter element) pressure

drop of 1,5 bar.

A Connection

1 1/2 SAE-3000 psi/M

1 1/2 SAE-3000 psi/UNC

2 SAE-3000 psi/M

2 SAE-3000 psi/UNC

1 1/2 SAE-6000 psi/M

1 1/2 SAE6000 psi/UNC

2 SAE-6000 psi/M

2 SAE-6000 psi/UNC

B

69.85

69.85

77.77

77.77

79.38

79.38

96.82

96.82

C

35.71

35.71

42.88

42.88

36.50

36.50

44.45

44.45

Filter

element

type

Bowl

Length

Port

Size

Flow rate

l/min

S Series

Flow rate

l/min

N Series

A03

A06

A10

M25

A03

A06

A25

A16

A25

M25

A03

A16

A10

650

700

250

220

370

400

450

-

280

320

400

530

550

-

-

520

350

410

615

560

A06

A10

A16

M25

A25

600

250

300

400

450

500

550

600

320

370

2

2

430

550

450

600

650

400

1

2

3

A03

680

720 -

580

440

490

655

630

A06

A10

A16

M25

A25

650

600

530

480

4

2

2

A03

700

750 -

630

520

580

685

660

A06

A10

A16

M25

A25

680

650

600

550

5

2

D

M12

1/2UNC

M12

1/2 UNC

M16

5/8UNC

M20

3/4 UNC

E

M12

1/2UNC

M12

1/2 UNC

M12

1/2 UNC

M12

1/2 UNC

Flange connections

FHP

SERIES

E K

N

V

6

5

6

5

38

38

7

6

38.5

Led

Z

A/F 30

A/F 30 A/F 30

A/F 32

3

5

4

14

2

A/F 32

Connection

A

1 1/2 BSP

1 1/2 NPT

SAE 24 (1 7/8 12 UN)

Filter

Length

1

2

3

4

5

Mounting Holes

E (0.59)

M12

1/2 UNC

1/2 UNC

H

334

424

500

657

823

Thread connections

5

D

H

1

5

5

1

4

5

5

8

1

1

A

170

B

C

160

Drain Plug

Drain Plug

133

60

A/F 46

A/F 46

FMP 500 4-5 Only

A

A

E - 4 Mounting

holes

Indicator Port

T2 Plug A/F 30

Flange

connections

6

Absolute filter elements have been tested by the following independent institutes.

Hydraulic System Component Cleanliness Levels

Servo valve

Proportional valve

Variable pump

Cartridge valve

Fixed piston pump

Vane pump

Pressure/flow control valve

Solenoid valve

ISO cleanliness

NAS cleanliness

Recommended micron size

Syst em component Typi cal Cl eanl i ness Speci fi cat i on

12/10/7 13/11/8 14/12/9 15/13/10 16/14/11 17/15/12 18/16/13 19/17/14 20/18/15

1 2 3 4 5 6 7 8 9

6 micron 10 micron >10 3 micron

FHP500

SERIES

Square wire mesh filtration degree is defined in microns by the maximum diameter of a sphere

corresponding to the mesh size.

Characteristics of the filter element with nominal filtration M / T series

Multipass method for evaluating

Filtration performance according to ISO16889.

ISO MTD text dust

Multipass method for evaluating

Filtration performance

according to ISO 4572.

ACFTD text dust

Dimensions for values 2 10 75 100 200 1000 Dimensions for values 200

Efficiency in % 50% 90% 98,70% 99% 99,50% 99,90% Efficiency in % 99,50%

Elements media (m ) m

A03 <3 <3 <3 <3 3,30 4,2 A03 3m 3

A06 <3 <3 4,31 4,53 5,07 6,3 A06 6m 6

A10 <6 <6 6,12 6,41 7,12 9,0 A10 10m 10

A16 <7 <7 10,45 10,97 12,13 13,9 A16 16m 16

A25 <9 12,34 15,82 16,30 17,46 19,3 A25 25m 25

The data are reported to a value of final p equal to 16 bar

7

FHP

SERIES

Orderi ng i nformati on

Data held in this publication is given only for indicative purposes. MP Filtri reserves to introduce

modifications to described items for technical or commercial reasons. Copyright reserved.

MP Filtri - Filtration products will only be guaranteed if original MP Filtri

replacement elements and spares are used

FHP 500

1 2 3 4 5 6 7a

1 2 5 6 7b

8

HP 500

1 - Filter Length

1 H = 334 mm

2 H = 424 mm

3 H = 500 mm

4 H = 657 mm

5 H = 823 mm

2 - Integral bypass valve

S Without bypass

B With bypass

W With reverse flow

D With bypass & Check valve

T With Check valve

3 - Seals

A Buna-N

V Viton

E EPDM

4 - Port options

G1 1 1/2 BSP

G2 1 1/2 NPT

G3 SAE 24 (1 7/8 12 UN)

F1 1 1/2SAE - 3000 PSI/M

F2 1 1/2SAE - 3000 PSI/UNC

F3 2SAE - 3000 PSI/M

F4 2SAE - 3000 PSI/UNC

F5 1 1/2SAE - 6000 PSI/M

F6 1 1/2SAE - 6000 PSI/UNC

F7 2SAE - 6000 PSI/M

F8 2SAE - 6000 PSI/UNC

5 - Filter elements

A03 Inorganic microfibre 3 m Bx 200

A06 Inorganic microfibre 6 m Bx 200

A10 Inorganic microfibre 10 m Bx 200

A16 Inorganic microfibre 16 m Bx 200

A25 Inorganic microfibre 25 m Bx 200

M25 Square wire mesh

6 - Collapse pressure series

N 20 bar

S 210 bar

7 - Options

a)Filter

P01 MP Filtri with standard

P02 MP with change element of the cover

(only length 4 & 5)

Pxx Costumer required

b)Element

P01 MP Filtri standard element

Pxx Costumer required

8 - Filter condition indicator

Z7 Visual (Pop-up) 5 bar N8 Electrical 5 bar

Z8 Visual (Pop-up) 7 bar E7 Visual-electrical 5 bar

V7 Visual 5 bar E8 Visual-electrical 7 bar

V8 Visual 7 bar K7* Visual-electrical 5 bar

N7 Electrical 7 bar K8* Visual-electrical 7 bar

*{

1 - Voltage 24 Volt

2 - Voltage 110 Volt

3 - Voltage 220 Volt

Fi l ter el ement

Fi l ter assembl y

Example: FHP 500 4 B A G1 A10 N P01 / V7

Example: HP500 4 A10 A N P01

Head Quar t er :

MP FILTRI S.p.A. It al y

Via Matteotti, 2

20060 Pessano con Bornago (Milano) Italy

Tel. ++39.02/95703.1

Fax ++39.02/95741497-95740188

email: sales@mpfiltri.com

http://www.mpfiltri.com

GREAT BRITAIN

MP FILTRI U.K. Lt d.

Bourton Industrial Park

Bourton on the Water

Gloucestershire GL54 2HQ UK

Phone: 01451-822522

Fax: 01451-822282

email: sales@mpfiltri.co.uk

http://www.mpfiltri.co.uk

GERMANY

MP FILTRI D GmbH

Am Wasserturm 5

D-66265 Heusweiler/Holz

Phone: 06806/85022-0

Fax: 06806/85022-18

email: mpfiltrink@aol.com

FRANCE

MP FILTRI FRANCE

B.P. 325

01603 Trevoux Cedex

Tel: 04.74.08.84.78

Telefax: 04.74.08.80.45

email: mpfiltrifrance@wanadoo.fr

USA

MP FILTRI USA Inc.

2055 Quaker Pointe Drive

Quakertown, PA 18951

Phone: 215-529-1300

Fax: 215-529-1902

email: mpusasales@aol.com

http://www.mpfiltriusa.com

CANADA

MP FILTRI CANADA Inc.

210 Jacob Keffer Parkway Concord,

Ontario Canada L4K 4W3

Phone: 905-303-1369

Fax: 905-303-7256

email: mail@mpfiltricanada.com

http://www.mpfiltricanada.com

Você também pode gostar

- Valvula de Acc Manual - E150Documento4 páginasValvula de Acc Manual - E150DANIZACHAinda não há avaliações

- Check d180 - HR KRDocumento4 páginasCheck d180 - HR KRDANIZACHAinda não há avaliações

- Check en Linea - c406Documento2 páginasCheck en Linea - c406DANIZACHAinda não há avaliações

- 305 TransmissionDocumento2 páginas305 TransmissionDANIZACHAinda não há avaliações

- Valvula Tn10 - Dke E025Documento4 páginasValvula Tn10 - Dke E025DANIZACHAinda não há avaliações

- En - b1 - 070 PATINES LINEALESDocumento2 páginasEn - b1 - 070 PATINES LINEALESDANIZACHAinda não há avaliações

- Catalogo Componentes 2007Documento39 páginasCatalogo Componentes 2007DANIZACHAinda não há avaliações

- Divisor Pld-02-T-ADocumento20 páginasDivisor Pld-02-T-ADANIZACHAinda não há avaliações

- Pump KappaDocumento112 páginasPump KappaDANIZACHAinda não há avaliações

- Pump Polaris SeriesDocumento47 páginasPump Polaris SeriesDANIZACHAinda não há avaliações

- Valvula de Asiento - Dloh E041Documento4 páginasValvula de Asiento - Dloh E041DANIZACHAinda não há avaliações

- Cilindros Hidráulicos de Simple y Doble Efecto Single and Double Acting Hydraulic CylindersDocumento1 páginaCilindros Hidráulicos de Simple y Doble Efecto Single and Double Acting Hydraulic CylindersDANIZACHAinda não há avaliações

- Pump Magnun SeriesDocumento63 páginasPump Magnun SeriesDANIZACHAinda não há avaliações

- 742Documento52 páginas742DANIZACHAinda não há avaliações

- 4 - Way Directional Control Valve "HPV4": FeaturesDocumento2 páginas4 - Way Directional Control Valve "HPV4": FeaturesDANIZACHAinda não há avaliações

- H&P Reprints 2009Documento4 páginasH&P Reprints 2009DANIZACHAinda não há avaliações

- Re26892 2003-02Documento10 páginasRe26892 2003-02DANIZACHAinda não há avaliações

- Basic Training: Motors, Gears & DrivesDocumento80 páginasBasic Training: Motors, Gears & DrivesDANIZACH50% (2)

- 040404X57ZDocumento1 página040404X57ZDANIZACHAinda não há avaliações

- Flow Control Valves QV-06: Pressure Compensated, Two Way, ISO 4401 Size 06Documento2 páginasFlow Control Valves QV-06: Pressure Compensated, Two Way, ISO 4401 Size 06DANIZACHAinda não há avaliações

- Reductores - d140 - HG KGDocumento4 páginasReductores - d140 - HG KGDANIZACHAinda não há avaliações

- Breathers Mar 20 06Documento8 páginasBreathers Mar 20 06DANIZACHAinda não há avaliações

- TF4 Mar 20 06Documento6 páginasTF4 Mar 20 06DANIZACHAinda não há avaliações

- Alivio Cartucho - C010Documento6 páginasAlivio Cartucho - C010DANIZACHAinda não há avaliações

- Filter Cart Modelo SCFCDocumento1 páginaFilter Cart Modelo SCFCDANIZACHAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 5 34-10-17 PVT Analysis of Bottom Hole SampleDocumento21 páginas5 34-10-17 PVT Analysis of Bottom Hole SampleswpuxiaofanAinda não há avaliações

- Osu 1282140369Documento137 páginasOsu 1282140369sattar aljabairAinda não há avaliações

- Nonlinear Robust Control of A Hydraulic Elevator: Experiment-Based Modeling and Two-Stage Lyapunov RedesignDocumento15 páginasNonlinear Robust Control of A Hydraulic Elevator: Experiment-Based Modeling and Two-Stage Lyapunov RedesignbrgrAinda não há avaliações

- Fundamentals of Convection: Heat and Mass Transfer: Fundamentals & ApplicationsDocumento58 páginasFundamentals of Convection: Heat and Mass Transfer: Fundamentals & ApplicationsWalter Nuas100% (2)

- Bornemann Twin Screw Pumps Series W V U and TDocumento16 páginasBornemann Twin Screw Pumps Series W V U and TFelipeAinda não há avaliações

- Pipesize Documentation Chemeng SoftDocumento34 páginasPipesize Documentation Chemeng SoftvuongAinda não há avaliações

- Topic 1 - Latest Sem Dec-Mac 2014Documento53 páginasTopic 1 - Latest Sem Dec-Mac 2014songhahoonAinda não há avaliações

- Haake PDFDocumento26 páginasHaake PDFSimão PintoAinda não há avaliações

- UntitledDocumento15 páginasUntitledTural EmirliAinda não há avaliações

- Significance of Different Dimensionless NumbersDocumento16 páginasSignificance of Different Dimensionless NumbersMeetu KaurAinda não há avaliações

- Calculation Software For Efficiency and Penetration of A Fibrous Filter Medium Based On The Mathematical Models of Air FiltrationDocumento8 páginasCalculation Software For Efficiency and Penetration of A Fibrous Filter Medium Based On The Mathematical Models of Air FiltrationEman AbdAinda não há avaliações

- Computational Fluid Dynamics Technologies and Applications 6654Documento408 páginasComputational Fluid Dynamics Technologies and Applications 6654Rajneesh VachaspatiAinda não há avaliações

- Fluent-Intro 14.5 L03 Turbulence&HeatTransfer&Transient PDFDocumento72 páginasFluent-Intro 14.5 L03 Turbulence&HeatTransfer&Transient PDFWedye BagonkAinda não há avaliações

- Beijer Lundberg-On The Modelling of Piles in Sand in The Small Geotechnical CentrifugeDocumento10 páginasBeijer Lundberg-On The Modelling of Piles in Sand in The Small Geotechnical CentrifugeNadher Al-BaghdadiAinda não há avaliações

- Manual Elc ElectronicDocumento23 páginasManual Elc ElectronicRavi Dhamange100% (1)

- Fluids Notes 1,2.3Documento46 páginasFluids Notes 1,2.3Tobias Okoth100% (1)

- Toluene ViscosityDocumento8 páginasToluene ViscosityRajagopala Rao MandadapuAinda não há avaliações

- SEAKEEPING - Ship Behaviour in Rough Weather - A. R. J. M. LLOYDDocumento486 páginasSEAKEEPING - Ship Behaviour in Rough Weather - A. R. J. M. LLOYDTahsinul Haque Tasif100% (8)

- Viscosity Correction ChartDocumento1 páginaViscosity Correction ChartRodolfoAinda não há avaliações

- E2902 1 0 07 16 - MGE MotorenDocumento40 páginasE2902 1 0 07 16 - MGE MotorenAnimonga HajimeAinda não há avaliações

- Friction Losses in Valves and Fittings For Power-Law Fluids: Brazilian Journal of Chemical EngineeringDocumento9 páginasFriction Losses in Valves and Fittings For Power-Law Fluids: Brazilian Journal of Chemical EngineeringsadiqaAinda não há avaliações

- Vbar7002nptfm Data SheetDocumento8 páginasVbar7002nptfm Data SheetMariano JuárezAinda não há avaliações

- BSL - Chapter 3Documento60 páginasBSL - Chapter 3Cecilia CelineAinda não há avaliações

- Fluent-Intro 18.0 Module07 Turbulence PDFDocumento29 páginasFluent-Intro 18.0 Module07 Turbulence PDFAlex HolguinoAinda não há avaliações

- Manual de Serviço: CCD-TRV118Documento111 páginasManual de Serviço: CCD-TRV118LuizAinda não há avaliações

- Introducing Rheology - Sep 2017Documento34 páginasIntroducing Rheology - Sep 2017Daniel Perez ColmenaresAinda não há avaliações

- Application of Flexible Ring Net Barrier PDFDocumento9 páginasApplication of Flexible Ring Net Barrier PDFbunAinda não há avaliações

- Viscosities of FluidsDocumento6 páginasViscosities of Fluidsse781Ainda não há avaliações

- Fundamentals of Seismic Rock PhysicsDocumento15 páginasFundamentals of Seismic Rock Physicsmehrgini100% (5)

- 09 Fluid Mechanics and Hydraulic Machineries - IDocumento39 páginas09 Fluid Mechanics and Hydraulic Machineries - IManoj PokharelAinda não há avaliações