Escolar Documentos

Profissional Documentos

Cultura Documentos

Application of Predictive Microbiology To Estimate The Number of Bacillus Cereus in Pasteurised Milk at The Point of Consumption

Enviado por

Houssam Eddine Salama0 notas0% acharam este documento útil (0 voto)

43 visualizações16 páginasA procedure is presented to quantitatively estimate the growth of a particular organism in

a food product during chilled storage using predictive microbiology.

Título original

Application of predictive microbiology to estimate

the number of Bacillus cereus in pasteurised milk

at the point of consumption

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoA procedure is presented to quantitatively estimate the growth of a particular organism in

a food product during chilled storage using predictive microbiology.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

43 visualizações16 páginasApplication of Predictive Microbiology To Estimate The Number of Bacillus Cereus in Pasteurised Milk at The Point of Consumption

Enviado por

Houssam Eddine SalamaA procedure is presented to quantitatively estimate the growth of a particular organism in

a food product during chilled storage using predictive microbiology.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 16

International Journal of

Food Microbiology 30 (1996) 55-70

Application of predictive microbiology to estimate

the number of Bacillus cereus in pasteurised milk

at the point of consumption

M.H. Zwietering,*, J.C. de Wit, S. Notermansb

Department of Food Science, Wageningen Agricultural University, PO Box 8129, 6700 EV,

Wageningen, The Netherlands

bNational I nstitute of Public Health and the Environment, PO Box 1, 3720 BA, Bilthoven,

The Netherlands

Abstract

A procedure is presented to quantitatively estimate the growth of a particular organism in

a food product during chilled storage using predictive microbiology. This results in a

quantification of the contribution of every individual process step to the total number of

organisms, which may be a useful tool to support decisions on existing process lines as well

as in process and product design. It is demonstrated that predictive microbiology will only

estimate to within orders of magnitude of bacterial growth. This helps to pinpoint the most

important aspects of a line. The calculations can be helpful to set critical limits and to detect

hazards by performing what if analyses. The procedure is explained for the growth of

Bacillus cereus in milk. It is indicated, that with the current information, the effect of

time/temperature can be estimated. However, to make an accurate exposure analysis, more

information will be needed.

Keywords: Predictive microbiology; Milk; Bacillus; HACCP; Critical limits

* Corresponding author. Agricultural University, P.O. Box 8129 6700 EV, Wageningen, The Nether-

lands. Phone: + 31 317 484204, fax: + 31 317 482237. e-mail: Marcel.Zwietering@Algemeen@PK.

WAU.NL

0168-1605/96/$15.00 0 1996 Elsevier Science B.V. Ail rights reserved

PII SO168-1605(96)00991-9

56 M.H. Zwietering et al. / ht. J. Food Microbiology 30 (1996) 55 70

Due to the temperature applied during pasteurisation in milk the risks of

survival of vegetative pathogens and spoilage organisms are decreased consider-

ably. This is not the case for Bacillus cereus. The level of contamination with

this organism may be controlled by a low initial spore count, cooling after

pasteurisation, and limiting storage time. Both storage time and storage tempera-

ture are largely under control of the consumer. Therefore, the consumer is

informed about storage temperature and expiry date, which is presented on the

packages. From a risk analysis point of view, there is now interest to be in-

formed about, (i) the effect of time/temperature combination to control the level

of contamination and (ii) the consumer exposure upon consumption of pas-

teurised milk. There are several approaches to gather the necessary information,

including surveillance testing, storage tests and the application of predictive mi-

crobiology.

Predictive microbiology is a rapidly developing discipline, aiming at quantita-

tive estimation of microbial growth in foods using mathematical modelling. The

results of these models should not be relied on completely. They should be

regarded as tools to support decisions. They may be helpful to improve experi-

mental design and aid in the interpretation of experimental results. Moreover,

predictive microbiology can be helpful to decide which tests to perform and not

to put effort in things that are of little importance. Tools like microbial chal-

lenge tests, storage tests and surveillance tests may be just as useful. Together

these methods may provide better understanding and reliability of the predicted

results.

Predictive microbiology enables quantitative prediction based on the sequence

of events in the whole history of the product, and can be used to determine

what may happen in many different scenarios. However, predictions are based

on models and parameters which might not be correct in certain cases. Challenge

testing is carried out in those cases where the pathogenic organism is expected to

be present but only in low frequencies, indicating possible problems that may

occur. However, when an organism is able to grow in a certain product, it does

not always have to be a problem, since it may never be present in reality.

Storage tests give the actual growth in the product under study. However, rarely

found organisms might be overseen, and the actual storage conditions vary from

product to product, never exactly equalling the conditions of the storage test.

Surveillance tests give information on the actual numbers in the product at the

moment of consumption. It is however difficult to find out how these numbers

are reached and how they may be influenced. These methods are all giving

relevant answers, and the combination of these methods answers most of the

questions, i.e. the actual numbers and how they are reached, the effects of

various changes, etc. This information may be used as a basis for risk manage-

ment. In this paper predictive microbiology is applied to estimate the occurrence

of Bacillus cereus in milk and results are evaluated.

M.H. Zwietering et al. / Int. J. Food Microbiology 30 (1996) 55-70 51

2. Theory

2.1. Bacterial growth

For growth first order kinetics are assumed, possibly after a lag phase:

r,,

= ,uN (# .g-.h-) t>R

(1)

with Y, the organism production rate (growth in numbers per g per h), ,U the specific

growth rate (h _ ), N the concentration of organisms ( # /g), /i the lag time (h) and

# meaning number. In batch systems (which most foods are), the growth equals

the increase in numbers, resulting in:

(3)

N = N,exp[p(t - A)]

(5)

For prediction purposes this simple exponential model is chosen, since the accuracy

of the prediction will not justify the use of more sophisticated models (e.g.

sigmoidal).

2.2. Growth rate

The effect of temperature on growth rate is assumed to follow the square root

relation (Ratkowsky et al., 1982):

& = b(T- Twin) (6)

The b value is dependant on (among others) the pH and a, of the product and b

can be calculated on basis of these variables with the equation (McMeekin et al.,

1993; Wijtzes et al., 1995):

P = c(a),, - a

w,min)(PH - PHmi*KPHnux - PHMT - Tmin)2 (7)

For the parameters safe margins must be chosen, since for instance T,, is not the

lowest temperature in literature where growth is reported, it is the extrapolated

temperature at which no growth will occur. Since the growth rates around that

temperature are much too small to measure, the actual Tmj, will always be about

one degree lower than the minimal reported growth temperature (see Appendix 1).

The advantage of using this approach is that for every variable determining growth

rate (hurdle), the relative effect can be calculated, by separating the effects of the

various variables in Eq. (7), using the relative growth rate:

58

with:

M.H. Zwietering et al. / ht. J . Food Microbiology 30 (1996) 55-70

dT) = (;y-T;:i?)

(PH - PfL36Hmax - PW

y(pH) = cPf&, - ~fLi&fL, -P&J =

W - pHti,)(2 .P&, -P&C, - PW

(PHqz - PHmiJ 2

a, - %,h

Y@w) = l _ a

w,min

(10)

(11)

In a chilled food y(T) will usually be small, in an acid sauce this is true for y(pH),

and in bread for ~(a,). Knowing which variables may be used to influence bacterial

growth is useful of course, but for optimum use of this notion, avoiding putting

unnecessary efforts, the effects should be quantified. It should be noted that in these

equations there are no interactive effects of the various variables (T,;, is no

function of pH, pHti is no function of T, etc.), and the combined effect is assumed

multiplicative. So if y(T) = 0.1 and y(pH) = 0.1, the overall y = 0.01. Thus, 10%

of the maximum specific growth rate due to the temperature and 10% due to the

effect of the pH gives together 1% of the maximum specific growth rate. The fact

that very low growth rates cannot be easily measured, might even result in an

apparent dependence of the various variables (see Appendix 1).

For a food product with a given pH and a, the only adjustable variable is the

temperature. To describe the effect of temperature for this food product, the b value

of Eq. (6) may be estimated as follows:

(13)

This procedure, which is indicated as the gamma concept, needs only six

parameters (Tmi, Topt, PHmin, pHopt, aw,tin,

and popt) which are all easy to interpret,

and may be looked up in literature. These parameters can be easily adjusted if new

more tolerant strains emerge.

The (weighted) derivative of the gammas to the variable might also be of interest.

This gives the sensitivity of the growth rate to the variable, indicating how much

the growth rate may be changed with that variable (sensitivity) (see Appendix 2).

2.3. Predictions using the Pathogen Mode&g Program and Food Micromodel

Using the Pathogen Modeling Program (USDA, 1994) and Food MicroModel

version (Food MicroModel Ltd. Leatherhead Surrey UK), the growth of B. cereus

M.H. Zwietering et al. /ht. J. Food Microbiology 30 (1996) 55-70 59

can be predicted at various temperatures. For this the temperature, pH and

water activity (or salt concentration) must be entered. For the Pathogen Model-

ing Program a salt concentration of 1.3% (a, = 0.993) is entered and for Food

MicroModel a salt concentration of 1.2% (a, = 0.993) is entered, to result in

the same water activity.

2.4. Data based on storage tests

Results from storage tests obtained in the past (Dufeu and Leesment, 1974;

Griffiths and Phillips, 1990) and recently by us have been applied to compare

the various predictions. Own results were obtained in two different labora-

tories and two different experimental procedures (see Materials and methods,

Section 3).

3. Materials and methods

3.1. Lab 1

Semi-skimmed pasteurized milk (Campina Melkunie Woerden) was used. At

time zero the filling of the cartons was used. At four different moments a series

of cartons was taken from a milk processing line. Two series (one of 10 cartons

and one of 15) were stored at 7C and two at 10C (15 bottles and 5 car-

tons). After taking the cartons or bottles they were transported to the laboratory

at T < 7C. There they were placed at the desired incubation temperature

and sampling started next day. Samples were taken and the appropriate dilu-

tion was made. For counting the number of Bacilfus cereus MYP (mannitol

egg yolk polymyxin agar, prepared from Cereus selective agar base (Merck)

with egg yolk emulsion SR047C (Oxoid) and polymyxin-B-sulphate (B. cereus

selective supplement SR099E)) was used. The plates were incubated for 1 day at

30C.

3.2. Lab 2

Semi-skimmed pasteurized milk was used originating from different factories.

Immediately after filling, the cartons were transported to the laboratory at refrig-

erating conditions ( < 7C). In the laboratory 100 ml portions of each carton

was transferred to sterile 200 ml Erlenmeyer flasks and incubated at 6, 8, 10,

and 12C respectively. Sampling started next day and B. cereus were enumerated

as described above. Suspected colonies were confirmed by the following biochem-

ical reactions: gelatine ( + ), Voges Proskaner ( + ), nitrate reduction ( + ) and

glucose fermentation ( + ).

60 M.H. Zwietering et al. 1 ht. J. Food Microbiology 30 (1996) ST-70

4. Results

4.1. Predictions using the gamma concept

For B. cereus (T,i, = OC, T,,, = 37, pH,i = 4.9, pH,,, = 6.5, aw,,,in =

0.95, &pt

= 2 h-) in milk (T = 7C pH = 6.6, and a, = 0.993), the gamma

factors can be calculated with Eqs. (9)-(11) as: y(T) = 0.036, y(pH) = 0.996,

~(a,) = 0.86 (Table 1). The total y value is 0.031, so the growth rate is estimated

as 0.061. This gives a quantification of the hurdle concept. We can see from these

numbers that pH and a, give almost no reduction of growth rate (0.4% and 14%

respectively), and that the main reduction is achieved with temperature (96.4%).

For the example of Bacillus in milk the b-value may be estimated from Eq. (13) as:

b = 0.996.0.86- = /-T 0.0354

leading to an estimate for the growth rate:

J1 = O.O354(T- T,i,) = 0.0354. T

(14)

(15)

4.2. Comparison of the predictions

The results of the gamma concept, Food MicroModel (FMM), Pathogen Model-

ing Program (PMP-model), and literature data are presented in Table 2 and Fig. 1.

It should be noted that for any of these programs it only takes about 15 min to

produce results. Collecting and interpreting literature values takes about 1 day (8

h). Comparison of the growth rate predictions in Table 2 and Fig. 1 shows that the

various models and literature data agree very well. The PMP model shows too

small growth rates at low temperatures. However, it is clearly stated in the

program, that the parameters of the model for B. cereus are determined for a

mesophilic strain, and might not apply for psychrophilic strains. Considering this,

the predictions are not bad at all. The agreement between the various models and

the literature data shows that the concept of predictive microbiology can give

appropriate predictions.

Table 1

Data to calculate gamma for Bucihs in milk

Min

Opt

Actual y

T (C) 0 31 I (7 - 0)2/(37 - 0)2 = 0.036

PH 4.9 6.5 6.6 (6.6 - 4.9).(8.1 - 6.1)/(6.5 - 4.9) = 0.996

a, 0.95 1.00 0.993 (0.993 - 0.95)/0.05 = 0.86

p 0-l) 2.0

2 Total 0.031

Ratkowsky parameter b is equal to 0.0354

M.H. Zwietering et al. / ht. J . Food Microbiology 30 (1996) 55-70 61

Table 2

Growth rate (hh) predictions at various temperatures

T CC)

Dufeu and Leesment (1974) Griffiths and Phillips (1990) Gamma FMM PMP

3

6

8

10

17

25

30

38

0.0128

0.0555 0.0301, 0.0365

0.0462, 0.0578

0.0762

0.173, 0.231

0.289

0.408

0.533

0.147

0.0112 - -

0.0451 0.0524

0.0801 0.0794 0.0398

0.125 0.118 0.0686

0.361 0.415 0.325

0.782 1.34 1.02

1.13 2.42 1.53

1.807 - 1.89

Food MicroModel (Food MicroModel Ltd. Leatherhead Surrey U.K.).

bPathogen Modeling Program (USDA, 1994).

Program predictions are multiplied by 2.303[ln(lO)] to convert to specific growth rate (h- ).

4.3. Experimental ver$cation

The observed agreement between literature values and the various model calcula-

tions gives much confidence, however, to increase confidence, extra experiments

may be performed to determine the growth rate of Bacillus in milk. To perform

these experiments takes a lot of time. For testing 20 packages of milk applying four

incubation temperatures and a sampling frequency of every l-2 days during a

period of about lo-20 days, about 400 h are needed. The estimated growth rates

from those experiments where the distribution of data was well over all phases of

the growth curve (lag, exponential, and asymptotic phase), are plotted in Fig. 2 and

compared with the prediction of the gamma concept (Eq. (15)). In this graph it can

again be seen that these predictions agree very well with the experimental data.

4.4. Use of models to predict the number of bacilli in milk and comparison with

storage test results

Now that we have a model to predict the growth rate as function of temperature

we can make predictions of the growth in various cases. For the prediction of the

growth of Bucillus in milk we assume the absence of a lag phase. To estimate the

increase in numbers of organisms we need the following data: N,, b, Tminr

temperatures and residence times. The Ratkowsky parameters used, are those

predicted by the gamma concept (b = 0.0354, T,, = OC). We assume the initial

number of Bacillus present per bottle of 1 1 is 10 (N, = O.Ol/ml) (note that this

assumption is necessary, however, it can easily be checked what happens if there are

for instance 1 per ml).

To validate this procedure the experimentally determined number of organisms,

and the predictions at 6, 7, 8, 10 and 12C are given in Figs. 3-7. These figures

show that there is a large variation between various cartons of milk, as well as

62 M.H. Zwietering et al. / Int. J. Food Microbiology 30 (1996) 55-70

between various batches. However, the predicted numbers agree quite well, and

predict the correct order of magnitude for the increase of numbers in time. The

large variation between the different cartons shows that models need not be very

accurate for prediction (they can never be better than reality, and reality has large

variation in this case). The results from the two different laboratories show the

same behaviour.

4.5. Estimation of human exposure to B. cereus.

The number of organisms in various phases, of duration ti with temperature pi,

can be easily calculated with:

In(N) = ln(N,) + Cpiti = WV,) + Cb(T, - Ld2ti

(16)

i i

This equation can be converted to the logarithm with. base 10 yielding:

log(N) = log(N,) +

&zb2CTi - Tmin)2ti

I

(17)

1

/

/ ,/*

/

/ *

,/

0.8

=

c

F 0.8

$

c

3 0.4

$

0.2

0

0 5 10 15 20 25

temperature (OC)

Fig. I. Comparison of the predicted growth rates of various models and literature data. n Griffiths and

Phillips (1990); + Dufeu and Leesment (1974); ~- Gamma model; - - - Food MicroModel (Food

MicroModel Ltd. Leatherhead Surrey U.K.); PMP model (USDA, 1994).

M.H. Zwietering et al. / ht. J . Food Microbiology 30 (1996) 55-70 63

0 5 10 15

temperature (C)

20 25

Fig. 2. Comparison of the predicted growth rate of the Gamma model and newly performed experi-

ments. A experiment; -- Gamma concept.

Using the above given parameters and converting the time from hours to days, this

equation becomes:

log(N) = - 2 +

(0.0;354);.24TT?ri

(18)

Alog = O.O130CTf&

(19)

Lets assume the following scenario: company storage (2 days, 4C), retail (2 days,

7C) consumer storage (5 days, 7C). We can predict now the number of organisms

in all the stages (Table 3). These calculations can be very easily set up in a

spreadsheet program and it is clear that all kind of scenarios can be calculated this

way, showing the relative importance of the various phases, and pinpointing the

critical stages. Limits may be set for the various times and temperatures in a

quantitative way. This procedure can be extremely useful for a what if analysis.

For instance the remaining shelf life for various storage conditions (T,, t,) can be

calculated using Eq. (19), and the conditions in the company and at retail as given

in Table 3:

log(N) = log(N,) + 0.0130(16.2 + 49.2 + T,2t,)

If we set as limit N = lo5 this results in:

(20)

64 M.H. Zwietering et al. / ht. J . Food Microbiology 30 (1996) 55-70

5 - lo

0.0130

- 32-98 = Tzt,

(21)

Some results for various values of N, and T, are given in Table 4. It is clearly

demonstrated that the storage time depends both on the initial contamination and

the storage temperature. From this analysis it can be concluded that the relative

effect of each phase is equal to (T, - T~n)*ti (in this case T,i, was equal to zero

resulting in T2ti). So by just using the minimum growth temperature of the relevant

microorganism, and the temperature and the residence time, the relative effect of

the various phases can be determined.

From the foregoing it has become clear that if the history (initial B. cereus count,

storage time and storage temperature) of the pasteurised milk is known, the number

of organisms can be estimated. However, this only applies for the optimum growth

conditions. As a consequence a worst case result is obtained. Another aspect is that

there are indications that the initial count in milk is season dependant (own

observations) which thwarts an exact calculation. Furthermore, the storage temper-

ature and time of the milk for an individual consumer are difficult to estimate.

These data may be obtained by sentinel studies. These studies will show that both

the storage temperature and time will show a statistical distribution. The fact that

these distributions may be dependent, again complicates an exact estimation of

human exposure.

6-

-4

f. I ,

0 200 400

time (h)

600 800

Fig. 3. Comparison of the predicted number of organisms and the measured number at 6C. Various

symbols give various cartons (lab 2); __- Model prediction.

M.H. Zwietering et al. / ht. J. Food Microbiology 30 (1996) 55-70 65

6

0 400 600

time (h)

Fig. 4. Comparison of the predicted number of organisms and the measured number at 7C. n Series

1 (lab 1); + Series 2 (lab 1); __- Model prediction.

5. Conclusions

Predictive models may give a useful estimation of the growth of spoilage and

pathogenic organisms in foods. The predictions must, however, always be critically

evaluated, and not be relied on exclusively. Various modeis, literature data and

storage tests are in very good agreement. The models can be used to calculate the

effect of various storage scenarios. The use of these models is easy, costs very little

time and can give much insight. Comparing model predictions with literature data

may add confidence to the most relevant assumptions (the difference in time of

making model predictions and searching literature storage tests is about a factor

30).Finally, well designed storage, surveillance or challenge testing can be used to

increase the confidence to a desired level. Since this takes about a factor 1000 more

in time, these tests should be well designed and must not be done if not necessary.

The storage tests appeared to show very large variation between various cartons.

So, there is no need to predict the growth by any sigmoidal curve. In the prediction

of the growth only an order of magnitude prediction can be obtained. It is then not

relevant to describe exactly the curves in the growth response. The simple exponen-

tial growth model is sufficient. For data treatment of individual growth curves

sigmoidal models are useful, however. One individual growth curve shows a smooth

transition for lag to exponential and exponential to stationary phase. Therefore,

models to describe one set of growth data need to show sigmoidal behaviour.

66 M.H. Zwietering et al. /ht. J . Food Microbiology 30 (1996) 55-70

Of course many other important factors can be included in this procedure. For

instance the experimental determination and possible implementation of the lag

time can be a next step. Also the experimental determination of the (statistical

distribution of the) starting level will give the predictions a better basis. The

variation in temperatures and in residence times can be implemented and the effect

of these can be determined for instance by Monte-Carlo simulation. Maybe such

more detailed studies may explain the variation in numbers as found in this study.

If the cause of the variation is known, maybe it can give directions to diminish it.

This is only possible if the cause of this variation lies in controllable circumstances.

However, it might be that the variation is caused by biological variation (variability

of the state of the organism after the heat treatment, variation in sporulation).

Biological variation is difficult to influence, and we have to live with that. In that

case, simple calculations as given in this paper may still provide an effective

quantification of the number of Bacillus during storage. This then can be used to set

critical limits, determine hazards, and to design relevant experiments.

Together with storage tests, surveillance tests, sentinel studies, and dose response

relations, predictive microbiology may be employed to get an estimate of human

risk from pathogenic microorganisms. All these methods must deal with the

problems of inaccuracies, and statistical variability. Yet, in certain cases, decisions

must be made. These decisions can be based on experience. To lend quantitative

6

0

-2

time(h)

406 600

Fig. 5. Comparison of the predicted number of organisms and the measured number at 8C. Various

symbols give various cartons (lab 2); ~ Model prediction.

M.H. Zwietering et al. / ht. J. Food Microbiology 30 (1996) 55-70

67

10

8

6

z

4

s

-0

2

0

-2

-4

/

L

l l l

:

l

1

0 200

time (h)

400 600

Fig. 6. Comparison of the predicted number of organisms and the measured number at 10C. n Series

1 (lab I); + Series 2 (lab 1); A Series 3 (lab 2); -- Model prediction.

6

4 6 8 10

time (h)

Fig. 7. Comparison of the predicted number of organisms and the measured number at 12C. Various

symbols give various cartons (lab 2); __ Model prediction.

68 M.H. Zwietering et al. 1 ht. J . Food Microbiology 30 (1996) 55- 70

Table 3

Calchlation of the number of organisms, given a certain scenario

Phase

Initial

Company

Retail

Consumer

T(C)

Time (days)

4 2

7 2

7 5

T2t

d lW(W h&V

-2

32 0.417 - 1.6

98 I .278 -0.3

245 3.196 2.9

Table 4

Results of a what if analysis. Storage times (in days) giving a final level of log(N) = 5 (the conditions

in the factory and retail are the same as in Table 3)

Initial number (NJ Consumer storage temperature (C)

6 7 8 9 10 11 12

0.001 13.4 9.9 7.6 6.0 4.8 4.0 3.4

0.01 11.3 8.3 6.4 5.0 4.1 3.4 2.8

0.1 9.2 6.7 5.2 4.1 3.3 2.7 2.3

I 7.0 5.2 4.0 3.1 2.5 2.1 1.8

10 4.9 3.6 2.8 2.2 1.8 1.5 1.2

support to these decisions, models as presented in this paper, can be used. For a

start, the decision may be on the safe side (worst case). To move away from this

safe estimate, ever more specific information must be gathered.

Acknowledgements

The authors would like to thank Dr. Buchanan- for his free donation of the

Pathogen Modeling Program and Food MicroModel for the permission to use

predictions. We thank I. Dijkstra and J. Dufrenne for the experimental work. Part

of the experimental work was carried out at Campina Melkunie, and we would like

to thank-J. Dijkers for making this possible.

Appendix A

It should be noted that for the parameters safe margins must be built in, since for

instance Tt i , is not the lowest temperature in literature where growth is reported,

it is the extrapolated temperature at which no growth will occur. Since the growth

rates around that temperature are much too small to measure, the actual Tmi , will

always be about one degree lower than the minimum reported growth temperature.

If we assume an experiment that lasts six tionths (without a lag phase) and we

M.H. Zwietering et al. /ht. J.

assume that the detection of growth is a

rate is

In $ = ln(2) = ,ut

0 0

ln(2)

__ = 1.58~10-4h-

= 182.24

& = &%%= = 0.0126 =

Food Microbiology 30 (1996) 55- 70 69

factor two, the minimum detectable growth

(22)

(23)

b(T-T,,,,,) = b.AT

(24)

With a b value of 0.0354 (Eq. (15)) this results in difference between Tmin and the

minimum detectable growth temperature of:

0.0126

AT=----=

0.0354

0.36

(If the experiment would only have been pursued for 20 days, the difference would

be 1.07 degrees).

Often at these low temperatures there will be a lag phase, which is of the order

of twice the inverse of the growth rate (between zero and 2/p)

ln(2) = ,~(t - /i) = p. t - p. ;1 x p. t - 2

(26)

,u .t = 2.69

(27)

2.69

___ = 6.13.10-4

= 183.24

(28)

4; = dm = 0.0248 = bAT

With a b value of 0.0354 for Bacillus (Eq. (15)) this results in:

(29)

0.0248

AT=-----=

0.0354

0.70

(If the experiment would only have been pursued for 20 days, the difference would

be 2.12 degrees),

At less fdvourable conditions (lower pH or a,) the b value decreases and the

difference between the minimum growth temperature and the detectable minimum

growth temperature becomes larger. This might result even in an apparent depen-

dency between the minimum growth temperature and for instance the a,. For

instance for a product of a, = 0.96 and optimum pH the b value becomes:

b=

J

(a+r,f?;mi,) =

J

(0.96 - 0.95). 2

(1 -0.95) (37-0)2 = 0.0171

(31)

AT = 0.0248

- = 1.45

0.0171

(32)

(If the experiment would only have been pursued for 20 days, the difference would

be 4.38 degrees).

70 M.H. Zwietering et al. / ht. J . Food Microbiology 30 (1996) 55-70

Appendix B

The derivative of the gammas to the variable can be calculated as:

Y = Y(T)YW)Y(G)

dy MT)

dT = ~YWJ)YW =

WT) Y

dT Y(T)

(33)

Therefore, the specific (relative) change can be defined:

1 dy 1 &G)

-=

ydT Y(T) dT

(34)

The derivatives are:

MT) W- Tmi,) &Wf) dy(d

1

-= -=

XP& - PH) _

dT (T,,z - Twin)* dpH WC,,, -P%,)* da, l - %,min

(35)

The specific (relative) changes are:

1 dy 1 MT)

2

ydT= y(T) dT =(T- Tmin)

1 @OH) 2(PH,,, - PH)

Y (pff) dpH = @H - PHmd(2PHo~t - PHmin - PH)

1 Ma,)

1

Y(G) da, = a, - G,min

(36)

The derivatives to the three variables can be weighted, since it is easy to change the

temperature by one unit, however, it is impossible to change the a, one unit. The

weights could be 1 for temperature, 0.2 for pH and 0.002 for a,. These weights are

determined from a range in temperature between 0 and 25 (weight l), pH between

4 and 9 (weight 5/25), and water activity between 0.95 and 1 (weight 0.05/25). This

means that 1 degree, 0.2 pH unit and 0.002 a, unit are equally desired or possible.

These weighted specific changes can be used to determine the possibilities to change

growth rate or shelf life with a certain variable.

References

Dufeu, J.N. and Leesment, H. (1974) Growth and resistance characteristics of some psychrotrophic

sporeformers isolated from raw milk. XIX International Dairy Congress, India, Vol. 1, pp. 535-536.

Griffiths, M.W. and Phillips, J.D. (1990) Incidence, source and some properties of psychrotrophic

Bacillus spp found in raw and pasteurized milk. J. Sot. Dairy Technol. 43, 62-66.

McMeekin, T.A., Olley, J.N., Ross, T. and Ratkowsky, D.A. (1993) Predictive Microbiology. Wiley,

Chichester, UK.

Ratkowsky, D.A., Olley, J., McMeekin, T.A. and Ball, A. (1982) Relationship between temperature and

growth rate of bacterial cultures. J. Bacterial. 149, 1-5.

USDA, (1994) Pathogen Modeling Program version 4.0. Microbial Food Safety Research Unit. USDA

ARS Eastern Regional Research Centre. Philadelphia, USA.

Wijtzes, T., de Wit, J.C., Huis int Veld, J.H.J., vant Riet, K. and Zwietering, M.H. (1995) Modelling

bacterial growth of Lactobacillus curvatus as a function of acidity and temperature. Appl. Environ.

Microbial. 61, 2533-2539.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- On Bottom Stability of PipelinesDocumento62 páginasOn Bottom Stability of PipelinesVictor DaggersAinda não há avaliações

- Carreon WS06Documento4 páginasCarreon WS06Keneth CarreonAinda não há avaliações

- Statistical Process Control (SPC)Documento52 páginasStatistical Process Control (SPC)starchess22Ainda não há avaliações

- Account Mapping Transformation FileDocumento174 páginasAccount Mapping Transformation FileIrvandias AnggriawanAinda não há avaliações

- Design of Formed VesselDocumento16 páginasDesign of Formed VesselTito FebriantoAinda não há avaliações

- KLT DSP Part1Documento39 páginasKLT DSP Part1Ifrah AlamAinda não há avaliações

- NMDocumento12 páginasNMShravan KumarAinda não há avaliações

- Electric Circuits Lab 15EE103L PDFDocumento61 páginasElectric Circuits Lab 15EE103L PDFMadhavanInduAinda não há avaliações

- Applications of Linear AlgebraDocumento4 páginasApplications of Linear AlgebraTehmoor AmjadAinda não há avaliações

- Deterministic and Probabilistic Liquefac PDFDocumento6 páginasDeterministic and Probabilistic Liquefac PDFFarras Puti DzakirahAinda não há avaliações

- Machine LearningDocumento216 páginasMachine LearningTharshninipriya RajasekarAinda não há avaliações

- Currently Studying in IX AOP Sample PaperDocumento7 páginasCurrently Studying in IX AOP Sample PapersakshiAinda não há avaliações

- Stability Analysis Using MatlabDocumento1 páginaStability Analysis Using MatlabcdasAinda não há avaliações

- Cost-Volume-Profit Relationships: © 2010 The Mcgraw-Hill Companies, IncDocumento97 páginasCost-Volume-Profit Relationships: © 2010 The Mcgraw-Hill Companies, IncInga ApseAinda não há avaliações

- Plate Element Stress - MX - My Vs Global Moment - Bentley - STAAD Products - Eng-TipsDocumento2 páginasPlate Element Stress - MX - My Vs Global Moment - Bentley - STAAD Products - Eng-Tipssom_bs79100% (1)

- 0607 s10 QP 2Documento12 páginas0607 s10 QP 2Amalia KorakakiAinda não há avaliações

- PMP Cheat SheetDocumento9 páginasPMP Cheat SheetzepededudaAinda não há avaliações

- Dokumen - Tips Stochastic Hydrology Nptel Ref Stochastic Hydrology by Pjayarami Reddy 1997Documento70 páginasDokumen - Tips Stochastic Hydrology Nptel Ref Stochastic Hydrology by Pjayarami Reddy 1997Fofo ElorfiAinda não há avaliações

- Basic ProbDocumento12 páginasBasic ProbChaaaAinda não há avaliações

- ISI - Sequence and SeriesDocumento44 páginasISI - Sequence and SeriesRajarshiAinda não há avaliações

- Operations On FilesDocumento12 páginasOperations On FilesVinayKumarSinghAinda não há avaliações

- Urdaneta City UniversityDocumento2 páginasUrdaneta City UniversityTheodore VilaAinda não há avaliações

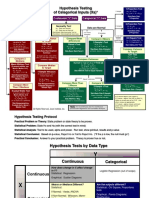

- Hypothesis Testing Roadmap PDFDocumento2 páginasHypothesis Testing Roadmap PDFShajean Jaleel100% (1)

- ATV600 - Communication - Parameters - EAV64332 - V1.3Documento46 páginasATV600 - Communication - Parameters - EAV64332 - V1.3Sugeng WahyudiAinda não há avaliações

- Graphology PDFDocumento5 páginasGraphology PDFpuneeth87Ainda não há avaliações

- Calculus Final Test 2017 - 2018 Semester 1Documento2 páginasCalculus Final Test 2017 - 2018 Semester 1Hoàng HàAinda não há avaliações

- REF615 Standard ConfigurationDocumento11 páginasREF615 Standard Configurationmaruf048Ainda não há avaliações

- Impact of Cash Conversion Cycle On Firm's ProfitabilityDocumento3 páginasImpact of Cash Conversion Cycle On Firm's ProfitabilityAnonymous 7eO9enzAinda não há avaliações

- MIT5 067F09 Lec1 DataDocumento28 páginasMIT5 067F09 Lec1 DataAlexandra BarthAinda não há avaliações

- CH 6Documento21 páginasCH 6Narendran KumaravelAinda não há avaliações