Escolar Documentos

Profissional Documentos

Cultura Documentos

Stator and Rotor Design Considerations For Integral HP Machines - Austin Bonnett PDF

Enviado por

uuur35100%(1)100% acharam este documento útil (1 voto)

111 visualizações109 páginasThe electrical motor is still the work horse of industry. 2 / 3 of all generated electricity is used to drive these motors. The stator is inseparable from the rotor through mutual inductance. Stator and rotor design can not be discussed in a vacuum.

Descrição original:

Título original

Stator and Rotor design considerations for integral HP machines - Austin Bonnett.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThe electrical motor is still the work horse of industry. 2 / 3 of all generated electricity is used to drive these motors. The stator is inseparable from the rotor through mutual inductance. Stator and rotor design can not be discussed in a vacuum.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(1)100% acharam este documento útil (1 voto)

111 visualizações109 páginasStator and Rotor Design Considerations For Integral HP Machines - Austin Bonnett PDF

Enviado por

uuur35The electrical motor is still the work horse of industry. 2 / 3 of all generated electricity is used to drive these motors. The stator is inseparable from the rotor through mutual inductance. Stator and rotor design can not be discussed in a vacuum.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 109

Austin Bonnett

EASA Education and

Technology Consultant

Gallatin, MO

2008 EASA

Convention

Dallas, TX

Stator & Rotor Design Considerations

for Integral HP Motors

Stator design can not be discussed in a vacuum

because it is inseparably connected to the rotor

through mutual inductance. Another critical

component is the motor enclosure which houses

the stator and rotor and facilitates the critical

cooling circuit.

Equivalent Circuit

Introduction

1. Influence of Application Requirements

2. Basic Motor Fundamentals

3. Stator Core Design Factors

4. Winding Elements

5. Stator and Frame Construction

6. Rotor Design and Construction

7. Motor Noise and Vibration

8. Questions and Answers

9. Appendix

The presentation is divided

into the following components:

WINDING OF A LARGE

HIGH-VOLTAGE STATOR

Typical cast rotor assembly

In order to achieve the desired motor

performance over a wide range of operation, it is

critical for the designer to have a clear definition

of the application requirements. Unnecessary,

contradictory, or confusing information can

adversely effect the desired outcome. There are

numerous compromises in the design of an

electric motor.

1. Influence of application

requirements

MOTOR POWERING ELECTRIC

UTILITY INDUCTED-DRAFT FAN

1. Efficiency vs. Power Factor

2. Current-Torque Characteristics

3. Noise vs. Efficiency

4. Size vs. Operating Temperature

5. Insulation Quality vs Operating Temperature

6. Cost vs. Performance

7. Reliability vs. Enclosure

The following are examples of the choices that

need to be made.

BOILER FEED PUMP

In summary the major application

requirements are:

1. Power and Speed Ratings

2. Power Source

3. Enclosure and Frame Selection

4. Speed-Torque Issues

5. Duty Cycle

6. Environmental Factors

The electrical motor is still the work horse of

industry. 2/3 of all generated electricity is used to

drive these motors which are converted of

electrical energy into mechanical energy.

2. Basic Motor Fundamentals

1. Motor Nomenclatures

2. The Motor as a Converter of Energy

3. Power Equations

4. Efficiency and Loss Management

5. The MMF Forces

6. Using Simple Design Ratios

7. Containment of Motor Forces and Stresses

Power engineers from all aspects of industry can

benefit from a basic understanding of the following

items.

BASIC MOTOR FUNDAMENTALS

15

Basic Motor Equations

Stator Stresses

Thremal stresses

Thermal aging

Voltage variation

Cycling

Loading

Ventilation

Ambient

Electrical stresses

Dielectric aging

Tracking

Corona

Transients

Mechanical stresses

Coil movement

Rotor strikes

Defective rotor

Flying objects

Lugging of leads

Environmental stresses

Moisture

Chemical

Abrasion

Damaged parts

Excessive ambient

Restricted ventilation

Rotor Assembly Stresses

Thremal

Thermal overload

Thermal unbalance

Excessive rotor losses

Hot spots

Sparking

Magnetic

Rotor pullover

Noise

Vibration

Off magnetic center

Saturation of lamintations

Circulating currents

Residual

Stress concentrations

Uneven bar stresses

Dynamic

Vibration

Rotor rub

Overspeeding

Cyclic stresses

Centrifugal force

Environmental

Contamination

Abrasion

Foreign particles

Excessive ambient

Restricted ventilation

Rotor Assembly Stresses-cont.

Mechanical

Casting variations

Loose laminations

Incorrect shaft/core fit

Fatigue or broken part

Poor rotor-to-stator geometry

Material deviations

Other

Misapplications

Poor design practices

Manufacturing variation

Loose bars, core

Transient torques

Wring direction of rotation

TYPICAL SPEED-TORQUE/

CURRENT CURVE

1. Basic elements of thermal circuit.

a. Stator.

b. Rotor.

c. Bearing and lubrication system.

2. The thermal aging process and insulation life.

3. NEMA/IEEE insulation classifications and temperature rise.

4. Impact of service factor.

5. Altitude considerations.

6. Usual and unusual service considerations.

7. Special ambient considerations.

8. Voltage variation.

9. The effect of unbalanced voltage.

10. Harmonic impact including variable frequency.

AC Squirrel Cage Induction Motor

Temperature Considerations

Sources of Heat and Air Flow

Within Motors

Tube-Cooled Air-to-Air Heat

Exchanger

Oxidation

Loss of Volatile Product

Molecular Polymerization

Reaction to Moisture

Chemical Breakdown

Vulnerable to Other Stresses

Terminal Aging Processes

Temp. vs. Life Curves for Insulation

Systems by AIEE 510 Method

*Assumes life

doubles for a 10 C

decrease in

temperature.

Allowable Winding Thermal Load vs. Ambient

(Class F System)

WINDING TEMPERATURE ALLOCATIONS

Typical Stator-Rotor Cross-section

1. Laminations

2. Electrical Steel

3. Magnetic Circuit Design

4. Winding Configuration

5. Loss Distribution

6. Slot Combination

7. L/D Ratio

The seven key elements of stator core design

can be summarized as follows:

3. Stator Core Design Factors

The stacked stator core (SSC) can be defined as the

stator laminations, air ducts (if needed), and any

clamping plate or fingers needed to hold the assembly

together prior to insertion into the stator frame. In these

cases, this assembly is usually stacked on some sort of

arbor to control the stator slot geometry. In larger sizes,

the lamination may be stacked directly into the frame,

which serves as tooling to control the geometry. These

laminations normally are ring laminations made as a full

circle. On stators larger than 45 in diameter, a

segmented laminations are used.

The Stacked Stator Core

Ring Laminations

Segmented Laminations

Stacked and Welded Stator Core

GENERAL CLASSES

Non-Oriented (AISI Grades M15 - M47)

Grain Oriented (AISI Grades M2 - M6)

Fully Processed

Semi-Processed

SURFACE INSULATION

Oxidation

Core Plate

STEEL LOSSES

Core Loss (1.6 w/# - 3.1 w/# Range)

Hysteresis Loss

Eddy Current Loss

ANNEALING

Simple Stress Relief

Stress Relief Plus Decarburization

(Grain Growth)

Electrical Steel Characteristics

Watts Loss Per Pound

Permeability - Amount of Flux

Density Without Saturation

Thermal Conductivity - Ability to

Dissipate Heat

Steel Thickness - Loss vs. Strength

(.018 x .025 Range)

Criteria for Motor Efficiency

Typical Motor Grade Electrical

Steels

Low magnetic flux densities often indicate inefficient use of the

magnetic materials. However, low is relative, and there are legitimate

reasons for using low flux densities than ODP motors simply because

there is more magnetic material per horsepower in the TEFC motors,

and to use air gap flux density equivalent to that of ODP motors would

create starting current problems. Also, low flux density is often

inherent in the slow speed of two-speed winding motors. The

magnetization of the steel core is not a linear function. The core steel

will saturate with flux. When the densities reach saturation, the

ampere-turns required to magnetize the steel will increase rapidly,

causing high magnetizing current and low motor power factor. Also,

high magnetic flux densities in the steel will cause high eddy current

and hysteresis losses in the steel, thus lowering the efficiency of the

motor and possibly causing it to run too hot.

Effects of Magnetic Flux Density

What are the limits for flux densities? Well, isnt a fixed

answer. Design target limits should be in the range of 110-

130 kilolines per square inch in the lamination teeth, and 80-

110 kilolines per square inch in the backiron. Maximum

should not exceed 138 in the teeth and 120 in the core, and

even this is too high for most small motors, and for high

speed large motors. The usually larger teeth and backiron of

high speed motors simply cannot handle the losses

associated with using high flux densities. (Backiron densities

on the rotors of solid core rotors is usually low because the

shaft carries part of the flux. On large rotors with air

passages in the rotor, the rotor backiron density must be

considered).

Effects of Magnetic Flux Density

The magnetization and loss characteristics of the

particular steel being used also must be considered. The

magnetization curves of various steels will vary only

slightly, affecting power factor to the extent that more or

less ampere-turns are required to establish the design flux

density. However, loss characteristics of lamination steels

will vary greatly, and certain steel may not be usable for a

particular rating. Good slot design is the key to optimum

utilization of the magnetic materials in the motor. Dont

look just at the flux densities, but also at the ampere-turns

required to magnetize the various parts of the motor. High

ampere-turn requirements for any part (except air gap) is

indicative of poor slot design.

Effects of Magnetic Flux Density

Mutual (Coupling) Flux (4-Pole)

Flux Linkage of Stator to Rotor

Leakage Flux

Development of Average Air Gap

Flux Density in Kiloline/Inches

2

Development of Average Air Gap

Flux Density in Kiloline/Inches

2

Bg =

E n P m 10

5

13.95 f T N

1

D

i

Lg Kp Kd

KILOLINES

INCHES

2

Form-Wound Stator

Stator Winding

4. Winding Elements

Types of windings

Random-wound lap

Random-wound

concentric

Form-wound

Types of varnish

Polyester

100% solid epoxy or

100% polyester

Magnet wire

Round

Rectangular

Coils

Random wound

Form wound

Slot insulation

Slot liner

Bottom sticks

Center sticks

Topsticks

Groundwall

4. Winding Elements-cont.

Group insulation

Phase paper

Sleeving

Center sticks

Connection

Lead cable

Sleeving

Tie cord

Coil bracing

Tie cord

Dacron felt

Surge rope

Tape

Treatment

Vacuum pressure

impregnation

Dip varnish

Abrasion-resistant

coating

Random wound

Form wound

All ratings over 700 hp should be form wound.

All ratings over 600 volts should be form wound.

Ratings 700 hp and less or 600 volts and less are

typically random wound with some exceptions.

Form wound is available on many ratings that are

normally random wound.

Criteria for Random-Wound

and Form-Wound Stators

In comparing the two processes, keep in mind the basic differences

in coil construction and the objectives of treating the coils. The form

wound coils are completely wrapped with many layers of non-porous

tape. It is voids which can result in hot spots or corona. The random

wound coil has no tape in the slot portion and is not susceptible to

corona. Because of these differences, several of the steps critical to

the form wound stator are not required on the random wound stator.

On the form wound construction, a pre-heat is necessary to remove

moisture due to the many layers of tape. On the random wound

construction, the moisture can be easily removed during the dry

vacuum cycle. Again, because of the form wound coil construction,

the pressure cycle is required to force the resin into small voids within

the coil, whereas on the random wound the coils are more directly

exposed to the resin and complete wetting and satisfactory slot fill is

obtained during the wet vacuum cycle.

Form Wound vs Random Wound

INSERTION OF STATOR COILS

WINDING OF A LARGE

HIGH-VOLTAGE STATOR

Terminal Markings and Connections

Three-Phase Motors - Single Speed

FORM-WOUND STATOR

Grouping, Pitch and Connection

POSSIBLE NUMBER OF CIRCUITS

Grouping, Pitch and Connection

Winding Movement and Bracing

Blocking and Tying

Insulation Extension at Slot Edge

Slot insulation should protrude at least 3/8 beyond

the end of the slot.

Phase Insulation

Phase insulation should protrude

past the phase coils.

Winding Movement

and End Turn Bracing

Straight Line Blocking

Straight Line Blocking

Winding Movement

and Coil Bracing

Two examples of alternative bracing on a random winding (left) and a form

winding (right). These examples use epoxy to simulate a surge.

The six key elements of stator frame design

can be summarized as follows:

1. Motor Enclosure Options for Horizontal and

Vertical Positions

2. Enclosure Impact on Motor Performance

3. Cast Iron vs. Fabricated Steel Materials

4. Noise and Vibration Issues

5. The Cooling Circuit

6. Environmental Considerations

5. Stator and Frame Construction

Motor

Nomenclature

for Horizontal

Motors

Typical Weather Protected I

Enclosure

Typical Weather Protected II

Enclosure

Typical Tube-Cooled (Air-to-Air)

Enclosure

Motor Air Flow

450 hp, open dripproof, 5000 frame, 8-pole motor.

WPI Base Air Flow

WPII Air Flow

8000 frame, WPII, 6-pole motor.

Stator/Rotor Cooling

Air Ducts

The ten key elements of rotor design can be

summarized as follows:

1. The Rotor Forces and Stresses

2. Cast vs. Fabricated

3. Bar Shapes and Fits

4. Aluminum vs. Copper Cages and Other Alloys

5. Rotor Skew and Air Gap

6. The Cooling Circuit

7. Length to Diameter Ratios

8. Speed Torque Characteristics and Slip

9. End Ring Forces

10. Unbalance Magnetic Forces and Noise

6. Rotor Design and Construction

Typical Cast Rotor Assembly

Typical Squirrel Cage

The majority of rotor failures are caused by a combination

of various stresses which act on the rotor.

In general terms, these stresses can be broken down as follows:

Thermal

Residual

Environmental

Electromagnetic

Dynamic

Mechanical

Rotor Forces

POTENTIAL ROTOR FORCES

Calculating Slip

Construction of Cast Rotors

A. Semi-processed, no insulation

B. Fully processed, core plate insulation

C. Semi-processed and annealed

B

A

C

Typical Rotor Laminations

A. Aluminum with hard anodize

B. Aluminum without insulation

C. Aluminum with light anodize

D. Copper without insulation

A

B

C

D

Sample Fabricated Rotor Bars

A Variety of Rotor Bar Shapes

(Courtesy of Darby Electric)

Explanation of Skin Effect

Stator

Air Gap

Rotor

Shaft

Typical lamination set showing relationship

between stator and rotor teeth and air gap.

Typical Lamination

Large Motor, Slow Speed

Spider Shaft

The two common rotor bar materials are copper and

aluminum. Traditionally, cast rotors have been aluminum;

fabricated rotors can be aluminum or copper. Aluminum

alloys and copper alloys have been available for special

purposes such as high slip (NEMA type C & D ). In recent

years a number of manufacturers have changed from

copper to aluminum fabricated rotors. Although the higher

conductivity of copper usually gives it a slight advantage

in running loss, this can be largely overcome by the

optimum shaping available in extruded aluminum bars.

Extruded shapes are also available in copper but are very

expensive.

Rotor Bar Material

Fabricated Rotors

Cast Rotor With Air Ducts

Side view of a large cast rotor showing the

position of the air ducts.

Fabricated Rotors With Various

Numbers of Air Ducts

Magnetic Centering Forces

and Air Gap

Air Gap

This photo illustrates the air gap between the stator

inside diameter and the rotor outside diameter.

Skewed Rotor Cage

Rotor With Skewed Bars

Skew is the angular twist of a slot away from the axial direction. Typical skew

is one stator slot pitch. The purpose of the skew is to reduce special

harmonics in the air gap flux that are introduced by a finite number of slots

and the slotting combination.

Skewing

The results of skewing are:

Reduction of induced E.M.F. in the rotor bar.

Decrease in rotor leakage reactance.

A non-uniform axial distribution of the air gap flux.

Skewed bars have a current that has a circumferential component

which develops a small axial force which imposes an additional load

on bearings.

Non-uniform air gap flux increases core and stray losses.

Improved speed-torque characteristics, including elimination of

locking torque at zero speed and cusps at various speeds.

Reduced likelihood of noise problems.

Sometimes it is necessary to tighten rotor bars during

the manufacturing process or during repair and

maintenance. Swaging is a relatively easy process

which has been used for years. Swaging can also be

used to tighten bars that have loosened in service and

minimize propagation of bar cracking. The following

slide shows a rotor bar before and after swaging.

Swaging of Rotor Bars

Swaging Rotor Bars

Before

swaging

After

swaging

Example of a rotor where bars

have been swaged.

Currently, the rotors of large induction motors are constructed of either

aluminum or copper and their associated alloys. It is interesting that

many people exhibit a preference of one or other of these materials in

the construction of the rotor, when it is the construction itself that is

important when considering rotor life. In fact, both have their advantages

and are justified depending upon the specific application.

Aluminum vs Copper Construction

Preference

Supporters of copper will argue that aluminum melts at 1250 F as

compared to coppers 1980 F melting point, and therefore has greater

stall capacity. While true, this disregards that most copper rotors are

brazed to the end rings with a brazing alloy that melts at 1100 F. The

results of a stall are no less disastrous with either material once the

temperature to obtain molten metal is achieved. Extensive testing shown

that either material, as normally applied, can be designed to exhibit

comparable thermal, electrical and physical characteristics, including

fatigue life as related to motor design.

Aluminum vs Copper Construction

Preference

End Ring Construction for a Typical

Aluminum Bar Rotor

Rotor bar

End Ring Construction for a Typical

Copper Bar Rotor

7. Motor Noise & Vibration As

Influenced by the Stator and

Rotor Design

Ventilation (windage) noise is created in the air stream

used to cool the motor. Windage noise is generated by the

air flowing in and around the motor, as follows:

1. Fan blades rotating in close proximity to mounting bolts or other

mechanical parts.

2. Restrictions in the air stream.

3. Abrupt changes in the direction of air flow.

4. Rotor air duct vent spacers passing by stationary stator vent

spacers.

Generally, the predominant noise source for six-pole and faster

motors (two- through eight-pole speeds for TEFC motors) is

ventilation noise. This is due to the higher fan speeds and

greater CFM. Thus, to reduce noise levels on two- through

six-pole motors, the ventilation noise must be reduced.

Ventilation Noise

1. Stator/Rotor Slot Combination (N

1

/N

2

)

2. Rotor Length to Diameter Ratio ( L/D)

3. Flux Density Saturation (B

g

)

4. Air Gap Geometry

5. Stator Core Stability and Frame Structure

6. Speed Options

7. Shaft Stiffness

8. Miscellaneous Factors

Major Electrical Noise/Vibration

Considerations

The magnetic flux in a motor is composed of the rotating fundamental sine-wave and the

harmonic components. Only the fundamental wave or field actually provides useful

tangential forces and usable rotating torque. Whereas the harmonic components of the

wave only produce Parasitic torques which distort the accelerating speed-torque

characteristic of the motor.

The presence of these non-sinusoidal fields in the air gap of the motor can result in any

of the following detrimental effects;

1. Starting or running noise

2. Synchronous locking torques

3. Dead points at zero speed

4. Torque dips

5. Stray losses

Although it is not practical to eliminate all of these parasitic torques, the proper selection

of the stator and rotor slots can minimize these influences. The proper selection of the

stator winding span and rotor skew can further reduce these influences.

Stator/Rotor Slot Combinations

Be sure you have a copy of the

2008 Select Presentations

CD-ROM

It contains most of the handouts plus many complete

technical papers from this years quality lineup of speakers!

(If you did not receive a CD in your packet as part of your registration, you

may purchase a copy for only $30. Visit www.easa.com for more information.)

Você também pode gostar

- Active Magnetic BearingDocumento7 páginasActive Magnetic BearingsomendratrivediAinda não há avaliações

- Improving Efficiency of Squirrel Cage Induction MotorsDocumento31 páginasImproving Efficiency of Squirrel Cage Induction MotorsDular PatelAinda não há avaliações

- To Study The Open Circuit/Core Losses of Single Phase TransformerDocumento5 páginasTo Study The Open Circuit/Core Losses of Single Phase TransformerTanzeel UR RehmanAinda não há avaliações

- 01 Transformer ConstructionDocumento32 páginas01 Transformer Constructionedin_huseinbegovicAinda não há avaliações

- 01 Transformer ConstructionDocumento32 páginas01 Transformer ConstructionaswardiAinda não há avaliações

- Study of Turbo-Generators.Documento37 páginasStudy of Turbo-Generators.Brijesh Kumar100% (5)

- Fault Zone Analysis RotorDocumento8 páginasFault Zone Analysis Rotorabhe prasetyaAinda não há avaliações

- PMBLDC Motor DriveDocumento55 páginasPMBLDC Motor DriveSushant SinghAinda não há avaliações

- 6 Motor Basics HandoutDocumento18 páginas6 Motor Basics HandoutTan Yit KeongAinda não há avaliações

- KATO GeneratorDocumento20 páginasKATO GeneratormotiondrillAinda não há avaliações

- Electric Machine Design (Module-4)Documento24 páginasElectric Machine Design (Module-4)karumAinda não há avaliações

- PCIC 2011 Using Magnetic Flux Monitoring To Detect Synchronous Machine Rotor Winding Shorts PDFDocumento7 páginasPCIC 2011 Using Magnetic Flux Monitoring To Detect Synchronous Machine Rotor Winding Shorts PDFabdul2wajidAinda não há avaliações

- Manufacturing of Turbo GeneratorsDocumento19 páginasManufacturing of Turbo GeneratorsKeerthana Kola100% (1)

- EPRI Licensed Material - Generators: Component Damage and InspectionDocumento34 páginasEPRI Licensed Material - Generators: Component Damage and InspectionShi YoshiAinda não há avaliações

- Design of Induction Motors PDFDocumento108 páginasDesign of Induction Motors PDFMaverick Naidu100% (3)

- Introduction to Three-Phase and Single-Phase Induction MotorsDocumento17 páginasIntroduction to Three-Phase and Single-Phase Induction MotorsFadroStepakyuOsirisRedAinda não há avaliações

- Generador KatoDocumento20 páginasGenerador KatoVelasquez DavisAinda não há avaliações

- RMD Motor TypesDocumento19 páginasRMD Motor TypesMuhammed AyyubAinda não há avaliações

- Insocoat: - Electrically Insulated Rolling BearingsDocumento12 páginasInsocoat: - Electrically Insulated Rolling Bearingsiyilmaz1Ainda não há avaliações

- Unit 5 Induction Motor: StructureDocumento27 páginasUnit 5 Induction Motor: StructureSivasubramani ShanmugaveluAinda não há avaliações

- AC MotorsDocumento50 páginasAC MotorsDanzel SepilloAinda não há avaliações

- Rotor ManufacturingDocumento4 páginasRotor ManufacturingSatyam MadameAinda não há avaliações

- Energy Saving Opportunities in Electric Motors: Power Supply QualityDocumento10 páginasEnergy Saving Opportunities in Electric Motors: Power Supply Qualitydev1992Ainda não há avaliações

- 2-Pole Turbine Generators: WEG GroupDocumento12 páginas2-Pole Turbine Generators: WEG GroupVasudev AgrawalAinda não há avaliações

- Basics of Motors & Control PanelDocumento59 páginasBasics of Motors & Control PanelPraveen BalakrishnanAinda não há avaliações

- 8000 DC AlternatorDocumento4 páginas8000 DC Alternatorsamcalkin1Ainda não há avaliações

- Brushed DC Motors GuideDocumento32 páginasBrushed DC Motors GuideEvren SoydanAinda não há avaliações

- P1719 Working Document R8 October 2007Documento26 páginasP1719 Working Document R8 October 2007metha.d8070Ainda não há avaliações

- Report On Transformer ManufacturingDocumento36 páginasReport On Transformer ManufacturingRaj Moyal89% (57)

- Recent Endwinding Vibration Problems in Air-Cooled Turbine GeneratorsDocumento8 páginasRecent Endwinding Vibration Problems in Air-Cooled Turbine GeneratorsAnonymous BBX2E87aHAinda não há avaliações

- Case Study: CrankshaftsDocumento12 páginasCase Study: CrankshaftsDHRUV SINGHALAinda não há avaliações

- Rishabh Prasad (0068) Presentation - Mpia Lab-1Documento34 páginasRishabh Prasad (0068) Presentation - Mpia Lab-1Pradyum ThakurAinda não há avaliações

- DC Motor ControlDocumento10 páginasDC Motor ControlIbrahim KhleifatAinda não há avaliações

- Insocoat: - Electrically Insulated Rolling BearingsDocumento12 páginasInsocoat: - Electrically Insulated Rolling Bearingsmsb42Ainda não há avaliações

- Introduction To Modern Electrical Machine DesignDocumento26 páginasIntroduction To Modern Electrical Machine DesignUSMANAinda não há avaliações

- Failure Analysis of A Helical Gear in A Gearbox Used in A Steel Rolling MillDocumento7 páginasFailure Analysis of A Helical Gear in A Gearbox Used in A Steel Rolling MillymsyaseenAinda não há avaliações

- Electrical Machine Design: EMD-I EL0604Documento20 páginasElectrical Machine Design: EMD-I EL0604NanduAinda não há avaliações

- Permanent Magnet Motor GuideDocumento36 páginasPermanent Magnet Motor GuidekkarthiksAinda não há avaliações

- Replacement of Main Electrical Generator in NPP Krsko IRMC 2017Documento6 páginasReplacement of Main Electrical Generator in NPP Krsko IRMC 2017NeopeakAinda não há avaliações

- Universal MotorDocumento4 páginasUniversal MotorBobAinda não há avaliações

- EEM Motor Losses & Efficiency OptimizationDocumento13 páginasEEM Motor Losses & Efficiency OptimizationV.shivaAinda não há avaliações

- MagneticMotors PDFDocumento34 páginasMagneticMotors PDFJoao CarlosAinda não há avaliações

- Generator EdcDocumento77 páginasGenerator EdcAJAY KUMAR100% (1)

- Permanent Magnet brushless DC Motor overviewDocumento61 páginasPermanent Magnet brushless DC Motor overviewRishabhAinda não há avaliações

- A Practical Guide To Understanding Bearing Damage Related To PWM Drives - CNFDocumento7 páginasA Practical Guide To Understanding Bearing Damage Related To PWM Drives - CNFjoe4709Ainda não há avaliações

- NAM Cat CombinedCh1Documento16 páginasNAM Cat CombinedCh1Thanh Do VanAinda não há avaliações

- BHEL Manufactures Turbo Generators up to 200MWDocumento8 páginasBHEL Manufactures Turbo Generators up to 200MWPraveen KumarAinda não há avaliações

- Mca On DC MotorsDocumento6 páginasMca On DC MotorsAsaithambi DorairajAinda não há avaliações

- Eliminating Rotor ProblemsDocumento6 páginasEliminating Rotor Problemssuzette TabladaAinda não há avaliações

- Induction Motor PresentationDocumento48 páginasInduction Motor PresentationMark Oliver Bernardo100% (2)

- Description of The Studied Device and PhenomenaDocumento7 páginasDescription of The Studied Device and PhenomenaTusharAinda não há avaliações

- Universal Motor: Wound Motor Where The Stator's Field Coils AreDocumento8 páginasUniversal Motor: Wound Motor Where The Stator's Field Coils AreItho MisaAinda não há avaliações

- Vibration Monitoring For Fault Motors Diagnosis PDFDocumento8 páginasVibration Monitoring For Fault Motors Diagnosis PDFuuur35100% (1)

- Electric MotorsDocumento13 páginasElectric MotorsCholan PillaiAinda não há avaliações

- Induction MotorDocumento27 páginasInduction MotorNandhini SaranathanAinda não há avaliações

- Weld Like a Pro: Beginning to Advanced TechniquesNo EverandWeld Like a Pro: Beginning to Advanced TechniquesNota: 4.5 de 5 estrelas4.5/5 (6)

- Study of a reluctance magnetic gearbox for energy storage system applicationNo EverandStudy of a reluctance magnetic gearbox for energy storage system applicationNota: 1 de 5 estrelas1/5 (1)

- ReadmeDocumento4 páginasReadmevishiwizardAinda não há avaliações

- Part Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisDocumento6 páginasPart Winding Startting The Three-Phase Squirrel Cage Induction Motor Air Gap Magnetic Field AnalysisIjabiAinda não há avaliações

- Hardware Inloop Simulation IEEE LabVIEWDocumento1 páginaHardware Inloop Simulation IEEE LabVIEWvishiwizardAinda não há avaliações

- ACM2 TAU Datasheet enDocumento5 páginasACM2 TAU Datasheet envishiwizardAinda não há avaliações

- 50 SCS Automotive Coatings - Rev0913Documento4 páginas50 SCS Automotive Coatings - Rev0913vishiwizardAinda não há avaliações

- 5 SmanualDocumento16 páginas5 SmanualMark ThomasAinda não há avaliações

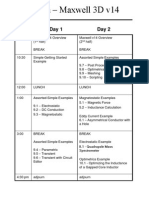

- Maxwell 3D v14 Training AgendaDocumento1 páginaMaxwell 3D v14 Training AgendavishiwizardAinda não há avaliações

- Electric Vehicle Motor Design NotesDocumento131 páginasElectric Vehicle Motor Design NotesvishiwizardAinda não há avaliações

- LJLVJK LVJJV LKJVDocumento5 páginasLJLVJK LVJJV LKJVvishiwizardAinda não há avaliações

- FAB Resistivity White PaperDocumento8 páginasFAB Resistivity White PapervishiwizardAinda não há avaliações

- Engineered PlasticsDocumento61 páginasEngineered Plastics고병석Ainda não há avaliações

- TRL Definitions PDFDocumento1 páginaTRL Definitions PDFBHARadwajAinda não há avaliações

- Recent Advances in Materials For Use in Permanent Magnet Machines - A ReviewDocumento7 páginasRecent Advances in Materials For Use in Permanent Magnet Machines - A ReviewvishiwizardAinda não há avaliações

- Jeas 1012 787Documento5 páginasJeas 1012 787vishiwizardAinda não há avaliações

- Op - XT546 246 346 - Op288 V03Documento2 páginasOp - XT546 246 346 - Op288 V03vishiwizardAinda não há avaliações

- Nit 3600 1Documento5 páginasNit 3600 1vishiwizardAinda não há avaliações

- Maxwell 2dDocumento7 páginasMaxwell 2dvishiwizardAinda não há avaliações

- How to Check a MOSFETDocumento2 páginasHow to Check a MOSFETvishiwizardAinda não há avaliações

- Big Energy Series 11.5.2012 Qing-Chang ZhongDocumento1 páginaBig Energy Series 11.5.2012 Qing-Chang ZhongvishiwizardAinda não há avaliações

- Electrical Resin BenefitsDocumento2 páginasElectrical Resin BenefitsvishiwizardAinda não há avaliações

- Brushless Motor FundamentalsDocumento13 páginasBrushless Motor FundamentalsvishiwizardAinda não há avaliações

- Presentation 1Documento1 páginaPresentation 1vishiwizardAinda não há avaliações

- Sensors Used in HEVDocumento4 páginasSensors Used in HEVvishiwizard100% (1)

- Wittich2011 SonkusaleVanderveldeDocumento1 páginaWittich2011 SonkusaleVanderveldevishiwizardAinda não há avaliações

- FTF Aut f0234Documento38 páginasFTF Aut f0234vishiwizardAinda não há avaliações

- Cam DesignDocumento13 páginasCam DesignvishiwizardAinda não há avaliações

- Lit Survey RamamurthyDocumento9 páginasLit Survey RamamurthyvishiwizardAinda não há avaliações

- Motor Primer1Documento2 páginasMotor Primer1vishiwizardAinda não há avaliações

- Sona SPEED CatalogueDocumento13 páginasSona SPEED CataloguevishiwizardAinda não há avaliações

- A Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesDocumento1 páginaA Brief Overview of Electric & Hybrid Electric Vehicle TechnologiesvishiwizardAinda não há avaliações