Escolar Documentos

Profissional Documentos

Cultura Documentos

Chapter 1

Enviado por

Renu Sekaran0 notas0% acharam este documento útil (0 voto)

14 visualizações16 páginasGas System Material and Components

Título original

chapter 1

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoGas System Material and Components

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

14 visualizações16 páginasChapter 1

Enviado por

Renu SekaranGas System Material and Components

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 16

LOGO

BKG3493 GAS SYSTEM

MATERIALS & COMPONENTS

CHAPTER 1

REVIEW OF GAS SYSTEMS

TOPIC OUTCOMES

At the end of this chapter you should be able to:

i) Explain the overview of gas industry in Malaysia

ii) Differentiate between NG, LPG and LNG supply

chains

iii) Explain the supply pressure and materials used

for transporting NG, LPG and LNG to the users

Worldwide Natural Gas Consumption

An increasing demand for natural gas as

a fuel as well as a feed for

petrochemical and chemicals plants

throughout the world.

Natural gas has played a major role in

meeting energy demand in North

America, Western and Eastern European

countries, and industrialized Asia due to

its availability and environmental

acceptance.

Advantages of using natural gas includes

abundance resources compared to

crude oil, most clean burning, efficient,

economic, etc.

Among the multinational companies in

gas (and oil) industry

Natural Gas Supply Chain

Offshore Exploration and

Production platforms

(Lawit, Jernih, Resak,

Duyong, Bekok, Sotong,

Guntong, and etc)

Gas Processing

Plants (A & B)

City Gate Odorizer Station

District Station

Area Station

Service Station

Subsea

Pipeline

PGU

Line

Feeder

Line

Regulating

Station

Service Station

Distribution

Line

Industrial/

Cogenaration

Commercial

Commercial

Residential

500-1000

psig

260 psig

60 psig

> 29 psig

Supply pressure

dictates the material

used for the pipeline!

LPG Supply Chain/ LPG Reticulation System

LPG Manifold

System

First Stage

Regulator

Second Stage

Regulator

LPG Bulk Storage

(60 to 80 psi)

Residential &

Commercial

Customers

5.0 psi 0.5 psi

LNG Supply Chain

Gas Field

Liquefaction Plant Shipping

Receiving Terminal

+

Re-gasification

Pipeline &

Distribution

Load Centers

Load Centers

Cryogenic condition mainly dictates the

materials used for piping and storage systems!

Gas Utilization Policy in Malaysia

In Peninsular Malaysia, natural gas and LPG are mainly utilized

for meeting continuous domestic demands from

residential/household, commercial and industrial users.

Domestic/household utilizations water heating and boiling,

cooking, drying and etc.

Commercial utilizations restaurants (heating and cooking),

hotels (heating, sauna, Jacuzzi), malls (heating, air

conditioning), and etc.

Industrial utilizations heating, production of steam, power

generations, NGV, feedstock for chemicals productions, and

etc.

In East Malaysia, particularly in Sarawak, natural gas is exported

in the form of LNG.

Peninsular Gas Utilisation (PGU) Project

Owned by Petronas Gas Berhad (PGB)

Started on 1983 and completed on 1999/2000

GPP A (1,2,3 & 4) and GPP B (5 & 6)

3 phases

Phase I from Kertih to Paka and to Kuantan

Phase II from Kuantan to Singapore and Klang (via

Segamat)

Phase III from Klang to Padang Besar

Parallel line act as loop

Gas Processing Plant and Gas Liquefaction

Plant

Produce treated natural gas (sales gas) to meet pipeline

requirements and customers specifications

Involve several processing steps such as gas dehydration, gas

sweetening, gas conditioning, dew point control, and etc.

In LNG production, raw natural gas must be treated to avoid

equipment plugging during liquefaction process.

Gas Processing Plant

GPP Capacity (mmscfd) Gas in

1 250 1984

2 250 1992

3 250 1992

4 250 1994

5 500 1998

6 500 1999

Gas Piping System in Malaysia

Gas Transmission System

Steel pipe with high tensile strength

Pipe diameter ranges from 24 inches to 36 inches

Pressure ranges from 500 psig to 1000 psig (3400-6900

kPa)

Capable of transporting large volume of gas

Comprise large compression station (such as in Segamat)

Gas distribution

Distribute gas to the customers/users

Gas users are from industrial, commercial and residential

System components

City Gates and Odorisation Station

District Station

Service Station

Piping comprises of

Feeder line (steel pipe)

Distribution line (steel pipe or PE pipe)

Service line (steel pipe or copper pipe)

Internal pipe (carbon steel or copper pipe)

Pipe size less than 24 inches

Operated by Gas Malaysia Sdn. Bhd (GMSB)

Gas Piping System in Malaysia

Codes and Standards

(Malaysian) Related

to Piping Materials

MS 930 Code of Standards for the Installation of Gas Piping

System and Appliances

MS 830 Code of Standards for the Storage, Handling and

Transportation of Liquefied Petroleum Gas (LPG)

Q & A

LIST DOWN

Characteristics of piped gas

Safety requirements in design,

construction and maintenance of LPG and

NG

www.themegallery.com

LOGO

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Science Form 1Documento15 páginasScience Form 1Renu SekaranAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- For Section A, Write Your Answer in The Answer Sheet Provided in Page 12Documento12 páginasFor Section A, Write Your Answer in The Answer Sheet Provided in Page 12Renu SekaranAinda não há avaliações

- Wesley Methodist School Klang MONTHLY TEST 1 (2019) Chemistry Form 4 Total: 50 MarksDocumento8 páginasWesley Methodist School Klang MONTHLY TEST 1 (2019) Chemistry Form 4 Total: 50 MarksRenu SekaranAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Cell As A Unit of LifeDocumento40 páginasCell As A Unit of LifeRenu SekaranAinda não há avaliações

- Lesson Plan (Subject: SCIENCE)Documento3 páginasLesson Plan (Subject: SCIENCE)Renu SekaranAinda não há avaliações

- Lesson Plan Format 24-2 (Opal)Documento3 páginasLesson Plan Format 24-2 (Opal)Renu SekaranAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Lesson Plan Format 27-1 (Opal)Documento4 páginasLesson Plan Format 27-1 (Opal)Renu SekaranAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Intensive 4 Page 4Documento1 páginaIntensive 4 Page 4Renu SekaranAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Intensive 4 Page 2Documento1 páginaIntensive 4 Page 2Renu SekaranAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Lesson Plan (Subject: SCIENCE)Documento2 páginasLesson Plan (Subject: SCIENCE)Renu SekaranAinda não há avaliações

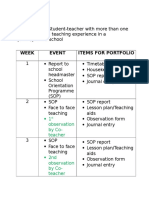

- MODE 1: For Student-Teacher With More Than One: 1 Observation by Co-TeacherDocumento4 páginasMODE 1: For Student-Teacher With More Than One: 1 Observation by Co-TeacherRenu SekaranAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Lesson Plan Format 27-1Documento4 páginasLesson Plan Format 27-1Renu SekaranAinda não há avaliações

- E E:sl: Et Isl If:: I Ii:i I Il", 3:p:r I Et:sfDocumento1 páginaE E:sl: Et Isl If:: I Ii:i I Il", 3:p:r I Et:sfRenu SekaranAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Form 2 - Page 1Documento1 páginaForm 2 - Page 1Renu SekaranAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Intensive 3 Page 2Documento1 páginaIntensive 3 Page 2Renu SekaranAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- 1 PGDIPEDU (UAB) MyVLE Practicum SlideDocumento17 páginas1 PGDIPEDU (UAB) MyVLE Practicum SlideRenu SekaranAinda não há avaliações

- MODE 2: For Student-Teacher With Less Than One: 1 Observation by Co-TeacherDocumento4 páginasMODE 2: For Student-Teacher With Less Than One: 1 Observation by Co-TeacherRenu SekaranAinda não há avaliações

- Form 1 Assessment OCTOBER 2015 Form 1 Science: (Duration: 25 Minutes)Documento8 páginasForm 1 Assessment OCTOBER 2015 Form 1 Science: (Duration: 25 Minutes)Renu SekaranAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Chapter 2b Molecular Diffusion in LiquidDocumento12 páginasChapter 2b Molecular Diffusion in LiquidRenu SekaranAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)