Escolar Documentos

Profissional Documentos

Cultura Documentos

Turn C

Enviado por

el_morshedyTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Turn C

Enviado por

el_morshedyDireitos autorais:

Formatos disponíveis

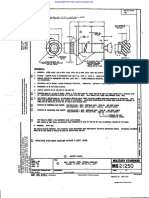

Cutting tools from Sandvik Coromant

Turning tools

GENERAL TURNING | PARTING & GROOVING | THREADING | TOOLING SYSTEMS

2012

TURN - ENG

THREADING

How to choose threading tool

How to choose threading tool

Define your type of operation

Select your method for threading page C4:

- External or internal threading

- Right hand threads or left hand threads

- Select the thread type

Select insert size, grade, geometry and type of infeed

Select tooling system and type of holder

Select suitable shim

Select size, number of passes and speed

Choose your pitch and size of insert. If possible choose a multipoint insert for better productivity.

Choose your geometry, grade and type of infeed. Detailed

recommendations on page C81

Choose Coromant Capto or shank tool, depending on clamping

possibilities in turret/spindle,on page G5.

Choose type of holder and coupling size or shank on page C7.

The insert seat must correspond to the size of the insert.

Choose correct shim for your pitch/workpiece diameter. See page

C46 for CoroThread 266 and page C58 for T-Max U-Lock.

Shims are used to give different tilts to the insert and are available

in 1 steps from -2 to +4.

Threading holders are supplied as standard with a shim giving +1

inclination angle.

Note: No shims for smaller diameter bars as the angle is fixed at

+2.

The recommendations are intended as starting values. (Page C71)

Cutting speed recommendations, page C82.

For more technical information, see our

Metalcutting Technical guide

THREADING How to choose threading tool

C2

External threading

Coromant Capto

unit

Inserts

Conversion table, formulas and

definitions

Internal threading

Shank holder

Spare parts/accessories

Grade descriptions

CoroTurn SL

internal adaptors

Boring bar

Sleeves

Technical information

Build-in tools

Tooling system

How to choose tool,

overview

Tailor Made options

TURN - ENG

A

Content

THREADING

THREADING

Applications

Threading profiles

Methods for external and internal machining

B

C4

C6

Products

Tool holder overview

C7

CoroThread 266 for threading and grooving

C9

Inserts

Insert code key

V-profile 60 and 55

Engineering industry MM, UN

Pipe fittings WH, NT

Pipe threads PT, NF

Pipe couplings RN

Aerospace threads MJ, UNJ

Trapezoidal screw threads TR, AC, SA

Oil and gas threads V-, RD, BU

Holders

Tool holder code key

Selecting shims

C10

C11

C14

C19

C22

C24

C25

C27

C30

C35

C34

C46

T-Max U-Lockfor threading

C48

Inserts

V-profile 60 and 55

Engineering industry MM, UN

Pipe fittings WH, NT

Holders

Selecting shims

C48

C49

C51

C52

C58

T-Max Twin-Lock for oil pipe threading

Code key

Inserts

Holders

CoroTurn SL flexible system

C59

C60

C61

I1

Other systems for threading

CoroCut XS, external tools for small part machining

CoroTurn XS, internal tools for small part machining

CoroCut MB, internal tools for precision machining

Spare parts

B85

A325

B92

C64

Cutting data

Infeed recommendations

Cutting speed recommendations

C71

C82

Grade information

C86

THREADING Content

C3

TURN - ENG

THREADING

Choosing inserts and tools

All types of threads

CoroThread 266

Ultra-rigid threading, insert sizes 16, 22 and 27

T-Max U-Lock

Insert size 11

Threading profiles

Thread type

General usage for all segments

of engineering industry.

CoroThread

266R/LG

266R/LL

External

Internal

V-profile 60

V-profile 55

Metric 60?

UN 60

VM

VW

MM

UN

C11

C13

C14

C17

Whitworth 55

NPT 60

WH C19

NT C21

T-Max U-Lock

R/L166.0L

Internal

V-profile 60

V-profile 55

Metric 60?

UN 60

VM

VW

MM

UN

C48

C48

C49

C50

Whitworth 55

NPT 60

WH C51

NT C51

Pipe fittings and couplings for

gas, water and sewage.

Page

Page

T-Max Twin-Lock

R/L166.39G

External

R/L166.39L

Internal

CoroCut XS

V-profile 60

B90

External

MATR/L

CoroTurn XS

Internal

V-profile 60

Metric 60

UN 60

VM A339

MM A339

UN A339

Whitworth 55

NPT 60

WH A339

NT A339

V-profile 60

Metric 60?

VM B102

MM B102

Whitworth 55

NPT 60

WH B102

NT B102

UN 60

UN B102

CXSCoroCut MB

Internal

MB-

THREADING Choosing inserts and tools

C4

Pipe threads for steam, gas and

water lines

Page

BSPT 55

NPTF 60?

PT C22

NF C23

TURN - ENG

A

Choosing inserts and tools

THREADING

T-Max Twin-Lock

Small part machining

Threading in oil and gas industry primarily casing and tubing

CoroCut XS for external and CoroTurn XS for internal threading

CoroCut MB for internal precision threading

Pipe couplings in food and fire

fighting industries

Aerospace threads.

Page

Round DIN 405

RN C24

Screw threads for motion

transmissions

Page

MJ 60

UNJ 60

MJ C25

NJ C26

Oil and gas

Page

ISO Trapezodial

ACME

STUB-ACME

TR C27

AC C28

SA C28

Page

API 60

API Buttress

V C30

RD C31

BU C32

Casing and tubing

API Round Vee

API Buttress?

ISO Trapezodial

TR

A339

ACME

STUB-ACME

AC

SA

C28

C29

RD

BU

C60

C60

THREADING Choosing inserts and tools

C5

TURN - ENG

THREADING

Choosing inserts and tools

Selecting the method of thread cutting

The machine tool and the design of the workpiece determine which

method is to be used to cut a thread. Working towards the chuck is the

most common method.

The advantage of using right hand tools for right hand threads and left

hand tools for left hand threads is that the holder design is made to give

maximum suport to the insert.

Working away from the chuck is also possible but when producing right

hand threads with left hand tools and vice versa, compensation must be

made for the negative helix angle by means of changing the shim.

Note that holder and insert of the same hand must be used together for

the CoroThread and U-Lock programme.

C

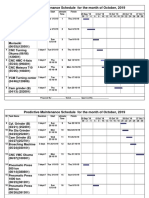

Methods for external threading

Right hand threads

Right hand tools/

inserts

Left hand threads

Right hand tools/

inserts

Left hand tools/

inserts (negative

helix angle)

Pull threading

Pull threading

Left hand tools/

inserts

Left hand tools/

inserts

Right hand tools/

inserts (negative

helix angle)

Pull threading

Pull threading

Methods for internal threading

Right hand threads

Left hand threads

Right hand tools/

inserts

Left hand tools/inserts

(negative helix angle)

I

Pull threading

THREADING Choosing inserts and tools

C6

Left hand tools/inserts

Right hand tools/

inserts (negative helix

angle)

Pull threading

TURN - ENG

A

Choosing inserts and tools

THREADING

External threading and circlip grooving

General threading

For swiss machines

Threading of slender components and

against live centre

To be used with CoroThread 266 inserts

CoroThread

266R/LFG

Insert size, mm (iC,

inch)

Coromant Capto

sizes

Shank size, mm

CoroThread

266R/LFG

CoroThread

266R/LFA

T-Max U-Lock

R/L166.5FA

T-Max U-Lock

R/L166.5FA

16, 22, 27 (3/8, 1/2, 5/8) 16, 22, 27 (3/8, 1/2, 5/8) 16 (3/8)

16 (3/8)

16 (3/8)

C3-C8

C3-C6

1616-4040

1010-1616

1212-2525

Shank size, inch

.750-1.500

.375-.750

.500-1.250

Page

C35

C36

C37

C52

C53

Drop head design for upside down mounting

CoroThread 266 SL- external

cutting head

To be used with CoroThread

266 inserts

CoroThread

266R/LFGZ

16, 22, 27 (3/8, 1/2, 5/8)

CoroThread

266R/LFGZ

16, 22 (3/8, 1/2)

T-Max U-Lock

R/L166.5FAZ

16 (3/8)

CoroThread

SL-266R/LFG

16 (3/8)

C4-C6

C3-C6

2525-3232

Shank size, inch

.750-1.250

Coupling size

20-40

Page

C35

C36

C52

I53

T-Max Twin-Lock

Small part machining

Insert size, mm (iC,

inch)

Coromant Capto

sizes

Shank size, mm

QS holding system

R166.39FG

QS-266 RFA

Insert size, mm (inch)

24 (.945)

16 (3/8)

Shank size, mm

3232

1010-1616

Shank size, inch

1.260

.376-.825

Page

C61

C38

THREADING Choosing inserts and tools

C7

TURN - ENG

THREADING

Choosing inserts and tools

Internal threading and circlip grooving

Coromant Capto

Carbide reinforced

bars

Drop head design for

upside down mounting

T-Max U-Lock

R/L166.0KF

T-Max U-Lock

R/L166.0KFZ

Cylindrical, cylindrical

with flats

Insert size, mm (iC,

inch)

Coromant Capto

sizes

Bar diameter, mm

(inch)

Page

CoroThread

266R/LKF

T-Max U-Lock

R/L166.0KF

CoroThread

266R/LKF

R254R/LKF

16-22 (3/8-1/2)

11 (1/4)

16, 22, 27 (3/8, 1/2, 5/8) 11 (1/4)

11 (1/4)

C3-C6

C3-C4

C3-C4

20-50 (.750-2.000)

10-12 (.375-.500)

C39

C54

C42

C56

C54

SL cutting head

Cartridges

Cutting head for CoroTurn SL

quick change

CoroThread

SL-266R/LKF

T-Max U-Lock

R/L566.0KFC

CoroThread

266

CoroThread

SL-266RKF

Insert size, mm (iC,

inch)

SL coupling size, mm

16, 22, 27 (3/8, 1/2, 5/8)

11 (3/4)

16, 22 (3/8, 1/2)

22, 27 (1/2, 5/8)

25-40

16-20

80

Cartridge size

16CA-20CA

Page

I54

I55

C45

I89

T-Max Twin-Lock

SL cutting head

Cartridge

T-Max P cartridge

T-Max Twin-Lock

R566.39KF

T-Max Twin-Lock

466.39

T-Max Twin-Lock

R466.3KW

EasyFix

Sleeves for cylindrical boring bars

131

132

Insert size, mm, (inch) 24 (.945)

24 (.945)

16 (3/8)

For bar diameter, mm For bar diameter, mm

Coupling size, mm

40

5-20

Cartridges size, mm

(inch)

18 (.709)

20 (.787)

For bar diameter, inch For bar diameter, inch

Page

THREADING Choosing inserts and tools

C8

C61

C62

C63

5-25

.197-.787

.197-.984

A322

A322

TURN - ENG

A

CoroThread 266 inserts

THREADING

CoroThread 266

Ultra rigid thread turning

B

For all types of threads

Insert sizes: 16, 22 and 27 mm

(3/8, 1/2 and 5/8 inch)

Insert sizes

H

- Full profile - for high productivity

Easy clamping of new

inserts on rail guide.

- V-profile - for minimum tool inventory

I

- Multi-point - for economic threading in

mass production

Grades for all materials

Basic grades

ISO application areas:

Unique Tailor Made service

GC1125

GC1135

GC1020

Enables you to order inserts for almost any thread

form or pitch. See page J3

THREADING CoroThread 266 inserts

C9

TURN - ENG

THREADING

CoroThread 266 inserts

Code key for CoroThread 266 inserts

B

1 Main code

266 = CoroThread 266

Thread profile

VM0 =

VW0 =

MM0 =

UN0 =

WH0 =

NT0 =

RN0 =

PT0 =

TR0 =

V-profile 60

V-Profile 55

Metric 60?

UN 60

Whitworth 55

NPT 60?

Round 30?

BSPT 55

Trapezoidal 30

2 Hand of tool

R = Right hand style

G = Inserts for external threading

L = Left hand style

L = Inserts for internal threading

H

7

3 Type of machining

Cutting edge condition

A = Edge rounded (ER)

F = Sharp cutting edge

C = Chip forming geometry

I

Tolerance of cutting edge position

M = 0.05 mm (.002 inch) axial

E = 0.01 mm (.0004 inch) axial

11

16 = iC 3/8'' = 9.52 mm

22 = iC 1/2'' = 12.70 mm

27 = iC 5/8'' = 15.88 mm

AC0 =

SA0 =

NJ0 =

MJ0 =

NF0 =

BU0 =

RD0 =

V38 =

V40 =

V50 =

ACME 29

STUB-ACME 29

UNJ 60

MJ 60

NPTF 60

Buttress

API Rd 60

V-0.038R

V-0.040

V-0.050

1 = 1 point

2 = 2 points

3 = 3 points

Pitch

9 Supplementary code

mm: pitch x 100

Inch: number of threads per inch x 10

Taper on diameter/inch per foot (i.p.f.)

1 = 1 i.p.f.

2 = 2 i.p.f.

3 = 3 i.p.f.

Marking:

All inserts are marked with the profile, grade and pitch:

internal inserts being identified with a circle. To prevent

erasure, the marking is laser cut on the side of the inserts.

Cubic boron nitride inserts

External right hand inserts

Internal left hand inserts

J

E = Edge rounded (ER)

External left hand inserts

Internal right hand inserts

THREADING CoroThread 266 inserts

C 10

Number of points per cutting edge

Varies from 1 to 3 points.

1)

10

4 Insert size/dimension

CoroThread 266 inserts

THREADING

V-profile 60 Non-topping

HC = HA-HB

Style shown: Right hand external, Left hand internal

Dimensions, mm (inch)

Pitch,

Pitch,

iC

TPI

mm

16

3/8

24-8

1.0-3.0

22

1/2

7-4

3.5-6.0

iC mm

9.53

12.7

d1

s

4.4 (.173) 3.97 (.156)

5.55 (.217) 5.56 (.219)

C

Even more possibilities thanks to tailored design! See page J3.

External

Pitch, mm Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

1/2

1-2.00

24-12

1.5-3

16-8

3.5-6

7-4

Ordering code

266R/LG-16VM01A001M

266RG-16VM01C001M

266RG-16VM01F001E

266R/LG-16VM01A002M

266RG-16VM01C002M

266RG-16VM01F002E

266R/LG-22VM01A001M

266RG-22VM01F001E

HA

mm

1.68

HA

in.

.0661

HB

mm

0.14

HB

in.

.0055

r

mm

0.13

r

in.

.0051

2.64

.1039

0.20

.0079

0.20

.0079

4.92

.1937

0.48

.0189

0.48

.0189

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

22

iC

3/8

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

Internal

Pitch, mm Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

22

iC

3/8

1/2

1-2.00

24-12

1.5-3

16-8

3.5-6

7-4

Ordering code

266R/LL-16VM01A001M

266RL-16VM01C001M

266RL-16VM01F001E

266R/LL-16VM01A002M

266RL-16VM01C002M

266RL-16VM01F002E

266R/LL-22VM01A001M

266RL-22VM01F001E

HA

in.

.0571

HB

mm

0.06

HB

in.

.0024

r

mm

0.06

r

in.

.0024

2.54

.1000

0.09

.0035

0.09

.0035

4.35

.1713

0.26

.0102

0.26

.0102

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

HA

mm

1.45

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

TURN - ENG

266R = Right hand, 266L = Left hand

= First choice

J

C8

C7

C82

C86

C2

J3

I8

THREADING CoroThread 266 inserts

C 11

TURN - ENG

THREADING

CoroThread 266 inserts

V-profile 60 Non-topping

Advanced cutting materials

For threading in hardened materials

HC = HA-HB

Style shown: Right hand external, Left hand internal

Dimensions, mm (inch)

Pitch,

Pitch,

iC

TPI

mm

16

3/8

24-8

1.0-3.0

iC mm

9.53

d1

4.4 (.173)

s

3.97 (.156)

External

Pitch, mm Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

iC

3/8

1-2.00

1.5-3

24-12

16-8

Ordering code

266RG-16VM01A001EE

266RG-16VM01A002EE

HB

mm

0.14

0.20

HB

in.

.0055

.0079

r

mm

0.13

0.20

r

in.

.0051

.0079

H15

16

HA

in.

.0661

.1039

7015

CB

HA

mm

1.68

2.64

G

Internal

Pitch, mm Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

1.5-3

16-8

HA

mm

2.54

Ordering code

266RL-16VM01A002EE

HA

in.

.1000

HB

mm

0.09

HB

in.

.0035

r

mm

0.09

r

in.

.0035

H15

16

iC

3/8

7015

CB

266R = Right hand

= First choice

J

C8

THREADING CoroThread 266 inserts

C 12

C7

C82

C86

C2

J3

I8

CoroThread 266 inserts

THREADING

V-profile 55 Non-topping

HC = HA-HB

Style shown: Right hand external, Left hand internal

Dimensions, mm (inch)

Pitch,

iC

TPI

16

3/8

28-8

22

1/2

7-4

iC mm

9.53

12.7

d1

4.4 (.173)

5.5 (.217)

s

3.97 (.156)

5.56 (.219)

C

Even more possibilities thanks to tailored design! See page J3.

External

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

28-14

14-8

1/2

7-4

HA

mm

1.68

HA

in.

.0661

HB

mm

0.13

HB

in.

.0051

r

mm

0.11

r

in.

.0043

2.79

.1098

0.26

.0102

0.23

.0091

5.23

.2059

0.53

.0209

0.48

.0189

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

22

Ordering code

266RG-16VW01A001M

266LG-16VW01A001M

266RG-16VW01C001M

266RG-16VW01F001E

266RG-16VW01A002M

266LG-16VW01A002M

266RG-16VW01C002M

266RG-16VW01F002E

266RG-22VW01A001M

266LG-22VW01A001M

266RG-22VW01F001E

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

Internal

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

28-14

14-8

22

1/2

7-4

Ordering code

266RL-16VW01A001M

266LL-16VW01A001M

266RL-16VW01C001M

266RL-16VW01F001E

266RL-16VW01A002M

266LL-16VW01A002M

266RL-16VW01C002M

266RL-16VW01F002E

266RL-22VW01A001M

266LL-22VW01A001M

266RL-22VW01F001E

HA

mm

1.60

HA

in.

.0630

HB

mm

0.12

HB

in.

.0047

r

mm

0.11

r

in.

.0043

2.80

.1102

0.25

.0098

0.23

.0091

5.18

.2039

0.53

.0209

0.47

.0185

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

TURN - ENG

266R = Right hand, 266L = Left hand

= First choice

J

C8

C7

C82

C86

C2

J3

I8

THREADING CoroThread 266 inserts

C 13

TURN - ENG

THREADING

CoroThread 266 inserts

Metric 60 Full form

Threads for general usage in all segments of engineering industry.

Single-point

Multi-point

ISO 965-1998 Tolerance class 6

266RG-16MM02A250E

|

2 = Two points

3 = Three points

Style shown: Right hand external, Left hand internal

Dimensions, mm (inch)

Pitch,

iC

iC mm

mm

16

3/8

0.5-3.0

9.53

22

1/2

2.5-6.0

12.7

d1

4.4 (.173)

5.5 (.217)

s

3.97 (.156)

5.56 (.219)

Even more possibilities thanks to tailored design!

See page J3.

External

Pitch, mm

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

0.50

0.75

0.80

1.00

1.25

1.50

H

1.75

2.00

2.50

HA

mm

0.37

HA

in.

.0146

HB

mm

0.08

HB

in.

.0031

0.56

.0220

0.11

.0043

0.60

0.75

.0236

.0295

0.11

0.15

.0043

.0059

0.93

.0366

0.19

.0075

1.12

.0441

0.22

.0087

1.31

.0516

0.25

.0098

1.50

.0591

0.29

.0114

1.87

.0736

0.36

.0142

2.25

.0886

0.42

.0165

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

3.00

Ordering code

266RG-16MM01A050M

266LG-16MM01A050M

266RG-16MM01A075M

266LG-16MM01A075M

266RG-16MM01F080E

266RG-16MM03A100M

266RG-16MM01A100M

266LG-16MM01A100M

266RG-16MM01C100M

266RG-16MM01F100E

266RG-16MM01A125M

266LG-16MM01A125M

266RG-16MM01C125M

266RG-16MM01F125E

266RG-16MM02A150M

266RG-16MM01A150M

266LG-16MM01A150M

266RG-16MM01C150M

266RG-16MM01F150E

266RG-16MM01A175M

266LG-16MM01A175M

266RG-16MM01C175M

266RG-16MM01F175E

266RG-16MM02A200M

266RG-16MM01A200M

266LG-16MM01A200M

266RG-16MM01C200M

266RG-16MM01F200E

266RG-16MM01A250M

266LG-16MM01A250M

266RG-16MM01C250M

266RG-16MM01F250E

266RG-16MM01A300M

266LG-16MM01A300M

266RG-16MM01C300M

266RG-16MM01F300E

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

266R = Right hand, 266L = Left hand

= First choice

Continued ...

J

C8

THREADING CoroThread 266 inserts

C 14

C7

C82

C86

C2

J3

I8

TURN - ENG

A

THREADING

CoroThread 266 inserts

... Continued

External

Pitch, mm

Dimensions, millimeter, inch (mm, in.)

D

22

iC

1/2

2.50

3.00

3.50

4.00

4.50

5.00

5.50

HB

mm

0.36

0.42

0.49

HB

in.

.0142

.0165

.0193

3.00

.1181

0.56

.0220

3.37

.1327

0.63

.0248

3.76

.1480

0.71

.0280

4.13

.1626

0.79

.0311

4.51

.1776

0.86

.0339

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

6.00

Ordering code

266RG-22MM02A250E

266RG-22MM02A300E

266RG-22MM01A350M

266LG-22MM01A350M

266RG-22MM01F350E

266RG-22MM01A400M

266LG-22MM01A400M

266RG-22MM01F400E

266RG-22MM01A450M

266LG-22MM01A450M

266RG-22MM01A500M

266LG-22MM01A500M

266RG-22MM01A550M

266LG-22MM01A550M

266RG-22MM01A600M

266LG-22MM01A600M

HA

in.

.0736

.0886

.1031

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

HA

mm

1.87

2.25

2.62

266R = Right hand, 266L = Left hand

= First choice

Continued ...

J

C8

C7

C82

C86

C2

J3

I8

THREADING CoroThread 266 inserts

C 15

TURN - ENG

THREADING

CoroThread 266 inserts

... Continued

Internal

Pitch, mm

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

0.50

0.75

1.00

1.25

C

1.50

1.75

2.00

G

2.50

3.00

22

1/2

2.50

3.00

3.50

4.00

4.50

5.00

5.50

HB

mm

0.03

HB

in.

.0012

0.47

.0185

0.04

.0016

0.64

.0252

0.06

.0024

0.79

.0311

0.07

.0028

0.96

.0378

0.09

.0035

1.11

.0437

0.11

.0043

1.27

.0500

0.12

.0047

1.59

.0626

0.16

.0063

1.92

.0756

0.19

.0075

1.59

1.98

2.24

.0626

.0780

.0882

0.16

0.19

0.26

.0063

.0075

.0102

2.56

.1008

0.30

.0118

2.89

.1138

0.33

.0130

3.21

.1264

0.38

.0150

3.54

.1394

0.40

.0157

3.86

.1520

0.47

.0185

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

6.00

Ordering code

266RL-16MM01A050M

266LL-16MM01A050M

266RL-16MM01A075M

266LL-16MM01A075M

266RL-16MM03A100M

266RL-16MM01A100M

266LL-16MM01A100M

266RL-16MM01C100M

266RL-16MM01F100E

266RL-16MM01A125M

266LL-16MM01A125M

266RL-16MM01C125M

266RL-16MM01F125E

266RL-16MM02A150M

266RL-16MM01A150M

266LL-16MM01A150M

266RL-16MM01C150M

266RL-16MM01F150E

266RL-16MM01A175M

266LL-16MM01A175M

266RL-16MM01C175M

266RL-16MM01F175E

266RL-16MM02A200M

266RL-16MM01A200M

266LL-16MM01A200M

266RL-16MM01C200M

266RL-16MM01F200E

266RL-16MM01A250M

266LL-16MM01A250M

266RL-16MM01C250M

266RL-16MM01F250E

266RL-16MM01A300M

266LL-16MM01A300M

266RL-16MM01C300M

266RL-16MM01F300E

266RL-22MM02A250E

266RL-22MM02A300E

266RL-22MM01A350M

266LL-22MM01A350M

266RL-22MM01A400M

266LL-22MM01A400M

266RL-22MM01A450M

266LL-22MM01A450M

266RL-22MM01A500M

266LL-22MM01A500M

266RL-22MM01A550M

266LL-22MM01A550M

266RL-22MM01A600M

266LL-22MM01A600M

HA

in.

.0126

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

HA

mm

0.32

266R = Right hand, 266L = Left hand

= First choice

J

C8

THREADING CoroThread 266 inserts

C 16

C7

C82

C86

C2

J3

I8

THREADING

CoroThread 266 inserts

UN 60 Full form

Threads for general usage in all segments of engineering industry.

Single-point

Multi-point

ISO 5864-1978

Style shown: Right hand external, Left hand internal

Tolerance class 2B, int.

Tolerance class 2A, ext.

Dimensions, mm (inch)

Pitch,

iC

iC mm

TPI

16

3/8

32-8

9.53

22

1/2

7-4

12.7

266RG-16UN0

d1

4.4 (.173)

5.5 (.217)

s

3.97 (.156)

5.56 (.219)

3A180M

|

2 = Two points

3 = Three points

Even more possibilities thanks to tailored design!

See page J3.

External

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

32

28

24

20

18

16

14

13

12

11

10

9

Ordering code

266RG-16UN01A320M

266LG-16UN01A320M

266RG-16UN01A280M

266LG-16UN01A280M

266RG-16UN01A240M

266LG-16UN01A240M

266RG-16UN01C240M

266RG-16UN01F240E

266RG-16UN01A200M

266LG-16UN01A200M

266RG-16UN01C200M

266RG-16UN01F200E

266RG-16UN03A180M

266RG-16UN01A180M

266LG-16UN01A180M

266RG-16UN01C180M

266RG-16UN01F180E

266RG-16UN02A160M

266RG-16UN01A160M

266LG-16UN01A160M

266RG-16UN01C160M

266RG-16UN01F160E

266RG-16UN02A140M

266RG-16UN01A140M

266LG-16UN01A140M

266RG-16UN01C140M

266RG-16UN01F140E

266RG-16UN01A130M

266LG-16UN01A130M

266RG-16UN02A120M

266RG-16UN01A120M

266LG-16UN01A120M

266RG-16UN01C120M

266RG-16UN01F120E

266RG-16UN01A110M

266LG-16UN01A110M

266RG-16UN01A100M

266LG-16UN01A100M

266R/LG-16UN01A090M

HA

mm

0.59

HA

in.

.0232

HB

mm

0.10

HB

in.

.0039

0.68

.0268

0.12

.0047

0.79

.0311

0.14

.0055

0.95

.0374

0.16

.0063

1.05

.0413

0.18

.0071

1.19

.0469

0.20

.0079

1.35

.0531

0.23

.0091

1.46

.0575

0.25

.0098

1.58

.0622

0.28

.0110

1.72

.0677

0.30

.0118

1.90

.0748

0.33

.0130

2.11

.0831

0.37

.0146

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

TURN - ENG

266R = Right hand, 266L = Left hand

= First choice

C8

C7

C82

C86

C2

J3

I8

Continued ...

THREADING CoroThread 266 inserts

C 17

TURN - ENG

THREADING

CoroThread 266 inserts

... Continued

External

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

iC

32

22

1/2

7

6

5

4.5

4

Ordering code

266RG-16UN01A080M

266LG-16UN01A080M

266RG-16UN01C080M

266RG-16UN01F080E

266RG-22UN01A070M

266RG-22UN01A060M

266RG-22UN01A050M

266RG-22UN01A045M

266RG-22UN01A040M

HB

mm

0.41

HB

in.

.0161

2.70

3.16

3.81

4.23

4.76

.1063

.1244

.1500

.1665

.1874

0.49

0.57

0.69

0.77

0.87

.0193

.0224

.0272

.0303

.0343

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

16

HA

in.

.0937

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

HA

mm

2.38

266R = Right hand, 266L = Left hand

= First choice

Internal

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

32

28

24

20

18

16

14

12

11

10

9

8

22

1/2

7

6

5

4.5

4

HA

mm

0.50

0.58

0.67

0.80

HA

in.

.0197

.0228

.0264

.0315

HB

mm

0.04

0.05

0.06

0.07

HB

in.

.0016

.0020

.0024

.0028

0.89

.0350

0.08

.0031

1.00

.0394

0.09

.0035

1.13

.0445

0.11

.0043

1.33

.0524

0.13

.0051

1.45

.0571

0.14

.0055

1.59

.0626

0.16

.0063

1.77

2.00

.0697

.0787

0.18

0.20

.0071

.0079

2.31

2.70

3.25

3.62

4.08

.0909

.1063

.1280

.1425

.1606

0.26

0.32

0.38

0.41

0.49

.0102

.0126

.0150

.0161

.0193

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

Ordering code

266RL-16UN01A320M

266RL-16UN01A280M

266RL-16UN01A240M

266RL-16UN01A200M

266LL-16UN01A200M

266RL-16UN01C200M

266RL-16UN01A180M

266LL-16UN01A180M

266RL-16UN01C180M

266RL-16UN01A160M

266LL-16UN01A160M

266RL-16UN02A160M

266RL-16UN01C160M

266RL-16UN01F160E

266RL-16UN01A140M

266LL-16UN01A140M

266RL-16UN01C140M

266RL-16UN01A120M

266LL-16UN01A120M

266RL-16UN02A120M

266RL-16UN01C120M

266RL-16UN01F120E

266RL-16UN01A110M

266LL-16UN01A110M

266RL-16UN01A100M

266LL-16UN01A100M

266R/LL-16UN01A090M

266RL-16UN01A080M

266LL-16UN01A080M

266RL-16UN01C080M

266RL-22UN01A070M

266RL-22UN01A060M

266RL-22UN01A050M

266RL-22UN01A045M

266RL-22UN01A040M

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

266R = Right hand, 266L = Left hand

= First choice

J

C8

THREADING CoroThread 266 inserts

C 18

C7

C82

C86

C2

J3

I8

THREADING

CoroThread 266 inserts

Whitworth 55 (BSW, BSF, BSP) Full form

Threads for pipe fittings and couplings for gas, water and sewage.

Single-point

Multi-point

ISO 228-1982

BS 2779-1973

BS 84-1956

Class A tolerance

Pipe threads 55

External: G thread

Internal: G/Rp threads

Style shown: Right hand external, Left hand internal

Dimensions, mm (inch)

Pitch,

iC

TPI

16

3/8

28-8

22

1/2

11-4

266RG-22WH0 2A110E

|

2 = Two points

3 = Three points

iC mm

9.53

12.7

d1

4.4 (.173)

5.5 (.217)

s

3.97 (.156)

5.56 (.219)

C

Even more possibilities thanks to tailored design!

See page J3.

External

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

28

26

20

19

18

16

14

12

11

22

1/2

10

9

8

11

7

6

5

4.5

4

Ordering code

266RG-16WH01A280M

266RG-16WH01A260M

266RG-16WH01A200M

266RG-16WH01A190M

266LG-16WH01A190M

266RG-16WH03A190M

266RG-16WH01C190M

266RG-16WH01F190E

266RG-16WH01A180M

266RG-16WH01A160M

266RG-16WH01A140M

266LG-16WH01A140M

266RG-16WH02A140M

266RG-16WH01C140M

266RG-16WH01F140E

266RG-16WH01A120M

266RG-16WH01A110M

266LG-16WH01A110M

266RG-16WH01C110M

266RG-16WH01F110E

266RG-16WH01A100M

266RG-16WH01A090M

266RG-16WH01A080M

266RG-22WH02A110E

266RG-22WH01A070M

266RG-22WH01A060M

266RG-22WH01A050M

266RG-22WH01A045M

266RG-22WH01A040M

HA

mm

0.72

0.77

1.01

1.06

HA

in.

.0283

.0303

.0398

.0417

HB

mm

0.13

0.14

0.18

0.19

HB

in.

.0051

.0055

.0071

.0075

1.12

1.26

1.44

.0441

.0496

.0567

0.20

0.23

0.26

.0079

.0091

.0102

1.68

1.83

.0661

.0720

0.31

0.34

.0122

.0134

2.02

2.24

2.52

1.83

2.88

3.37

4.04

4.49

5.06

.0795

.0882

.0992

.0720

.1134

.1327

.1591

.1768

.1992

0.37

0.42

0.47

0.34

0.54

0.64

0.77

0.85

0.96

.0146

.0165

.0185

.0134

.0213

.0252

.0303

.0335

.0378

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

TURN - ENG

266R = Right hand, 266L = Left hand

= First choice

Continued ...

J

C8

C7

C82

C86

C2

J3

I8

THREADING CoroThread 266 inserts

C 19

TURN - ENG

THREADING

CoroThread 266 inserts

... Continued

Internal

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

26

20

19

18

16

14

12

11

22

1/2

HB

mm

0.13

0.17

0.18

0.19

0.22

0.25

HB

in.

.0051

.0067

.0071

.0075

.0087

.0098

1.67

1.83

.0657

.0720

0.30

0.33

.0118

.0130

2.02

2.24

2.53

1.83

2.88

3.36

4.03

4.48

5.04

.0795

.0882

.0996

.0720

.1134

.1323

.1587

.1764

.1984

0.37

0.41

0.47

0.33

0.53

0.62

0.76

0.85

0.96

.0146

.0161

.0185

.0130

.0209

.0244

.0299

.0335

.0378

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

10

9

8

11

7

6

5

4.5

4

Ordering code

266RL-16WH01A260M

266RL-16WH01A200M

266RL-16WH01A190M

266RL-16WH01A180M

266RL-16WH01A160M

266RL-16WH01A140M

266LL-16WH01A140M

266RL-16WH02A140M

266RL-16WH01C140M

266RL-16WH01F140E

266RL-16WH01A120M

266RL-16WH01A110M

266LL-16WH01A110M

266RL-16WH01C110M

266RL-16WH01F110E

266RL-16WH01A100M

266RL-16WH01A090M

266RL-16WH01A080M

266RL-22WH02A110E

266RL-22WH01A070M

266RL-22WH01A060M

266RL-22WH01A050M

266RL-22WH01A045M

266RL-22WH01A040M

HA

in.

.0307

.0390

.0413

.0437

.0492

.0563

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

HA

mm

0.78

0.99

1.05

1.11

1.25

1.43

266R = Right hand, 266L = Left hand

= First choice

J

C8

THREADING CoroThread 266 inserts

C 20

C7

C82

C86

C2

J3

I8

THREADING

CoroThread 266 inserts

NPT 60 NPSC, NPTR, LINE PIPE1) Full form

Threads for pipe fittings and couplings for gas, water and sewage.

Single-point

Multi-point

ANSI B.1.20.1-1983

Style shown: Right hand external, Left hand internal

Dimensions, mm (inch)

Pitch,

iC

TPI

16

3/8

27-8

22

1/2

11-4

266RG-22NT0 2A115E

|

2 = Two points

iC mm

9.53

12.7

d1

4.4 (.173)

5.5 (.217)

s

3.97 (.156)

5.56 (.219)

C

Even more possibilities thanks to tailored design!

See page J3.

External

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

27

18

14

11.5

8

1/2

11.5

HA

mm

0.76

HA

in.

.0299

HB

mm

0.05

HB

in.

.0020

1.14

.0449

0.08

.0031

1.46

.0575

0.09

.0035

1.79

.0705

0.11

.0043

2.57

.1012

0.14

.0055

1.79

.0705

0.11

.0043

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

22

Ordering code

266RG-16NT01A270M

266LG-16NT01A270M

266RG-16NT01A180M

266LG-16NT01A180M

266RG-16NT01A140M

266LG-16NT01A140M

266RG-16NT01C140M

266RG-16NT01F140E

266RG-16NT01A115M

266LG-16NT01A115M

266RG-16NT01C115M

266RG-16NT01F115E

266RG-16NT01A080M

266LG-16NT01A080M

266RG-22NT02A115E

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

Internal

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

14

11.5

8

22

1/2

11.5

Ordering code

266RL-16NT01A140M

266LL-16NT01A140M

266RL-16NT01C140M

266RL-16NT01F140E

266RL-16NT01A115M

266LL-16NT01A115M

266RL-16NT01C115M

266RL-16NT01F115E

266RL-16NT01A080M

266LL-16NT01A080M

266RL-22NT02A115E

HA

mm

1.46

HA

in.

.0575

HB

mm

0.09

HB

in.

.0035

1.79

.0705

0.11

.0043

2.57

.1012

0.14

.0055

1.79

.0705

0.11

.0043

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

TURN - ENG

1) The insert can give a slightly bigger truncation for LINE PIPE 14 TPI.

266R = Right hand, 266L = Left hand

= First choice

J

C8

C7

C82

C86

C2

J3

I8

THREADING CoroThread 266 inserts

C 21

TURN - ENG

THREADING

CoroThread 266 inserts

BSPT 55 Full form

Pipe threads for steam, gas and water lines

ISO 7/1

BS21:1985

Pipe threads

External: R thread

Internal: Rc thread

Style shown: Right hand external, Left hand internal

Dimensions, mm (inch)

Pitch,

iC

TPI

16

3/8

28-8

iC mm

9.53

d1

4.4 (.173)

s

3.97 (.156)

Even more possibilities thanks to tailored design! See page J3.

External

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

28

19

14

11

HA

mm

0.70

1.04

HA

in.

.0276

.0409

HB

mm

0.13

0.19

HB

in.

.0051

.0075

1.41

.0555

0.26

.0102

1.80

.0709

0.34

.0134

2.47

.0972

0.47

.0185

P20

P25

M20

M25

K15

K20

N20

N25

S20

S25

Ordering code

266RG-16PT01A280E

266RG-16PT01A190E

266LG-16PT01A190E

266RG-16PT01A140E

266LG-16PT01A140E

266RG-16PT01A110E

266LG-16PT01A110E

266RG-16PT01A080E

1125

1135

1125

1135

1125

1135

1125

1135

1125

1135

GC GC GC GC GC GC GC GC GC GC

Internal

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

28

19

14

11

HA

mm

0.71

1.03

1.40

HA

in.

.0280

.0406

.0551

HB

mm

0.12

0.18

0.25

HB

in.

.0047

.0071

.0098

1.80

.0709

0.33

.0130

2.48

.0976

0.47

.0185

P20

P25

M20

M25

K15

K20

N20

N25

S20

S25

Ordering code

266RL-16PT01A280E

266R/LL-16PT01A190E

266RL-16PT01A140E

266LL-16PT01A140E

266RL-16PT01A110E

266LL-16PT01A110E

266RL-16PT01A080E

1125

1135

1125

1135

1125

1135

1125

1135

1125

1135

GC GC GC GC GC GC GC GC GC GC

266R = Right hand, 266L = Left hand

= First choice

J

C8

THREADING CoroThread 266 inserts

C 22

C7

C82

C86

C2

J3

I8

THREADING

CoroThread 266 inserts

NPTF 60 Full form

Pipe threads for steam, gas and water lines.

ANSI B1.20.3-1976

Tolerance class 2

Style shown: Right hand external

Left hand internal

Dimensions, mm (inch)

Pitch,

iC

TPI

16

3/8

27-8

iC mm

9.53

d1

4.4 (.173)

s

3.97 (.156)

C

Even more possibilities thanks to tailored design! See page J3.

External

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

P M K N S

27

18

14

11.5

8

HA

mm

0.75

1.14

1.49

1.81

2.60

Ordering code

266RG-16NF01A270E

266RG-16NF01A180E

266RG-16NF01A140E

266RG-16NF01A115E

266RG-16NF01A080E

HA

in.

.0295

.0449

.0587

.0713

.1024

HB

mm

0.11

0.13

0.13

0.17

0.21

HB

in.

.0043

.0051

.0051

.0067

.0083

P20

M20

K15

N20

S20

16

iC

3/8

1125

1125

1125

1125

1125

GC GC GC GC GC

Internal

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

P M K N S

D

16

iC

3/8

14

11.5

8

HA

mm

1.49

1.81

2.60

Ordering code

266RL-16NF01A140E

266RL-16NF01A115E

266RL-16NF01A080E

HA

in.

.0587

.0713

.1024

HB

mm

0.13

0.17

0.21

HB

in.

.0051

.0067

.0083

1125

1125

1125

1125

1125

GC GC GC GC GC

P20

M20

K15

N20

S20

TURN - ENG

266R = Right hand, 266L = Left hand

= First choice

J

C8

C7

C82

C86

C2

J3

I8

THREADING CoroThread 266 inserts

C 23

TURN - ENG

THREADING

CoroThread 266 inserts

Round 30 Full form

Threads for pipe couplings in food and fire fighting industry.

DIN 405.

Tolerance class 7 on effective dia.

Tolerance class 6 on major (external) and minor (internal) dia.

Dimensions, mm (inch)

Pitch,

iC

TPI

16

3/8

10-8

22

1/2

4

iC mm

9.53

12.7

d1

4.4 (.173)

5.5 (.217)

Style shown: Right hand external, Left hand internal

s

3.97 (.156)

5.56 (.219)

Even more possibilities thanks to tailored design! See page J3.

External

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

10

8

6

1/2

HA

in.

.1169

HB

mm

1.72

HB

in.

.0677

3.72

.1465

2.14

.0843

4.98

.1961

2.86

.1126

7.45

.2933

4.30

.1693

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

22

HA

mm

2.97

Ordering code

266R/LG-16RN01A100M

266RG-16RN01F100E

266R/LG-16RN01A080M

266RG-16RN01F080E

266R/LG-16RN01A060M

266RG-16RN01F060E

266R/LG-22RN01A040M

266RG-22RN01F040E

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

Internal

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

10

8

6

1/2

HA

in.

.1130

HB

mm

1.58

HB

in.

.0622

3.59

.1413

2.00

.0787

4.79

.1886

2.66

.1047

7.17

.2823

3.98

.1567

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

22

HA

mm

2.87

Ordering code

266R/LL-16RN01A100M

266RL-16RN01F100E

266R/LL-16RN01A080M

266RL-16RN01F080E

266R/LL-16RN01A060M

266RL-16RN01F060E

266R/LL-22RN01A040M

266RL-22RN01F040E

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

266R = Right hand, 266L = Left hand

= First choice

J

C8

THREADING CoroThread 266 inserts

C 24

C7

C82

C86

C2

J3

I8

THREADING

CoroThread 266 inserts

MJ 60 Full form

Aerospace threads.

ISO 5855-1983

Tolerance class 4 on pitch diameter.

Tolerance class 6 on major (external) and

minor (internal) dia.

Dimensions, mm (inch)

Pitch,

iC

iC mm

d1

mm

16

3/8 1.5-2.0

9.53

4.4 (.173)

Style shown: Right hand external, Left hand internal

s

3.97 (.156)

Even more possibilities thanks to tailored design! See page J3.

External

Pitch, mm

Dimensions, millimeter, inch (mm, in.)

P M K N S

D

16

iC

3/8

1.50

2.00

HA

mm

1.12

1.50

Ordering code

266R/LG-16MJ01A150E

266R/LG-16MJ01A200E

HA

in.

.0441

.0591

HB

mm

0.25

0.34

HB

in.

.0098

.0134

1125

1125

1125

1125

1125

GC GC GC GC GC

P20

M20

K15

N20

S20

TURN - ENG

266R = Right hand, 266L = Left hand

= First choice

Internal

Note: To turn an internal MJ thread, use a CoroTurn 107 boring

bar and insert to turn correct internal diameter and then produce

the thread with a corresponding ISO metric 60 (MM) insert.

J

C8

C7

C82

C86

C2

J3

I8

THREADING CoroThread 266 inserts

C 25

TURN - ENG

THREADING

CoroThread 266 inserts

UNJ 60 Full form

Aerospace threads.

ISO 3161-1977

BS 4084-1978

Tolerance class 3A

Dimensions, mm (inch)

Pitch,

iC

TPI

16

3/8

32-8

Style shown: Right hand external, Left hand internal

iC mm

9.53

d1

4.4 (.173)

s

3.97 (.156)

Even more possibilities thanks to tailored design! See page J3.

External

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

P M K N S

D

16

iC

3/8

HA

in.

.0232

.0264

.0311

.0370

.0413

.0465

.0531

.0622

.0744

.0937

HB

mm

0.13

0.15

0.18

0.21

0.23

0.26

0.30

0.36

0.42

0.53

HB

in.

.0051

.0059

.0071

.0083

.0091

.0102

.0118

.0142

.0165

.0209

P20

M20

K15

N20

S20

32

28

24

20

18

16

14

12

10

8

HA

mm

0.59

0.67

0.79

0.94

1.05

1.18

1.35

1.58

1.89

2.38

Ordering code

266RG-16NJ01A320E

266RG-16NJ01A280E

266RG-16NJ01A240E

266RG-16NJ01A200E

266RG-16NJ01A180E

266RG-16NJ01A160E

266RG-16NJ01A140E

266RG-16NJ01A120E

266RG-16NJ01A100E

266RG-16NJ01A080E

1125

1125

1125

1125

1125

GC GC GC GC GC

266R = Right hand, 266L = Left hand

= First choice

Internal

Note: To turn an internal UNJ thread use a CoroTurn 107 boring

bar and insert to turn correct internal diameter and then produce

the thread with a corresponding UN 60 insert.

J

C8

THREADING CoroThread 266 inserts

C 26

C7

C82

C86

C2

J3

I8

THREADING

CoroThread 266 inserts

ISO Trapezoidal 30 Chamfered crest form

Trapezoidal screw threads for motion transmission.

ISO 2901-2904

DIN 103-1977

Tolerance class 7

Style shown: Right hand external, Left hand internal

Dimensions, mm (inch)

Pitch,

iC

mm

16

3/8

1.5-3.0

22

1/2

4.0-7.0

27

5/8

8.0

iC mm

9.53

12.7

15.88

d1

4.4 (.173)

5.5 (.217)

6.5 (.256)

s

3.97 (.156)

5.56 (.219)

7.0 (.276)

Even more possibilities thanks to tailored design! See page J3.

External

Pitch, mm

Dimensions, millimeter, inch (mm, in.)

D

22

1/2

27

5/8

1.50

2.00

3.00

4.00

5.00

6.00

7.00

8.00

HA

mm

1.85

2.44

3.63

4.82

6.01

7.20

8.38

9.57

Ordering code

266R/LG-16TR01F150E

266R/LG-16TR01F200E

266R/LG-16TR01F300E

266R/LG-22TR01F400E

266R/LG-22TR01F500E

266R/LG-22TR01F600E

266R/LG-22TR01F700E

266RG-27TR01F800E

HA

in.

.0728

.0961

.1429

.1898

.2366

.2835

.3299

.3768

HB

mm

0.88

1.13

1.82

2.50

3.18

3.62

4.31

5.00

HB

in.

.0346

.0445

.0717

.0984

.1252

.1425

.1697

.1969

WT

mm

0.47

0.61

0.98

1.34

1.70

1.94

2.31

2.68

WT

in.

.0185

.0240

.0386

.0528

.0669

.0764

.0909

.1055

P20

P25

M20

M25

K15

K20

N25

N25

S20

S25

16

iC

3/8

1020

1135

1020

1135

1020

1135

1020

1135

1020

1135

GC GC GC GC GC GC GC GC GC GC

Internal

Pitch, mm

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

22

1/2

27

5/8

2.00

3.00

4.00

5.00

6.00

7.00

8.00

HA

mm

2.41

3.59

4.77

5.96

7.14

8.32

9.49

Ordering code

266R/LL-16TR01F200E

266R/LL-16TR01F300E

266R/LL-22TR01F400E

266R/LL-22TR01F500E

266R/LL-22TR01F600E

266R/LL-22TR01F700E

266RL-27TR01F800E

HA

in.

.0949

.1413

.1878

.2346

.2811

.3276

.3736

HB

mm

1.08

1.76

2.45

3.13

3.56

4.25

4.93

HB

in.

.0425

.0693

.0965

.1232

.1402

.1673

.1941

WT

mm

0.58

0.94

1.31

1.68

1.91

2.28

2.64

WT

in.

.0228

.0370

.0516

.0661

.0752

.0898

.1039

1020

1135

1020

1135

1020

1135

1020

1135

1020

1135

GC GC GC GC GC GC GC GC GC GC

P20

P25

M20

M25

K15

K20

N25

N25

S20

S25

TURN - ENG

266R = Right hand, 266L = Left hand

= First choice

J

C8

C7

C82

C86

C2

J3

I8

THREADING CoroThread 266 inserts

C 27

TURN - ENG

THREADING

CoroThread 266 inserts

ACME 29 Chamfered crest form

Trapezoidal screw threads for motion transmission.

ANSI B1.5-1988

Tolerance class 2G

Dimensions, mm (inch)

Pitch,

iC

TPI

16

3/8

16-8

22

1/2

6-4

27

5/8

3

D

C

Style shown: Right hand external, Left hand internal

iC mm

9.53

12.7

15.9

d1

4.4 (.173)

5.5 (.217)

6.5 (.256)

s

3.97 (.156)

5.56 (.219)

7.0 (.276)

Even more possibilities thanks to tailored design! See page J3.

External

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

22

1/2

27

5/8

HA

in.

.0780

.0890

.1039

.1244

.1551

.2067

.2476

.3098

.4122

HB

mm

1.04

1.21

1.43

1.61

2.08

2.84

3.47

4.41

5.95

HB

in.

.0409

.0476

.0563

.0634

.0819

.1118

.1366

.1736

.2343

WT

mm

0.54

0.63

0.74

0.83

1.08

1.47

1.79

2.28

3.08

WT

in.

.0213

.0248

.0291

.0327

.0425

.0579

.0705

.0898

.1213

P20

P25

M20

M25

K15

K20

N25

N25

S20

S25

16

14

12

10

8

6

5

4

3

HA

mm

1.98

2.26

2.64

3.16

3.94

5.25

6.29

7.87

10.47

Ordering code

266RG-16AC01F160E

266RG-16AC01F140E

266R/LG-16AC01F120E

266R/LG-16AC01F100E

266R/LG-16AC01F080E

266R/LG-22AC01F060E

266R/LG-22AC01F050E

266R/LG-22AC01F040E

266RG-27AC01F030E

1020

1135

1020

1135

1020

1135

1020

1135

1020

1135

GC GC GC GC GC GC GC GC GC GC

Internal

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

22

1/2

27

5/8

16

14

12

10

8

6

5

4

3

HA

mm

1.97

2.25

2.62

3.13

3.90

5.19

6.22

7.77

10.31

Ordering code

266RL-16AC01F160E

266RL-16AC01F140E

266R/LL-16AC01F120E

266R/LL-16AC01F100E

266R/LL-16AC01F080E

266R/LL-22AC01F060E

266R/LL-22AC01F050E

266R/LL-22AC01F040E

266RL-27AC01F030E

HA

in.

.0776

.0886

.1031

.1232

.1535

.2043

.2449

.3059

.4059

HB

mm

1.00

1.16

1.37

1.54

2.00

2.76

3.37

4.28

5.80

HB

in.

.0394

.0457

.0539

.0606

.0787

.1087

.1327

.1685

.2283

WT

mm

0.52

0.60

0.71

0.80

1.03

1.43

1.74

2.21

3.00

WT

in.

.0205

.0236

.0280

.0315

.0406

.0563

.0685

.0870

.1181

P20

P25

M20

M25

K15

K20

N25

N25

S20

S25

16

iC

3/8

1020

1135

1020

1135

1020

1135

1020

1135

1020

1135

GC GC GC GC GC GC GC GC GC GC

266R = Right hand, 266L = Left hand

= First choice

J

C8

THREADING CoroThread 266 inserts

C 28

C7

C82

C86

C2

J3

I8

THREADING

CoroThread 266 inserts

STUB-ACME 29 Chamfered crest form

Trapezoidal screw threads for motion transmission.

ANSI B1.8-1988

Tolerance class 2G

Style shown: Right hand external, Left hand internal

Dimensions, mm (inch)

Pitch,

iC

TPI

16

3/8

16-8

22

1/2

6-4

27

5/8

3

iC mm

9.53

12.7

15.9

d1

4.4 (.173)

5.5 (.217)

6.5 (.256)

s

3.97 (.156)

5.56 (.219)

7.0 (.276)

Even more possibilities thanks to tailored design! See page J3.

External

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

1/2

27

5/8

HA

in.

.0732

.0835

.0972

.1161

.1445

.1913

.2295

.2862

.3803

HB

mm

1.21

1.40

1.65

1.87

2.39

3.27

3.98

5.05

6.81

HB

in.

.0476

.0551

.0650

.0736

.0941

.1287

.1567

.1988

.2681

WT

mm

0.63

0.72

0.85

0.97

1.24

1.69

2.06

2.61

3.52

WT

in.

.0248

.0283

.0335

.0382

.0488

.0665

.0811

.1028

.1386

P20

P25

M20

M25

K15

K20

N25

N25

S20

S25

22

16

14

12

10

8

6

5

4

3

HA

mm

1.86

2.12

2.47

2.95

3.67

4.86

5.83

7.27

9.66

Ordering code

266R/LG-16SA01F160E

266R/LG-16SA01F140E

266R/LG-16SA01F120E

266R/LG-16SA01F100E

266R/LG-16SA01F080E

266R/LG-22SA01F060E

266R/LG-22SA01F050E

266R/LG-22SA01F040E

266RG-27SA01F030E

1020

1135

1020

1135

1020

1135

1020

1135

1020

1135

GC GC GC GC GC GC GC GC GC GC

Internal

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

22

1/2

27

5/8

16

14

12

10

8

6

5

4

3

HA

mm

1.81

2.07

2.40

2.88

3.59

4.77

5.71

7.13

9.49

Ordering code

266RL-16SA01F160E

266RL-16SA01F140E

266R/LL-16SA01F120E

266R/LL-16SA01F100E

266R/LL-16SA01F080E

266R/LL-22SA01F060E

266R/LL-22SA01F050E

266R/LL-22SA01F040E

266RL-27SA01F030E

HA

in.

.0713

.0815

.0945

.1134

.1413

.1878

.2248

.2807

.3736

HB

mm

1.15

1.34

1.59

1.80

2.31

3.18

3.87

4.91

6.64

HB

in.

.0453

.0528

.0626

.0709

.0909

.1252

.1524

.1933

.2614

WT

mm

0.59

0.72

0.85

0.93

1.24

1.64

2.00

2.54

3.43

WT

in.

.0232

.0283

.0335

.0366

.0488

.0646

.0787

.1000

.1350

1020

1135

1020

1135

1020

1135

1020

1135

1020

1135

GC GC GC GC GC GC GC GC GC GC

P20

P25

M20

M25

K15

K20

N25

N25

S20

S25

TURN - ENG

266R = Right hand, 266L = Left hand

= First choice

J

C8

C7

C82

C86

C2

J3

I8

THREADING CoroThread 266 inserts

C 29

TURN - ENG

THREADING

CoroThread 266 inserts

API 60 Full form for shouldered connections

V-0.038R, V-0.040, V-0.050

Threads for oil and gas.

Me = Cone

2 i.p.f 446

3 i.p.f 707

API spec.7

Dimensions, mm (inch)

Pitch,

iC

TPI

22

1/2

4-5

27

5/8

4-5

Style shown: Right hand external, Left hand internal

iC mm

12.7

15.9

d1

5.5 (.217)

6.5 (.256)

s

5.57 (.219)

7.0 (.276)

Even more possibilities thanks to tailored design! See page J3.

External

TPI

Taper on dia.

Dimensions, millimeter, inch (mm, in.)

D

22

iC

1/2

i.p.f.

4

2

3

2

3

2

3

2

3

TPI

Taper on dia.

5/8

HA

mm

HA

in.

HB

mm

HB

in.

4.03

4.02

.1587

.1583

0.95

0.95

.0374

.0374

3.47

.1368

0.50

.0197

4.36

4.35

.1717

.1713

0.62

0.62

.0244

.0244

4.03

4.02

.1587

.1583

0.95

0.95

.0374

.0374

3.47

.1368

0.50

.0197

4.36

4.35

.1717

.1713

0.62

0.62

.0244

.0244

P20

P20

M20

M20

K15

K15

N25

N20

S20

S20

27

Ordering code

V-0.038R

266RG-22V381A0402E

266RG-22V381A0403E

V-0.040

266RG-22V401A0503E

V-0.050

266RG-22V501A0402E

266RG-22V501A0403E

V-0.038R

266RG-27V381A0402E

266RG-27V381A0403E

V-0.040

266RG-27V401A0503E

V-0.050

266RG-27V501A0402E

266RG-27V501A0403E

1020

1125

1020

1125

1020

1125

1020

1125

1020

1125

GC GC GC GC GC GC GC GC GC GC

H

Internal

Dimensions, millimeter, inch (mm, in.)

D

22

iC

1/2

2

3

2

3

2

3

2

3

Ordering code

V-0.038R

266RL-22V381A0402E

266RL-22V381A0403E

V-0.040

266RL-22V401A0503E

V-0.050

266RL-22V501A0402E

266RL-22V501A0403E

V-0.038R

266RL-27V381A0402E

266RL-27V381A0403E

V-0.040

266RL-27V401A0503E

V-0.050

266RL-27V501A0402E

266RL-27V501A0403E

5/8

HB

mm

HB

in.

4.03

4.02

.1587

.1583

0.95

0.95

.0374

.0374

3.47

.1368

0.50

.0197

4.36

4.35

.1717

.1713

0.62

0.62

.0244

.0244

4.03

4.02

.1587

.1583

0.95

0.95

.0374

.0374

3.47

.1368

0.50

.0197

4.36

4.35

.1717

.1713

0.62

0.62

.0244

.0244

P20

P20

M20

M20

K15

K15

N25

N20

S20

S20

27

i.p.f.

HA

in.

1020

1125

1020

1125

1020

1125

1020

1125

1020

1125

GC GC GC GC GC GC GC GC GC GC

HA

mm

266R = Right hand, 266L = Left hand

= First choice

C8

THREADING CoroThread 266 inserts

C 30

C7

C82

C86

C2

J3

I8

THREADING

CoroThread 266 inserts

API Round 60 Full form

Threads for oil and gas.

API spec.5B

Style shown: Right hand external, Left hand internal

Dimensions, mm (inch)

Pitch,

iC

TPI

16

3/8

10-8

22

1/2

10-8

iC mm

9.53

12.7

d1

4.4 (.173)

5.5 (.217)

s

3.97 (.156)

5.56 (.219)

C

Even more possibilities thanks to tailored design! See page J3.

External

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

10

8

1/2

10

8

HA

mm

1.76

HA

in.

.0693

HB

mm

0.36

HB

in.

.0142

2.23

.0878

0.43

.0169

1.76

2.23

.0693

.0878

0.36

0.43

.0142

.0169

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

22

Ordering code

266RG-16RD01A100E

266RG-16RD01C100M

266RG-16RD01A080E

266RG-16RD01C080M

266RG-22RD01A100E

266RG-22RD01A080E

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

Internal

Pitch, TPI

Dimensions, millimeter, inch (mm, in.)

D

16

iC

3/8

10

8

22

1/2

10

8

Ordering code

266RL-16RD01A100E

266RL-16RD01C100M

266RL-16RD01A080E

266RL-16RD01C080M

266RL-22RD01A100E

266RL-22RD01A080E

HA

in.

.0693

HB

mm

0.36

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

1020

1125

1135

GC GC GC GC GC GC GC GC GC GC GC GC GC GC GC

HA

mm

1.76

HB

in.

.0142

2.24

.0882

0.43

.0169

1.76

2.24

.0693

.0882

0.36

0.43

.0142

.0169

P20

P20

P25

M20

M20

M25

K15

K15

K20

N25

N20

N25

S20

S20

S25

TURN - ENG

266R = Right hand

= First choice

J

C8

C7

C82

C86

C2

J3

I8

THREADING CoroThread 266 inserts

C 31

TURN - ENG

THREADING

CoroThread 266 inserts

API Full form for tubes and casings

Threads for oil and gas.

Me = Cone

3/4 i.p.f 147 for diameter 4 1/2 13 3/8

1 i.p.f 223 for diameter 16

Buttress

API spec. 5B

Style shown: Right hand external, Left hand internal

Dimensions, mm (inch)

Pitch,

iC

TPI

22

1/2

5

iC mm

12.7

d1

5.5 (.217)

s

5.57 (.219)

Even more possibilities thanks to tailored design! See page J3.

External

Pitch, TPI Taper on dia.

Dimensions, millimeter, inch (mm, in.)

D

22

iC

1/2

i.p.f.

1

3/4

Ordering code

266RG-22BU01A0501E

266RG-22BU01A050E

HB

mm

10.60

10.47

HB

in.

.4173

.4122

WP

mm

2.61

2.58

WP

in.

2.6100

2.5800

P20

P20

M20

M20

K15

K15

N25

N20

S20

S20

HA

in.

.4748

.4744

1020

1125

1020

1125

1020

1125

1020

1125

1020

1125

GC GC GC GC GC GC GC GC GC GC

HA

mm

12.06

12.05

Internal

Pitch, TPI Taper on dia.

Dimensions, millimeter, inch (mm, in.)

D

22

i.p.f.

1

3/4

Ordering code

266RL-22BU01A0501E

266RL-22BU01A050E

HA

mm

12.04

12.18

HA

in.

.4740

.4795

HB

mm

10.62

10.60

HB

in.

.4181

.4173

WP

mm

2.61

2.61

WP

in.

2.6100

2.6100

P20

P20

M20

M20

K15

K15

N25

N20

S20

S20

iC

1/2

1020

1125

1020

1125

1020

1125

1020

1125