Escolar Documentos

Profissional Documentos

Cultura Documentos

Thermal Analysis of Shell and Tube Heat Exchanger

Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Thermal Analysis of Shell and Tube Heat Exchanger

Direitos autorais:

Formatos disponíveis

IJRET: International Journal of Research in Engineering and Technology ISSN: 2319-1163

__________________________________________________________________________________________

Volume: 01 Issue: 03 | Nov-2012, Available @ http://www.ijret.org 276

THERMAL ANALYSIS OF SHELL AND TUBE HEAT EXCHANGER

USING MAT LAB AND FLOEFD SOFTWARE

A.GopiChand

1

, A. V. N. L. Sharma

2

, G. Vijay Kumar

3

, A.Srividya

4

1

AssocProf,

2

HOD,

3,4

STUDENT, MECHANICAL ENGINEERING, SWARNANDHRA COLLEGE OF ENGINEERING

AND TECHNOLOGY ANDHRA PRADESH, INDIA, allakagopichand@gmail.com, avnls277522 @gmail.com

vijayramuk311@gmail.com, srividya330@gmail.com

Abstract

In this paper, a simplified model for the study of thermal analysis [1] of shell-and-tubes heat exchangers of water and oil type is

proposed..Shell and Tube heat exchangers are having special importance in boilers, oil coolers, condensers, pre-heaters. They are

also widely used in process applications as well as the refrigeration and air conditioning industry. The robustness and medium

weighted shape of Shell and Tube heat exchangers make them well suited for high pressure operations. In this paper we have shown

how to done the thermal analysis by using theoretical formulae for this we have chosen a practical problem of counter flow shell and

tube heat exchanger of water and oil type, by using the data that come from theoretical formulae we have design[2] a model of shell

and tube heat exchanger using Pro-e and done the thermal analysis by using Floefd software and comparing the result that obtained

from Floefd software and theoretical formulae. For simplification of theoretical calculations we have also done a Matlab code which

is useful for calculating the thermal analysis of a counter flow of water-oil type shell and tube heat exchanger.

I ndex Terms: Counter flow of shell and tube heat exchanger of oil and water type, Floefd software, Matlab software.

--------------------------------------------------------------------- *** ------------------------------------------------------------------------

1. HEAT EXCHANGER

A device whose primary purpose is the transfer of energy

between two fluids is named a heat exchanger[4]. Aheat

exchanger may be defined as an equipment which transfers

the energy from a hot fluid to a cold fluid, with maximum

rate and minimum investment and running costs[5].

1.1 Shell and Tube Heat exchanger

In this type of heat exchanger one of the fluids flow through a

bundle of tubes enclosed by a shell. the outer fluid is forced

through a shell and it flows over the outside surface of the

tubes . such an arrangement is employed where reliability and

heat transfer effectiveness[4]. It is the most common type of

heat exchanger in oil refineries and other large chemical

processes, and is suited for higher-pressure applications. This

type of heat exchanger consists of a shell (a large pressure

vessel) with a bundle of tubes inside it. One fluid runs through

the tubes, and another fluid flows over the tubes (through the

shell) to transfer heat between the two fluids

Fig-1:Shell and Tube Heat exchanger of type Water to oil .

2. FLOEFD

FloEFD can be used to study the fluid flow and heat transfer

for a wide variety of engineering equipment. In this example

we use FloEFD to determine the efficiency of a counter flow

heat exchanger and to observe the temperature and flow

patterns inside of it.

With FloEFD the determination of heat exchanger efficiency

is straightforward and by investigating the flow and

temperature patterns, the design engineer can gain insight into

the physical processes involved thus giving guidance for

improvements to the design.

A convenient measure of heat exchanger performance is its

efficiency in transferring a given amount of heat from one

fluid at higher temperature to another fluid at lower

temperature. The efficiency can be determined if the

temperatures at all flow openings are known. In FloEFD the

temperatures at the fluid inlets are specified and the

temperatures at the outlets can be easily determined.

3. DESIGN CALCULATIONS [1]

3.1 THEORITICAL DESIGN CALCULATIONS:

-

c

m =Mass flow rate of cold fluid

IJRET: International Journal of Research in Engineering and Technology ISSN: 2319-1163

__________________________________________________________________________________________

Volume: 01 Issue: 03 | Nov-2012, Available @ http://www.ijret.org 277

c

m =0.9

sec

kg

-

h

m =Mass flow rate of hot fluid

2.5

sec

h

kg

m =

-

c

cp = Specific heat of cold fluid

4.2

c o

kj

cp

kg k

=

-

h

cp = Specific heat of hot fluid

2.5

h

o

kj

cp

kg k

=

-

hi

T =Inlet temperature of hot fluid

383

o

hi

T k =

-

2 h

T = Outlet temperature of hot fluid

2

360

o

h

T k =

-

1 c

T = Inlet temperature of cold fluid

1

308

o

c

T k =

-

2 c

T = Outlet temperature of cold fluid

- =Density of oil

3

850

kg

m

=

-

o

U =Overall heat transfer coefficient

- E =Effectiveness of heat exchanger

2

350

o o

w

U

m k

=

-

lm

T A = Logarithmic mean temperature difference

-

Q =

Total heat transfer

c c lm

Q m c T = A

Q=heat gain by the cold liquid=heat loss by the hot liquid

c c lm h h lm

Q m c T m c T = A = A

2

0.9 4.2 ( 308) 2.5 2.5 (383 360)

346.029

c

T

k

=

=

- Outlet temperature of cold liquid

2

346

o

c

T k =

c c lm

Q m c T = A

0.9 4.2 (346 308)

143.74kw

=

=

- Rate of heat transfer

143.74 Q kw =

- Logarithmic mean temperature distribution for

counter flow heat exchanger(LMTD)

1

2

1 2

ln( )

lm

T

T

T T

T

A

A

A A

A =

1 1 2

2 2 1

h c

h c

T T T

T T T

A =

A =

(383 346)

(360 308)

(383 346) (360 308)

ln( )

44.07

o

k

=

=

Area of shell

0 lm

Q

A

U T

=

A

3

2

143.74 10

350 44

9.318

A

A m

=

- Area of tube

h

t

m

A

v

=

2

2.5

0.0084

850 0.35

m = =

2

0.0084

t

A m =

- Number of tubes

2

2

4

4

t

t

d

A n

A

n

d

= H

=

H

2

0.0084 4

(0.02 )

26.93 27 n tubes

=

[

= =

IJRET: International Journal of Research in Engineering and Technology ISSN: 2319-1163

__________________________________________________________________________________________

Volume: 01 Issue: 03 | Nov-2012, Available @ http://www.ijret.org 278

- Length of tubes

9.318

27 0.02

5.49

A n dL

L

L m

= [

=

[

=

- Shell outer diameter

O

A

D

L

=

[

9.318

0.540

5.49

m = =

[

0.540

o

D m =

- Effectiveness

max 1 2

min 1 1

( )

( )

h h

h c

C T T

C T T

E =

max

max C of =

h

C or Cc

min

min C of =

h

C or Cc

min

max

0.9 4.2 3.78

2.5 2.5 6.25

c c

h h h

C Cc m Cp

C C m Cp

= = = =

= = = =

1 2

1 1

( )

( )

h c

h c

Cc T T

Ch T T

6.25(383 360)

0.507050

3.78(383 308)

= =

0.507050 E =

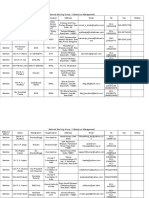

3.2 THERMAL ANALYSIS CALCULATIONS BY

USING MATLAB.

For thermal analysis calculations by using Matlab program

we have to provide some parameters like mass flow rate of hot

liquid and cold liquid. Temperatures of inlet and outlet of hot

liquid and inlet temperature of cold liquid.

Input

Output

IJRET: International Journal of Research in Engineering and Technology ISSN: 2319-1163

__________________________________________________________________________________________

Volume: 01 Issue: 03 | Nov-2012, Available @ http://www.ijret.org 279

4. MODELING OF SHELL AND TUBE

HEATEXCHNAGER USING PRO-E

SHELL

Outer diameter of the shell is 540mm

Inner diameter of the shell is 520mm

Thickness of the shell is 10mm

Material we have taken for shell is stainless steel

Length of the shell 5.49m

Inlet and outlet nozzle diameter of the shell is 100mm

Thickness is 10mm

Fig 2 SHELL

FLANGE

Outer Diameter of the flange is 540mm

Inner Diameter of the flange is 520mm

Thickness is 10mm

Outer diameter of the nozzle is 100mm

Inner diameter of the nozzle is 80mm

Fig 3: FLANGE

BAFFLE END PLATE

Diameter of the baffle end plate is 520mm

Number of holes on the baffle end plate is 28

Hole diameter is 20mm

Figure 4. BAFFLE END PLATE

BAFFLE PLATE

Baffle cut is 25%

Thickness of the baffle plate is 10mm

IJRET: International Journal of Research in Engineering and Technology ISSN: 2319-1163

__________________________________________________________________________________________

Volume: 01 Issue: 03 | Nov-2012, Available @ http://www.ijret.org 280

Fig 5:- BAFFLE PLATE

TUBE

Outer diameter of the tube is 20mm

Inner diameter of the tube is 16.4mm

Length of the tube is 5.49m

Number of the tubes is 28

Fig 6:TUBE

PRO-E Assembly Model

Fig 7: Model of shell and tube heat exchanger

5. THERMAL ANALYSIS USING FLOEFD

By using the thermal analysis result that obtained from

theoretical formulae. We have designed a Pro-e Model, and

the materials we used for thermal analysis for tubes is copper

and shell is stainless steel because Copper is one of the best

conductors of heat, while stainless steel is a mediocre

conductor. Using copper would increase the rate at which heat

was transferred from oil to the water which is imported into

the FLOEFD software and started the analysis, the results that

obtained from FLOEFD where represented by contour plots.

Figure 5.1:Contour Plot Results of Temperatures of Inlet and

Outlet temperatures of Hot and cold liquids.

Figure 5.2:-Halfcutted Contour Plot results that showing the

temperature of Outlet Hot oil(Yellow color) and Inlet

Temperature of cold water(Blue color).

IJRET: International Journal of Research in Engineering and Technology ISSN: 2319-1163

__________________________________________________________________________________________

Volume: 01 Issue: 03 | Nov-2012, Available @ http://www.ijret.org 281

Figure 5.3: Half cutted Contour plot results that showing the

temperatures of Inlet Hot Oil(red colour)and outlet

temperature of cold water(greenish colour).

CONCLUSIONS

We have done the thermal analysis of water to oil type of shell

and tube heat exchanger using Matlab and by using the output

that come from Matlab we have modeled a shell and tube heat

exchanger using Pro-e and imported this model in Floefd

software and we have run the thermal analysis and we

compared the both results and we are getting an error of 0.02

3in effectiveness .By using above process we can do the

thermal analysis in less time and our analysis report also most

accurate .

ACKNOWLEDGEMENTS

We thanks to our Assoc.Prof.R.Samsukumar for providing

Necessary support doing this work. we acknowledge the

diligent efforts of Ramgopal Varma Dandu,Applicant

Engineer,Trident Tech Lab for doing thermal Anaylsis.

REFERENCES

[1]International Journal of Ambient Energy, Volume 31,

Number 4Thermal analysis of counterflow heat exchanger

with a heat source Assad, Kotiaho

[2].http://www.copper.org/applications/rodbar/alloy360/cu_ste

el.html

[3]. MNL 032A Issued 29 August 08, Prepared by

J.E.Edwards of P & I Design Ltd, Teesside, UK

www.pidesign.co.uk

[4]Shah, R. K. and Seculik, D. P. Fundamentals of Heat

Exchanger Design. Wiley: New York, 2 0 0 3 .

[5].Fundamentals of Engineering Heat and mass transfer by

R.C.Sachdva

Você também pode gostar

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1No EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Nota: 3.5 de 5 estrelas3.5/5 (3)

- ME 4226 Heat Exchanger Compiled WconclusionDocumento26 páginasME 4226 Heat Exchanger Compiled Wconclusionhamish888Ainda não há avaliações

- Optimization of Shell and Tube Heat ExchangerDocumento29 páginasOptimization of Shell and Tube Heat ExchangerAna QuintanaAinda não há avaliações

- New Microsoft Word Document 4.1Documento19 páginasNew Microsoft Word Document 4.1prashantmaukaAinda não há avaliações

- Effect of Nanofluids and Mass Flow Rate of Air On Heat Transfer Rate in Automobile Radiator by CFD AnalysisDocumento6 páginasEffect of Nanofluids and Mass Flow Rate of Air On Heat Transfer Rate in Automobile Radiator by CFD AnalysisInternational Journal of Research in Engineering and TechnologyAinda não há avaliações

- A New Optimization Method For Evaluating Thermal Parameters in A Single Segmental Shell and Tube Heat ExchangerDocumento8 páginasA New Optimization Method For Evaluating Thermal Parameters in A Single Segmental Shell and Tube Heat Exchangertotok89Ainda não há avaliações

- Universiti Kuala Lumpur Malaysian Institute of Chemical and Bioengineering TechnologyDocumento24 páginasUniversiti Kuala Lumpur Malaysian Institute of Chemical and Bioengineering TechnologyHanif YusofAinda não há avaliações

- Issn: 2349-3860Documento18 páginasIssn: 2349-3860Pat TejAinda não há avaliações

- An Investigation On Thermo-Hydraulic Performance of Shell and Tube Heat Exchanger With RecyclesDocumento14 páginasAn Investigation On Thermo-Hydraulic Performance of Shell and Tube Heat Exchanger With RecyclesTJPRC PublicationsAinda não há avaliações

- Experimental and Comparison Study of Heat Transfer Characteristics of Wickless Heat Pipes by Using Various Heat InputsDocumento12 páginasExperimental and Comparison Study of Heat Transfer Characteristics of Wickless Heat Pipes by Using Various Heat InputsIJRASETPublicationsAinda não há avaliações

- Enhancement of Heat Transfer Rate of Tube in Tube Helical Coil Heat ExchangerDocumento7 páginasEnhancement of Heat Transfer Rate of Tube in Tube Helical Coil Heat ExchangerInternational Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- Thermal Analysis of Shell & Tube Heat Exchanger by Using HTRI 42608Documento4 páginasThermal Analysis of Shell & Tube Heat Exchanger by Using HTRI 42608Johnson WickyAinda não há avaliações

- Dphe PDFDocumento4 páginasDphe PDFMutiaraAinda não há avaliações

- Dphe PDFDocumento4 páginasDphe PDFMutiaraAinda não há avaliações

- Experimental Investigations On A Compact Heat Exchanger and Optimization Using Taguchi TechniqueDocumento7 páginasExperimental Investigations On A Compact Heat Exchanger and Optimization Using Taguchi TechniqueesatjournalsAinda não há avaliações

- A Review To Optimize The Heat Transfer Rate and Increase The Efficiency of The Cooling TowerDocumento6 páginasA Review To Optimize The Heat Transfer Rate and Increase The Efficiency of The Cooling TowerEditor IJRITCCAinda não há avaliações

- Experimental Investigation of Forced Draft Counter Flow Cooling Tower With Twisted Tape Insert Horizontal & VerticalDocumento4 páginasExperimental Investigation of Forced Draft Counter Flow Cooling Tower With Twisted Tape Insert Horizontal & VerticalEditor IJRITCCAinda não há avaliações

- 6.ISCA-RJRS-2012-141 DoneDocumento6 páginas6.ISCA-RJRS-2012-141 DoneAanand Rishabh DagaAinda não há avaliações

- JCIT3528PPLDocumento8 páginasJCIT3528PPLgajendra2010Ainda não há avaliações

- Reducing Major Defects in Radiators Manufacturing: Kumar P., Sonawane B.S., Sontakke R.R., Surves.B., Wasnik A.RDocumento5 páginasReducing Major Defects in Radiators Manufacturing: Kumar P., Sonawane B.S., Sontakke R.R., Surves.B., Wasnik A.RKrushnaAinda não há avaliações

- Design and Analysis of Heat ExchangerDocumento34 páginasDesign and Analysis of Heat ExchangerAkshat Rathi100% (2)

- M.E LAB 3 Experiment 4 Heat Losses From PipesDocumento14 páginasM.E LAB 3 Experiment 4 Heat Losses From PipesDrw ArcyAinda não há avaliações

- Fall 2016 Lab Manual - CHEG455 (Sec 51 & 52) PDFDocumento68 páginasFall 2016 Lab Manual - CHEG455 (Sec 51 & 52) PDFMashaelAinda não há avaliações

- CFD Analysis of An Elliptical Pin Fin Heat Sink Using Ansys Fluent v12.1Documento8 páginasCFD Analysis of An Elliptical Pin Fin Heat Sink Using Ansys Fluent v12.1Kelsey RyanAinda não há avaliações

- CFD Anysis of A Double Pipe Heat Exchanger Using: International Journal of Advance Engineering and Research DevelopmentDocumento6 páginasCFD Anysis of A Double Pipe Heat Exchanger Using: International Journal of Advance Engineering and Research DevelopmentSai Krishna SKAinda não há avaliações

- Enhance The Heat Transfer Rate of Finned Tube Heat Exchanger: A ReviewDocumento6 páginasEnhance The Heat Transfer Rate of Finned Tube Heat Exchanger: A ReviewEditor IJRITCCAinda não há avaliações

- Simplified Numerical Model For A Flat Continuous Triangle Fins Air Cooled Heat Exchanger Using A Step by Step TechniqueDocumento23 páginasSimplified Numerical Model For A Flat Continuous Triangle Fins Air Cooled Heat Exchanger Using A Step by Step TechniquemunkkkkAinda não há avaliações

- To Study of Parametric Analysis of Shell and Tube Heat ExchengerDocumento9 páginasTo Study of Parametric Analysis of Shell and Tube Heat ExchengerManish PrajapatiAinda não há avaliações

- Mme20120400001 99189738 PDFDocumento5 páginasMme20120400001 99189738 PDFAnimesh JainAinda não há avaliações

- Modelling The Effects of Cooling ModerateDocumento10 páginasModelling The Effects of Cooling ModerateDr.Hesham BaejAinda não há avaliações

- Exergy Analysis of Inlet Water Temperature of Condenser: Doi Aysakhanam M, I.J.PatelDocumento4 páginasExergy Analysis of Inlet Water Temperature of Condenser: Doi Aysakhanam M, I.J.PatelmechveenaAinda não há avaliações

- CFD Analysis of Superheater in View of Boiler Tube Leakage: Ajay N. Ingale, Vivek C. Pathade, Dr. Vivek H. TatwawadiDocumento3 páginasCFD Analysis of Superheater in View of Boiler Tube Leakage: Ajay N. Ingale, Vivek C. Pathade, Dr. Vivek H. Tatwawadidinesh23cbeAinda não há avaliações

- Project HEDocumento19 páginasProject HEPritirajputAinda não há avaliações

- Automotive Radiator Sizing and Rating - Simulation Approach: P. S. Amrutkar, S. R. PatilDocumento5 páginasAutomotive Radiator Sizing and Rating - Simulation Approach: P. S. Amrutkar, S. R. PatilPacific NguyenAinda não há avaliações

- Optimizing IC Engine Exhaust Valve Design Using Finite Element AnalysisDocumento5 páginasOptimizing IC Engine Exhaust Valve Design Using Finite Element AnalysisIJMERAinda não há avaliações

- G J E S R: Lobal Ournal of Ngineering Cience and EsearchesDocumento7 páginasG J E S R: Lobal Ournal of Ngineering Cience and EsearchesUNITED CADDAinda não há avaliações

- Improve The Efficiency of Heat Exchanger in Oil CoolerDocumento29 páginasImprove The Efficiency of Heat Exchanger in Oil CoolerMuhammad RustamAinda não há avaliações

- Presentation Heat ExchhangerDocumento25 páginasPresentation Heat ExchhangernagrajAinda não há avaliações

- IRJET Experimental Investigations of Double Pipe Heat Exchanger With Triangular Baffles PDFDocumento5 páginasIRJET Experimental Investigations of Double Pipe Heat Exchanger With Triangular Baffles PDFRidhoQodriAinda não há avaliações

- Tube To TS Joint Design PDFDocumento8 páginasTube To TS Joint Design PDFprad021adAinda não há avaliações

- Review Paper On Investigation of Perfomance For Shell and Tube Heat Exchanger - 45688Documento5 páginasReview Paper On Investigation of Perfomance For Shell and Tube Heat Exchanger - 45688lvmengke1994Ainda não há avaliações

- Shell & Tube HEDocumento6 páginasShell & Tube HEvinodAinda não há avaliações

- Design Analysis of Shell Tube Type Heat Exchanger IJERTV9IS010215Documento16 páginasDesign Analysis of Shell Tube Type Heat Exchanger IJERTV9IS010215Harshil ChangelaAinda não há avaliações

- The Design of Earth Air Tunnel Heat Exchanger System For An Institute LibraryDocumento5 páginasThe Design of Earth Air Tunnel Heat Exchanger System For An Institute LibraryInnovative Research PublicationsAinda não há avaliações

- CHAPTER 8 Sizing and CostingDocumento20 páginasCHAPTER 8 Sizing and CostingNurul Amelia Mustaffa0% (1)

- Improving The Performance of Shell-and-Tube Heat Exchangers by The Addition of SwirlDocumento26 páginasImproving The Performance of Shell-and-Tube Heat Exchangers by The Addition of Swirlabdullah mubasharAinda não há avaliações

- 47 CeDocumento4 páginas47 CeZohaib AliAinda não há avaliações

- Heat Transfer Systems CalculationDocumento18 páginasHeat Transfer Systems CalculationAshish SutharAinda não há avaliações

- Eteiac1411 (Heat Exchanger)Documento6 páginasEteiac1411 (Heat Exchanger)Evans IraborAinda não há avaliações

- CLB21003 Process Heat Transfer - Mini Project: Design of Heat ExchangerDocumento21 páginasCLB21003 Process Heat Transfer - Mini Project: Design of Heat ExchangerSiti Hajar Mohamed83% (6)

- Wiryanta 2018 J. Phys. Conf. Ser. 953 012060Documento8 páginasWiryanta 2018 J. Phys. Conf. Ser. 953 012060vinodAinda não há avaliações

- IJRAR1CXP057Documento7 páginasIJRAR1CXP057Enrique FloresAinda não há avaliações

- Design and Development of Automotive Radiator Aided With Nanoparticles As Cooling FluidDocumento8 páginasDesign and Development of Automotive Radiator Aided With Nanoparticles As Cooling FluidKaushik PatelAinda não há avaliações

- Article CFB Anslysis On Coal State Test of 300MW CFB BoilerDocumento8 páginasArticle CFB Anslysis On Coal State Test of 300MW CFB Boilernguyenhuutan91Ainda não há avaliações

- HT Lab File D3mea2Documento17 páginasHT Lab File D3mea2preetAinda não há avaliações

- HT Lab File D3mea2Documento17 páginasHT Lab File D3mea2preetAinda não há avaliações

- Design of Roll Bond Evaporator For Room Air ConditionerDocumento6 páginasDesign of Roll Bond Evaporator For Room Air Conditionerimamul haqueAinda não há avaliações

- ME34 - ME Laboratory 2 - : Signature of Student Under Printed NameDocumento12 páginasME34 - ME Laboratory 2 - : Signature of Student Under Printed NameSky FallAinda não há avaliações

- Buku Panduan P2K2 FINALDocumento44 páginasBuku Panduan P2K2 FINALHandayani lestariAinda não há avaliações

- Real Time Blood Type Determination by Gel Test Method On An Embedded SystemDocumento4 páginasReal Time Blood Type Determination by Gel Test Method On An Embedded Systemngocbienk56Ainda não há avaliações

- IEC 61439 - 2011 New Standard PDFDocumento21 páginasIEC 61439 - 2011 New Standard PDFSamsung JosephAinda não há avaliações

- Ultrasonic Levndsgjalshfgkdjakel Endress Hauser Fmu 40 Manual BookDocumento84 páginasUltrasonic Levndsgjalshfgkdjakel Endress Hauser Fmu 40 Manual BookrancidAinda não há avaliações

- Workshop Manual Group 21-26 - 7745282 PDFDocumento228 páginasWorkshop Manual Group 21-26 - 7745282 PDFabdelhadi houssinAinda não há avaliações

- TDS - Masterkure 106Documento2 páginasTDS - Masterkure 106Venkata RaoAinda não há avaliações

- OneDesk QuickStartGuideDocumento5 páginasOneDesk QuickStartGuidefivel84Ainda não há avaliações

- 2006 AcrotechDocumento32 páginas2006 Acrotechkaniappan sakthivelAinda não há avaliações

- 1.1 Iom Miller-Pickingtm Customtm Air Handling Unit (Page 62)Documento84 páginas1.1 Iom Miller-Pickingtm Customtm Air Handling Unit (Page 62)khanh phanAinda não há avaliações

- Solid Desiccant DehydrationDocumento5 páginasSolid Desiccant Dehydrationca_minoAinda não há avaliações

- Tutorial Label MatrixDocumento66 páginasTutorial Label MatrixLuisa Adriana Perez GutierrezAinda não há avaliações

- C D C SDocumento4 páginasC D C SandriAinda não há avaliações

- TCAD Workshop Volume IDocumento69 páginasTCAD Workshop Volume IVipan SharmaAinda não há avaliações

- A Tracer Study On Btte GraduatesDocumento15 páginasA Tracer Study On Btte GraduatesOzalleAngryBertAinda não há avaliações

- Contact List For All NWGDocumento22 páginasContact List For All NWGKarthickAinda não há avaliações

- Micro Teaching English Year 4: Presented By: Hasirulnizam Bin Hashim Arfanizam Bin Mohd Hafiz Bin SaatDocumento33 páginasMicro Teaching English Year 4: Presented By: Hasirulnizam Bin Hashim Arfanizam Bin Mohd Hafiz Bin SaatZaila ZaihaAinda não há avaliações

- Mitac 6120N ManualDocumento141 páginasMitac 6120N ManualLiviu LiviuAinda não há avaliações

- Bolted Tank Specifications Final 11-5-15Documento6 páginasBolted Tank Specifications Final 11-5-15Rodrigo ZapataAinda não há avaliações

- Bearer Independent Call Control Protocol (Cs2) and Signalling System No.7 - Isdn User Part General Functions of Messages and ParametersDocumento31 páginasBearer Independent Call Control Protocol (Cs2) and Signalling System No.7 - Isdn User Part General Functions of Messages and Parameterssahil_chandna25Ainda não há avaliações

- Monthly Ladder Inspection ChecklistDocumento4 páginasMonthly Ladder Inspection ChecklistPeter Sare WolloAinda não há avaliações

- Vatan Katalog 2014Documento98 páginasVatan Katalog 2014rasko65Ainda não há avaliações

- Presentation On FacebookDocumento39 páginasPresentation On FacebookShaswat SinghAinda não há avaliações

- Firearms in America 1600 - 1899Documento310 páginasFirearms in America 1600 - 1899Mike100% (3)

- cm6800 48x8 NewDocumento98 páginascm6800 48x8 Newvijayakumar3661Ainda não há avaliações

- Vmware Validated Design 41 SDDC Architecture DesignDocumento226 páginasVmware Validated Design 41 SDDC Architecture DesignmpuriceAinda não há avaliações

- Introduction To Compressed Air SystemDocumento23 páginasIntroduction To Compressed Air SystemMohd Zulhairi Mohd NoorAinda não há avaliações

- Python - Tutorial: #!/usr/bin/python Print "Hello, Python!"Documento174 páginasPython - Tutorial: #!/usr/bin/python Print "Hello, Python!"ankitAinda não há avaliações

- Remuz TreeDocumento608 páginasRemuz TreeEdward JonesAinda não há avaliações

- How To Effectively Implement DCIM and Bridge The Gap Between IT and FacilitiesDocumento11 páginasHow To Effectively Implement DCIM and Bridge The Gap Between IT and FacilitiesAbednego TariganAinda não há avaliações

- Assessment of Learning 1 Quiz 1Documento3 páginasAssessment of Learning 1 Quiz 1imalwaysmarked100% (4)