Escolar Documentos

Profissional Documentos

Cultura Documentos

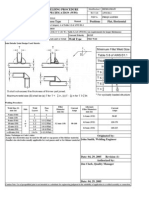

Inspection and Test Plan For Storage Tank

Enviado por

pluton1954Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Inspection and Test Plan For Storage Tank

Enviado por

pluton1954Direitos autorais:

Formatos disponíveis

www.inspection for industry.

com

Remark

Manuf. TPI Client

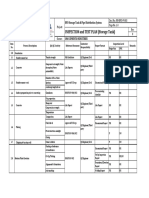

1 Pre Inspection Meeting Spec. Spec. MOM H H H

2

Approval of Mechanical

Calculation Books

Data sheets, PO, Spec. API 650, Spec. Calcualtion Book H H A

3

Approval of Fabrication

Drawings

DWG, Spec. API 650, Spec. DWG H H A

4

Review mill test

certificates of plates

DWG, Certificates ASME SEC II Certificates H W R

5

Review mill test

certificates of pipe, flange,

etc.

DWG, Certificates ASME SEC II, 16.5 Certificates H W R

6

Review mill test

certificates of welding

consumable material

WPS, Certificates ASME SEC II Certificates H W R

7

Visual & Dimensional

Check

DWG, Spec. ASME SEC II Report H W R

8 Bottom Plates DWG, WPS, Spec. API 650, Spec. Report H SW R

9 Annular Plates DWG, WPS, Spec API 650, Spec. Report H SW R

During manufacturing Marking, Cutting, Beveling and Grinding

Inspection and Test Plan for Storage Tank

Activity By

No. Inspection and Test Plan Reference Document Acceptance Criteria Verifying Document

Befor Manufacturing

Materials

1

www.inspection for industry.com

10 Shell Courses DWG, WPS, Spec API 650, Spec. Report H SW R

11 Roof Plates DWG, WPS, Spec API 650, Spec. Report H SW R

12 Roof Structures DWG, WPS, Spec API 650, Spec. Report H SW R

13 Wind Griders (If required) DWG, WPS, Spec API 650, Spec. Report H SW R

14 Top Angles (if required) DWG, WPS, Spec API 650, Spec. Report H SW R

15 Reinforcement Pads DWG, WPS, Spec API 650, Spec. Report H SW R

16

Manhole Nozzle Neck

(From Plates)

DWG, WPS, Spec API 650, Spec. Report H SW R

17

Pipe For Column (if

required)

DWG, WPS, Spec API 650, Spec. Report H SW R

18 Pipe For Nozzles DWG, WPS, Spec API 650, Spec. Report H SW R

19 Internal Pipes DWG, WPS, Spec API 650, Spec. Report H SW R

20

Internal or External

Supports

DWG, WPS, Spec API 650, Spec. Report H SW R

21 Sumps DWG, WPS, Spec API 650, Spec. Report H SW R

22

Spiral Stairway &

Platforms

DWG, WPS, Spec API 650, Spec. Report H SW R

23

Visual & Dimensional

Check of Loose Parts

DWG, WPS, Spec API 650, Spec. Report H H R

24 Shell Courses DWG, Spec. API 650, Spec. Report H W R

25 Sumps DWG, Spec. API 650, Spec. Report H SW R

26 Top Angles DWG, Spec. API 650, Spec. Report H W R

27

Manhole Nozzle Neck

(From Plates)

DWG, Spec. API 650, Spec. Report H SW R

During manufacturing Forming and Rolling

2

www.inspection for industry.com

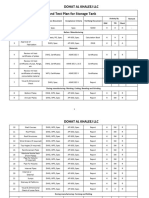

28

Visual & Dimensional

Check

DWG, Spec. API 650, Spec. Report H H R

29

Levelness of Ring

Wall (if applicable)

DWG, Spec. API 650, Spec. Report H H R

30 Center Point and Radius DWG, Spec. API 650, Spec. Report H H R

31 Flatness & Slope DWG, Spec. API 650, Spec. Report H H R

32 Orientation DWG, Spec. API 650, Spec. Report H H R

33

Anchor

bolts(Distance,

Projection ,etc.) as

required

DWG, Spec. API 650, Spec. Report H H R

34 WPS & PQR DWG, WPS, PQR, Spec ASME SEC IX Report H R/A R

35

Welder/Welding

Operator

Qualification

DWG, WPS, WQT, Spec ASME SEC IX Report H R/A R

36

NDT Operator

Certificate Check

Certificates API 650, Spec. Report H R/A R

37 Fit up of bottom plates DWG, WPS, Spec API 650, Spec. Report H H R

38

Welding sequence

implementation

DWG, WPS, Spec API 650, Spec. Report H H R

39

Visual inspection of

weldment

DWG, WPS, Spec API 650, Spec. Report H H R

40

Vacuum box test of

bottom plates

Spec. API 650, Spec. Report H H R

During Manufacturing Welding

During Manufacturing Foundation

3

www.inspection for industry.com

41

Annular plate

orientation check

DWG, Spec. API 650, Spec. Report H H R

42

Fit up & welding of

annular plate

DWG, WPS, Spec API 650, Spec. Report H H R

43

NDT of annular plate

/ Vacuum Test(If required)

Spec. API 650, Spec. Report H H R

44 Fit up of Shell Plate DWG, WPS, Spec API 650, Spec. Report H H R

45 Welding of Shell Plate DWG, WPS, Spec API 650, Spec. Report H H R

46 PWHT (if Required) WPS, Spec API 650, Spec. Report H H R

47 NDT of Shell Plate Spec. API 650, Spec. Report H H R

48

Oil Test of Annular Plate

to shell Plate

Spec. API 650, Spec. Report H H R

49

Fit up & welding

compression ring & roof

plate

DWG, WPS, Spec API 650, Spec. Report H H R

50 Welding of roof plates DWG, WPS, Spec API 650, Spec. Report H H R

51 Air test of roof plate Spec. API 650, Spec. Report H H R

52

Air test of

reinforcements

Spec. API 650, Spec. Report H H R

53 Plumbness DWG, Spec. API 650, Spec. Report H H R

54 Roundness DWG, Spec. API 650, Spec. Report H H R

55 Peaking & Banding DWG, Spec. API 650, Spec. Report H H R

During Manufacturing Dimentional Check

4

www.inspection for industry.com

56

Nozzle Elevation,

Orientation and Projection

DWG, Spec. API 650, Spec. Report H H R

57

Manhole Elevation,

Orientation and Projection

DWG, Spec. API 650, Spec. Report H H R

58

Verification of

Test Package

Reports API 650, Spec. Report H H R

59

Hydro test(Water

level/Holding time)

Spec. API 650, Spec. Report H H H

60

Settlement check

(Refer to applicable

procedure)

DWG, Spec. API 650, Spec. Report H H R

61 Water discharge Spec. API 650, Spec. Report H W R

62 Cleaning check Spec. API 650, Spec. Report H H R

63

Painting material

identification/check

Spec. API 650, Spec. Report H H R

64

Weather condition &

Surface Preparation

(Blasting)

Spec. API 650, Spec. Report H H R

65

Primer Layer Inspection

(Including Dry Thickness

check)

Spec. API 650, Spec. Report H H R

66

Intermediate/Final Layer

Inspection (Including

Dry Thickness check)

Spec. API 650, Spec. Report H H R

During Manufacturing Hydro Static Test

During Manufacturing Painting Activities

During Manufacturing Cathodic Protection and Electrical

5

www.inspection for industry.com

67

Check of material prior to

installation

Spec. API 650, Spec. Report H H R

68

Installation of Earthing

Bosses

Spec. API 650, Spec. Report H H R

69 Anode Installation Spec. API 650, Spec. Report H H R

70

Check of Anode &

conductor

Spec. API 650, Spec. Report H H R

71

Check the Bonding

of UG Pipe

Spec. API 650, Spec. Report H H R

72 Cable Installation Spec. API 650, Spec. Report H H R

73

Check the Test Box,

Reference Electrode

Spec. API 650, Spec. Report H H R

74

installation of reference

electrode including cable

Spec. API 650, Spec. Report H H R

SW: Spot Witness = for items with spot witness manufacture shall notify TPI inspector as fulfilling the monitoring;

For example one random visit for whole UT tests or one or two visits for whole surface preparation works for painting.

P.O: Purchase Order

MOM: Minute of Meeting

Abbreviations:

H: Hold Point = Hold on the production till TPI Inspector performs inspection and supervise the required test

W: Witness Point = Manufacture shall notify client and TPI Inspector but there is no hold on the production;

Client can waive this inspection based on his discretion and informs TPI Inspector accordingly.

R: Document Review = Review means Review document, which includes of material test certificates, WPS, PQR, NDT Procedures and etc.

A: Approval

6

Você também pode gostar

- Basic Fabrication Process FlowchartDocumento1 páginaBasic Fabrication Process FlowchartMorjhan MJ86% (29)

- Standard Manhour Estimation: Fabrication & WeldingDocumento3 páginasStandard Manhour Estimation: Fabrication & WeldingPratik Desai100% (7)

- ITP Installation of Boiler - R1Documento14 páginasITP Installation of Boiler - R1crys100% (4)

- Contractor Quality Control Plan For Storage Tank ErectionDocumento2 páginasContractor Quality Control Plan For Storage Tank ErectionHamid Alilou100% (4)

- ITP ValveDocumento5 páginasITP ValveJayaram MV100% (3)

- Smaw Fillet Aws d1.1Documento1 páginaSmaw Fillet Aws d1.1fallalovaldes100% (1)

- Inspection and Test Plan For Storage TankDocumento7 páginasInspection and Test Plan For Storage TankAhmed100% (5)

- Tank Erection Itp & Org ChartDocumento34 páginasTank Erection Itp & Org Charthasan_676489616100% (2)

- Inspection and Test Plan For Shell and Tube Heat ExchangerDocumento6 páginasInspection and Test Plan For Shell and Tube Heat ExchangertomychalilAinda não há avaliações

- Inspection and Test Plan For Pressure VesselDocumento4 páginasInspection and Test Plan For Pressure VesselNurul Amirah Princesza100% (3)

- Welding Report For Tank 1Documento1 páginaWelding Report For Tank 1Rifki HasyaAinda não há avaliações

- Inspection of Storage Tank API - 650Documento4 páginasInspection of Storage Tank API - 650Michael Albuquerque0% (1)

- QA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsDocumento1 páginaQA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsvinothAinda não há avaliações

- WPS Resrvoire Sous Pression Smaw SawDocumento6 páginasWPS Resrvoire Sous Pression Smaw SawDanem HalasAinda não há avaliações

- Air Cooled Heat Exchanger Inspection and Test Plan SampleDocumento4 páginasAir Cooled Heat Exchanger Inspection and Test Plan Samplemkash028Ainda não há avaliações

- The Application of PUR Hotmelt Adhesive As Sealant For Washing MachineDocumento4 páginasThe Application of PUR Hotmelt Adhesive As Sealant For Washing MachinePankaj Choure100% (1)

- Hal Helicopter Division Training ReportDocumento41 páginasHal Helicopter Division Training ReportMayank Gupta67% (9)

- 10) Itp - Tank Fabrication PDFDocumento6 páginas10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- Inspection and Test Plan For Storage TankDocumento7 páginasInspection and Test Plan For Storage Tankgst ajahAinda não há avaliações

- Vacuum Box Testing ProcedureDocumento6 páginasVacuum Box Testing ProcedureKandula Raju100% (1)

- SOP Hydrotest Storage TankDocumento3 páginasSOP Hydrotest Storage TankRidwan Nursalam100% (1)

- Itp Storage TankDocumento10 páginasItp Storage Tankmuhammad afrizalAinda não há avaliações

- 5 - Tank Itp - Inspection & Test Plan For TanksDocumento9 páginas5 - Tank Itp - Inspection & Test Plan For Tanksmandi100% (1)

- Itp - Tanks - 01Documento10 páginasItp - Tanks - 01ravigurajapuAinda não há avaliações

- Pickling Procedure 20 - 08Documento2 páginasPickling Procedure 20 - 08Siriepathi SeetharamanAinda não há avaliações

- ITP For Field Erected Tank Rev ADocumento9 páginasITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- Site Erected Atmospheric Pressure Storage TankDocumento16 páginasSite Erected Atmospheric Pressure Storage TankRakesh RanjanAinda não há avaliações

- Hydrostatic Test Report SummaryDocumento1 páginaHydrostatic Test Report SummaryCipta AdikaryaAinda não há avaliações

- Vessel Inspection ProcedureDocumento17 páginasVessel Inspection ProcedureVimal RajAinda não há avaliações

- MS For Fabrication of Above-Ground Storage TankDocumento8 páginasMS For Fabrication of Above-Ground Storage Tankdadz mingiAinda não há avaliações

- To Commissioning Manual: Appendix No. 1Documento7 páginasTo Commissioning Manual: Appendix No. 1Bassem BalghouthiAinda não há avaliações

- Air Leak TestingDocumento5 páginasAir Leak TestingsarikaAinda não há avaliações

- Cairn Energy India Pty Limited Mangala Process Terminal Piping Fabrication ProcedureDocumento16 páginasCairn Energy India Pty Limited Mangala Process Terminal Piping Fabrication Procedurevpsimbu86Ainda não há avaliações

- Inspection & Test Plan TankDocumento3 páginasInspection & Test Plan TankJOSHUA SULLEGUE100% (1)

- 24.tank Oil Chalk TestDocumento3 páginas24.tank Oil Chalk TestShubham ShuklaAinda não há avaliações

- Tank Inspection NotesDocumento5 páginasTank Inspection Notesaneeshjose013Ainda não há avaliações

- Hydrostatic Test Procedure Storage TankDocumento15 páginasHydrostatic Test Procedure Storage TankYuwantoniAl75% (4)

- 3.painting InspectionDocumento2 páginas3.painting InspectionSRINIVASAN S M100% (1)

- Water Fill Up Testing Procedure-R3 07.07.2011sohar 2Documento7 páginasWater Fill Up Testing Procedure-R3 07.07.2011sohar 2AjeetKumarAinda não há avaliações

- Sample WPS 1Documento13 páginasSample WPS 1waqas pirachaAinda não há avaliações

- SOP Tank ConstructionDocumento24 páginasSOP Tank ConstructionSuci YatiningtiyasAinda não há avaliações

- ITP-PRESSURE VESSEL ExistingDocumento2 páginasITP-PRESSURE VESSEL ExistingArisAinda não há avaliações

- LAPESADocumento16 páginasLAPESAmusewejamesoumaAinda não há avaliações

- Inspection and Test Plan For Process PipingDocumento4 páginasInspection and Test Plan For Process PipingRobin GuAinda não há avaliações

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocumento19 páginasHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdAinda não há avaliações

- Hydro Vs PneumaticDocumento4 páginasHydro Vs PneumaticAnonymous rYZyQQot55Ainda não há avaliações

- Hydrostatic and Settlement Tests ProcedureDocumento12 páginasHydrostatic and Settlement Tests Procedureツ ツ100% (1)

- Qap HPCLDocumento13 páginasQap HPCLdarshan100% (1)

- Inspection RoleDocumento18 páginasInspection Rolesribd9128Ainda não há avaliações

- Pneumatic Test Procedure for Industrial SuppliersDocumento4 páginasPneumatic Test Procedure for Industrial SuppliersSalman Khan100% (1)

- Hindustan Petroleum Standard Piping Inspection Test PlanDocumento6 páginasHindustan Petroleum Standard Piping Inspection Test Planمحمد أزها نو الدينAinda não há avaliações

- Inspection and Test Plan for Storage TankDocumento7 páginasInspection and Test Plan for Storage TankABDELKADER BENABDALLAHAinda não há avaliações

- The Basics of API 650: Ir - SadaniDocumento98 páginasThe Basics of API 650: Ir - SadaniFadhilah QomariyantoAinda não há avaliações

- Inspection Plan For Tank With No Floating Part Needs To Be ImprovedDocumento6 páginasInspection Plan For Tank With No Floating Part Needs To Be ImprovedHussain M.SukarAinda não há avaliações

- Inspection and Test Plan For Storage Tank CompressDocumento6 páginasInspection and Test Plan For Storage Tank CompressSmit BhivgadeAinda não há avaliações

- Inspection-and-Test-Plan-for-Storage-TankDocumento6 páginasInspection-and-Test-Plan-for-Storage-TankVinayaga MoorthiAinda não há avaliações

- Inspection and Test Plan For Storage TankDocumento7 páginasInspection and Test Plan For Storage Tankzeeshan khanAinda não há avaliações

- Itp PipingDocumento4 páginasItp Pipingerdemlix100% (2)

- Inspection and Test Plan For Storage TankDocumento8 páginasInspection and Test Plan For Storage TankAndreas AlexanderAinda não há avaliações

- Inspection and Test Plan for SwitchgearDocumento12 páginasInspection and Test Plan for SwitchgearShahadat HossainAinda não há avaliações

- Process Piping Inspection and Test PlanDocumento6 páginasProcess Piping Inspection and Test Planmanoj thakkarAinda não há avaliações

- Inspection and Test Plan For Shell and Tube Heat ExchangerDocumento6 páginasInspection and Test Plan For Shell and Tube Heat ExchangerRobin Gu50% (2)

- Siemens: 1200 MW DGEN Mega Power ProjectDocumento4 páginasSiemens: 1200 MW DGEN Mega Power ProjectJuzer MadarwalaAinda não há avaliações

- Inspection and Test Plan For Switchgear: Before ManufacturingDocumento5 páginasInspection and Test Plan For Switchgear: Before ManufacturingzsmithAinda não há avaliações

- Inspection and Test Plan For Line Pipe PDFDocumento4 páginasInspection and Test Plan For Line Pipe PDFsherviny100% (1)

- Met-L-Chek penetrant inspection guideDocumento18 páginasMet-L-Chek penetrant inspection guidepluton1954Ainda não há avaliações

- Sonatest PDFDocumento16 páginasSonatest PDFpluton1954Ainda não há avaliações

- Sonatest PDFDocumento16 páginasSonatest PDFpluton1954Ainda não há avaliações

- NDT Cataloque PDFDocumento10 páginasNDT Cataloque PDFpluton1954Ainda não há avaliações

- Twin Compression PDFDocumento17 páginasTwin Compression PDFpluton1954Ainda não há avaliações

- WPS KinaDocumento17 páginasWPS Kinapluton1954Ainda não há avaliações

- RT API 650 BiHDocumento2 páginasRT API 650 BiHpluton1954Ainda não há avaliações

- Welding DefectsDocumento5 páginasWelding Defectspluton1954Ainda não há avaliações

- Vidi OvoDocumento2 páginasVidi Ovopluton1954Ainda não há avaliações

- WELLCAT Data Sheet 2 3Documento2 páginasWELLCAT Data Sheet 2 3Andres SilveyraAinda não há avaliações

- Aerated Lagoon: Types of Aerated Lagoons or BasinsDocumento4 páginasAerated Lagoon: Types of Aerated Lagoons or BasinsRaajiv MenonAinda não há avaliações

- Presentation GaN - Based Gas SensorsDocumento21 páginasPresentation GaN - Based Gas SensorsHaseeb Ud DinAinda não há avaliações

- QA-QC Requirement For Centrifugal Pump PartDocumento3 páginasQA-QC Requirement For Centrifugal Pump PartRuthai KomthaisongAinda não há avaliações

- Navy Welding ManualDocumento194 páginasNavy Welding Manualeugenemic100% (1)

- Language Selection: Search Site MenuDocumento6 páginasLanguage Selection: Search Site Menuprojit basuAinda não há avaliações

- 20 - Nordic - Mood 2021aDocumento22 páginas20 - Nordic - Mood 2021adisiya238Ainda não há avaliações

- Wikipedia - FoundaryDocumento7 páginasWikipedia - Foundaryshovit singh100% (1)

- Steel Suppliers in Doha - Qatar Business and Directory Listings PDFDocumento3 páginasSteel Suppliers in Doha - Qatar Business and Directory Listings PDFuzairmetallurgistAinda não há avaliações

- Berger: Product SpecificationsDocumento2 páginasBerger: Product SpecificationsAabhas UpadhyayaAinda não há avaliações

- Eu 01-6-0600Documento4 páginasEu 01-6-0600Faiz FSAinda não há avaliações

- Jig DesignDocumento23 páginasJig DesignЦырен ЖалсаповAinda não há avaliações

- Low Temperature Corossion (Molten Salt Corossion) in Black Liquor Recovery BoilersDocumento108 páginasLow Temperature Corossion (Molten Salt Corossion) in Black Liquor Recovery BoilersSIL PROJECTSAinda não há avaliações

- API 653 Minimum Thk. CalculationDocumento1 páginaAPI 653 Minimum Thk. CalculationSiva baalan0% (1)

- Oxyfuel Cutting - Process and Fuel GasesDocumento6 páginasOxyfuel Cutting - Process and Fuel Gasesunknown8787Ainda não há avaliações

- Steel As Construction MaterialDocumento5 páginasSteel As Construction MaterialYashi ShrivastavaAinda não há avaliações

- Sae Split Flange s1fs-32 - DWG - 1Documento1 páginaSae Split Flange s1fs-32 - DWG - 1kaliya12Ainda não há avaliações

- Matte Tin FaqDocumento2 páginasMatte Tin FaqBill TangelAinda não há avaliações

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocumento3 páginasWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaAinda não há avaliações

- C: T F F: Orrosion AND Abrasion HE Inal RontierDocumento3 páginasC: T F F: Orrosion AND Abrasion HE Inal Rontier1977julAinda não há avaliações

- BS en ISO 5457 Drawing Sheet SizesDocumento2 páginasBS en ISO 5457 Drawing Sheet SizesSai CharanAinda não há avaliações

- XcfbrochuDocumento6 páginasXcfbrochuuniversal8888Ainda não há avaliações

- Las Smaw 9 - Q2 W3-4Documento20 páginasLas Smaw 9 - Q2 W3-4Daryl TesoroAinda não há avaliações

- STRING WOUND CPPW Cartridge ContinentalDocumento1 páginaSTRING WOUND CPPW Cartridge ContinentalIndoarthawa FilterAinda não há avaliações

- Wire MeshDocumento2 páginasWire MeshsurangaAinda não há avaliações

- Tooling by Design - Hole Extrusions Part 1Documento2 páginasTooling by Design - Hole Extrusions Part 1BalaAinda não há avaliações