Escolar Documentos

Profissional Documentos

Cultura Documentos

01 Introduction To Lean 6 Sigma

Enviado por

Mohamed Maghawry0 notas0% acharam este documento útil (0 voto)

20 visualizações36 páginasLean 6 sigma is a management methodology and its goal is to improve dramatically the speed and the quality of all your processes, services and products. Lean origins 1900-1940 1945-1990 1996 2002-Present "Mass production of inexpensive cars using the assembly line" "toyota quality house" JIDOKA: Hilighting / Visualization of problems quality must be built in during the manufacturing process!

Descrição original:

Título original

01 Introduction to Lean 6 Sigma

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoLean 6 sigma is a management methodology and its goal is to improve dramatically the speed and the quality of all your processes, services and products. Lean origins 1900-1940 1945-1990 1996 2002-Present "Mass production of inexpensive cars using the assembly line" "toyota quality house" JIDOKA: Hilighting / Visualization of problems quality must be built in during the manufacturing process!

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

20 visualizações36 páginas01 Introduction To Lean 6 Sigma

Enviado por

Mohamed MaghawryLean 6 sigma is a management methodology and its goal is to improve dramatically the speed and the quality of all your processes, services and products. Lean origins 1900-1940 1945-1990 1996 2002-Present "Mass production of inexpensive cars using the assembly line" "toyota quality house" JIDOKA: Hilighting / Visualization of problems quality must be built in during the manufacturing process!

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 36

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

1

Introduction to Lean Six Sigma

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

2

Objectives

> Understand what is lean six sigma

> Understand what does a 6 sigma performance mean

> Learn what is the DMAIC framework

> Understand what are the opportunities to achieve the goal of 6 sigma

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

3

What is Lean 6 sigma?

1st) Lean 6 Sigma is a management methodology and its goal is to improve

dramatically the speed and the quality of all your processes, services and

products. It is:

> The combination of Lean with Six Sigma

> A problem solving method which is Customer centric

> It allows decision making based on data, measurements & statistics

> A pragmatic & disciplined approach (no solution before measurement

of problem and its root cause analysis plus control of implemented

solution over time)

> Business oriented, providing high returns

> Focused on reducing variability, defects and non value added tasks

> A philosophy, a common language and a goal to reach

2

nd

) A performance level: an indication of how well a process is performing

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

4

Lean Six Sigma

Lean Six Sigma is the integration of Lean and Six Sigma

! Increase speed of processes

! Eliminate the Wastes

! Improve quality

! Reduce defects and variation

An operational excellence methodology centered on Customers

A pragmatic, disciplined and results oriented approach

Lean Six Sigma

Resulting into

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

5

Lean origins

1900-1940 1945-1990 1996 2002-Present

Mass production of

inexpensive cars using

the assembly line

Toyota

Production

System

Lean

Thinking Five

Principles

Lean and

Six Sigma

Integration

Womack & Jones Michael George

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

6

Toyota Quality House

JIDOKA:

Hilighting/

Visualization of problems

Quality must be built in

during the manufacturing

process!

JIT:

Just In Time

Productivity Improvement

Making only "what is needed,

when t is needed,

and in the amount needed!"

Superior Quality

Reduce Costs & Delays

Improve Safety & Morale

+

Heijunka (Sequence plan) Standard Work Kaizen

Operational Stability

The Toyota Quality House was developed by Taiichi Ohno and Eiji Toyoda to make it easy to explain Toyota's

continuous improvement system to employees and suppliers. The aim of TPS is to eliminate all muri, mura,

muda (overburden, unevenness, waste) from the operations.

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

7

Lean five principles

Specify Value from the customers point of view

Identify Value Stream map process & see wastes

Flow move one piece at a time continuously

Pull let the customer pull your product

Perfection always improve the process

From Lean Thinking by James P. Womack and Daniel T. Jones, Free Press

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

8

Lean tools

Lean designates a set of tools which has been first used in Manufacturing in

the 60s (coming mainly from the Toyota Production System) and now used in

the service industry (business transactional processes). The Lean tools allow

the optimization of production and transactional processes:

> 7 forms of wastes (Mudas)

> 5 S (Clean, order and optimize the workplace)

> Kaizen event (Change to become good)

> Jidoka (Highlighting/Visualization of problems)

> Value Stream Mapping (Process value & Time analysis)

> Just in Time, Pulling systems & Kanban refurbishing systems

> Quick Changeover or SMED (Single Minute of Exchange of Dices - Setup time

optimization)

> TPM (Total Productive Maintenance)

> Process Standardization: alignment of the production with the demand (Takt time

synchronization, Heijunka (sequence plan), Standard Work)

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

9

Six Sigma origins

1989- 1990- 1994- 1995-Present

Premise of Six

Sigma

Adopters

of 6 sigma

1st Six Sigma

Consulting

company

Six Sigma

expanded to non

manufacturing

functions +

DFSS

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

10

Assumption:

Normal distribution

If I can place six times my

sigma value (standard

deviation) between my

process mean and a

specification limit then I am

operating at six sigma

6 sigma performance measurement

Characteristic

frequency

0

defects

3

10

1 2

50

!

Histogram

Specification

limit

> Sigma is a Greek letter which represents the standard deviation in

statistics.

> Performing at six sigma means that our process produces only 3.4 defects

per million of operations long term!!

6*!

Six Sigma

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

11

6 sigma scale

Z

ST

value

1.5 !

2 !

3 !

3.82 !

4 !

5 !

6 !

Defects* per million of

opportunities (dpmo)

500000

308537

66807

10000

6210

233

3.4

% defects

50.0000%

30.8537%

6.6807%

1.0000%

0.6210%

0.0233%

0.00034%

*observed with long term data. With Z

ST

=Z

LT

+1.5

! ,

defects

Z

LT

value

0 !

0.5 !

1.5 !

2.32 !

2.5 !

3.5 !

4.5 !

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

12

Six Sigma in terms of performance

Performance Commercial flights KPIs

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

13

What does 6 ! mean in financial services

Performance (simulation)

" 14 billions of transactions per day*

" 4 billions checks per year*

" 4 billions credit card transactions per year*

" 2 billions financial transactions per year*

A 19649 defect reduction factor between 3 ! and 6 ! !

at 6! at 3! (6,68% defects)

" 47600 defects

" 13600 defects

" 13600 defects

" 6800 defects

" 935 Millions defects

" ~267 Millions defects

" ~267 Millions defects

" ~134 Millions defects

Processes

*EDS data

**VISA data

Services traditional performance

" 19.789 billions credit & debit card

transactions per year**

" 67283 defects " 1.322 billion defects

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

14

Who is applying Lean Six Sigma?

> ALLIANZ

> AIRBUS

> AXA

> BANK OF AMERICA

> CLARIANT

> DEUTSCHE TELEKOM

> DHL

> GENERAL ELECTRIC

> HSBC

> SIEMENS AG

> ..

> 95%+ of Fortune 100 companies

GE advertised that by applying Lean Six Sigma/simplification to its core

processes it will deliver 8% organic growth GE Nov. 05 Immelt update

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

15

Lean 6 sigma financial impact

Cost of poor quality

(in % Sales)

40%

35%

30%

20%

15%

10%

5%

DPMO 3.4 233 6210 66807 308537 500000

Sigma 6 5 4 3 2 1

Budget :

I sell 10 $ every unit

Operational margin = 25% (2.50 $)

every defect costs me 24 $!

at 2,67 ! (12,08% defects) I lost 40 cents for

every unit I sold!!

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

16

Lean Six Sigma benefits

> Revenue growth through:

increased customer satisfaction

introduction of quality products & services

> Margin increase through:

less non quality costs (reduction of defects, wastes and manual

rework)

more productivity and capacity (reduced cycle times)

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

17

Optimization Potentials with one project

> Cycle times: reduction of 30%-70%

> Defects: reduction of 70%

> Costs: reduction of 30%-50%

> Capacity: increased by 20%

> Productivity: increased by 20%-25%

> ROI of 3 to 4

> 4 months projects. Typical projects brings 300 to 400 K" of benefits

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

18

Lean Six Sigma for which project?

Initial situation: I have an issue/project:

> I know the solution:

> I do not know the solution:

> It is an existing process or an

existing product:

> It is a new process or a new

product to design:

JUST DO IT

DMAIC

DFSS

(DMADV)

Method Timing

Immediate

4 to 6 months

6 months

KAIZEN 1 week

OTHERS 1+ year

Lean Six Sigma focus

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

19

How to get the benefits of Lean 6 Sigma?

Select, train & coach people

Select key processes

Select Lean 6 Sigma projects

Complete Lean 6 Sigma projects#""

Market

/Customer

expectations

Company strategy

CTQs*

Cycle time

*CTQ Critical To Quality

Customer eyes

Quality

Cost

Processes

Voice of Customer

Continuous

Improvement

Loop

Risk

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

20

Customer impact

mean moved from 3 days to 2.2

days. We are improving!

Traditional view

Lean 6 sigma view

mean moved from 3 days to 2.2

days and standard deviation from

0.5 to 1. With a spec of 4 days

maximum, we have more issues.

We are improving our internal

process from 7% of defects to

6.5%. Our customers will be

happier!

We measured end to end and

found out that our customer

process did not yet improve.

Not sure

Not sure certain

certain

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

21

Who is doing what in Lean Six Sigma?

Top Management

Champion

Sponsor

Stakeholders

Finance

Master Black Belt/Expert

Black Belt/Project Leader

Green Belt/Team member

Engage/promote Lean 6 sigma

Select processes, projects & people.

Make plan. Change Agent

Has a business issue. Pays the costs of

the project and gets the benefits

Represent the functional teams which

will be impacted by pthe project

Validate the business case

Is a Lean Six Sigma expert. Train and

coach Black Belts and Green Belts

Delivers Lean 6 Sigma projects. Full

time project leader.

Contributes/leads Lean 6 Sigma

projects

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

22

Lean 6 sigma example

Lets take an example:

> The cycle time of a distribution company, from customer order to

customer delivery should not exceed 3 days (our contractual terms &

conditions)

> The Customers complain.

> The competitors are better than us. They never exceed 3 days

> The Management says we are loosing money

> The team in place says we dispatch in average the same day we receive

the order and we always use a 24 hours delivery carrier

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

23

What says Lean 6 sigma

> If there is an output, there is a process!

> If there is a process there is a performance variation

> If there is variation there is a probability of defect (missing our customer

specifications or our contractual obligations!)

> The customer feels always the output process variation. This is how he

perceives your quality!

> A 6 sigma process produces only 3.4 defects per million of operations

> A process operating at 3 sigma produces 66807 defects per million of

opportunities

> A 3 sigma process cost you up to 20 % of your sales revenue

> A 6 sigma process cost you less than 1% of your sales revenue

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

24

The 5 phases of a Lean 6 Sigma project

(DMAIC framework)

Define

Measure

Analyze

Improve

Control

Define your business problem

Measure your process (Y) performance

Find the root causes (Xs) of the problem

Improve, implement new solution

Deliver Y performance over time

Close project

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

25

The 5 phases of a Lean 6 Sigma project

Define

Measure

Analyze

Improve

Control

Define Y

Y AS IS Process performance

Find the root causes (As Is Y=f(Xs))

Y To Be Process

Y To Be Process performance over time

Close project

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

Define

Define your business problem, your objective and your project plan

1. Deliver a Project Charter with:

Problem, Objective, Scope, Business Case, Risks identified

Process Map, Indicator, Project plan, Resources

Improve

M

A

I

C

D

Measure Measure your process performance (Y) and its defects

2. Define your CTQ(s)

3. Analyze the measurement system (Gage R&R)

4. Measure the current process performance and capability

Find 20% of root causes (Xs) which create 80% of the issues

5. AS IS process analysis (VSM, Cause and Effect analysis, FMEA, )

6. Data analysis (graphical analysis, statistical analysis)

7. Main root causes analysis synthesis

Design & implement solution(s) which fix the main root causes of issues

8. Design and develop solutions

9. Implement the solutions (Pilot and/or Deployment)

10. Control that the performance is better

Control that the performance is stable over time (stable solution)

11. Establish a Statistical Process Control

12. Close project, Verify financial gains

Analyze

Control

The 12 steps of a Lean 6 Sigma project

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

27

process felt by the customer

Customer

Input

Order

Output

Unit delivery

Definition Specification Performance

limit

Targets/goal

CTQ* Lead time 3 days 99% < 3 days

Procurement

Collect Order &

Forward

to delivery dept

Ship

to Customer & Bill

Customer

Lead time is the measurement

*Critical To Quality

Problem statement: we miss our contractual obligations of delivering in less than 3 days

Process in which we have a business problem:

Define

?

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

28

Measure

Measure your problem and your defects

Lead time distribution

Time from

order to delivery

in days

nb of

occurences

0

defects

Contractual/Customer

Specification

Limit

3 days

10

1 day 2 days

50

Histogram

Observed probability

of defects=12.03%

26/216

Variation

Trend

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

29

Measure conclusion

I observed a probability of defect of 12.03%!

My performance is 2.67 !ST*. We have a problem!

6 sigma goal is to reach 0.00034% of probability of defect!

ZST value*

2 !

3 !

4 !

5 !

6 !

Defects per million of

opportunities

308537

66807

6210

233

3.4

% defects

30.8537%

6.6807%

0.6210%

0.0233%

0.00034%

12.03% 2.67 !

* For long term data with ZST=ZLT+1.5

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

30

Analyze

Analysis finding the root causes (Xs)!

> Pareto chart of the 26 defects

Miss 3 pm

carrier for

outside

Paris

region

20

77%

Incomplete

shipping

address

4

15%

Other

2

8%

> 2 causes represent 92% of my defects

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

31

Improve

2 actions taken:

> Speed cycle by

processing Outside

Paris region orders

first & organize an

earlier transfer to

shipping department

by removing some

non value added

tasks (unnecessary

sign offs)

> Change address

format and control it

at order time (avoid

quality issues)

Time from

order to delivery

in days

nb of

occurences

0

defects

Contractual/Customer

Specification

Limit

3 days

10

1 day 2 days

50

Histogram

Short term data

Observed probability

of defects=0%

Expected performance: 6 !

I can place 6 ! between

and the spec. limit and the

distribution is normal!

!

6x!

New Cycle time from order to delivery distribution

KAIZEN

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

32

Control

2003 Delivery time performance

P99 = percentile 99%

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

33

Take orders offline

(laptop)

Submit order to

Manufacturing

Sales

Repr.

Update orders

on Intranet

Synchronize orders

by email connection

Coordi

nator

orders

eBook

Production

orders

Nb of Manual

Human Interactions*

Before

4

6

After

1

1

W

e

b

O

r

d

e

r

B

o

o

k

p

r

o

j

e

c

t

* averages

st dev 1.6 st dev 1

What could Lean 6 Sigma do for you?

520 K$ of

saving

TOTAL 10 2

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

34

% of time spent by 8 persons doing financial manual

entries before and after FPA project implementation

27% reduction of time spent by 8 financial analysts

gives 1.75 Full Time Employee proven benefit!

> 140 K$ saving

> Overtime reduced

> Interim reduced

> More time for analysis

(added value task)

Base Costs

What could Lean 6 sigma do for you?

Before After

100%

50%

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

35

Summary

> Lean six sigma is a problem solving methodology that speaks with data,

which takes into account only the customer point of view & experience

and which propose solutions only after analysis, not before

> Six sigma performance is equivalent to 3.4 defects per million of

operations

> There is a direct link between our current level of performance and the

margins we are making

> Lean and Six Sigma have been integrated into Lean Six Sigma to achieve

one goal: reduce variation, wastes and non value activities in our

processes

> DMAIC is the framework to solve a problem and to complete a lean six

sigma project

Copyright 2009-2010 Equable

All rights reserved

01 Introduction to lean 6 sigma

36

www.equable.fr

email: franck.strub@equable.fr

Six Sigma is a federally registered trademark of Motorola, Inc. Lean Six Sigma is a registered trademark of George Group Consulting, L.P..

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Best Practices in Management AccountingDocumento275 páginasBest Practices in Management AccountingmostfaAinda não há avaliações

- CNAF NAE GB Student Book (Ver 1070)Documento190 páginasCNAF NAE GB Student Book (Ver 1070)Joshua StuartAinda não há avaliações

- MOT Presentation 12Documento118 páginasMOT Presentation 12Kaushal Shrestha50% (2)

- LEGO Simulation OverviewDocumento17 páginasLEGO Simulation Overviewleansimulation810667% (6)

- Operational Excellence Masterclass For Business GrowthDocumento12 páginasOperational Excellence Masterclass For Business GrowthVijayAinda não há avaliações

- Six Sigma Is A Business Management Strategy, Originally Developed byDocumento68 páginasSix Sigma Is A Business Management Strategy, Originally Developed by9897856218Ainda não há avaliações

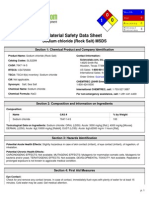

- Sodium Chloride (Rock Salt) MSDS: Section 1: Chemical Product and Company IdentificationDocumento6 páginasSodium Chloride (Rock Salt) MSDS: Section 1: Chemical Product and Company IdentificationMohamed MaghawryAinda não há avaliações

- Sodium Hydroxide, Pellets, Reagent ACS MSDS: Section 1: Chemical Product and Company IdentificationDocumento6 páginasSodium Hydroxide, Pellets, Reagent ACS MSDS: Section 1: Chemical Product and Company IdentificationMohamed MaghawryAinda não há avaliações

- Calcium Hypochlorite MSDS: Section 1: Chemical Product and Company IdentificationDocumento6 páginasCalcium Hypochlorite MSDS: Section 1: Chemical Product and Company IdentificationMohamed MaghawryAinda não há avaliações

- xMSDS-Ferrous Sulfate Heptahydrate-9924057 PDFDocumento6 páginasxMSDS-Ferrous Sulfate Heptahydrate-9924057 PDFMohamed MaghawryAinda não há avaliações

- Sodium Chloride (Rock Salt) MSDS: Section 1: Chemical Product and Company IdentificationDocumento6 páginasSodium Chloride (Rock Salt) MSDS: Section 1: Chemical Product and Company IdentificationMohamed MaghawryAinda não há avaliações

- Sodium Hypochlorite, 12% MSDS: Section 1: Chemical Product and Company IdentificationDocumento6 páginasSodium Hypochlorite, 12% MSDS: Section 1: Chemical Product and Company IdentificationMohamed MaghawryAinda não há avaliações

- Sodium Hydroxide, Pellets, Reagent ACS MSDS: Section 1: Chemical Product and Company IdentificationDocumento6 páginasSodium Hydroxide, Pellets, Reagent ACS MSDS: Section 1: Chemical Product and Company IdentificationMohamed MaghawryAinda não há avaliações

- Ivy Tech Course DescriptionsDocumento172 páginasIvy Tech Course DescriptionsEA MorrAinda não há avaliações

- The Toyota Way in Services: The Case of Lean Product DevelopmentDocumento18 páginasThe Toyota Way in Services: The Case of Lean Product DevelopmentErnesto GPAinda não há avaliações

- CHAPTER 1 - History of Kaizen & Lean ManagementDocumento8 páginasCHAPTER 1 - History of Kaizen & Lean Managementsam100% (1)

- Lean Manufacturing and Kaizen Theory PowerpointDocumento8 páginasLean Manufacturing and Kaizen Theory Powerpointapi-175031154Ainda não há avaliações

- SynopsisDocumento6 páginasSynopsisSagar JoshiAinda não há avaliações

- Harvey 2016 - 5s Impact On Safety Climate of Manufacturing WorkersDocumento29 páginasHarvey 2016 - 5s Impact On Safety Climate of Manufacturing WorkersShanil ShahAinda não há avaliações

- Competitive Manufacturing Systems Software, Simulation, and DatabaseDocumento11 páginasCompetitive Manufacturing Systems Software, Simulation, and DatabasekarthipriyaAinda não há avaliações

- 1 s2.0 S2351978920301281 MainDocumento10 páginas1 s2.0 S2351978920301281 MainHa M ZaAinda não há avaliações

- Project SampleDocumento63 páginasProject SampleNilesh SatoseAinda não há avaliações

- IJPR2016 Lacerda Xambre Alvelos 2Documento14 páginasIJPR2016 Lacerda Xambre Alvelos 2Finda Bangkit WidiartoAinda não há avaliações

- 10 1108 - Ijqrm 09 2020 0328Documento32 páginas10 1108 - Ijqrm 09 2020 0328Oscar ResurreccionAinda não há avaliações

- GRC Acctg For Mats, Labor, & OH ModuleDocumento15 páginasGRC Acctg For Mats, Labor, & OH ModuleKirk EscanillaAinda não há avaliações

- Braun Ma3 SM 04.doccvbcvbDocumento82 páginasBraun Ma3 SM 04.doccvbcvbKia PottsAinda não há avaliações

- PuSm - Lecture 1 - Chapter 1 - Slides - Online (1) - CópiaDocumento38 páginasPuSm - Lecture 1 - Chapter 1 - Slides - Online (1) - CópiaLaura FernandesAinda não há avaliações

- Makalah 122130082Documento12 páginasMakalah 122130082Annisa Bintang AyuAinda não há avaliações

- A Proposed Dynamic Model For A Lean Roadmap PDFDocumento12 páginasA Proposed Dynamic Model For A Lean Roadmap PDFPramod AthiyarathuAinda não há avaliações

- CIM JournalDocumento22 páginasCIM JournalInjamamul HaqueAinda não há avaliações

- Demand Driven MRPDocumento16 páginasDemand Driven MRPManel VazquezAinda não há avaliações

- Corporate Profile - Shrishti Consultants 20Documento37 páginasCorporate Profile - Shrishti Consultants 20Shrishti ConsultantsAinda não há avaliações

- Bussiness Excelence)Documento20 páginasBussiness Excelence)KelensantAinda não há avaliações

- CL 3 Advanced Management AccountingDocumento236 páginasCL 3 Advanced Management Accountingsanu sayed100% (1)

- KaizenDocumento5 páginasKaizenMaison_Orion_9800Ainda não há avaliações

- Acct 3314 Assignment 1Documento3 páginasAcct 3314 Assignment 1RCG92% (13)

- Gemba Kaizen by Masaaki ImaiDocumento4 páginasGemba Kaizen by Masaaki ImaiReynold EdpAinda não há avaliações