Escolar Documentos

Profissional Documentos

Cultura Documentos

Alco EC2-5x1

Enviado por

IonutCiobanuTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Alco EC2-5x1

Enviado por

IonutCiobanuDireitos autorais:

Formatos disponíveis

Copeland EazyCool

TM

outdoor condensing units

A

p

p

l

i

c

a

t

i

o

n

G

u

i

d

e

l

i

n

e

s

Controller EC2-5X1

Application Guideline: Copeland EazyCool

TM

outdoor condensing unit controller EC2-5X1

1 Safety Instructions..................................................................................................... 3

1.1 ICON EXPLANATION .................................................................................................. 3

1.2 SAFETY STATEMENTS ............................................................................................... 3

2 Product Description .................................................................................................. 4

2.1 EC2-5X1 NOMENCLATURE....................................................................................... 4

2.2 EC2-511 CONDENSING UNIT CONTROLLER............................................................... 5

2.3 EC2-551 CONDENSING UNIT CONTROLLER............................................................... 6

3 Display ........................................................................................................................ 7

3.1 NEURON ID / SERVICE BUTTON ................................................................................ 7

3.2 LOAD DEFAULT PARAMETERS ................................................................................... 7

4 Parameters ................................................................................................................. 8

4.1 SELECT PARAMETER CONFIGURATION........................................................................ 8

4.2 PARAMETER MODIFICATION ...................................................................................... 8

4.3 SPECIAL FUNCTIONS................................................................................................. 8

5 Indications on the Display ........................................................................................ 9

5.1 CONTROLLER 1........................................................................................................ 9

5.2 CONTROLLER 2........................................................................................................ 9

5.3 OTHER DISPLAY INDICATIONS .................................................................................... 9

6 List of Parameters ..................................................................................................... 9

6.1 CONTROLLER 1 (COMPRESSOR CAPACITY STAGING CONTROLLER)............................ 10

6.2 CONTROLLER 2 (FAN CONTROLLER)........................................................................ 15

6.3 IMPORTANT PARAMETERS ON EC2-551................................................................... 17

6.3.1 EC2-551 FOR TWO-COMPRESSOR UNITS WITH FAN SPEED CONTROLLER.......... 17

6.3.2 EC2-551 FOR UNITS WITH COPELAND DIGITAL SCROLL COMPRESSOR ............. 17

7 Alarms and Messages ............................................................................................. 18

7.1 ALARM CODES........................................................................................................ 18

7.2 MESSAGES............................................................................................................. 20

8 Technical Specifications......................................................................................... 21

8.1 SAFETY STANDARD ................................................................................................ 21

C6.1.3/0505-0705/E Part no: 3125495

Condensing Unit Controller EC2-5X1

E

n

g

l

i

s

h

F

r

e

n

c

h

G

e

r

m

a

n

1 Safety Instructions

1.1 Icon explanation

WARNI NG

This Icon indicates instructions to avoid heavy personnel injuries and heavy material

damage.

Hi gh Vol t age

This icon indicates operations with a danger of an electric shock.

Danger of bur ni ng or f r ost bi t e

This icon indicates operations with a danger of burning or frostbite.

Ex pl osi on Hazar d

This Icon indicates operations with a danger of explosion.

CAUTI ON

This Icon indicates instructions to avoid property damage without or with low personnel

injuries.

I MPORTANT

This icon indicates instructions to avoid malfunction of the compressor.

NOTE this word indicates a recommendation for easier operations.

1.2 Safety statements

Only qualified and authorised refrigeration personnel are allowed to do the

installation, commissioning and maintenance.

Qualified electrical personnel must connect the condensing unit and its

accessories.

All valid standards for connecting electrical and refrigeration equipment must be

observed.

C6.1.3/0505-0705/E Part no: 3125495 3

Condensing Unit Controller EC2-5X1

2 Product Description

The EC2-5X1 electronic condensing unit controller has been specially developed for the

Copeland EazyCool condensing unit range.

The EC2-5X1 electronic condensing unit controller is mounted as standard in the

following Copeland EazyCool condensing units:

Copeland EazyCool stand alone two compressor condensing units: EC2-

511

Copeland EazyCool stand alone Digital Scroll condensing units: EC2-

551

o Single compressor condensing unit

o Two compressor condensing unit

Copeland EazyCool condensing units for refrigeration networks: EC2-

551

The electronic controller enables:

1. Compressor modulation and/or staging based on suction pressure

2. LON (Local Operating Network) communication if connected to a PC with a

LON interface installed, monitoring of operation parameters (pressures,

temperatures as well as alarm states) becomes possible.

3. Fan speed control if an Alco Controls FSP150 fan speed driver is installed

(available as a factory fitted option).

2.1 EC2-5X1 Nomenclature

* Max. 2 compressor with on/off modulation

* Max. 2 condenser fans with on/off modulation

* Max. 2 compressors with on/off modulation, including

optional fan speed controller AlcoControls FSP150 with analog

output or

* Max. 2 compressors with one of compressors being a

Copeland Digital Scroll

TM

and including optional fan speed

controller AlcoControls FSP150 with analog output

5X1

X =1: EC2-511

X =5: EC2-551

EC2-

EC2 Platform

similar to Alco Controls EC2 electronic temperature /

superheat controllers

The next pages contain a description of these controllers and the parameters that can be

changed. The controller has been pre-programmed with a number of parameter values

that are most likely correct. Individual installation requirements however may make it

necessary to alter parameter settings (e.g. suction pressure settings for compressor

capacity staging, control dead band, refrigerant parameter).

Hi gh Vol t age

Attention: Before carrying out work on the condensing unit, make sure that main power

supply to the unit has been switched off!

4 Part no: 3125495 C6.1.3/0505-0705/E

Condensing Unit Controller EC2-5X1

2.2 EC2-511 Condensing Unit Controller

Copeland EazyCool condensing units with 2 compressors are equipped with an EC2-

511 electronic Controller modulating compressors and fans in commercial refrigeration

applications.

In fact there are two controllers present in the EC2-511 condensing unit controller:

1 (one) for controlling compressor capacity and,

1 (one) for controlling condenser pressure.

The control target of the compressor controller is to maintain the suction pressure at a

defined value by varying the available compressor capacity based on the ON/OFF of the

compressors (EC2-511 controller).

The control target for the condenser controller is to maintain the condensing pressure at

a defined value by switching fans on/off on the Standard version (Two-compressor unit

without fan speed controller - EC2-511 Controller)

For the measurement of the suction pressure and the condensing pressure, two Alco

Controls PT4 pressure sensors with 4~20 mA interfaces are connected to the condensing

unit controller.

The controller has:

Four relay outputs; 2 for compressor control and 2 for fan control

Three digital inputs for Volt-free input contacts are available

o two of these are used for compressor serial alarm

o the third - available for a fan serial alarm - is provided with a link, which

should be removed, for use with an external serial alarm loop.

The display can show values with a decimal point in the range between -19.9 and +19.9

otherwise without decimal point.

An IR receiver for the optional IR remote control unit is built-in.

For communication purposes, an Echelon LONWorksinterface is provided (TP/FT-10

transceiver type).

The supply voltage is 24 V AC. A transformer for 230V main supply to 24 V AC is fitted in

the Copeland EazyCool condensing unit electrical panel.

E

n

g

l

i

s

h

F

r

e

n

c

h

G

e

r

m

a

n

C6.1.3/0505-0705/E Part no: 3125495 5

Condensing Unit Controller EC2-5X1

2.3 EC2-551 Condensing Unit Controller

The Condensing unit controller EC2-551 is fitted as standard on:

Copeland EazyCool condensing units with Copeland Digital Scroll

compressors

Copeland EazyCool condensing units with two compressors and equipped with

fan speed controller module Alco Controls FSP150 (optional).

Copeland EazyCool condensing units for refrigeration networks

The condensing unit may have up to two compressors (of which one can be a Copeland

Digital Scroll compressor) and 2 fans. Both fans can be fan speed controlled using a FSP

150 module (optional or fitted as standard, depending on the condensing unit model),

using the analogue output of the EC2-551.

In fact there are two controllers present in the EC2-551 controller:

one for controlling the compressor capacity, and

one for controlling the condenser pressure.

The control target of the compressor controller is to maintain the suction pressure at a

defined value by varying the available compressor capacity.

The control target for the condenser controller is to maintain the condensing pressure at

a defined value by varying the fan speed.

For the measurement of the suction pressure and the condensing pressure, two Alco

Controls PT4 pressure sensors with 4~20 mA interface can be connected to the

controller.

The controller has:

relay outputs to switch the compressors

a 0-10V output to control the fan speed

1 Triac for modulation of the Copeland Digital Scroll compressor

3 digital inputs for Volt-free input contacts are available:

o 2 for compressor serial alarm,

o 1 for fan serial alarm.

6 Part no: 3125495 C6.1.3/0505-0705/E

Condensing Unit Controller EC2-5X1

The display can show values with a decimal point in the range between -19.9 and +19.9

otherwise without decimal point.

An IR receiver for the optional IR remote control unit is build-in.

For communication purposes, an Echelon LONWorksinterface is provided with

transceiver type FTT10A.

The supply voltage is 24 V AC. A transformer for 230V main supply to 24 V AC is fitted in

the Copeland EazyCool condensing unit electrical panel.

3 Display

The data to be shown on the display can be selected by the user. In case of on alarm, the

alarm code is displayed alternately with the selected data.

The data shown on the display are the compressors and fans states (default), the

suction pressure, the saturation temperature from the suction pressure, the condensing

pressure and the saturation temperature from condensing pressure.

To scroll through all possible displayable data press the SEL button. The display will

show for one second the numerical identifier of the data and then the selected data. After

2 minutes the display will return to the selected data.

3.1 Neuron ID (unique 12 digit identity number, required for LON

communication) / Service Button

Press the button for approximately 1 second to send the Neuron ID.

An LED (Service) in the left upper corner will indicate the transmission of the Neuron ID.

3.2 Load Default Parameters

By pressing the service pin key on the controller and switching on the power supply,

the EC2-551 will be reset to default parameters.

Controller 2: Fan

Value to be displayed :

LED ON: pressure

LED OFF: temperature

Compressor 1 :on

Fan : on

Compressor 2 :on

IR service LED

E

n

g

l

i

s

h

F

r

e

n

c

h

G

e

r

m

a

n

Active alarm

Controller 1: Compressor

C6.1.3/0505-0705/E Part no: 3125495 7

Condensing Unit Controller EC2-5X1

4 Parameters

4.1 Select parameter configuration

The configuration parameters can be protected by a numerical password. A value of 0

disables this protection (default password: 12). To select the parameter configuration:

Press the PRG button for more than 5 seconds

In case of password value equal to 0:

The first modifiable parameter code is displayed (/1).

To modify parameters see Parameter modification below.

In case of password value not equal to 0:

A flashing 0 is displayed

Press or until the password value is displayed.

Press SEL to confirm password

The first modifiable parameter code is displayed (/1).

To modify parameters see Parameters modification below.

4.2 Parameter Modification

Press or to show the code of the parameter that has to be changed;

Press SEL to display the selected parameter value;

Press or to increase or decrease the value;

Press SEL to temporally confirm the new value and display its code

Repeat the procedure from the beginning "press or to show..." to modify another

parameter, etc.

To exit modifying the parameters with the new values:

Press PRG to confirm the new values and exit the parameter modification

procedure.

To exit without modifying any parameter:

Do not press any button for at least 60 seconds (TIME OUT).

4.3 Special Functions

Press and together for more than 5 seconds: a flashing 0 is displayed.

Press or until the password is displayed (default =12). If password was

changed, select the new password.

Then press SEL to confirm password

A 0 is displayed and the special function mode is activated.

Press or to select function (see list below)

Press SEL to activate the function and dont leave the special function mode.

Press PRG to activate the function and leave the special function mode.

Most of the special functions work in a toggle mode, the first call activates the

function and the second call deactivates the function. The indication of the

function can only be displayed when the special function mode will be left.

0: display test function

3: resets all parameters to the default factory settings

1 & 2: not active for EC2-511 and EC2-551

8 Part no: 3125495 C6.1.3/0505-0705/E

Condensing Unit Controller EC2-5X1

E

n

g

l

i

s

h

F

r

e

n

c

h

G

e

r

m

a

n

5 Indications on the Display

EC2 controller includes 2 control modules, the first is dedicated for compressor(s)

modulation (controller 1), the second is dedicated for fan(s) modulation (controller 2).

5.1 Controller 1

Controller 1 state (compressor controller)

Controller 1 alarm in combination with alarm message and alarm LED

Suction pressure or saturation temperature from suction pressure

Controller 1 parameter

5.2 Controller 2

Controller 2 state (condenser fan controller).

Controller 2 alarm in combination with alarm message and alarm LED

Condensing pressure or saturation temperature from condensing pressure

Controller 2 parameter

5.3 Other display indications

Pressure: Pressure value in bar(g)

Alarm: Alarm condition

IR: IR communication enabled

Service: Transmission of Neuron ID indicator

NOTE: Concerning the indicated parameters, it is recommended to check - before

installing - if the factory value is suitable for the required use.

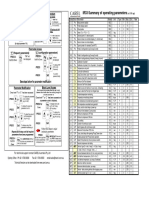

6 List of Parameters

Parameter

/ Display Parameters Min Max Unit Def Min Max Unit Def

/1 Value to be shown on display 0 4 - 0 0 7 - 0

EC2-551 EC2-511

/1 Value to show on display

0 =compressors and fans states (controller 1 =Compressor(s), and controller 2 =Fan(s))

1 =suction pressure (bar(g))

2 =saturation temperature from suction pressure (C)

3 =condensing pressure (bar(g))

4 =saturation temperature from condensing pressure (C)

5 =Digital Scroll capacity (%)

6 =Fan speed (%) Only for controller EC2-551

7 =Digital Scroll discharge temperature (C)

C6.1.3/0505-0705/E Part no: 3125495 9

Condensing Unit Controller EC2-5X1

6.1 Controller 1 (Compressor capacity staging controller)

Parameter

P Set Point Parameters Min Max Unit Def Min Max Unit Def

P0 Pressure set-point (suction) for compressor circuit -1.0 50.0 bar(g) 3.0 -1.0 50.0 bar(g) 3.0

P1

Pressure band (control band for P/PI, dead band for

control mode)

0.0 50.0 bar 2.0 0.0 50.0 bar 2.0

P3 Fast recovery from low pressure -9.9 50.0 bar(g) -9.9 -9.9 50.0 bar(g) -9.9

P8 High discharge pressure recovery -9.9 50.0 bar(g) 50.0 -9.9 50.0 bar(g) 50.0

EC2-511 EC2-551

P0: Set point for modulation should be fixed to the suction pressure required by

installation.

P1: Dead band default setting point should be around 2 bar in medium temperature and

should be reset to around 0.4 bar for low temperature. Dead band should be proportional

to the pressure set point (i.e.: P0 =0.4 - P1 =0.2 or P0 =2 - P1=1).

3: This is a threshold to protect compressors from running at low suction pressures.

protect the refrigeration system from running into high pressure

tive

P

When reached, all compressors are switched off instantly without obeying any delay

times (not active by default). In case of activation, set point should be above the low-

pressure switch setting.

P8: This is a threshold to

limits. When limits are reached, if all compressors are running, one of the running

compressors is switched off, if necessary without obeying of the delay times (not ac

by default). In case of activation, set point should be below the high pressure switch

setting.

10 Part no: 3125495 C6.1.3/0505-0705/E

Condensing Unit Controller EC2-5X1

E

n

g

l

i

s

h

F

r

e

n

c

h

G

e

r

m

a

n

Parameter

t Time Parameters Min Max Unit Def Min Max Unit Def

t1

1)

Time delay before adding capacity 0 99 10sec 3 0 99 10sec 3

t2

1)

Time delay before removing capacity 0 99 10sec 3 0 99 10sec 3

t3

1)

Compressor minimum on time 0 99 10sec 6 0 99 10sec 6

t4

1)

Compressor minimum off time 0 99 10sec 6 0 99 10sec 6

t5 Maximum compressor switching 0 199 1/hr 0 0 199 1/hr 0

Parameter

A Alarm Parameters Min Max Unit Def Min Max Unit Def

A2 Minimum suction pressure alarm limit -1.0 50.0 bar(g) 0.0 -1.0 50.0 bar(g) 0.0

A3 Maximum suction pressure alarm limit -1.0 50.0 bar(g) 50.0 -1.0 50.0 bar(g) 50.0

A4

1)

Delay time for minimum pressure alarm limit 0 99 10sec 0 0 99 10sec 0

A5

1)

Delay time for maximum pressure alarm limit 0 99 10sec 0 0 99 10sec 0

A6

High discharge temperature cut-out

(cut-in =cut out -10C)

- - - - 100 140 C 130

A8

1)

Compressor serial alarm delay 0 99 10sec 0 0 99 10sec 0

A9

2)

Compressor run limit before Maintenance 0 99 10k Hr 0 0 99 10k Hr 0

EC2-511 EC2-551

EC2-511 EC2-551

1)

Value shown in display is 10 times lower

2)

These values have a resolution of 10.000 hours, on the local display. Example: value 1

means 10.000 hours.

A2: Minimum limit for suction pressure alarm Value will be fixed on same value than the

mechanical LP safety switch

A3: Maximum limit for suction pressure alarm Inactive by default

If this function is active and the suction pressure is above the maximum value A3, an hP1

alarm signal will appear, followed by the measured pressure value. It is important to know

that the alarm signal will stay until temperature decreases and suction pressure stabilises

below maximum value A3.

A6: High discharge temperature cut-out for Digital Scroll compressor only fixed at

130C

Parameter

u Step enable Parameters Min Max Unit Def Min Max Unit Def

u0 Reset operating time 0 3 - 0 0 3 - 0

u1 Enable/disable compressor 1 0 1 flag 1 0 1 flag 1

u2 Enable/disable compressor 2 0 1 flag 1 0 1 flag 1

EC2-511 EC2-551

u0 Compressor reset operating time

0 =do nothing

1 =reset operating time compressor 1

2 =reset operating time compressor 2

3 =reset operating time all compressors

C6.1.3/0505-0705/E Part no: 3125495 11

Condensing Unit Controller EC2-5X1

Parameter

c Application Parameters Min Max Unit Def Min Max Unit Def

c1 Number of compressors 1 2 - 2 1 2 - 2

c3 Control mode (network system) 2 3 - 2 2 3 - 2

c4 Compressor 1 control mode 0 1 - 0 0 2 - 0

c5 Compressor switch logic 0 1 flag 1 0 1 flag 1

c6

Number of compressor to switch on in case of sensor

failure

0 2 - 0 0 2 - 0

EC2-511 EC2-551

c1 Number of compressors

This default parameter is set to 2 for two-compressor Copeland EazyCool condensing

units.

For single-compressor Copeland EazyCool condensing units with Copeland Digital

Scroll, c1 should be changed to 1.

c3 Control mode

This parameter is not active for stand alone units, it only applies to units used in

refrigeration networks.

c4 Compressor 1 control mode

0 =compressor 1 in standard control loop

1 =compressor 1 act as base load compressor

2 =compressor 1 act as modulating (PWM control for Copeland Digital Scroll

compressor only - not in use for EC2-511)

c5 Compressor switch logic

0 =FILO logic (FILO =First In, Last Out)

Capacity demand: adds first compressor out of available compressors.

(available compressors: compressors where min off time (t3) is fulfilled)

Capacity excess: removes last compressor out of available compressors.

(available compressors: compressors where min on time (t4) is fulfilled)

1 =Rotation enabled, FIFO logic (FIFO =First In, First Out)

Capacity demand: adds compressor with lowest runtime out of available

compressors.

(available compressors: compressors where min off time (t3) is fulfilled)

Capacity excess: removes compressor with highest runtimes out of available

compressors.

(available compressors: compressors where min on time (t4) is fulfilled)

c6 Number of compressor to switch on in case of sensor failure

Compressor(s) will be switched on and run only. Suction pressure control by LP switch,

system protected by the mechanical safety devices (HP & LP switches).

12 Part no: 3125495 C6.1.3/0505-0705/E

Condensing Unit Controller EC2-5X1

E

n

g

l

i

s

h

F

r

e

n

c

h

G

e

r

m

a

n

Parameter

r Sensor Parameters Min Max Unit Def Min Max Unit Def

r0 Suction pressure sensor min. value -1.0 50.0 bar -0.8 -1.0 50.0 bar -0.8

r1 Suction pressure sensor max. value -1.0 50.0 bar 7.0 -1.0 50.0 bar 7.0

r2 Pressure offset for suction pressure -1.0 1.0 bar 0.0 -1.0 1.0 bar 0.0

r3 Refrigerant type 0 5 - 4 0 5 - 4

EC2-511 EC2-551

r0 & r1 parameters setting value depends of the refrigerant choice r3.

r3 is set as default for R404A.

r3 Refrigerant

0 =no temperature conversion

1 =R22

2 =R134a (not possible for units including Copeland Digital Scroll compressors)

3 =R507

4 =R404A

5 =R407C (not possible for units including Copeland Digital Scroll compressors)

NOTE: R134a cannot be used for Copeland EazyCool condensing units with two

compressors, as LP and HP switch are not set for R134a.

C6.1.3/0505-0705/E Part no: 3125495 13

Condensing Unit Controller EC2-5X1

Parameter

F Modulating Parameters Min Max Unit Def Min Max Unit Def

F2 Minimum output value - - - - 10.0 100.0 % 20.0

F3 Maximum output value - - - - 10.0 100.0 % 100.0

F6 PWM rate (Digital Scroll compressor) - - - - 10 20 sec 20

EC2-511 EC2-551

Modulation range of Copeland Digital Scroll compressor:

F2 will set minimum capacity of Copeland Digital Scroll compressor

Minimum capacity: F2 =>10%

With a two compressor unit, a small capacity step occurs when the second

compressor starts: capacity when second compressors starts=50% (fixed

capacity compressor) +F2/2 Digital Scroll compressor capacity

F3 will set max capacity: with F3 =80%, compressor will pump during max 80%

of the 20 sec cycle, so max 16 seconds.

Modulation parameter

PWM Cycle - Modulation cycle

F2 =20% 4 sec

F3 =100% 16 sec

0 4 10

PWM Cycle in sec

Load Sequence

Unload Sequence

Modulation parameter

PWM Cycle - Modulation cycle

F2 =20% 4 sec

F3 =100% 16 sec

20 0 4 10 20 0 4 10

PWM Cycle in sec

Load Sequence

Unload Sequence

20

F6: The Pulse Width Modulated signal (PWM signal) is the modulation period of a

Copeland Digital Scroll compressor which can be adjusted from 10 to 20 seconds to

ensure the closest modulation time period.

Digital running only

Digital

Digital

T

o

t

a

l

O

u

t

p

u

t

Fixed

Capacity

# comp

9.4

19.8

C

a

p

a

c

i

t

y

(

k

W

)

Digital & Fixed running Digital running only

Digital

Digital

T

o

t

a

l

O

u

t

p

u

t

Fixed

Capacity

# comp

9.4

19.8

C

a

p

a

c

i

t

y

(

k

W

)

Digital & Fixed running

Digital

Digital

T

o

t

a

l

O

u

t

p

u

t

Fixed

Capacity

# comp

9.4

19.8

C

a

p

a

c

i

t

y

(

k

W

)

Digital running only Digital & Fixed running

Digital

Digital

T

o

t

a

l

O

u

t

p

u

t

Fixed

Capacity

# comp

9.4

19.8

C

a

p

a

c

i

t

y

(

k

W

)

Digital running only Digital & Fixed running

Example OMTQ-90D

1 Digital Comp with F2 =20% & F3 =100%

1 fixed capacity comp

Example OMTQ-90D

1 Digital Comp with F2 =10% & F3 =100%

1 fixed capacity comp

14 Part no: 3125495 C6.1.3/0505-0705/E

Condensing Unit Controller EC2-5X1

E

n

g

l

i

s

h

F

r

e

n

c

h

G

e

r

m

a

n

6.2 Controller 2 (Fan controller)

Two compressor Copeland EazyCool condensing units without fan speed controller are

equipped with EC2-511, controller 2 is switching fan ON/OFF.

Two compressor Copeland EazyCool condensing units with fan speed controller

(option) as well as a two compressor Copeland EazyCool condensing units including a

Copeland Digital Scroll compressor are equipped with EC2-551, controller 2 is

modulating fan(s) speed.

Parameter

P Set Point Parameters Min Max Unit Def Min Max Unit Def

P0 Pressure set-point (condensing) for fan circuit -1.0 50.0 bar(g) 14.0 -1.0 50.0 bar(g) 14.0

P1

Pressure band (control band for P/PI, dead band for

control mode)

0.0 50.0 bar 4.0 0.0 50.0 bar 4.0

P3 Fast recovery from low pressure -9.9 50.0 bar(g) -9.9 - - - -

EC2-511 EC2-551

P0: Set point for fan modulation

P1: Dead band default setting point is 4 bar.

Parameter

t Time Parameters Min Max Unit Def Min Max Unit Def

t1

1)

Time delay before adding fan(s) 0 99 10sec 3 - - - -

t2

1)

Time delay before removing fan(s) 0 99 10sec 3 - - - -

Parameter

A Alarm Parameters Min Max Unit Def Min Max Unit Def

A2 Minimum condensing pressure alarm limit -1.0 50.0 bar(g) 10.0 -1.0 50.0 bar(g) 10.0

A3 Maximum condensing pressure alarm limit -1.0 50.0 bar(g) 27.0 -1.0 50.0 bar(g) 27.0

A4

1)

Delay time for minimum pressure alarm limit 0 990 10sec 0 0 990 10sec 0

A5

1)

Delay time for maximum pressure alarm limit 0 990 10sec 0 0 990 10sec 0

A8

1)

Fan serial alarm delay 0 990 10sec 0 0 990 10sec 0

A9

2)

Fan run limit 0 990 k Hr 0 0 990 k Hr 0

EC2-551

EC2-511 EC2-551

EC2-511

1)

Value shown in display is 10 times lower

2)

These values have a resolution of 10.000 hours, on the local display. Example: value 1

means 10.000 hours.

C6.1.3/0505-0705/E Part no: 3125495 15

Condensing Unit Controller EC2-5X1

Parameter

u Step enable Parameters Min Max Unit Def Min Max Unit Def

u0 Reset operating time 0 1 - 0 0 1 - 0

u1 Enable/disable fan1 0 1 flag 1 0 1 flag 1

u2 Enable/disable fan2 0 1 flag 1 - - - -

EC2-511 EC2-551

u0 Fan Reset operating time

0 =do nothing

1 =reset operating time fan 1

2 =reset operating time fan 2

u1 & u2 Enable/Disable fan

Disconnect one of the two fans in case of fan break-down

Parameter

c Application Parameters Min Max Unit Def Min Max Unit Def

c1 Number of fans 1 2 - 2 - - - -

c3 Control mode (dead band) 2 2 - 2 - - - -

c5 Fan switch logic (Rotation) 0 1 flag 1 - - - -

c6 Number of fans to switch on in case of sensor failure 0 2 - 0 0 1 - 0

Parameter

r Sensor Parameters Min Max Unit Def Min Max Unit Def

r0 Condensing pressure sensor min. value -1.0 50.0 bar 0.0 -1.0 50.0 bar 0.0

r1 Condensing pressure sensor max. value -1.0 50.0 bar 30.0 -1.0 50.0 bar 30.0

r2 Pressure offset for condensing pressure -1 1 bar 0 -1 1 bar 0

Parameter

H Other Parameters Min Max Unit Def Min Max Unit Def

H2 Keyboard and IR Remote Control 0 3 - 3 0 3 - 3

H3 IR Remote control access code 0 199 - 0 0 199 - 0

H5 Password 0 199 - 12 0 199 - 12

Parameter

F Modulating Parameters Min Max Unit Def Min Max Unit Def

F2 Minimum output value - - - - 0.0 100.0 % 0.0

F3 Maximum output value - - - - 0.0 100.0 % 100.0

EC2-511 EC2-551

EC2-511 EC2-551

EC2-511 EC2-551

EC2-511 EC2-551

H2 Keyboard and IR remote control

0 =all disabled (Caution, access to controller only via LON network possible)

1 =Keyboard enabled

2 =IR remote control enabled

3 =Keyboard and IR remote control enabled

16 Part no: 3125495 C6.1.3/0505-0705/E

Condensing Unit Controller EC2-5X1

E

n

g

l

i

s

h

F

r

e

n

c

h

G

e

r

m

a

n

6.3 Important parameters on EC2-551 to configure according to Copeland

EazyCool model

6.3.1 EC2-551 for Copeland EazyCool condensing unit with two

compressors with fan speed controller FSP150

Major parameters for operation

Parameter

c Application Parameters Min Max Unit Def

c1 Number of compressors 1 2 - 2

c3 Control mode (network system) 2 3 - 2

c4 Compressor 1 control mode 0 2 flag 0

c5 Compressor switch logic 0 1 flag 1

c6

Number of compressor to switch on in case of sensor

failure

0 2 - 0

EC2-551

c4 Compressor 1 control mode

0 =compressor 1 in standard control loop

1 =compressor 1 act as base load compressor

2 =compressor 1 act as modulating (PWM control for Copeland Digital Scroll

compressor only)

NOTE: c4 parameter should be either 0 or 1

6.3.2 EC2-551 for Copeland EazyCool condensing unit with Copeland

Digital Scroll compressor

Major parameters for operation

Parameter

c Application Parameters Min Max Unit Def

c1 Number of compressors 1 2 - 2

c3 Control mode (network system) 2 3 - 2

c4 Compressor 1 control mode 0 2 flag 2

c5 Compressor switch logic 0 1 flag 1

c6

Number of compressor to switch on in case of sensor

failure

0 2 - 0

EC2-551

c4 Compressor 1 control mode

0 =compressor 1 in standard control loop

1 =compressor 1 act as base load compressor

2 =compressor 1 act as modulating (PWM control for Copeland Digital Scroll

compressor only)

NOTE: For a digital condensing unit c4 should only be fixed on 2

C6.1.3/0505-0705/E Part no: 3125495 17

Condensing Unit Controller EC2-5X1

Parameter

F Modulating Parameters Min Max Unit Def

F2 Minimum output value 10 100 % 20

F3 Maximum output value 10 100 % 100

EC2-551

Minimum & Maximum output value could be adjusted

In case of a single compressor Copeland EazyCool condensing unit with a Copeland

Digital Scroll compressor, the maximum output could be set below 100% if system

requests less than the maximum capacity. In that case F3 > F2.

7 Alarms and Messages

7.1 Alarm codes

hP High pressure alarm signal flashing before indicating the actual pressure value of the

system

Controller 1: suction pressure higher than the maximum limit A3 (inactive by

default)

Controller 2: condensing pressure higher than the maximum limit A3

Alarm during the pull down period in case A3 is fixed around 6 bar:

During the pull down period, alarm hP1 will be flashing until the condensing unit

reaches a value below the A3 set-point (by default 6 bar).

Pull down curve

0

2

4

6

8

10

12

t=0 t=1 t=2 t=3 t=4 t=5 t=6 t=7 t=8 t=9 t=10 t=11

P0 - (P1)/2)

P0 +(P1)/2)

P0: Modulation set-point (suction pressure)

A2: Min. suction pressure Iimit (alarm)

A3: Max. suction pressure Iimit (alarm)

If A3 is fixed at 6 bar, hP1 alarm

will flash until suction pressure

reaches a value below A3

18 Part no: 3125495 C6.1.3/0505-0705/E

Condensing Unit Controller EC2-5X1

E

n

g

l

i

s

h

F

r

e

n

c

h

G

e

r

m

a

n

lP Low pressure alarm signal flashing before indicating the actual pressure value of the

system

Controller 1: suction pressure lower than the minimum limit A2 (0 bar by default)

Controller 2: condensing pressure lower than the minimum limit A2

EP Error pressure

Controller 1: suction pressure sensor failure

Controller 2: condensing pressure sensor failure

Fr Fast recovery alarm (if P3 active) signal flashing before indicating the actual pressure

value

Controller 1: fast recovery from low suction pressure. Signal just before

compressor stops.

Controller 2: fast recovery from low condensing pressure (only for EC-2-511 if

active). Signal just before fan stops.

hr High discharge pressure alarm (if P8 active) signal flashing before indicating the

actual pressure value

Controller 1: high discharge pressure recovery

Emergency run

Controller 1: runs with c6 numbers of compressors

Controller 2: runs with c6 numbers of fans

cE Communication error

Controller 1: Communication error if binding for paralleling is used. A slave

controller then goes to emergency master mode and works with local pressure

sensor and set point.

d1 Discharge temperature alarm

Digital Scroll compressor only: Discharge end temperature is too high

compressor stop.

E1 Feedback alarm 1 safety loop failure of compressor 1 (safety loop, HP or LP

pressure switches, or oil level control)

Controller 1: digital input associated with compressor 1 has changed into alarm

state (safety chain)

E2 Feedback alarm 2 safety loop failure of compressor 2 (safety loop, HP or LP

pressure switches, or oil level control)

n1 Service alarm 1

Controller 1: compressor 1 operating time higher than service limit

Controller 2: fan 1 operating time higher than service limit

n2 Service alarm 2

Controller 1: compressor 2 operating time higher than service limit

Controller 2: fan 2 operating time higher than service limit

Er Data error

Data send to the display is out of range

C6.1.3/0505-0705/E Part no: 3125495 19

Condensing Unit Controller EC2-5X1

7.2 Messages

In Configuration data initialisation

The display will show an In when the configuration data are initialised with the

factory default values.

Id Wink request received

The display will show a flashing Id when the wink request was received. The

node will receive the flashing Id will be shown on the display until the service

button will be pressed, or a 30 min delay timer will expire or a second wink

request. (NEURON ID)

oF Offline

The node is offline: no application is running. This is the result of a network

management command.

- -- --- Controller disabled, waiting for restart

After a major change of the configuration parameter, the compressor capacity

controller and the condenser fan controller are disabled for 20 seconds. After this

delay the controllers restart automatically.

The compressor controller and the condenser controller are disabled.

20 Part no: 3125495 C6.1.3/0505-0705/E

Condensing Unit Controller EC2-5X1

E

n

g

l

i

s

h

F

r

e

n

c

h

G

e

r

m

a

n

8 Technical Specifications

Enclosure

Operating 0 / +50C or 32 / +122F

Storage - -10 / +70C or 14 / +158F

Power supply: 24 V AC, -15%, +10%

Consumption: 12 VA

Case: Auto extinguishing Plastic, 75 x 33 x 73 mm

Mounting:

Controller; Panel mounting

Connections: Plug in connectors for cables of max. 1.5 mm, min. 0.5 mm

section

Display: 2 digits

Indicators LED: Controller 1, controller 2, pressure, IR activated, alarm & neuron

ID

Inputs: Feedback failure contact for compressor 1 to 2.

Pressure sensor: 2 x 4- 20 mA (2 wires)

Outputs: 2 x Relays SPDT

Imax =8A res (2A), V AC max =250V :

Compressor relays 1 to 2,

1 x Triac for 24 V AC Solenoid

1 x 0-10V Analog output

Environmental pollution non aggressive atmosphere

Protection class IP65 (frontal protection with gasket)

Insulation class II

I MPORTANT

Keep controller and sensor lines separated from mains cable with at least 3 cm.

NOTE When cleaning the display use damp cloth and neutral detergent

8.1 Safety Standard

In order to comply the safety standard (CEI 107-70) see the following:

1. Connection cables should be suitable for 90C operation.

2. Class II transformers 24 V AC double insulated has been used

C6.1.3/0505-0705/E Part no: 3125495 21

Emerson Climate Technologies - European Headquarters - Pascalstrasse 65 - 52076 Aachen, Germany

Phone: +49 (0) 2408 929 0 - Fax: +49 (0) 2408 929 570 - Internet: www.emersonclimate.eu

The Emerson Climate Technologies logo is a trademark and service mark of Emerson Electric Co. Emerson Climate Technologies Inc. is a subsidiary of Emerson Electric Co.

Copeland is a registered trademark and Copeland Scroll is a trademark of Emerson Climate Technologies Inc.. All other trademarks are property of their respective owners.

Information contained in this brochure is subject to change without notication.

2011 Emerson Climate Technologies, Inc.

For more details, see www.emersonclimate.eu

BENELUX

Deltakade 7

NL-5928 PX Venlo

Tel. +31 77 324 02 34

Fax +31 77 324 02 35

benelux.sales@emerson.com

UK & IRELAND

Unit 17, Theale Lakes Business Park

Reading, Berks RG7 4GB

Tel: +44 1189 83 80 00

Fax: +44 1189 83 80 01

uk.sales@emerson.com

BALKAN

Selska cesta 93

HR-10 000 Zagreb

Tel. +385 1 560 38 75

Fax +385 1 560 38 79

balkan.sales@emerson.com

GERMANY, AUSTRIA & SWITZERLAND

Senefelder Str. 3

DE-63477 Maintal

Tel. +49 6109 605 90

Fax +49 6109 60 59 40

ECTGermany.sales@emerson.com

SWEDEN, DENMARK, NORWAY & FINLAND

Pascalstr. 65

DE-52076 Aachen

Tel. +49 2408 929 0

Fax +49 2408 92 95 28

nordic.sales@emerson.com

UKRAINE

Turgenevskaya Str. 15, ofce 33

UA-01054, Kiev

Tel. +38 - 44 - 4 92 99 24

Fax. +38 - 44 - 4 92 99 28

Andrey.Gladchenko@emerson.com

FRANCE, GREECE & MAGHREB

8, Alle du Moulin Berger

FR-69130 Ecully Cdex

Tel. +33 4 78 66 85 70

Fax +33 4 78 66 85 71

mediterranean.sales@emerson.com

EASTERN EUROPE & TURKEY

Pascalstr. 65

DE-52076 Aachen

Tel. +49 2408 929 0

Fax +49 2408 929 525

easterneurope.sales@emerson.com

ROMANIA

Tel. +40 - 364 - 73 11 72

Fax. +40 - 364 - 73 12 98

Camelia.Tiru@emerson.com

ITALY

Via Ramazzotti, 26

IT-21047 Saronno (VA)

Tel. +39 02 96 17 81

Fax +39 02 96 17 88 88

italy.sales@emerson.com

POLAND

Szturmowa 2

PL-02678 Warsaw

Tel. +48 22 458 92 05

Fax +48 22 458 92 55

poland.sales@emerson.com

MIDDLE EAST & AFRICA

PO Box 26382

Jebel Ali Free Zone - South, Dubai - UAE

Tel. +971 4 811 81 00

Fax +971 4 886 54 65

mea.sales@emerson.com

SPAIN & PORTUGAL

C/ LLull, 321 (Edici CINC)

ES-08019 Barcelona

Tel. +34 93 412 37 52

Fax +34 93 412 42 15

iberica.sales@emerson.com

RUSSIA & CIS

Letnikovskaya 10, Bld. 2, oor 5

RU-115114 Moscow

Tel. +7 495 981 98 11

Fax +7 495 981 98 16

ECT.Holod@emerson.com

C

6

.

1

.

3

/

0

5

0

5

-

0

7

0

5

/

E

(

P

a

r

t

N

o

:

3

1

2

5

4

9

5

)

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Audio Transformers ChapterDocumento30 páginasAudio Transformers Chapterforing100% (4)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Delcos PDFDocumento40 páginasDelcos PDFKabul Abdullah92% (12)

- Am-Fm MCQSDocumento25 páginasAm-Fm MCQSJans Borlagdan86% (7)

- Book MCQ Numericals Naidu and Wadhwa Combined PDFDocumento90 páginasBook MCQ Numericals Naidu and Wadhwa Combined PDFPushpak Ladhe83% (6)

- Carel Ir33 Programming Guide PDFDocumento2 páginasCarel Ir33 Programming Guide PDFIonutCiobanuAinda não há avaliações

- TD BrazeTec s15 EDocumento1 páginaTD BrazeTec s15 EIonutCiobanuAinda não há avaliações

- Controler Elliwel E37Documento3 páginasControler Elliwel E37IonutCiobanuAinda não há avaliações

- BT Silfos 15 ENDocumento1 páginaBT Silfos 15 ENIonutCiobanuAinda não há avaliações

- Technical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet Brazetec S Brazetec S Brazetec S Brazetec S 5 5 5 5Documento1 páginaTechnical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet Brazetec S Brazetec S Brazetec S Brazetec S 5 5 5 5IonutCiobanuAinda não há avaliações

- k65 Fittings - UnlockedDocumento4 páginask65 Fittings - UnlockedIonutCiobanuAinda não há avaliações

- Model: ZF13K4E-TFD: Technical DataDocumento6 páginasModel: ZF13K4E-TFD: Technical DataIonutCiobanuAinda não há avaliações

- Riello 40 Gs Series Package Gas BurnerDocumento6 páginasRiello 40 Gs Series Package Gas BurnerIonutCiobanuAinda não há avaliações

- Traxoil OM3 - OM4Documento5 páginasTraxoil OM3 - OM4IonutCiobanuAinda não há avaliações

- Outdoor Condensing UnitDocumento27 páginasOutdoor Condensing UnitIonutCiobanuAinda não há avaliações

- High Res PowerCad-5 4pp BrochureDocumento2 páginasHigh Res PowerCad-5 4pp Brochure322399mk7086Ainda não há avaliações

- Chapter 9 New 1Documento81 páginasChapter 9 New 1Minn Nyi SheinAinda não há avaliações

- Theoretical Impedance of Capacitive ElectrodesDocumento106 páginasTheoretical Impedance of Capacitive ElectrodesJJacquelin100% (3)

- LG Room Air Conditioner: Owner'S ManualDocumento35 páginasLG Room Air Conditioner: Owner'S ManualMalay K GhoshAinda não há avaliações

- VRV - ADocumento48 páginasVRV - Amuzakir ludinAinda não há avaliações

- Lc32le240-340m EN SVC PDFDocumento70 páginasLc32le240-340m EN SVC PDFKenneth S.Ainda não há avaliações

- Flashpak Datasheet 28F010Documento30 páginasFlashpak Datasheet 28F010Will ?Ainda não há avaliações

- Data Sheet: Automatic Dissipation Factor and Resistivity Test Equipment Dieltest DTLDocumento4 páginasData Sheet: Automatic Dissipation Factor and Resistivity Test Equipment Dieltest DTLFany OchAinda não há avaliações

- Omron F7 Frequency Converter User ManualDocumento389 páginasOmron F7 Frequency Converter User ManualAbdulrahmanAinda não há avaliações

- Ampl 12AU7Documento6 páginasAmpl 12AU7Adinei HamradioAinda não há avaliações

- CBSE Class 12 Physics Worksheet - Electric Potetial & CapacitanceDocumento1 páginaCBSE Class 12 Physics Worksheet - Electric Potetial & CapacitanceSanjukthAinda não há avaliações

- Measurement of High VoltageDocumento22 páginasMeasurement of High Voltagesumit tiwariAinda não há avaliações

- Doha CablesDocumento174 páginasDoha Cablesshaik abdullahAinda não há avaliações

- Demos: Capacitor Separation With Distance - Introduce Dielectrics (Foam, Glass) and See The Voltage Decrease As The Capacitance IncreasesDocumento94 páginasDemos: Capacitor Separation With Distance - Introduce Dielectrics (Foam, Glass) and See The Voltage Decrease As The Capacitance IncreasesZim ShahAinda não há avaliações

- Activity 1.2 Familiarization of Components and EquipmentsDocumento7 páginasActivity 1.2 Familiarization of Components and EquipmentsMALAKIPWETKOAinda não há avaliações

- Speed Control MotorDocumento32 páginasSpeed Control MotorMASOUD0% (1)

- 2 1 A Student Investigates The Motion of A Trolley On A Wooden Surface, As Shown in Fig. 1.1Documento6 páginas2 1 A Student Investigates The Motion of A Trolley On A Wooden Surface, As Shown in Fig. 1.1Nadia WandaputriAinda não há avaliações

- Xtr30010 High Temperature PWM Controllers Family Ds 0001 10Documento14 páginasXtr30010 High Temperature PWM Controllers Family Ds 0001 10aimateeadAinda não há avaliações

- WAEC Syllabus For PhysicsDocumento32 páginasWAEC Syllabus For Physicstrustphli73Ainda não há avaliações

- Frecon FR 100 MANUAL PDFDocumento105 páginasFrecon FR 100 MANUAL PDFJahidur Rahman50% (2)

- Common Base - Collector - Frequency ResponseDocumento38 páginasCommon Base - Collector - Frequency Responsekoolking786Ainda não há avaliações

- PsiiDocumento8 páginasPsiiandhracollegesAinda não há avaliações

- Clock Generator FunctionDocumento16 páginasClock Generator FunctionBala GopalAinda não há avaliações

- YCT Capacitance NEET JEE Questions PracticeDocumento152 páginasYCT Capacitance NEET JEE Questions Practicetechnicalfacts31Ainda não há avaliações

- MSP430 Update PresentationDocumento118 páginasMSP430 Update PresentationNguyên ThảoAinda não há avaliações

- C 300 ManualDocumento116 páginasC 300 ManualPhan Giang ChâuAinda não há avaliações