Escolar Documentos

Profissional Documentos

Cultura Documentos

NT2-L3-M-000!21!00022 MS For Oil Flushing of The Fuel Oil Piping System

Enviado por

Huynh Thanh Tam0 notas0% acharam este documento útil (0 voto)

124 visualizações15 páginasDOCUMENT STATUS : For Reference A 18-10-2010 Issue for Reference Ng Van Du Krit K. Sumeth Y. Rev. Date Description Prepd. Chkd. Appd. Project No : NT 2 Format : A4 Total Pages : Designed by : TORISHIMA Consortium.

Descrição original:

Título original

NT2-L3-M-000!21!00022 MS for Oil Flushing of the Fuel Oil Piping System

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDOCUMENT STATUS : For Reference A 18-10-2010 Issue for Reference Ng Van Du Krit K. Sumeth Y. Rev. Date Description Prepd. Chkd. Appd. Project No : NT 2 Format : A4 Total Pages : Designed by : TORISHIMA Consortium.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

124 visualizações15 páginasNT2-L3-M-000!21!00022 MS For Oil Flushing of The Fuel Oil Piping System

Enviado por

Huynh Thanh TamDOCUMENT STATUS : For Reference A 18-10-2010 Issue for Reference Ng Van Du Krit K. Sumeth Y. Rev. Date Description Prepd. Chkd. Appd. Project No : NT 2 Format : A4 Total Pages : Designed by : TORISHIMA Consortium.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 15

DOCUMENT STATUS : For Reference

A 18102010 IssueforReference NgVanDu KritK. SumethY.

Rev. Date Description Prepd. Chkd. Appd.

Project :

Owner : Consultant:

EPC Contractor:

Consultant:

Subcontractor :

Document Title : Method Statement for Oil Flushing of The Fuel Oil Piping System

Project No : NT 2 Format :

A4

Total Pages :

Designed by : Torishima Consortium Checked by :

Function Name Sign Date Function Name Sign Date

Approved

Sumeth Y.

18-10-2010

SM

Checked

Krit K.

18-10-2010

ME

Prepared

Ng Van Du.

18-10-2010

ME

Document No : NT2-L3-M-000-21-00022

Date:

18-10-2010

Rev.

A

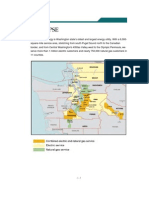

NHON TRACH 2 - 750MW COMBINED CYCLE POWER PLANT PROJECT

PETRO VIETNAM

NHON TRACH 2 POWER

JOINT STOCK COMPANY

LILAMA PVC CONSORTIUM

FICHTNER GmbH & Co.KG CONNELL WAGNER (AURECON)

TORISHIMA - AFCOLENCO - LILAMA 18 JSC.

TORISHIMA AF COLENCO-LILAMA 18 JSC

76BUI THI XUAN,HAI BA TRUNG DI STRI CT, Tel : 84-4-943 7880

HANOI, VIETNAM Fax : 84-4-943 7875/7876

Doc. No.: NT2-L3-M-000-21-00022 Page 2 of 11 Rev.A

Torishima-AF Colenco-Lilma 18 J SC

Nhon Trach 2-750MW CCPP/ Lot 3 Balance of Plant

TORISHIMA AF COLENCO-LILAMA 18 JSC

76BUI THI XUAN,HAI BA TRUNG DI STRI CT, Tel : 84-4-943 7880

HANOI, VIETNAM Fax : 84-4-943 7875/7876

Doc. No.: NT2-L3-M-000-21-00022 Page 3 of 11 Rev.A

CONTENTS

Page

1. Purpose .4

2. Scope .4

2.1 Pipeline Circuit No. 1 4

2.2 Pipeline Circuit No. 2 4

3. Basic Requirement .......4

4. Safety and Precaution ..5

5. Preparation for Flushing .5

5.1 Oil Flushing Pumps ........5

5.2 Temporary Storage Tank ........6

5.3 Pipeline Circuit No. 1 .........6

5.4 Pipeline Circuit No. 2 .........6

6. Flushing Media ..7

7. Flushing Procedure .......7

7.1 Step I Flushing of Pipeline Circuit No. 1..........8

7.2 Step II Flushing of Pipeline Circuit No. 2 ........8

8. Cleanliness Check and Acceptance Criteria .......9

9. Preservation .......9

10. Documentation .......9

11. Appendix .9

TORISHIMA AF COLENCO-LILAMA 18 JSC

76BUI THI XUAN,HAI BA TRUNG DI STRI CT, Tel : 84-4-943 7880

HANOI, VIETNAM Fax : 84-4-943 7875/7876

Doc. No.: NT2-L3-M-000-21-00022 Page 4 of 11 Rev.A

1. Purpose

In order to fulfill the cleanliness requirements for rapid commissioning and trouble-free

operation of the power plant, the fuel oil piping system (FOPS) shall be cleaned before

commissioning.

This method statement describes all activities which covers the detail of work to be carried out

for oil flushing of fuel oil piping system in scope of Balance of Plant System (BOP) for Nhon

Trach 2 750 MW Combined Cycle Power Plant Project.

Special attention must be paid to clean equipment in the system. Steps must be taken to prevent

foreign substances being carried forward and damaging or plugging the apparatus.

This method statement shall serve as basic guideline only which at site the procedure may

adapt to suit conditions, material availability, actual completion for each segment of piping in

the system and actual system piping layout.

2. Scope

After the fuel oil piping system have been finished of pressure testing and pigging cleaning

process and before it is put into service, oil flushing shall be performed.

The fuel oil piping system shall be cleaned by oil flushing before put into the service includes:

2.1 Pipeline Circuit No. 1

Fuel oil pipelines from terminal point TPDO-1 to fuel oil storage tank (see Appendix A).

2.2 Pipeline Circuit No. 2

Fuel oil pipelines from fuel oil storage tank to terminal point TP2r and TP2v (see

Appendix B).

3. Basic Requirement

The purpose of performing an oil flush is to remove any and all foreign material from a system

or component.

To most efficient method of maintaining system cleanliness is to prevent entry of foreign

material into system piping or components during installation.

In general, manufacture and shop assembly of the components are conducted in such a way

that a clean condition is guaranteed which is in compliance with the function of the component

or system. The preservation and installation on site shall also be conducted with adequate care

in order not to impair this clean condition.

TORISHIMA AF COLENCO-LILAMA 18 JSC

76BUI THI XUAN,HAI BA TRUNG DI STRI CT, Tel : 84-4-943 7880

HANOI, VIETNAM Fax : 84-4-943 7875/7876

Doc. No.: NT2-L3-M-000-21-00022 Page 5 of 11 Rev.A

Cleanliness during installation requires the inspection of the pipe spools for contamination, lost

tools, etc. in pre-erected pipes before further erection; cleaning if necessary. After the pipe is

installed, any open ends should be capped using a suitable cover.

Once complete of pressure testing and pigging cleaning, the pipeline is to be air blown

continuously in order to ensure all lines are dried and free of contaminants.

4. Safety and Precaution

This subject is described to provide safe practices for oil flushing operations of the fuel oil

piping system.

- Good coordination is essential to avoid any hazards.

- Prior to oil flushing operation, work permit shall be issued and announcement is required.

- All equipment associated with oil flushing operation must be checked to assure that it in

good condition.

- The areas of temporary storage tanks and oil flushing pumps must be surrounded with

barricade and warning signs shall be posted as required.

- All workers who shall work in oil flushing operation must receive a toolbox talk to good

understand the activities.

- All workers must equip with appropriate PPE during pigging operation.

- All mechanical/ integrity work shall be completed before oil flushing operation

commences.

- All potential ignition sources must be eliminated.

- The necessary safety equipment must be available at the areas of temporary storage tanks

and oil flushing pumps all times e.g. fire extinguishers, breathing apparatus, etc.

5. Preparation for Flushing

5.1 Oil Flushing Pumps

Oil flushing pumps are temporary pumps that required for pumping the flushing media

from the temporary storage tanks.

The oil flushing pumps are end volute suction centrifugal pump type and equipped with

inlet/ outlet pressure gauges for monitoring the pumps during operation.

The oil flushing pumps shall be operated at two to three times the rated flow of the

system in order to increase the oil flushing velocity.

TORISHIMA AF COLENCO-LILAMA 18 JSC

76BUI THI XUAN,HAI BA TRUNG DI STRI CT, Tel : 84-4-943 7880

HANOI, VIETNAM Fax : 84-4-943 7875/7876

Doc. No.: NT2-L3-M-000-21-00022 Page 6 of 11 Rev.A

5.2 Temporary Storage Tanks

Two (2) temporary storage tanks with capacity 50 m3 each are required for storage the

flushing media. The temporary storage tanks are fabricated of steel with cylindrical

horizontal type.

Size of each tank shall be chosen on the basis of the maximum estimated flushing media

consumption.

The tanks fabricated equipped with inlet, outlet, vent, drain, and overflow nozzles and

tank manhole and nozzles for level measurement.

5.3 Pipeline Circuit No. 1 (Refer to Appendix A)

a) Install temporary pipe connect between oil flushing pumps to the pipeline 10EGA10

BR001 at terminal point TPDO-1.

b) Install temporary pipe from the pipeline 10EGB11 BR001 before the flexible joint

10EGB11 AB001 and from the pipeline 10EGB12 BR001 before the flexible joint

10EGB12 AB001 and then connect to the temporary storage tanks.

c) Remove the permanent filter element of strainer 10EGA10 AT001 & 10EGA10

AT002 and place on a temporary screening element of 100 mesh.

d) Close the following valves:

- 10EGA10 AA001

- 10EGA10 AA002, 10EGA10 AA003

- 10EGA10 AA004, 10EGA10 AA005

- 10EGA10 AA007

- 10EGA10 AA301, 10EGA10 AA302

- 10EGB05 AA301

Note: Other valves in the pipeline circuit are not specified to closing, it shall be

opened.

e) Isolate the temperature indicator 10EGB05 CT501.

5.4 Pipeline Circuit No. 2 (Refer to Appendix B)

a) Install temporary pipe from discharge of oil flushing pumps to the pipeline 10EGB10

BR001 after the flexible joint 10EGB20 AB003 and to the pipeline 10EGB20 BR001

after the flexible joint 10EGB20 AB004.

b) Install temporary pipe from the pipeline 10EGB10 BR004 before the flexible joint

10EGB10 AB003 and from the pipeline 10EGB20 BR004 before the flexible joint

10EGB20 AB002 and then connect to the temporary storage tanks.

TORISHIMA AF COLENCO-LILAMA 18 JSC

76BUI THI XUAN,HAI BA TRUNG DI STRI CT, Tel : 84-4-943 7880

HANOI, VIETNAM Fax : 84-4-943 7875/7876

Doc. No.: NT2-L3-M-000-21-00022 Page 7 of 11 Rev.A

c) Install temporary pipe connect between the pipeline 10EGC11 BR007 before valve

10EGC11 AA005 and the pipeline 10EGC11 BR002 after valve 10EGC11 AA003 in

order to bypassing the simplex strainer 10EGC11 AT001 and DO forwarding pump

10EGC11 AP001.

d) Install temporary pipe connect between the pipeline 10EGC12 BR007 before valve

10EGC12 AA005 and the pipeline 10EGC12 BR002 after valve 10EGC12 AA003 in

order to bypassing the simplex strainer 10EGC12 AT001 and DO forwarding pump

10EGC12 AP001.

e) Install temporary pipe connect between the pipeline 10EGC21 BR007 before valve

10EGC21 AA005 and the pipeline 10EGC21 BR002 after valve 10EGC21 AA003 in

order to bypassing the simplex strainer 10EGC21 AT001 and DO forwarding pump

10EGC21 AP001.

f) Install temporary pipe connect between the pipeline 10EGC22 BR007 before valve

10EGC22 AA005 and the pipeline 10EGC22 BR002 after valve 10EGC22 AA003 in

order to bypassing the simplex strainer 10EGC22 AT001 and DO forwarding pump

10EGC22 AP001.

g) Remove the permanent filter element of strainer 10EGC30 AT001 & 10EGC30

AT002 and place on a temporary screening element of 200 mesh.

h) Close the following valves:

- 10EGC11 AA001, 10EGC11 AA301

- 10EGC12 AA001, 10EGC12 AA301

- 10EGC21 AA001, 10EGC21 AA301

- 10EGC22 AA001, 10EGC22 AA301

- 10EGC13 AA001, 10EGC23 AA001

- 10EGC30 AA301

- 10EGC30 AA004, 10EGC30 AA005

- 10EGC30 AA011

- 10EGC50 AA005

Note: Other valves in the pipeline circuit are not specified to closing, it shall be

opened.

i) Isolate the temperature indicator 10EGC30 CT501.

6. Flushing Media

Fuel oil no. 2 in accordance with project specification shall be used for flushing.

If possible, this flushing oil should be taken from NT1 which routes into the temporary storage

tanks via a temporary flow meter.

TORISHIMA AF COLENCO-LILAMA 18 JSC

76BUI THI XUAN,HAI BA TRUNG DI STRI CT, Tel : 84-4-943 7880

HANOI, VIETNAM Fax : 84-4-943 7875/7876

Doc. No.: NT2-L3-M-000-21-00022 Page 8 of 11 Rev.A

7. Flushing Procedure

The temporary storage tanks should be filled with fuel oil about to high level. When the oil

flushing pumps are turn on for filling the pipeline circuit to be flushed, oil level in the

temporary storage tanks will decrease. Make-up oil need to be added to maintain oil level in

the temporary storage tank is always above the suction of oil flushing pumps during oil

flushing operations.

The major steps for oil flushing are as follow:

7.1 Step I Flushing of Pipeline Circuit No. 1

a) Install all temporary equipment and pipes as required.

b) Check correct positioning of valves.

c) Flush the pipeline circuit by circulating the flushing oil.

d) Check for dirt at temporary screening element at the strainer 10EGA10 AT001 &

10EGA10 AT002.

e) If too much contamination still exists in the pipeline circuit, flushing shall be

repeated.

f) If cleanliness is satisfactory, the pipeline circuit shall be treated as follow:

- Draining the flushing oil from the pipeline circuit back into the temporary storage

tank until emptied.

- Remove all temporary and reinstate the fuel oil piping system to its original.

- Fill the piping with fuel oil to prevent corrosion.

7.2 Step II Flushing of Pipeline Circuit No. 2

a) Install all temporary equipment and pipes as required.

b) Check correct positioning of valves.

c) Flush the pipeline circuit by circulating the flushing oil.

d) Check for dirt at temporary screening element at the strainer 10EGC30 AT001 &

10EGC30 AT002.

e) If too much contamination still exists in the pipeline circuit, flushing shall be

repeated.

TORISHIMA AF COLENCO-LILAMA 18 JSC

76BUI THI XUAN,HAI BA TRUNG DI STRI CT, Tel : 84-4-943 7880

HANOI, VIETNAM Fax : 84-4-943 7875/7876

Doc. No.: NT2-L3-M-000-21-00022 Page 9 of 11 Rev.A

f) If cleanliness is satisfactory, the pipeline circuit shall be treated as follow:

- Draining the flushing oil from the pipeline circuit back into the temporary storage

tank until emptied.

- Remove all temporary and reinstate the fuel oil piping system to its original.

- Fill the piping with fuel oil to prevent corrosion.

8. Cleanliness Check and Acceptance Criteria

To determine the cleanliness of the pipeline circuit, checks must be carried out. The evaluation

of the check results is done by the involved parties.

The criteria for completion of oil flushing for fuel oil piping system are the size and numbers

of particles still present in the circuit:

- Check of particles: No particle >1.0 mm. should be presented in the circuit.

- Check that no foreign matters such as plastic sheets, paper and biological matter are

trapped in the circuit.

9. Preservation

In general, after the oil flushing has been completed the piping system should be made ready

for normal operation as soon as possible after circuit cleaning. Pipelines completely filled with

fuel oil provide wet preservation.

10. Documentation

Immediately after cleanliness check, all inspection shall be recorded and signed by the parties

involved.

11. Appendix

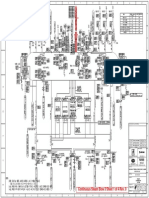

- Appendix A: Oil Flushing of Fuel Oil Piping System Pipeline Circuit No. 1

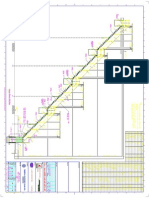

- Appendix B: Oil Flushing of Fuel Oil Piping System Pipeline Circuit No. 2

TORISHIMA AF COLENCO-LILAMA 18 JSC

76BUI THI XUAN,HAI BA TRUNG DI STRI CT, Tel : 84-4-943 7880

HANOI, VIETNAM Fax : 84-4-943 7875/7876

Doc. No.: NT2-L3-M-000-21-00022 Page 10 of 11 Rev.A

Appendix A

Oil Flushing of Fuel Oil Piping System Pipeline Circuit No. 1

TORISHIMA AF COLENCO-LILAMA 18 JSC

76BUI THI XUAN,HAI BA TRUNG DI STRI CT, Tel : 84-4-943 7880

HANOI, VIETNAM Fax : 84-4-943 7875/7876

Doc. No.: NT2-L3-M-000-21-00022 Page 11 of 11 Rev.A

Appendix B

Oil Flushing of Fuel Oil Piping System Pipeline Circuit No. 2

Você também pode gostar

- NT2-L3-M-000!21!00010 MS For Cleaning & Flushing of BOP Piping SystemDocumento7 páginasNT2-L3-M-000!21!00010 MS For Cleaning & Flushing of BOP Piping SystemHuynh Thanh TamAinda não há avaliações

- Tank Fabrication & ErectionDocumento72 páginasTank Fabrication & ErectionPramod GrAinda não há avaliações

- MD1-0-T-030-05-00397-A - ITP For STGDocumento25 páginasMD1-0-T-030-05-00397-A - ITP For STGTran KhuynhAinda não há avaliações

- 20.12 - GEK72281f Steam Purity Recommendations For Steam TurbinesDocumento14 páginas20.12 - GEK72281f Steam Purity Recommendations For Steam TurbinesLIUAinda não há avaliações

- VA1 NHI 00100 M M1C MAN 1001 Rev0 MGS4766 Double Inlet and Double Outlet Coal Mill Instruction (Dextral)Documento5 páginasVA1 NHI 00100 M M1C MAN 1001 Rev0 MGS4766 Double Inlet and Double Outlet Coal Mill Instruction (Dextral)hoangduythanhqbAinda não há avaliações

- Aux Boiler Steam Blow ProcedureDocumento30 páginasAux Boiler Steam Blow ProcedureAnonymous JtYvKt5XEAinda não há avaliações

- Spare Parts ListDocumento1 páginaSpare Parts ListCristobal GuzmanAinda não há avaliações

- TA-Luft:: Cummins Engine Company, Inc FR-10302 QSX15-G8Documento1 páginaTA-Luft:: Cummins Engine Company, Inc FR-10302 QSX15-G8mohsen_cumminsAinda não há avaliações

- VA1-LLM18-00100-GE-M8-PRO-00005 Rev.A (Cover)Documento1 páginaVA1-LLM18-00100-GE-M8-PRO-00005 Rev.A (Cover)Anonymous JtYvKt5XEAinda não há avaliações

- Continuous Steam Blow 3 Sheet 1 of 4 Rev. 0Documento4 páginasContinuous Steam Blow 3 Sheet 1 of 4 Rev. 0Anonymous JtYvKt5XEAinda não há avaliações

- BE Engineering Guide VDC Air Cooled CondenserDocumento46 páginasBE Engineering Guide VDC Air Cooled Condensernauta007Ainda não há avaliações

- Eagle Burgmann API PlanDocumento43 páginasEagle Burgmann API PlanONURAinda não há avaliações

- Guideline On Testing Procedures160519 IEA Task 49 D3 1Documento53 páginasGuideline On Testing Procedures160519 IEA Task 49 D3 1Antonio PatauAinda não há avaliações

- Expansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)Documento14 páginasExpansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)dodonggAinda não há avaliações

- Rev 02Documento7 páginasRev 02Oğuzcan ŞahinAinda não há avaliações

- Energies 10 00205Documento19 páginasEnergies 10 00205radanpetricaAinda não há avaliações

- HD1-2M90-1042-006 - B - Inspetion Test Plan - CODE BDocumento5 páginasHD1-2M90-1042-006 - B - Inspetion Test Plan - CODE Bfreeman11072000Ainda não há avaliações

- Indian - Standards - BIS ConnectDocumento433 páginasIndian - Standards - BIS ConnectVaradha rajanAinda não há avaliações

- Vv31g0-002-A-105 - 1 - 001 Method Statement For Piping and Equipments InstallationDocumento30 páginasVv31g0-002-A-105 - 1 - 001 Method Statement For Piping and Equipments InstallationPhong ĐỗAinda não há avaliações

- RAPID Project Package 3 Equipment Erection ProcedureDocumento26 páginasRAPID Project Package 3 Equipment Erection ProcedureLongTuanAinda não há avaliações

- Work Procedure Bitumen Mastic FlooringDocumento6 páginasWork Procedure Bitumen Mastic FlooringSWARUP MONDALAinda não há avaliações

- Static Equipment Installation ProceduresDocumento14 páginasStatic Equipment Installation ProceduresNovan RosyandyAinda não há avaliações

- 1242352015di400100 D1Documento6 páginas1242352015di400100 D1Cristinel NechiforAinda não há avaliações

- Nqd-Valve Installation ReportDocumento21 páginasNqd-Valve Installation ReportprathameshAinda não há avaliações

- Practical Guidelines For Determining Electrical Area ClassificationDocumento17 páginasPractical Guidelines For Determining Electrical Area ClassificationOmar AzzainAinda não há avaliações

- Pttep Painitng of Offshore FacilitiesDocumento66 páginasPttep Painitng of Offshore FacilitiesSufianAinda não há avaliações

- Corporate Proposal For Vertical Flare Stack InstallationiDocumento13 páginasCorporate Proposal For Vertical Flare Stack InstallationiJude EdohorAinda não há avaliações

- INSPECTION AND TEST PLAN FOR AIR PREHEATERDocumento27 páginasINSPECTION AND TEST PLAN FOR AIR PREHEATERBui van DiepAinda não há avaliações

- NE1 700MW CSP + 250MW PV Hybrid Project Punch Items ListDocumento10 páginasNE1 700MW CSP + 250MW PV Hybrid Project Punch Items ListFuqingliAinda não há avaliações

- Piping Material Class Description SummaryDocumento22 páginasPiping Material Class Description SummaryFabio S.Ainda não há avaliações

- Requisition For HRSG Packages: (10301-H-PKG & 10401-H-PKG)Documento206 páginasRequisition For HRSG Packages: (10301-H-PKG & 10401-H-PKG)ThiruppathirajanAinda não há avaliações

- Bifold UpdatedDocumento8 páginasBifold UpdatedGopinath GunasekaranAinda não há avaliações

- MD1-0-T-030-05-00072 - ITP For AG Piping of Alloy SteelDocumento8 páginasMD1-0-T-030-05-00072 - ITP For AG Piping of Alloy SteelTran KhuynhAinda não há avaliações

- HSVC Ol1/ Zone 2 Hydro Test Organization Chart: PhoneDocumento4 páginasHSVC Ol1/ Zone 2 Hydro Test Organization Chart: PhoneTuấn PhạmAinda não há avaliações

- 29H-YM English PDFDocumento108 páginas29H-YM English PDFdeni subandiAinda não há avaliações

- 0127-Tp-01ab - Sample Tie in PackageDocumento11 páginas0127-Tp-01ab - Sample Tie in Packagemengelito almonteAinda não há avaliações

- Installation Method for Key Process EquipmentDocumento54 páginasInstallation Method for Key Process EquipmentNGUYEN VINHAinda não há avaliações

- Cooler Drawin API-23 Seal PlanDocumento5 páginasCooler Drawin API-23 Seal PlankishorsinghAinda não há avaliações

- Turbine BOP Drawing SubmissionDocumento1 páginaTurbine BOP Drawing SubmissionAnonymous JtYvKt5XEAinda não há avaliações

- Equipment Preservation Standard Specification - MCE EG016 CDocumento4 páginasEquipment Preservation Standard Specification - MCE EG016 CSenol LimanAinda não há avaliações

- Specification For Hdpe (3lpe) Coating of Carbon Steel PipesDocumento21 páginasSpecification For Hdpe (3lpe) Coating of Carbon Steel PipesDanish MohammedAinda não há avaliações

- Hydrotest Schematic Diagram Stage-2 (From Valve Station-2 To Valve Station-1)Documento1 páginaHydrotest Schematic Diagram Stage-2 (From Valve Station-2 To Valve Station-1)mansih457100% (1)

- Air, Steam Vent Silencer - Enquiry Data SheetDocumento1 páginaAir, Steam Vent Silencer - Enquiry Data Sheetkishore1214Ainda não há avaliações

- Irp 2011Documento771 páginasIrp 2011Eric RehmAinda não há avaliações

- 100004846-TS002 - Pump Skid + Pipework Rev 2Documento13 páginas100004846-TS002 - Pump Skid + Pipework Rev 2javier cabrera picassoAinda não há avaliações

- GA Drawing Deluge Valve System - R2Documento4 páginasGA Drawing Deluge Valve System - R2Keannu Radhika Putra WibowoAinda não há avaliações

- GS P&D Archsd 2012Documento127 páginasGS P&D Archsd 2012Andy Lee100% (1)

- Design and Fabrication of Heat Exchanger Using PCMDocumento13 páginasDesign and Fabrication of Heat Exchanger Using PCMArjun Gr0% (1)

- Technical Bid No 1Documento235 páginasTechnical Bid No 1kaushalAinda não há avaliações

- Renderoc TGDocumento2 páginasRenderoc TGMansoor Ali50% (2)

- CIT Procedure - 14.02.2020 - Rev.01 PDFDocumento9 páginasCIT Procedure - 14.02.2020 - Rev.01 PDFAashish MoyalAinda não há avaliações

- Hydrostatic Testing SpecificationDocumento17 páginasHydrostatic Testing Specificationmahdi_g100% (1)

- Lowering Pipe SafelyDocumento5 páginasLowering Pipe SafelyLarry Ubu100% (1)

- Factors Contributing To Foarming Crude OilDocumento11 páginasFactors Contributing To Foarming Crude OilSang Duong Van100% (1)

- Procedure for hydro & pneumatic tank testingDocumento3 páginasProcedure for hydro & pneumatic tank testingNupesh katreAinda não há avaliações

- JP CO2, FM-200 & Fire Alarm SystemDocumento9 páginasJP CO2, FM-200 & Fire Alarm SystemL KISHORE REDDYAinda não há avaliações

- Modelling of A Coil Steam Generator For CSP ApplicationsDocumento10 páginasModelling of A Coil Steam Generator For CSP ApplicationsAnonymous 3fTYXaW7WAinda não há avaliações

- NT2 L3 M 000 21 00015 - Pigging - CleaningDocumento26 páginasNT2 L3 M 000 21 00015 - Pigging - CleaningHuynh Thanh Tam100% (1)

- Procedure for Steam Blowing & Oil Flushing of F.O. SystemDocumento9 páginasProcedure for Steam Blowing & Oil Flushing of F.O. Systemsrigirisetty208Ainda não há avaliações

- 40 m3 Diesel Tank User ManualDocumento10 páginas40 m3 Diesel Tank User ManualAhmed MagdAinda não há avaliações

- InsulationDocumento63 páginasInsulationSH1961Ainda não há avaliações

- Kaneko Sangyo Co.,LtdDocumento28 páginasKaneko Sangyo Co.,LtdHuynh Thanh TamAinda não há avaliações

- Mittal Plate Fabrication GuideDocumento101 páginasMittal Plate Fabrication GuideSridharan ChandranAinda não há avaliações

- Effect of Rim Seal On Evaporation Loss From Khark Island Storage Tanks 2157 7463 1 103 PDFDocumento7 páginasEffect of Rim Seal On Evaporation Loss From Khark Island Storage Tanks 2157 7463 1 103 PDFHuynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-015 - 0 - 002 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-015 - 0 - 002 Layout1Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-023 - 0 - 003 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-023 - 0 - 003 Layout1Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-020 - 0 - 003 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-020 - 0 - 003 Layout1Huynh Thanh TamAinda não há avaliações

- GrothCorporationIndustrialCatalog (TTT)Documento194 páginasGrothCorporationIndustrialCatalog (TTT)Huynh Thanh TamAinda não há avaliações

- 200MW Volume 1Documento350 páginas200MW Volume 1api-19984595100% (9)

- Installation and Operation Instructions PDFDocumento39 páginasInstallation and Operation Instructions PDFHuynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-017 - 0 - 002 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-017 - 0 - 002 Layout1Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-013 - 0 - 003 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-013 - 0 - 003 Layout1Huynh Thanh TamAinda não há avaliações

- T 2171 - Diesel Storage TankDocumento2 páginasT 2171 - Diesel Storage TankHuynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-019 - 0 - 003 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-019 - 0 - 003 Layout1Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-022 - 0 - 003 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-022 - 0 - 003 Layout1Huynh Thanh TamAinda não há avaliações

- CM1 L3 C 10uej 55 000006 010Documento1 páginaCM1 L3 C 10uej 55 000006 010Huynh Thanh TamAinda não há avaliações

- CM1 L3 C 10uej 55 000006 005Documento1 páginaCM1 L3 C 10uej 55 000006 005Huynh Thanh TamAinda não há avaliações

- CM1 L3 C 10uej 55 000006 011Documento1 páginaCM1 L3 C 10uej 55 000006 011Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-008 - B - 002 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-008 - B - 002 Layout1Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-013 - 0 - 003 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-013 - 0 - 003 Layout1Huynh Thanh TamAinda não há avaliações

- CM1 L3 C 10uej 55 000006 010Documento1 páginaCM1 L3 C 10uej 55 000006 010Huynh Thanh TamAinda não há avaliações

- CM1 L3 C 10uej 55 000006 004Documento1 páginaCM1 L3 C 10uej 55 000006 004Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-013 - 0 - 003 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-013 - 0 - 003 Layout1Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-017 - 0 - 002 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-017 - 0 - 002 Layout1Huynh Thanh TamAinda não há avaliações

- CM1 L3 C 10uej 55 000006 011Documento1 páginaCM1 L3 C 10uej 55 000006 011Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-004 - B - 003 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-004 - B - 003 Layout1Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-004 - B - 003 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-004 - B - 003 Layout1Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-005 - B - 002 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-005 - B - 002 Layout1Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-004 - B - 003 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-004 - B - 003 Layout1Huynh Thanh TamAinda não há avaliações

- CM1-L3-C-10UEJ-55-000006-006 - B - 003 Layout1Documento1 páginaCM1-L3-C-10UEJ-55-000006-006 - B - 003 Layout1Huynh Thanh TamAinda não há avaliações

- BEB801 Engineering Project Literature SearchDocumento9 páginasBEB801 Engineering Project Literature SearchAaron PalmAinda não há avaliações

- Handbook of Energy Economic Statistics of Indonesia 2016Documento71 páginasHandbook of Energy Economic Statistics of Indonesia 2016Jeff LiewAinda não há avaliações

- MM SharmaDocumento2 páginasMM SharmaMahesh ParitAinda não há avaliações

- Ron Paul MdmaDocumento9 páginasRon Paul MdmaTeetje BelitzAinda não há avaliações

- Downhole Chemical Injection Lines Why Do They Fail Experiences Challenges and Application of New Test MethodsDocumento11 páginasDownhole Chemical Injection Lines Why Do They Fail Experiences Challenges and Application of New Test MethodsAcbal AchyAinda não há avaliações

- BKV Application Form (Sea Staff) Rev08Documento5 páginasBKV Application Form (Sea Staff) Rev08Mehmet ErgeanAinda não há avaliações

- Effect of Barite On Density of Drilling MudDocumento3 páginasEffect of Barite On Density of Drilling MudAtif MalikAinda não há avaliações

- Mechanical Engineering Steam Boilers MCQsDocumento46 páginasMechanical Engineering Steam Boilers MCQsl8o8r8d8s8i8v8Ainda não há avaliações

- ViscosityDocumento2 páginasViscosityworkover5Ainda não há avaliações

- Honda PDFDocumento1 páginaHonda PDFGiurgiu Revicom OilAinda não há avaliações

- PDFDocumento32 páginasPDFgharsallah mouna100% (1)

- TCS P 104 02 R0Documento13 páginasTCS P 104 02 R0sathishlinshanAinda não há avaliações

- Dando Mintec-18 - Mineral Exploration Rig AustraliaDocumento2 páginasDando Mintec-18 - Mineral Exploration Rig AustraliaTaylor Oughton50% (2)

- Blast Resistant Modular BuildingsDocumento6 páginasBlast Resistant Modular BuildingsJaime Hernandez100% (1)

- Sunflower Oils - Carriage On TankersDocumento3 páginasSunflower Oils - Carriage On TankerswisnukerAinda não há avaliações

- Alkylation, Dealkylation, and HydrodealkylationDocumento3 páginasAlkylation, Dealkylation, and HydrodealkylationJoy MorilesAinda não há avaliações

- Final Report - Khairina PWEDocumento51 páginasFinal Report - Khairina PWENurhafiza M GhaziAinda não há avaliações

- Variable Frequency DriveDocumento26 páginasVariable Frequency DriveAshish KatochAinda não há avaliações

- CASE 580 Super M Presentation PreliminaryDocumento6 páginasCASE 580 Super M Presentation PreliminaryDian SikumbangAinda não há avaliações

- Industrial charcoal production processesDocumento5 páginasIndustrial charcoal production processesjtreiber6627Ainda não há avaliações

- Alarmas y Paros Waukesha s-8382-03 PDFDocumento3 páginasAlarmas y Paros Waukesha s-8382-03 PDFmdo100% (1)

- HseDocumento14 páginasHseKiran KumarAinda não há avaliações

- Frequently Asked Questions On Natural Gas - Hindustan Petroleum Corporation Limited, IndiaDocumento5 páginasFrequently Asked Questions On Natural Gas - Hindustan Petroleum Corporation Limited, IndiaDAYARNAB BAIDYAAinda não há avaliações

- Filtros 793DDocumento4 páginasFiltros 793DDAnielAinda não há avaliações

- Engine Lubrication SystemsDocumento8 páginasEngine Lubrication SystemsMentsnot GetuAinda não há avaliações

- API 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical IndustriesDocumento3 páginasAPI 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical IndustriesMonica CifuentesAinda não há avaliações

- Descaling SOPDocumento2 páginasDescaling SOPTauqir ShaukatAinda não há avaliações

- Driver Manual Scania New - 1011 - en-GB PDFDocumento905 páginasDriver Manual Scania New - 1011 - en-GB PDFfajardiniant100% (6)

- ME6404-Thermal EngineeringDocumento17 páginasME6404-Thermal EngineeringAnonymous dIhhKAAinda não há avaliações