Escolar Documentos

Profissional Documentos

Cultura Documentos

QA For Biopharmaceuticals

Enviado por

sakib445Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

QA For Biopharmaceuticals

Enviado por

sakib445Direitos autorais:

Formatos disponíveis

YHdIM~CEIJTIC~

iZ(:TA HELVETIAE

ELSEVI ER Pharmaceutics Acta Helvetiae 71 (1996) 421-438

Quality assurance for biopharmaceuticals: An overview of regulations,

methods and problems

Kristian M. Miiller a,1, Mathias R. Gempeler b, Max-Werner Scheiwe , B. Tatjana Zeugin d3*

Biochemisches I nstitut der Uniuersitiit Ziirich, Winterthurerstr. 190, CH-8057 Zurich, Switzerland

b Pentapharm AG, Engelgasse 109, CH-4002 Basel, Switzerland

Mepha AC, Dornacherstrasse 114, Post$ach, CH-4147 Aesch, Switzerland

Regionale Fachstelle fir Heilmittelkontrolle, Missionsstrasse SO, Postfach, CH-4012 Basel, Switzerland

Received 8 May 1996; revised 18 June 1996; accepted 21 August 1996

Abstract

This paper provides an overview of regulations with special regard to Good Manufacturing Practice (GMP) of biopharmaceuticals in

different countries (Switzerland, European Union, USA). Problems during the set-up and maintenance of a cell bank and expression

system, fermentation, protein purification, and product testing are outlined as well as methods and techniques for quality assurance during

these processes. Freeze-dlying and aseptic filling of the finished dosage form are discussed.

Keywords: Biopharmaceuticals; Guidelines; Quality assurance; GMP; Fermentation: Purification; Lyophilization: Formulation

1. Introduction

Biopharmaceuticals, here defined as products manufac-

tured by biotechnological means and genetical engineering,

have become an important tool in medical therapy. Al-

though they are relatively young products and knowledge

on the handling of them is still growing they are consid-

ered as safe and efficient as conventional drugs by physi-

cians, patients and a wide part of the population (e.g.

antibiotics, insulin, interferons).

However, compared to conventional drugs most bio-

pharmaceuticals must be administered by parenteral route.

They mostly require careful handling and manufacturing

methods like lyophilization and aseptic filling and must be

stored at low temperatures to preserve stability. Biophar-

maceuticals are still developing products that demand

progress in analytical and manufacturing methods and

techniques, and they also demand new considerations of

how quality, safety and efJicacv can be achieved.

2. Regulations, authorities, quality assurance and GMP

Abbreviations: CPMP: Committee for Proprietary Medicinal Prod-

ucts; EC: European Commission; FDA: Food and Drug Administration;

IOCM/IKS: Intercantonal Office for the Control of Medicines/Interkan-

tonale Kontrollstelle ftir Heilmittel; ISO: International Standard Organiza-

tion; NIH: National Institutes of Health; OECD: Organization for Eco-

nomic Cooperation and Development; PIC: Pharmaceutical Inspection

Convention; WHO: World Health Organization

* Corresponding author. Tel.: +41-61.2672390; Fax: +41-61-

2672385.

E-mail: kristian@bioc.unizh.ch.

Biopharmaceuticals open the way to new forms of

therapy. They require a specific collaboration among uni-

versity, industry, and authorities. Regulations in this field

are manifold and it is not always easy to have an overview

on them, since their status in the legal hierarchy may

spread from law to strong recommendation. Due to this

fact the term legal requirements must be understood in a

widespread sense in this paper.

0031-6865/96/$15.00 Copyright 0 1996 Elsevier Science B.V. All rights reserved.

PII SOO31-6865(96)00050-7

422 K.M. Miiller et al. / Pharmaceutics Acta Heluetiae 71 (1996) 421-438

2.1. The role of regulatory bodies

Extensive documentation on chemical, pharmaceutical,

toxicological and clinical characteristics of the product are

required and examined by the authorities before a product

gets approval. This to make sure that the patient will get a

safe and efficient product of the quality needed. Since

biotechnological products are fast and steadily developing

drugs, every new product enhances the know-how in this

field. Thus regulatory bodies profit out of this fact, compil-

ing problems and solutions, and getting a good overview

on the latest findings and pivotal problems in the whole

field.

The mandate of regulatory authorities is to approve

products of state of the art quality, safety and efficacy. The

ongoing of worldwide collaboration in this field becomes

evident by the fact that in December 1995 the third

International Conference on Harmonization (ICH) took

place in Yokohama, Japan. Scientists and experts from

regulatory bodies and industry met there to discuss harmo-

nization issues concerning the approval requirements in

Europe, USA and Japan, however, implementation of har-

monized guidelines must still be adopted by the competent

authorities in the relevant countries.

Table 1 shows legal requirements concerning conuen-

tional and biotechnological products. Basically one can

say that biotechnologically and genetically engineered

products must fulfill the same criteria of quality, safety and

efficacy like conventional drugs. The structure of legal

requirements is world-wide approximately the same,

namely Good Clinical Practice (GCP), Good Laboratory

Practice (GLP), Good Manufacturing Practice (GMP),

biosafety requirements and application requirements, but

they have not always the same wording. Differences are

quite common and may jeopardize registration of a product

depending on the approving country. International meet-

ings like the ICH-Conference try to harmonize all the

various registration requirements. Table 1 also shows that

application requirements are a compilation of data from

particular requirements as GCP, GLP, GMP and biosafety

evaluation including environmental impact evaluation and

protection of the population and employees as well.

Two guidelines concerning the quality of biotechnologi-

cal products were adopted at the ICH meeting at Yoko-

hama, namely:

- Analysis of the expression construct in cells used for

production of r-DNA derived protein products

(CPMP/ICH/139/95, 1995).

* Stability testing of biotechnological/biological prod-

ucts (CPMP/ICH/138/95, 1995).

Further, one guideline concerning quality was given free as

a draft document for discussion, namely:

* Viral safety evaluation of biotechnology products de-

rived from cell lines of human and animal origin

(CPMP/ICH/295/95 Draft, 1995).

These three CPMP/ICH guidelines refer to the quality of

biotechnological products. Quality is one of the pivotal

issues when regulatory authorities examine the documents

of application. But examination is not enough. They will

also inspect the companies to have an insight on good

manufacturing practices (GMP) at the production site may

it be for the bulk substance or the bulk and finished

product.

Other ICH-guidelines that concern conventional and

Table 1

Legal requirements a concerning efficacy, safety and quality of pharmaceuticals

Legal requirements Purpose/function

Good Clinical Practice (GCP)

_

evaluation of the eflcacy and safety of the product

- safety for the test person (ethic requirements)

_

protection of the patients

Good Laboratory Practice (GLP) (OECD) - evaluation of the toxicological safety

_

protection of test persons/patients

Good Manufacturing Practice (GMP) - evaluation of the manufactured (built in) qualify of a product

_

protection of the product (safety, efficacy)

_

protection of the patient (safety, efficacy)

Biosafety requirements

- Environmental requirements

_

evaluation of the environment protection

_

protection of the environment and population

- Preventive health requirements - protection of the employees

Application requirements (registration)

_

requirements concerning the documentation to be submitted for examination to the authority

- documentation contains: compilation of sajery, efficacy and quality data

a See Section 2.

K.M. Miiller et al. /Pharmaceutics Acta Hehetiae 71 (1996) 421-438 423

biotechnological products were adopted in December 95 as

well. They regulate toxicological (GLP) and clinical topics

(GCP). So the titles were on

* Clinical study reports format and content

(CPMP/ICH/137/95, 1995).

- Guideline on the need for carcinogenicity studies of

pharmaceuticals (CPMP/ICH/140/95, 1995).

- Reproductive toxicology: toxicity to male fertility,

(CPMP/ICH/136/95, 1995).

* Stability testing requirements for new dosage forms

(CPMP/ICH/280/95, 1995).

- Validation of analytical procedure methodology

(CPMP/ICH/281/95, 1995).

.

Impurities of new drug products

(CPMP/ICH/282/95, 1995).

- Clinical safety data management: periodic safety up-

date reports for marketed drugs (CPMP/ICH/288/95,

1995).

Before quality assurance and GMP requirements will be

discussed in detail some short comments on GCP and GLP

requirements are given.

GCP requirements deal with the clinical evaluation of

the biopharmaceutical or drug and answer questions on

eficacy including potency and adverse reactions (safety).

GCP regulations have been adopted in Switzerland on 18

November 1993 by the IKS (IOCM/IKS, 1993). This

regulation adopted by IKS strongly involves the 26 can-

tons of Switzerland in applying the statements of this

regulation. This regulation is above all based on the Guide-

lines to Good Clinical Practice for Clinical Trials of

Medicines of July 1991 of the European Communities

(EC, 1991).

GLP requirements mustnt be mixed up with analytical

laboratory requirements concerning the control of bulk

substance, bulk product and finished product. Those qual-

ity control requirements are a part of GMP.

The connotation GLP is still dedicated to the first good

practice regulations that dealt with the conducting of non-

clinical laboratory studies (OECD, 1981; CFR/FDA,

1995a). Therefore GLP includes in vitro and in vivo

laboratory studies that determine the safe9 of a product

whereas GMP related analyses mainly determine quality.

2.2. Quality assurance and GMP requirements

Quality assurance (QA) is a system involving all re-

sources (manpower, machines, know-how, knowledge, etc.)

of a company to produce a product of the quality required

by the customer/authority and considered safe and effi-

cient by the authorities to the benefit of the employees, the

company and the patient.

QA involves all divisions of a firm and to be successful

QA must be aware of the key problems in the manufactur-

ing of drugs/biopharmaceuticals. QA must know what

level of quality has to be assured with the existing and

steadily progressing techniques/methods. Further, due to

the steadily progressing biotechnological and recombinant

techniques and even more recent ways of therapeutic

progress the firm and QA must steadily acquire new

knowledge and keep up with science and legal require-

ments. Science, development, research and legal/regu-

latory requirements are linked to each other, since develop-

ment will change the current state of the art, and regula-

tions will and must alter accordingly.

This definition shows that quality assurance is a quality

system applicable to conventional drugs as well as to

biopharmaceuticals. Development of quality concerning

aspects began with the quality control of a product, where

quality was analyzed into the product. Modem concepts

include quality assurance (QA) and quality management

(e.g. total quality management (TQM) and IS0 9000).

Basic requirements of GMP are applied to conventional

drugs as well as to biotechnological products, since the

aim to produce quality and the way to get there are

basically not different. So the following points are of great

importance:

The quality assurance (QAI department is responsible

to build up a quality system with the support of the

companys upper management. QA has a coordinating

function between the intercepts of a company and must

involve following points into a quality system:

- a documentation system,

- appropriate equipment and facilities, including engi-

neering and technical supply,

- well-defined and verified production processes and

verification that they lead to a suitable quality (valida-

tion, qualification),

* verification of quality control laboratories and verifica-

tion that their analyses/methods are reliable (valida-

tion, qualification),

- verification of the quality of design, dellelopment and

research (aims),

- need for skilled. well-trained personnel with adequate

and steadily growing knowledge and know-how,

- others: like hygiene-requirements, warehousing, elec-

tronic data processing (EDP), registration relevant re-

quirements, purchase and sales, legal (patents) and

medical department requirements.

2.3. GMP in Switzerland and Europe

All legal requirements undergo a certain hierarchy and

so do regulations on GMP in Switzerland as well as in

Europe and the USA (Table 2).

424 KM Miller et al. /Pharmaceutics Acta Heluetiae 71 (1996) 421-438

The manufacture of immunobiological (e.g. vaccines)

and blood and most blood-derived products in Switzerland

is regulated by the Federal Office of Health (BAG),

whereas all other medicinal products are regulated by the

Cantons. Switzerland is divided in 26 Cantons (comparable

to Bundeslander in Germany or States in the USA).

These 26 Cantons have founded a concordat called In-

terkantonale Vereinbanmg wherefrom the Intercantonal

Office for the Control of Medicines/Interkantonale Kon-

trollstelle fur Heilmittel (IOCM/IKS) emerged.

IOCM/IKS, on behalf of the cantons, is responsible for

the approval of medicinal products. GMP-matters, how-

ever, are still cantonal or regionally structured, e.g. there

already exist regional concordats of several cantons. In the

field of GMP the IOCM/IKS has issued Manufacturing

Guidelines (latest revision 18 May 1995) (IOCM/IKS,

1995) which adopt the Guide to Good Manufacturing

Practice of May 1992 issued by PIC and also consider

recommendations of the World Health Organization

(WHO). PIC is the Pharmaceutical Inspection Convention

that was founded in 1970 by EFTA-countries (Switzerland

was one of the founding countries). In brief one can say

that the GMP-Guidelines on Good Manufacturing Practice

for Medicinal Products are mandatory in the countries of

the European Union as well as in Switzerland.

Table 2

General regulations on GMP

IOCM/IKS Switzerland European Union

European directives and guidelines but also interna-

tional regulations (e.g. WHO, European Pharmacopoeia)

are considered in Swiss legislation and they are often

accordingly adapted into Swiss law.

2.3.1. Guidelines on GMP

Basic GMP-guidelines are the same for conventional

products as well as for biopharmaceuticals. With the bio-

pharmaceuticals some supplementary requirements have to

be considered. So the PIC- and EU-Guide (Guide to Good

Manufacturing Practice for Pharmaceutical Products, Doc-

ument PH 5/89 and amendment 5/92; The Rules govern-

ing Medicinal Products in the European Community, Vol.

IV, Guide to Good Manufacturing Practice for Medicinal

Products (EC Document 111/3093/92-EN, 1992)) are ap-

plicable to biopharmaceuticals and have virtually the same

wording with some minor exceptions. These two guide-

lines consist of the following chapters which point out the

pivotal items to consider in manufacturing, namely:

(1) Quality management and quality assurance

The requirements to get a product on the market are

complex and therefore quality management and quality

assurance are essential for a company. In fact without a

QA-system that systematizes and coordinates the manifold

issues, it is not possible nowadays to produce a GMP-con-

FDA; USA

Interkantonale Vereinbarung liber die Kontrolle

der Heilmittel (3rd June 19711 (IOCM/IKS,

1971) (Concordat of 26 Swiss Cantons = IKS)

Regulation on the Control of medicinal products

of 25th May 1972; amended 23rd November

1995 (I~CM/IKS, 1972/1995)

Richtlinien der IKS betr. die Herstellung von

Arzneimitteln (Manufacturing Guidelines of 18th

May 1995) (IOCM/IKS, 1995)

Convention for the Mutual Recognition of In-

spection in Respect of the Manufacture of Phar

maceutical Products: PIC-Guide to Good Manu-

facturing Practice for Pharmaceutical Products

PH 5/89 May 1989 (PIG, 1989); amended/sup-

plemented 1992 (PIG, 1992b) and adapted to

respective EC-regulations

Community procedures for the authorization and

supervision of medicinal products for human and

veterinary use and establishing a European

Agency for the Evaluation of Medicinal Products

(EMEA) + Council Regulations

Commission of the European Communities: Reg-

ulations or administrative action relating to pro-

prietary medicinal products: EC Council Direc-

tive 65/65/EEC (19651, amendments: EC

Council Directive 83/570/EEC; 87/21/EEC;

87/22/EEC; 89/341/EEC; 75/318/EEC:

75/319/EEC

Commission Directive 91/356/EEC: Guidelines

of good manufacturing practice for medicinal

products for human use (EC Directive

91/356/EEC, 19911

Committee for Proprietary Medicinal Products

(CPMP): The Rules Governing Medicinal Prod-

ucts in the European Community Volume IV:

Good Manufacturing Practice for Medicinal

Products (1989); amended/supplemented EC

Document 111/3093/92-EN, 1992

Federal Food, Drug and Cosmetic Act of 1983

(Congress)

Code of Federal Regulations 21 CFR: 21 CFR

200-299 (CFR/FDA, 1995b): 21 CFR 600-699

(CFR/FDA, 1995~1; Biologics

guidelines, guides

Several more specific guidelines, notes for guidance, points to consider (PTC).

K.M. Miiller et al./Phannaceutica Acta Heloetiae 71 (1996) 421-438 425

form product. QA and GMP begin even before product

development begins namely with project management and

planning.

(2) Personnel

The know-how of the personnel is most important, but

the company must also ensure that the know-how can be

kept on a high level. Therefore training is essential as well.

Further, there is not only the know-how on methods,

techniques, etc., the hygiene aspect must flow into every-

days behavior in the firm.

(3) Premises and equipment

Premises and equipment must be maintained and cali-

brated. But before maintenance becomes an issue equip-

ment must be qualified, carrying out installation and opera-

tion qualification where the proof must be given that they

fulfill the purpose they are supposed to do. This is true for

heating, ventilation, air supply, water supply and so on.

(4) Documentation

Everything that one carries out must be written down to

give proof that the work was really done. This means that

documentation has sometimes even an implicit role in QA.

Less stringent forms may be seen in other branches, but

not in the pharmaceutical field.

This means that already planning must be reported,

carrying out of the planned must be reported and finally

the conclusion drawn must be reported in a concise and

informative way. Therefore manufacturing protocols must

be rather detailed. It does not suffice if one writes down

that e.g. sugar was added, it must be said when it was

added and under which circumstances (e.g. temperature,

stirring speed and so on). Relevant documents are SOPS

(Standard Operating Procedures), master formulas, batch

records, specifications, certificates of analysis, analytical

methods, qualification and validation reports, development

reports and others.

(5) Production

This chapter describes items like prevention of cross-

contamination, which is linked to cleaning validation, vali-

dation, choosing of starting materials, processing opera-

tions of intermediate and bulk products, packaging materi-

als and operations, the finished product and rejected, re-

covered and returned material. Validation of production

processes has become a very important item and recently a

new PIC guideline (PH I /96 (PIC, 1996)) has been issued

on Principles of Qualification and Validation in Pharma-

ceutical Manufacture. This guideline comprises recom-

mendation on four topics:

- validation master plan,

- installation and operational qualification,

- non-sterile process validation,

- cleaning validation.

In the above mentioned guidelines process validation is

defined as: Documented verification that the integrated

system functions as intended, in its normal operating envi-

ronment. Validation is a project requiring collaboration

of experts of various disciplines and it is important and

more important than ever that specialists work together on

the verification of a process, piece of equipment and so on.

This might also be the challenge in todays world where

everybody gets trained as a specialist within its field and

must cooperate with others in their field. Therefore valida-

tion is a most demanding challenge.

(6) Quality control

Here we finally get to the laboratory and the control of

products and release of them. Quality control has changed

its status in the release of products since its unique impor-

tance to determine quality has been replaced by the con-

cept to directly produce quality and to already detect

quality problems during manufacturing applying in process

controls (IPC) and qualification and validation. However,

quality control confirms quality and it is therefore still the

last check before the products come to the market. Confir-

mation of quality or certifying quality is still an important

task and may be crucial.

(7) Contract manufacture and analysis

The outcontracting of process steps must thoroughly

define the contract givers and the contract acceptors

responsibilities, since misunderstandings could lead to a

product of insufficient quality.

(8) Complaints and product recall

Complaints may give hints with regard to problems

occurring during the manufacturing process. Therefore

there should be a system to review these complaints

according to written procedures. Further, a preventive sys-

tem should be established in case that a deficiency leads to

a recall from the market.

(9) Self inspection

Whether a system built up by a company does work,

should be checked internally carrying out self inspections.

The supplementary guideline that may be applied to

parenterally applied biopharmaceuticals and conventional

drugs is integrated in the above mentioned GMP-guides

and deals with the manufacturing of sterile pharmaceutical

products (PIG, 1992a).

Other guidelines that are relevant for biopharmaceuti-

cals are the supplementary EC/PIG-guideline to the

EU/PIC-GMP-Guide 012 manufacture of biological phar-

maceutical products for human use and others like

- EC Council Directive 87/22/EEC (1987) on the ap-

proximation of national measures relating to the placing

on the market of high-technology medicinal products,

particularly those derived from biotechnology.

- Ad hoc working party on biotechnology/pharmacy

111/3477/92 Note for Guidance concerning Production

426 K.M. Miiller et al. / Pharmaceutics Acta Heluetiae 71 (1996) 421-438

and Quality Control of Medicinal Products derived by

recombinant DNA technology.

2.4. GMP in the USA

The regulations and points of view of the US regulatory

authority Food and Drug Administration (FDA) are cer-

tainly important for every manufacturer all over the world.

Therefore we will first give a short overview how quality

relevant FDA regulations concerning the production of

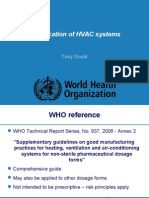

drugs/biopharmaceuticals are organized (Fig. 1).

The Congress enacts the Food, Drug and Cosmetic Act

(FD and CA) and FDAs existence is due to the mandate

to approve drugs based on the demonstration of safety,

efficacy and quality. FDA is divided in five divisions,

however, we are only interested in two of them, namely

CBER (Center for Biologics Evaluation and Research) and

CDER (Center for Drug Evaluation and Research). Nor-

mally CBER evaluates biotechnological products, but not

all biotechnologically manufactured products have been

Congress

c

Food, Drug & Cosmetic Act (FD&C Act)

I

f

FDA

(Food and Drug Administration)

// \\\

Food CBER CDER CVM Med. Devices

CBER: Center for Biologics Evakption and Research

CDER: Center for Drtk# Ev$uation aryJ Research

CVM: Center of etennary Medme

FDA

(FD&C Act)

c

Laws / Regulations

e.g. US Code of Federal Regulations

PlCFR; Parts 200 - 299: Drugs

Parts 600 - 699: Biologics

Guidelines / Guides / Points to Consider

W-1

(e.g. Biotechnology inspection Guide Nov. 91)

Fig. 1.

examined by CBER. For example, erythropoetin was regu-

lated by CDER.

In general, FDA like the European and Swiss authori-

ties has stated that drugs produced by the new biotech-

nology will be regulated in the same way as conventional

drugs.

As already mentioned in Table 2 laws and regulations

undergo a certain hierarchy, therefore the Code of Federal

Regulations (CFR) is on a higher legal level compared to

the guidelines and guides which have the status of recom-

mendations, however, most stringent recommendations.

Points to consider are even on a lower level, since they are

the reaction of the authority to keep up with the latest

trends in the pharmaceutical and/or biotechnological field.

If you can prove that you get a safe and efficient drug of

good quality with other adequate means than recom-

mended, then you neednt follow the recommendations,

but often the recommendations show you the latest level of

the state of the art and therefore they will become a must.

2.4.1. Specific guidelines on GMP / biotechnological

guidelines

In general GMP-guidelines must be applied with

biotechnological products as well. This is evident when we

take out the citations of other regulations from the Biotech-

nology Inspection Guide (Nov. 1991). The following

guidelines are cited in it:

Guideline on General Principles of Process Validation,

May 1987 (FDA, 1987a).

Guide to Inspections of High Purity Water Systems,

July 1993 (FDA, 1993a).

Guide to Inspections of Validation on Cleaning Pro-

cesses, July 1993 (FDA, 1993~).

Guideline on Sterile Drug Products Produced by Asep-

tic Processing, June 1987 (FDA, 1987b).

Guide to Inspections of Lyophilization of Parenterals,

1993 (FDA, 1993b).

U.S.P. Antimicrobial Preservative Effectiveness Test.

NIH (National Institute of Health&Guidelines for re-

combinant DNA research (1987, 1988).

Specific guidelines for biopharmaceuticals will be dis-

cussed in the subsequent part.

3. Problems and methods in the fermentation and pu-

rification of a recombinant protein

3.1. Quality assurance and control of the host and expres-

sion system

The variety of hosts used in research and industrial

biotechnology is enormous and includes species from all

K.M. Miiller et al. / Pharmaceutics Acta Helretiae 71 lI 996) 421-438 421

kingdoms. This enormous number of hosts can be nar-

rowed down to a handful of organisms and cell types,

mainly used as model systems in research for some time,

when biopharmaceuticals are considered. Typical hosts are

E. coli K12 derivatives, Saccharomyces cereuisiae, and

cell lines like CHO or C127. The difference originates

from the stringent requirements employed in the testing

and evaluation of each compound of the production pro-

cess, including the host and expression system.

The choice of the host is often determined by the

product as not all organisms can produce every protein.

This selection also greatly influences the whole down-

stream processing procedure. The same holds true for the

expression system, which is specific for each host. It is

obvious that an expression system that allows the purifica-

tion of the desired protein from a defined supematant or

that results in a high ratio of product to cell debris will

ease purification. Furthermore, and in the case of every

technology prerequisites for using an organism and its

expression system are knowledge, familiarity of staff with

the required procedures and availability of the necessary

equipment.

3.1.1. Problems that may encounter

The precise identification of the host can be a difficult

task when it has to be separated from closely related

organisms or cell types or in the case of an occurrence of a

genetic drift. Problems in detecting contaminating organ-

isms such as phages, related cells, bacteria including my-

coplasma, (retro-) viruses, and fungi increase with the

homology to the host, the decreasing size of these organ-

isms and with their ability to hide within the host. The

stability of the expression system is also a major concern,

especially if the product is toxic and leads to selective

stress for the host. Several types of stabilities, such as

segregational stability for plasmids, insertional stability

(transposon), structural stability (deletion, rearrangement),

sequence stability (base pair substitution, frameshift) have

also to be considered. In this respect, DNA whether de-

rived from the expression system itself or from an exoge-

nous source, can also be seen as a contamination. Unstable

or undefined hosts or expression systems may result in

production levels varying beyond specifications or even

lead to alterations that are dangerous and difficult to detect

in the product.

3.1.2. Approaches of the QA-system

Several guidelines and points to consider notes of the

authorities on how to maintain and identify a defined cell

stock have been published (PTC/FDA, 1987; PTC/FDA,

1994; EC Document 111/3477/92, 1994; FDA, 1991). A

seed lot system with standardized protocols for selection,

preparation, preservation, storage, and adventitious agent

testing of stock cultures should ensure the identity and

safety of the starting raw material.

According to FDA (PTC/FDA, 1987; FDA, 1991) a

cell seed or master cell bank (MCB) is defined as a

quantity of cells derived from a single colony (bacteria.

yeast) or a single eucaryotic cell. The MCB is stored

cryogenically (- 70C or below) in sufficient aliquots, one

or more of which would be used for the production of the

manufacturers working cell bank (WCB). The cell seed

for a diploid cell line should be prepared from cells at a

low doubling level or passage number. The working cell

bank is defined as a quantity of cells derived from one or

more ampoules of the master cell bank, stored cryogeni-

cally and used to initiate the production batch.

In addition a description of the cell strain including its

genealogy and identification characteristics (genotype,

phenotype) must be available and is part of a product

application (PTC/FDA, 1987; FDA, 1991). The origin,

form, storage, use, and expected duration at the anticipated

rate of use must be described in full for all cell banks (EC

Document 111/3477/92, 1994). A record of cell history

should be kept and the population doubling should not

exceed an upper limit specified on the basis of perfor-

mance of the cell culture (FDA, 1991; PTC/FDA, 1987).

Potential viral contamination, cross-contamination with

other cell lines and genetic instabilities should be antici-

pated.

The genetic part of a recombinant product requires the

same attention. A detailed description of the cloned gene

including its sequence and details of origin, identification

and isolation should be available. The origin and structure

of the expression vector should be known and a detailed

map with a complete annotated sequence of functionally

relevant regions is essential. Regions created by ligation

during vector construction and that affect the expression of

the inserted gene should be confirmed by sequencing. The

sequenced parts and those deduced from literature have to

be indicated. The development of modem sequencing tech-

nology should allow to sequence whole standard cloning

vectors.

The status of recombinant DNA within the host cell

should be described. For extrachromosomal expression

systems the copy number and proportion of host cells

retaining the expression construct should be determined.

For integrated copies of a gene the product should be

tested at the mRNA level (EC Document 111/3477/92,

1994). Immortalisation procedures should be described

(FDA, 1991).

EC regulations require that during the establishment of

the banks no other cell lines should be handled simultane-

ously in the same laboratory suite or by the same person

428 K.M. Miiller et al. /Pharmaceutics Acta Heluetiae 71 (1996) 421-438

(EC Document 111/3477/92, 1994). Presently FDA gener- continuous (multiple harvest fermentation). Each fermenta-

ally requires an approved product license application or tion starts with a small starting culture used to inoculate

amendment before a new master cell bank can be gener- the main culture with a volume varying from a few liters

ated (FDA, 1991). to several thousand liters.

3.1.3. Methods concerning host and expression systems

Checks concerning the identity of the host and of the

expression system should address both the genetic and the

protein levels. Table 3 shows tests that may be applied in

various combinations.

3.2.1. Problems that may be encountered

Newly developed expression constructs or cell lines

may help to minimize the problems of instability and false

product formation. For example, for E. coli the stability of

plasmids could be enhanced by the use of segregation loci

on plasmids, like the pat-B locus from the plasmid pSClO1

(Skogman et al., 1983) or postsegregational killing systems

like the hok/sok system (Gerdes, 1988). Recombinant

genes with host codon usage may reduce the incorporation

of incorrect amino acids, while optimized cell strains with

low by-product formation and defined deficiencies, for

example in proteases, may allow higher reproducibility in

expression.

Various factors may influence the reproducibility of a

fermentation run, e.g. varying composition of the media,

non-host contamination, genetic alteration of host or ex-

pression system, loss of expression system, and bad con-

trol of run and set-up parameters. In the case of the raw

materials, especially (bovine-) sera for mammalian cell

culture are of particular concern as they may harbor organ-

isms such as mycoplasm, the hoof and mouth disease or

the bovine spongioform encephalopathy (BSE) (FDA,

1991). Biosafety aspects and environmental concerns in-

crease with the potential toxicity of product or host and the

fermentation volume. The upscale of fermentation can

easily lead to alterations of the product, especially using

mammalian cells.

3.2. Quality assurance and control of the fermentation

process

There are several types of fermentation, which gener-

ally can be described as batch, fed batch (single harvest) or

3.2.2. Approaches of the QA-system

To achieve a high reproducibility of the fermentation

and the final cell suspension, all factors which may inter-

fere with growth and protein production have to be elimi-

nated.

A first step is the stringent control of the raw materials

Table 3

Methods concerning host and expression systems

Points to consider Test/method

Identity of the host and expression system

(especially cloned fragment) on the genetic level

Genomic integration of the vector

Transcription

Translation

Identity of the host and expression system

on the phenotype level

Microbial, viral, mycoplasma contamination

Stability of the expression system

- restriction enzyme mapping

- DNA fingerprinting

_

sequence analysis

- Southemblot analysis

- mRNA or cDNA sequencing

_

protein characterization according to Table 6 in product section

- karyological monitoring

_

characterization of nutrient requirements

_

isoenzyme analysis (e.g. by electrophoreses)

_

growth (doubling time)

_

morphological characterization

_

monitoring reproducibility of product production

_

contamination assays according to Table 6 in product section

_

continuous preparation and quantification of plasmids

_

restriction digest

- sequencing

_

nutritional markers

_

resistance markers (antibiotics)

_

plasmid contents by monitor enzymes (e.g. beta-lactamase),

reproducibility of protein production, and analysis of protein variants

K.M. Miiller et al./ Phamaceutica Acta Heluetiae 71 (1996) 421-438 429

calculation of

specific growth rate

@ = f(F, V, Cco,, Co,)

_<, ,^ **,,

process control

data monitoring

*:,:, .,_

I.

standard controls

glucore ammonia

fed batch mode:

&point for substrate pumps

_, .

offgas-analyzer

gasflow ratio controller

dosage controller

calculation of feeding rate

of growth limiting substrate

Fig. 2. Scheme of a fermentor for E. coli fed batch culture with equipment that allows continuous monitoring for reproducible results (courtesy of D.

Riesenberg and colleagues, HKI Jena).

including water. Sterilization of media prior to use and

aseptic inoculation, transfer and harvesting should prevent

contamination with other organisms. To avoid chemical

contamination the fermentation equipment should prefer-

ably be sterilized with steam. If the facility is used for

different fermentations additional testing for cross contam-

ination is required. Extensive in-process monitoring of the

fermentation parameters facilitates a uniform process and

where necessary an earlier rejection. An example for E.

coli is given in Fig. 2 (Horn et al., in press).

For single harvest production the generation number or

population doubling level should be specified on the basis

of the stability of the host-vector system. For a multiple

harvest production the period of fermentation should be

specified.

In most countries the biosafety requirements are regu-

lated by law and technical notes (NIH, 1986; NIH, 1987;

NIH, 1988). Exempt host-vector systems with inherent

biological safety such as non-pathogenicity, auxotrophy

and non-transmissible vector are generally regarded as safe

(GRAS) (Hasskarl, 1990; BG Chemie, 1991; BG Chemie,

1992). In general the Good Large-Scale Practice (GLSP)

applies (FDA, 1991).

3.2.3. Methods concerning the fermentation process

Table 4 describes methods used in fermentation.

Defined media based upon inorganic and synthetic

chemicals which have been developed in the last number

of years for bacterial (Horn et al., in press), yeast, and

mammalian cell culture (Jumarie and Malo, 199 1) simplify

the control and sterilization of the raw material and also

the task of downstream processing.

3.3. Quality assurance and control of the purification

process

The protein purification starts either with the culture

supematant as for example in the case of monoclonal

antibodies from hybridoma culture or the harvested cells of

the fermentation, e.g. E. coli or Saccharomyces cerevisiae,

in cases where no secretion systems are available. The aim

of purification is to remove all impurities such as product-

related proteins, other proteins, lipids, carbohydrates, nu-

cleic acids and all organisms, especially viruses.

Cells are generally disrupted by physical force, as in the

case of high pressure release in a French- or Gaulin press,

but enzymatic or chemical methods may also be applied.

Filtration or ultrafiltration are usually the first purification

step to concentrate the supematant or to separate the

desired product from cell debris. Further, purification steps

usually take advantage of well established chromatography

430 K.M. Miiller et al./Pharmaceutica Acta Helvetiae 71 (1996) 421-438

such as ion exchange and gel filtration. The most desired

purification is selective for the active protein like affinity

chromatography for antibodies (Scopes, 1994; Deutscher,

1990). Proteins from mammalian cell culture are normally

treated with an additional virus inactivation step, as viruses

are seen as one of the most dangerous contaminations and

therefore requiring special attention.

3.3.1. Problems that may be encountered

During the set-up phase of a purification procedure the

most crucial point is to select the right purification steps

with a capacity allowing to produce pure and active pro-

tein. Once a purification scheme has been established and

upscaled, the main challenge for quality assurance is the

performance of purification steps which are non-robust,

and the ageing of the filter and chromatographic material.

Chromatography media and biological ligands (antibodies)

in particular may leach and exhibit poorer performances.

Depending on the reproducibility of the previous fermenta-

tion and initial purification steps the amount of impurities

may vary, thus demanding constant control. Repeatedly

used columns are a potential source of microbial contami-

nation and bacterial endotoxins.

3.3.2. Approaches of the QA-system

One of the important points for the administration of the

purification process is that the correct validation of all

procedures is achieved. As the procedure behavior may

change with scale, tests should be performed with the final

set-up.

In most countries, chromatographic media in general

must be approved for pharmaceutical production. Media

with biological contents should be produced according to

pharmaceutical standards (e.g. immunoaffinity columns

must be virus free). The sanitation procedure of all mate-

rial involved in purification should be monitored with

challenge tests during the set-up stage and with continuous

controls in the production process. Data collected during

set-up and validation should be used to set the lifetime of

the material.

3.3.3. Methods concerning the purification process

Already well-known methods are generally easier to

validate than new and specific procedures (such as e.g.

affinity chromatography) that may, however, give better

results. A short list of the principle methods is presented in

Table 5.

The physico-chemical properties of the support mate-

rial have to be considered with regard to sanitation, ther-

mostability, etc.

Expression in inclusion bodies yielding highly enriched

protein in aggregates and refolding are techniques em-

ployed in recombinant expression in E. coli, which allow

the expression of disulfide containing proteins and the

circumvention of protease problems and toxic stress on the

host (Rudolph, 1990). In recent years the use of engineered

peptide or protein fusions have become a popular research

tool for protein purification due to their general usefulness

in purification (Nygren et al., 1994). Among these the

His-tag, consisting of five to six histidines fused to either

end of the protein, has been used in several promising

approaches to yield pharmaceutical grade protein (Casey et

al., 1995; Kaslow and Shiloach, 1994).

3.4. Quality assurance and control of the product and in

process controls tI PCJ

This section presents an overview of analytical methods

confirming protein product quality. Tests are most rigor-

Table 4

Methods concerning the fermentation process

Points to consider Test/method

Sterility of facility, media, and gas (aeration) - in place steam sterilizing is the method of choice for the facility

- media should be autoclaved, if impossible, filtration might be used

_

sterile filtration of gas

Filter validation

_

challenge test with Pseudomonas diminutu (FDA, 1987a; FDA, 1987b; FDA, 1987~)

In process control of fermentation - monitoring of growth, product formation and contamination: optical density, pH, temperature,

oxygen pressure, outlet gas, foam, nutrients, waste, by-product level, viscosity, addition of chemicals,

density, flow injection analysis is a good way to monitor metabolites

Lot test with respect to genetic drift

Lot test with respect to contamination

- see host and expression system section in Table 3

- fatty acid profile

- see also product section Table 6

K.M. Miiller et al. / Phannaceutica Acta Helvetiae 71 (1996) 421-438 431

ously applied during the set-up phase and mainly used for

product testing, but are also suitable as in-line process

controls. The more physical and biological properties of

the protein can be exploited and the more specific tests for

impurities are available the better. Although physico-

chemical methods might fully characterize a protein, con-

firmation of quality by biological testing in vitro or in vivo

is often desirable, because they often better reflect real

application. However, the advantage of the latter is some-

times overcome by consistency problems.

3.4.1. Problems challenging the QA-system

Testing protein drugs with their biological impurity

profile and special basic characteristics differs from con-

ventional drug testing. Proteins are of high molecular

weight ranging from lo4 to lo6 g/mol for proteins such

as IgM. The primary peptide sequence folds to secondary

and tertiary structures that might complex to a quartemary

structure. Intra and inter chain disulfide bridges, as well as

Table 5

Methods concerning the purification process

posttranslational modifications such as N- or O-glycosyla-

tion or the hydroxylation of proline are important for

function and immunogenicity. These highly sophisticated

properties give rise to many problems during synthesis,

purification, and product-filling. Proteins may form aggre-

gates or be partially degraded by proteases or thermally

denatured. The glycosylation pattern can vary with fermen-

tation conditions quite easily and wrong disulfide bridges

may be formed. Some amino acids are likely targets for

chemical modification: methionine is easily oxidized and

asparagine can be deamidated to aspartyl- or isoaspartyl-

rests. Trace amounts of cleaning agents or plasticizers may

also react with the product.

Apart from these product-related impurities, contamina-

tions from the host or expression system that are not

removed by the purification and adventitious organisms

require the same attention. As previously stated a virus

disease is most worrisome as it may not be limited to the

treated patient. At present blood derived products contami-

Points to consider Test/method

Purification

Chromatographic purification

Validation of purification

Cleaning and sanitation of

chromatographic media

Validation of sanitation

Virus removal/inactivation

Validation of virus removal

- precipitation of product or contaminants (e.g. ammoniumsulfate)

- filtration

_

ultrafiltration

_

centrifugation

- ion exchange chromatography (weak to strong anion or cation exchanging functional groups)

_

size exclusion chromatography (SEC) (also named gel filtration or gel permeation chromatography (GPC))

_

affinity chromatography (pseudo-) substrate affinity, immunoaffinity, immobilized metal affinity,

protein affinity (e.g. protein A))

- hydrophobic interaction chromatography (various short aliphatic or aromatic groups)

- adsorption chromatography (e.g. thiophilic adsorption, hydroxyapatite)

- Overloading/spiking of process steps with specific contaminants such as DNA or host cells might be a

way to demonstrate their ability

_

sodium hydroxide may be used to remove proteins, nucleic acids, endotoxins, and viruses

_

sodium chloride for the removal of proteins and nucleic acids

- detergents are used to remove hydrophobic proteins and lipids

_

challenge tests with various organisms e.g. Staphylococcus aweus (Gram-positive bacteria),

Escherichia coli (Gram-negative bacteria), Candida albicans (yeast) and Aspergillus niger

(mould) (Adner and Sofer, 1994)

- pH 3-4.5 is robust and yields a reported log virus removal of 3-3

- heat is robust and yields a reported log virus removal of 4

_

solvent/detergent is robust and yields a reported log virus removal of 5

_

filtration (0.02-0.04 pm) is robust and yields a reported log virus removal of 4-8

- detergent is not robust and yields a reported log virus removal of 4

_

affinity or ion exchange chromatography is not robust and yields a reported log virus removal

0f l-5 WC/FDA, 1994)

- for a virus challenge test, a group of viruses exhibiting a range of purification-relevant

physico-chemical properties should be selected and mixed with the crude preparation:

special guidelines cover the removal of viruses

432 K.M. Miiller et al. / Pharmaceutics Acta Heluetiae 71 (1996) 421-438

Table 6

Methods concerning quality control and IPC of the product

Points to consider Test/method

Physical and biological identity - chemical or enzymatic peptide mapping

_

sodiumdodecylsulfate polyacrylamide gel electrophoresis (SDS PAGE)

_

isoelectric focusing (IEF)

_

2-dimensional electrophoresis (IEF combined with SDS-PAGE)

_

high performance liquid chromatography (HPLC); especially reversed phase

_

enzyme linked immunosorbent assay (ELISA), radioactive immunoassay (RIA)

_

immuno blot (Western blot)

_

terminal protein sequencing

_

total amino acid analysis

_

mass spectroscopy (MS)

- capillary electrophoresis (CE)

- modem analysis combines several methods like peptide mapping with MS or CE

_

circular dichroism (CD) spectroscopy

_

nuclear magnetic resonance (NMR) spectroscopy

- X-ray crystallography

Quantity

Carbohydrates

Potency/activity

Protein contamination

Pyrogen contamination

Viral contamination

_

classical protein assays according to Lowry, Biuret, Bradford and their derivatives

_

ultra violet (UV) or fluorescence spectrophotometry

- HPLC

- SDS-PAGE

- glycosidases analysis in combination with SDS gel shift or mass spectrometry

_

immuno detection of specific glycosilation moieties

_

whole animal bioassay

_

cell culture bioassay

_

receptor based immunoassay

_

identification of agents that may adversely affect potency

_

evaluation of functional activity and antigen/antibody specificity (various immunodiffusion methods,

immunoblotting/radio- or enzyme linked immunoassay)

- HPLC validated to correlate certain peaks to biological activity

- SDS-PAGE with Coomassie staining or, for improved sensitivity, silver or fluorescent staining

- HPLC

- contaminant specific ELISA, RIA

- Western blot

_

USP United States Pharmacopoeia 23 (1995) rabbit pyrogen test

_

Limulus amebocyte lysate assay (LAL) (FDA, 1987~)

- endogenous pyrogen assay

_

cytopathic effect in several cell types

- hemabsorption

_

embryonated egg testing

_

polymerase chain reaction (PCR)

_

viral antigen and antibody immunoassay

_

mouse antibody production (MAP)

- reverse transcriptase assay

Microbial contamination

_

total plate count

(bacteria including mycoplasma, fungi, yeast)

- heterotrophic plate count and total yeast and molds

- Mycoplasma test (purification processes should show the clearance of at least six logs of

mycoplasma (Huxsoll, 199411

Nucleic acid detection

Chemical contamination

- hybridisation

_

whole DNA assay

_

same tests as with conventional drugs

K.M. Miiller et al./Phannaceutica Acta Heluetiae 71 (1996) 421-438 433

nated with HI-virus still leave their footsteps in the death

statistics of patients. Other impurities may lead to im-

munogenic reactions or unforeseen side effects as exempli-

fied in the tryptophan case (Mayeno and Gleich, 1994).

Other sources of contamination must be considered, e.g.

allergens, petroleum oils residual solvents, cleaning mate-

rials, and metal ions.

3.4.2. Approaches of the QA-system

Several points to consider are helpful for the develop-

ment of test procedures and in setting specification limits

(PTC/FDA, 1985; PTC/FDA, 1987; PTC/FDA, 1992).

Analysis data should be collected during the set-up and

from about five initial bulk lots of the product character-

ized to fullest available extent. These data give the basis

for the specification of the product. For routine analysis a

test set ensuring identity, purity, potency and stability of

the product should be selected (EC Document

111/3477/92, 1994). The extent of the contamination re-

moval should be confirmed by both validation studies and

end product testing. Assays used to qualify and quantify

the biological and physical properties of proteins should be

used to evaluate lot-to-lot consistency of the drug product

and to monitor the stability of the product with time. The

basic criterion for a standardized and reliable product is

the demonstration of lot-to-lot consistency with respect to

certain predetermined release specifications.

Tests for potency should consist of in vitro or in vivo

tests, which have been specifically designed for each prod-

uct so as to its potency. A reference preparation for

biological activity should be established and used to deter-

mine the bioactivity of the final product. In house biologi-

cal potency standards should be cross-referenced against

international standards (e.g. WHO, Ph. Eur. and USP

standards).

Although DNA content in biological drug products is

evaluated on case by case basis, FDA (CBER) guidelines

require a DNA assay to have a sensitivity in the order of

10 pg DNA per dose, and the WHO guidelines require less

than 100 pg per dose (CPMP, 1987).

Table 1

Compatibility of excipients

Topic Examples

3.4.3. Methods concerning quality control and IPC of the

product

Tests that are needed will depend on the process and the

intended use of the product. Aspects that should be consid-

ered and tested are shown in Table 6.

Viral assays that first employ amplification of the virus

and then detection in a cell culture system are more

sensitive than direct cell culture assays and thereby pro-

vide greater assurance of the absence of viruses.

From this wealth of tests only a few are used for routine

testing. E.g. Epogen from Amgen is tested in bulk by

SDS/Western blot, isoelectric focusing, size exclusion

chromatography, tryptic mapping, N-terminal sequencing,

radio immunoassay for activity, in vivo assay for activity,

HPLC for purity, DNA assay, immunoassay for contami-

nating proteins, mycoplasma assay, sterility, protein, and

endotoxin assay. The final product is checked for appear-

ance, activity in RIA, protein content, sterility, safety,

pyrogenicity/endotoxin content, identity, and amount of

excipients.

4. Quality aspects on development and formulation of

the final product (lyophilizate)

4.1. Pre-validation during development

The quality of the final product depends on the quality

and safety of each step of action during development and

manufacture of the product (Wichert, 1993). Validation

should begin as soon as possible (Laicher, 19891, e.g.

much of the validation should already be commenced

during the development. This may also be helpful when

more data are demanded during the approval process or in

any questions concerning product quality and safety later.

Thus the pharmaceutical, technical and developmental

steps dealing with compatibility studies, formula develop-

ment, and with the manufacturing are essential and are

looked at in more detail.

Solution medium, solubility, cryoprotectants,

other protectants, pH, buffers, temperature, light

Solubilizers

Impurities in medium

Packaging materials

water (WPI), polyethyleneglycol, NaCl, dimethylsulfoxide, hydroxyethylstarch, glycerol,

hypromellose, sorbitol, mannitol, xylitol, glucose, gelatine, glycine, alanin, valin

polysorbate ethoxylated ricinoleate, pluronics, cyclodextrins

metal ions

siliconized glass, plastics, colors in plastics, residual monomers

434 KM. Miller et al. /Pharmaceutics Acta Helvetiae 71 (1996) 421-438

4.2. Compatibility Table 8

In this stage the basic parameters necessary for formula-

tion have to be clarified. These parameters should include

activities necessary and related to any type of lyophilizate

for injection, and should be supplemented with specific

requirements for the products discussed. Table 7 summa-

rizes necessary activities on compatibility.

Formulation: How difficulties may be solved

Effect May be overcome by:

Degradation, chemical

Hydrolysis, deamidation, oxidation, - CaCl,

disulfide bonds exchange - low 02-level

- buffer-ions

The function of proteins is related to the secondary as

well as to the tertiary and quarternary structure; the spatial

structure influences surface effects and may influence pH

and temperature.

Stabilization in aqueous solutions is e.g. possible by

human serum albumin (HSA), sugar alcohols and sugars

(mannitol, xylitol, sorbitol, glucose, maltose), by peptides,

aminoacids (glycine, valine, alanine), polysorbate, and

buffers.

Degradation, physical

Adsorption, aggregation, precipitation, - ionic strength of buffers

loss of activity - cryoprotectants

Sticking to glass surface - polysorbate

Unstable at room temperature -pHnear7

_

sugar, sugaralcohols,

peptides, aminoacids

Sticking to glass surfaces may be overcome by polysor-

bate and decomposition by metal ions when using CaCl,

(woog, 1993).

4.3. Formulation

Due to the compatibility study, the choice of inactive

ingredients and conditions for establishing a galenical for-

mula may be defined. In this stage, the appropriate combi-

nation of excipients, pH, isotonicity, concentration, wall

material and rubber closure has to be found resulting in

adequate solubility, feasibility of lyophilization, stability

and sufficient dissolution properties (Eckardt, 1993; Woog,

1993) (Table 8).

It should be pointed out, that during freezing the pH

and the concentration of salts may change very much

(Kijrber and Scheiwe, 1983; Woog, 1993), but this can be

modified by cryoprotectants (Kiirber and Scheiwe, 1980)

or the selection of salts in buffers (Eckardt, 1993). These

effects are well known from the freezing of living eukary-

otes and prokaryotes. Since a living cell is more complex

than a single protein, the mechanisms and means for

cryopreservation established may possibly give hints how

to optimize the freeze-drying process for pharmaceutically

used proteins.

4.4. Lyophilization process

tively complex freeze-drying process largely affects and

determines product properties and should be validated

thoroughly. The temperature of glass formation and eutec-

tic crystallization should be established for the solution

used, and the process parameters must be adjusted (Franks,

1990). Adaption of the freeze-drying cycle to these de-

mands avoids collapsing of the lyophilization cake (result-

ing in irreversible insolubility and stickiness) and can be

achieved by avoiding any holding time near the glass-tran-

sition point. Respective data are discussed in the literature

(e.g. Korber and Scheiwe, 1980). Residual channels in the

lyophilization cake are necessary for the transport of vapor

and should be optimized in size and stability and to assure

redissolving. For example Rupprecht showed that cooling

with a rate of 3C/min gives 4 pm of diameter whereas

25C/min results in 1 pm pores in a dextran-solution

(Rupprecht, 1993). Further, the residual humidity is essen-

tial for proteins. An optimized water content for human

growth hormone has been found to be in the range of 0.6%

to 2.8% (Eckardt, 1993). Experts dont always consider

lyophilization as an advantageous possibility for stabilizing

a certain drug. It is pointed out that the lyophilization cake

has a very large surface and is thus susceptible to interac-

tions from the surrounding (e.g. germs). Also the residual

moisture may cause difficulties during stability testing. An

alternative could be embedding of proteins/peptides in

quickly dissolving polymer matrices. Up to now, however,

such formulations to our knowledge are not on the market.

The lyophilization process includes the following steps:

dissolution, sterilization of the bulk, filling and partial

stoppering, transport to the lyophilization chamber, freez-

ing, vacuum application and relief and complete stoppering

of the vials.

The set of physico-chemical parameters of the rela-

Using aseptic conditions, bioburden should be kept as

low as possible and environmental surveillance as well as

media fills are necessary tools to manage the system. The

equipment used offers several possible contamination

sources like leakage of the chamber during vacuum appli-

cation or contamination of the media employed for cooling

and heating. Finally the rather complex equipment may fail

KM. Miiller et al. / Pharrnaceutica Acta Helvetiae 71 (1996) 421-438 435

Table 9

Controls of lyophilizate and reconstituted product

Topic Necessary activity

Dry substance

Optical homogeneity

Weight

Moisture of cake

Isotropy of cake

Incomplete sublimation

Inner surface

Reconstituted solution

Optical appearance

Solubility in reconstitution medium

Physical parameters

Filtration

Chemical

Microbiological

_

visual control

_

net-weight

_

sorption-isotherms, residual equilibrium moisture, actual moisture

_

crystalline/amorphous state (differential scanning calorimetry, DSC)

_

tendency of meltback

- helium-pycnometer

_

turbidity, opalescence, lightscattering

_

clarity, turbidity, opalescence time for complete solution

- pH, viscosity, density, optical density, clearness, oxygen content

_

active loss on passing injection minifilter

_

content, activity, potency (bioassay)

_

sterility testing, pyrogen testing

or malfunction during the long lasting process. On the

other hand sterile filtration of the final product is often not

possible and mostly a preservative is not present in the

dissolving solution. From this situation the need arises for

thorough planning and validation of the aseptic steps of the

process (FDA, 1993b; FDA, 1987b).

Table 10

Formulation examples in the market

Recombinant alpha-2 b Recombinant alpha-2 a Interferon beta from fibroblasts

Intron-A Schering-Plough Roferon-A Roche Naferon Sclavo

Ingredients

Sodium chloride

Sodium phosphate anhydride

Sodium phosphate monobasic

Glycol

Human albumine

Mannitol

9.0 mg

2.27 mg

0.55 mg

20 mg

1 mg 5 mg 292

40 mg

Solwnt

Benzylic alcohol

Water for injection ad

9mg

1 ml 1 ml 1 ml

Urokinase

Kisolv Mundipharm

human Urokinase

Alfakinasi Alfa-Wasserm. a Urokinase Choay Purochin Sclavo

human Urokinase

Ingredients

Dextrane 100 mg

Sodium chloride 17.5 mg

Sodium-phosphate monosodium 2H,O 34 mg

Mannitol 20 mg 10-13.33 mg

Na-Edetat

2mg

Sodium phosphate 2.4 mg 9.5 mg

human albumin 25 mg

Solvent

Sodium chloride 18

mg

45

mg

9mg

Sodium phosphate monobasic 0.507 mg

Sodium-phosphate dibasic 7.79 mg

Water for injection ad 2 ml 2 ml 5 ml 2 ml

a Same formulation: Persolv Richter (Lepetit); Ukidan (Serono); Urokinasi (Iketon).

436 K.M. Miiller et al. / Phannaceutica Acta Helvetiae 71 (1996) 421-438

In summary, the following points must be considered

concerning the manufacture of products used for clinical

trials as well as products for the market:

Need for aseptic processing; environmental monitoring;

media fills with regard to filling, transportation into the

chamber and handling of the final stopper&g, etc. The

number of units filled during media fill should at least

be adequate to the normal load.

Sterilization and maintaining sterility in the lyophilizer.

Identification of procedures in case of malfunction of

the system, like failure of vacuum-pump, leakage, or

too much ice on the condenser.

Discussion of the rationale of a chosen cycle.

Lyophilizator design, including assurance of integrity of

air or gas filters, sterilization of the rods for stoppering

in the chamber, contamination of the condenser, and

opening in a clean area only.

Meltback and poor solubility of the final product result-

ing in losses of active ingredient on injection through

the normally used microfilters, and crystallinity status.

The FDA-Guide (FDA, 1993b) gives insights in the

problems that may occur during lyophilization and should

already be applied in the developmental stage (Table 9).

4.5. Formulation examples

From (1Informatore Farmaceutico, 1994) some actual

formulations are known, e.g. interferon and urokinase, they

are listed in Table 10.

The formulations show among normally used excipients

of parenteral lyophilizates also amino acids (glycine), hu-

man serum albumin, and NaEDTA. Some cryoprotectants

are used as well (e.g. glycol, mannitol, dextrane).

5. Conclusion

This paper may have revealed that the know-how on

biopharmaceuticals is steadily growing and that keeping up

with state of the art technologies and methods is not only

compelling for the manufacturers but also for the authori-

ties. Therefore, regulatory means like requirements on a

basically low enforcement level as e.g. points to consider

help to transfer the latest information in the relevant field.

Further, a certain degree of collaboration and harmoniza-

tion all over the world is urgently needed and the ICH is a

helpful tool for regulating authorities as well as the indus-

try. Harmonization, collaboration and coordination within

the company is of great importance to allow an adequate

transfer of know-how. QA- and GMP-issues may have

shown the complexity of requirements on the manufacture

of a product to achieve the quality required.

In the main part problems and methods in fermentation

and purification of a recombinant protein have been dis-

cussed trying to make QA- and GMP-related problems

evident, since QA can only be efficient and stake out its

claims if it knows the crucial points in good manufacturing

practice. Tables should enable the reader to get a fast

overview on methods used with the host and expression

system, with fermentation, purification and quality control

as well as IPC.

And finally some hints concerning the lyophilization of

the final product may have shown that from the active bulk

substance to the final product there is still a tremendous

developmental work left. Not to forget that from the final

formulation to the finished dosage form that comes to the

market there are still some further steps to consider.

References

Adner, N. and Sofer, G. (1994) Biotechnology Product Validation, Part 3:

Chromatography Cleaning Validation. Pharmaceutical Technology

Europe, April, pp. 22-28.

BG Chemie (1991) Eingruppierung Biologischer Agenzien Merkblltter

BOO4 (Viren), BOO5 (Parasiten), B 006 (Bakterien), BOO7 (Pilze), B

009 (Zellkulturen). Ed. Berufsgenossenschaft der chemischen Indus-

trie. Jedermann Verlag, Heidelberg.

BG Chemie (1992) Eingruppierung Biologischer Agenzien Merkblatter

BOO4 (Viren), BOO5 (Parasiten), B 006 (Bakterien), BOO7 (Pilze), B

009 (Zellkulturen). Ed. Berufsgenossenschaft der chemischen Indus-

trie, Jedermann Verlag, Heidelberg.

Casey, J.L., Keep, P.A., Chester, K.A., Robson, L., Hawkins, R.E. and

Begent, R.H.J. (1995) Purification of bacterially expressed single

chain Fv antibodies for clinical applications using metal chelate

chromatography. J. Immunol. Methods 179, 105-l 16.

CFR/FDA (1995a) Title 21 Code of Federal Regulations, Section 58.

Office of the Federal Register, National Archives and Records Ad-

ministration, 21 CFR 58.

CFR/FDA (1995b) Title 21 Code of Federal Regulations, Section 200 ff.

Office of the Federal Register, National Archives and Records Ad-

ministration, 21 CFR 200 ff.

CFR/FDA (199%) Title 21 Code of Federal Regulations Office of the

Federal Register, National Archives and Records Administration, 21

CFR 600 ff.

CPMP (1987) Notes to Applicants for Marketing Authorization on the

Product and Quality Control of Medicinal Products Derived by Re-

combinant DNA Technology.

CPMP/ICH/137/95 (1995) Clinical Study Reports: Format and Con-

tent.

CPMP/ICH/138/95 (1995) Stability Testing of Biotechnological/Bio

logical Products.

CPMP/ICH/139/95 (1995) Analysis of the Expression Construct in

Cells used for Production of r-DNA Derived Protein Products.

CPMP/ICH/140/95 (1995) Guideline on the Need for Carcinogenicity

Studies of Pharmaceuticals.

CPMP/ICH/136/95 (1995) Reproductive Toxicology: Toxicity to Male

Fertility.

CPMP/ICH/280/95 (1995) Stability Testing Requirements for New

Dosage Forms.

K.M. Miiller et al. / Pharnmceutica Acta Helcetiae 71 (1996) 421-438 437

CPMP/ICH/281/95 (1995) Validation of Analytical Procedure Method-

ology.

CPMP/ICH/282/95 (1995) Impurities of New Drug Products.

CPMP/ICH/288/95 (1995) Clinical Safety Data Management: Periodic

Safety Update Reports for Marketed Drugs.

CPMP/ICH/295/95 Draft (1995) Viral Safety Evaluation of Biotech-

nology Products Derived from Cell Lines of Human and Animal

Origin.

Deutscher, M.P. (Ed.) (1990) Guide to Protein Purification, Methods in

Enzymology, Vol. 182. Academic Press Inc., San Diego, USA.

Eckardt, B. (1993) in D. Essig and R. Oschmann (Eds), Lyophilization.

Paperback APV 35.

EC Council Directive 65/65/EEC (1965) Regulations or Administrative

Action relating to Proprietary Medicinal Products.

EC Council Directive 83/570/EEC; 87/21/EEC; 87/22/EEC;

89/341/EEC; 75/318/EEC; 75/319/EEC Amendments to

65/65/EEC.

EC Council Directive 87/22/EEC (1987) On the Approximation of

National Measures Relating to the Placing on the Market of High-

Technology Medicinal Products, particularly those derived from

Biotechnology.

EC Directive 91/356/EEC (1991) Guidelines of Good Manufacturing

Practice for Medicinal Products for Human Use.

EC (1991) Guidelines to Good Clinical Practice for Clinical Trials of

Medicines of July 1991 of the European Communities.

EC Document 111/3093/92-EN (1992) Guide to Good Manufacturing

Practice for Medicinal Products; The Rules governing Medicinal

Products in the European Community, Vol. IV.

EC Document 111/3477/92 (1994) Ad hoc Working Party on Biotech-

nology/Pharmacy, Production and Quality Control of Medicinal

Products Derived by Recombinant DNA Technology; Note for Guid-

ance, Revision 1994.

FDA (1987a) Guideline on General Principles of Process Validation, May

1987. Division of Manufacturing and Product Quality (HFD-320).

FDA (1987b) Guideline on Sterile drug Products Produced by Aseptic

Processing, June 1987. Division of Manufacturing and Product Qual-

ity (HFN320).

FDA (1987~) Guideline on Validation of the Limulus Amebocyte Lysate

Test as an End-Product Endotoxin Test for Human and Animal

Parenteral Drugs, Biological Products, and Medical Devices, Decem-

ber 1987. Division of Manufacturing and Product Quality (HFN-320).

FDA (1991) Biotechnology Inspection Guide, November 1991. Division

of Field Investigations (HFC- 130).

FDA (1993a) Guide to Inspections of High Purity Water Systems, July

1993. Division of Field Investigations.

FDA (1993b) Guide to Inspections of Lyophilization of Parenterals, July

1993. Division of Field Investigations.

FDA (1993~) Guide to Inspections of Validation of Cleaning Processes,

July 1993. Division of Field Investigations.

Franks, F. (1990) Freeze-drying: From empiricism to predictability.

Cryo-Letters I I, 93-110.

Gerdes, K. (1988) The parB (hok/sok) locus of plasmid RI: A general

purpose plasmid stabilization system. Biotechnology 6, 1402.

Hasskarl, H. (1990) Gentechnikrecht: Textsammlung Gentechnikgesetz

und Rechtsverordnungen, Anhang I: Risikobewertung von Organis-

men. Editio Cantor Verlag, Auiendorf.

Horn, U., Strittmatter, W., Krebber, A., Kniupfer, U., Kujau, M., Wen-

deroth, R., Miiller, K.M., Matzku, A., Pliickthun, A. and Riesenberg,

D. High volumetric yields of functional dimeric miniantibodies in

Escherichia coli using an optimized expression vector and high cell

density fermentation under non-limited growth conditions. Appl. Mi-

crobiol. Biotechnol., in press.