Escolar Documentos

Profissional Documentos

Cultura Documentos

Introduction Pumps

Enviado por

facebookshop0 notas0% acharam este documento útil (0 voto)

19 visualizações32 páginasPumps are machines which supply energy to a liquid in order to move it. The method that is used determines the category into which the pump is placed. There are two main categories of pump: Rotodynamic pumps and positive displacement pumps.

Descrição original:

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PPS, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoPumps are machines which supply energy to a liquid in order to move it. The method that is used determines the category into which the pump is placed. There are two main categories of pump: Rotodynamic pumps and positive displacement pumps.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPS, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

19 visualizações32 páginasIntroduction Pumps

Enviado por

facebookshopPumps are machines which supply energy to a liquid in order to move it. The method that is used determines the category into which the pump is placed. There are two main categories of pump: Rotodynamic pumps and positive displacement pumps.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPS, PDF, TXT ou leia online no Scribd

Você está na página 1de 32

AN INTRODUCTION TO PUMPING EQUIPMENT

Principle, Operation & Maintenance

INTRODUCTION

Introduction

WHAT IS THE PUMP?

Pumps are machines which supply energy to a liquid in

order to move it from place to another.

Introduction

Refinery Water Flood

Transportation

The method that is used to supply this energy to the liquid determines

the category into which the pump is placed and the system between the

pump and the liquid final destination defines the application.

Introduction

Pumps enable a liquid to:

1. Flow from a region or low pressure to one of high pressure.

2. Flow from a low level to a higher level.

3. Flow at a faster rate.

Introduction

Pumps vary considerably in their size, construction

and principle of operation.

There are two main categories of pump:

Rotodynamic pumps.

Positive displacement pumps.

Introduction

Diaphragm

Piston

Plunger

Reciprocating Rotary

Mixed flow

Gear

Lobe

Sliding Vane

Screw

Axial flow

Centrifugal

Rotodynamic

Turbine

PUMP

Positive displacement

Introduction

Centrifugal Pumps:

Also known as rotary pumps, centrifugal pumps have a rotating

impeller, also known as a blade, that is immersed in the liquid.

Liquid enters the pump near the axis of the impeller, and the

rotating impeller sweeps the liquid out toward the ends of the

impeller blades at high pressure.

For low flows and high pressures, the action of the impeller is

largely radial.

For higher flows and lower discharge pressures, the direction of

the flow within the pump is more nearly parallel to the axis of the

shaft, and the pump is said to have an axial flow. The impeller in

this case acts as a propeller.

Introduction

Centrifugal Pumps:

The transition from one set of flow conditions to the other is

gradual, and for intermediate conditions, the device is called a

mixed-flow pump.

Introduction

Positive-displacement Pumps:

A variety of positive-displacement pumps are also available,

generally consisting of a rotating member with a number of lobes

that move in a close-fitting casing. The liquid is trapped in the

spaces between the lobes and then discharged into a region of

higher pressure. A common device of this type is the gear pump,

which consists of a pair of meshing gears. The lobes in this case

are the gear teeth

Introduction

The main difference between kinetic and positive

displacement pumps lies in the method of fluid

transfer.

What is the main difference

between kinetic and positive

displacement pumps ?

Introduction

A kinetic pump imparts velocity energy to the fluid,

which is converted to pressure energy upon exiting

the pump casing

Introduction

A positive displacement pump moves a fixed volume

of fluid within the pump casing by applying a force to

moveable boundaries containing the fluid volume.

Introduction

Positive displacement pumps are also divided into two

major pump categories : reciprocating & rotary.

Reciprocating pumps transfer a volume of fluid by a

crankshaft, eccentric cam or an alternating fluid

pressure acting on a piston, plunger or a diaphragm in

a reciprocating motion.

Introduction

The Table below outlines some of the main differences

between centrifugal pumps, reciprocating pumps and

rotary pumps. Note that centrifugal, reciprocating

and rotary pumps are all relatively broad

categories. The table below provides a comparison of

features between these pump categories that generally

holds true.

Also, note that Table lists typical maximum flow rates

and heads. It is possible to build special pumps

outside the upper bounds of the pressures and flow

rates listed, but such pumps would be prohibitively

expensive for most applications.

Introduction

Rotary Pumps Reciprocating Pumps Centrifugal Pumps Parameter

Low/Medium Capacity,

Low/Medium Pressure

Low Capacity,

High Pressure

Medium/High Capacity,

Low/Medium Pressure

Optimum Flow and

Pressure Applications

10,000+ GPM 10,000+ GPM 100,000+ GPM Maximum Flow Rate

Yes Yes No Low Flow Rate Capability

4,000+ PSI 100,000+ PSI 6,000+ PSI Maximum Pressure

Yes Yes No Requires Relief Valve

Smooth Pulsating Smooth Smooth or Pulsating Flow

Constant Constant Variable Variable or Constant Flow

Yes Yes No Self-priming

Requires Less Space Requires More Space Requires Less Space Space Considerations

Lower Initial

Lower Maintenance

Lower Power

Higher Initial

Higher Maintenance

Lower Power

Lower Initial

Lower Maintenance

Higher Power

Costs

Requires clean, clear, non-

abrasive fluid due to close

tolerances

Optimum performance with

high viscosity fluids

Higher tolerance for

entrained gases

Suitable for clean, clear, non-

abrasive fluids. Specially-

fitted pumps suitable for

abrasive-slurry service.

Suitable for high viscosity

fluids

Higher tolerance for

entrained gases

Suitable for a wide range

including clean, clear, non-

abrasive fluids to fluids with

abrasive, high-solid content.

Not suitable for high viscosity

fluids

Lower tolerance for entrained

gases

Fluid Handling

Introduction

Centrifugal Pumps Capacity:

The wide variety of centrifugal pumps manufactured offer a

relatively large range of available capacities. Radial-flow and

mixed flow pumps are used for low to medium capacity

applications. For high capacity applications, axial-flow pumps are

capable of delivering flow rates in excess of 100,000 gpm.

Centrifugal pumps are not stable at low flow rates, although there

are special low-flow centrifugal pumps available that can deliver

flow rates less than 10 gpm. However, for extreme low-flow

applications (< 1 gpm), positive displacement pumps are a better

selection.

Introduction

Reciprocating & Rotary Pumps Capacity:

Reciprocating and rotary pumps are capable of capacities ranging

from low to medium, with flow rates peaking at 10,000+ gpm. In

theory, reciprocating pumps can be manufactured to deliver more

capacity, but they become prohibitively large and expensive at

high flow rates. Both reciprocating and rotary pumps are capable

of delivering product at extremely low flow rates (fractions of a

gpm), making them particularly suitable for many chemical

injection applications.

Introduction

Centrifugal Pumps Pressure:

Centrifugal pumps and rotary pumps are best suited for low to

medium pressure applications.

A centrifugal pumps pressure rise is limited to the shut-off

pressure on the pump curve, which is always less than the design

pressure of the pump (and the piping system if properly

designed).

Multi-stage centrifugal pumps can deliver at pressures of 6,000+psi and

may be the most economical choice at this pressure in high capacity

applications.

Introduction

Reciprocating & Rotary Pumps Pressure:

Rotary pumps as Centrifugal pumps are best suited for low to

medium pressure applications. Reciprocating pumps are usually

specified for high pressure service, with capabilities exceeding

100,000 psi.

In most applications exceeding 1,000 psig, reciprocating pumps

are more suitable, particularly in low to medium capacity service.

Introduction

Because both reciprocating and rotary pumps will continually

increase pressure when pumping against a closed discharge to the

extent allowed by the drivers horsepower. This can result in

overpressure of the pump or piping components, so it is necessary

to install a relief valve on the discharge of the pump capable of

discharging the full capacity of the pump.

Why it is necessary to install a relief

valve on the discharge of the

Reciprocating or Rotary pumps ?

Introduction

Why it is not necessary to install a

relief valve on the discharge of the

Centrifugal pumps ?

A centrifugal pumps pressure rise is limited to the shut-off

pressure on the pump curve, which is always less than the design

pressure of the pump (and the piping system if properly

designed). A relief valve is only needed if no other measures are

provided to detect low flow conditions and shut down the pump to

prevent damage. The relief valve need only be sized to pass the

minimum flow rate required to maintain stable flow and prevent

excessive temperature rise.

Introduction

Centrifugal pumps and most rotary pumps provide smooth,

non-pulsating flow, while reciprocating pumps produce a

pulsating flow.

A pulsating flow may require special design considerations in the

piping system. If the pump is not located near the suction source,

then acceleration head can contribute to low NPSHA problems,

which may require the installation of a suction stabilizer.

A pulsation dampener may need to be installed in the discharge

piping to reduce pressure surges resulting from the pulsating flow.

Introduction

Centrifugal pumps operate on a variable-flow, variable-head

curve. As the discharge pressure decreases, the pump delivers a

higher flow rate.

Centrifugal pumps are favored where process conditions often

require varying flow rates. For example, a level control valve must

throttle the flow rate from a vessel to maintain a constant level in

the vessel. A centrifugal pump is well suited to handle this

process condition.

Centrifugal Pumps Variable or Constant Flow:

Introduction

Reciprocating & Rotary Pumps Variable or

Constant Flow:

whereas a positive displacement pump would either require a

continuous recycle to suction or a variable speed driver to

accommodate the variable flow.

At any given speed, reciprocating and rotary pumps operate at a

constant flow rate regardless of the discharge pressure. There are

specific applications that require either constant flow or variable

flow. Metering pumps rely on a constant flow at varying pressures,

which makes reciprocating pumps and rotary pumps suitable for

this application. Piston pumps used for metering will often use an

adjustable stroke length to allow the operator to vary the flow rate

to meet the system requirements.

Introduction

Self-priming :

Reciprocating and rotary pumps are self-priming. This is an

important consideration where a prime cannot be maintained on

the pump. Centrifugal pumps are not inherently self-priming,

although some manufacturers do specially design self-priming

units. External priming sources, such as an eductor or vacuum

pump can also be employed.

Introduction

Costs Considerations :

The reciprocating pump will generally have higher initial capital

costs and will require more space relative to the centrifugal pump

or the rotary pump.

The reciprocating pump will generally have higher maintenance

costs relative to the centrifugal pump or the rotary pump.

The centrifugal pump will generally have higher annual power

consumption costs relative to the reciprocating pump or the rotary

pump because of lower efficiencies.

Introduction

Costs Considerations :

A pump that is selected for an application outside of its optimum

operating parameters will almost certainly not follow these

rules. For example, a rotary pump operating in a high pressure,

abrasive-slurry service would probably have higher maintenance

costs than a properly selected reciprocating pump. The close

running clearances (particularly for high pressure service)

required in the rotary pump would likely result in premature wear

and frequent maintenance.

Introduction

Centrifugal Pumps Fluid Handling:

Centrifugal pumps are suitable for transferring a variety of fluids

ranging from clean, clear non-abrasive fluids to abrasive-

slurries. However, a centrifugal pump is not the best choice for

pumping highly viscous fluids due to dramatic drops in efficiency

at high viscosities. Centrifugal pumps are not normally specified

for viscosities higher than about 4,000 SSU. Centrifugal pumps

are also not well suited to pumping entrained air. Most centrifugal

pumps can handle up to about 2% entrained gas and specially-

designed pumps can handle up to about 10%.

Introduction

Reciprocating Pumps Fluid Handling:

Reciprocating pumps are well suited for transferring clear, non-

abrasive fluids, as well as abrasive slurries. In fact, the relatively

low velocities of moving parts within a reciprocating pump make it

particularly resistant to erosion in abrasive-slurry applications,

provided that the pump is properly designed for the

service. Reciprocating pumps maintain high efficiencies when

pumping highly viscous fluids and can easily handle 50% and

higher volumes of entrained gas.

Introduction

Rotary Pumps Fluid Handling:

Rotary pumps can also handle high viscosity fluids and high

volumes of entrained gas. In fact, many rotary pumps operate at

their best efficiency at higher viscosities. However, rotary pumps

are not well suited for pumping corrosive fluids or fluids with

abrasive solids because of close clearances between rotating and

static pump components.

Introduction

Summary

there are many different subcategories of pumps within these

broad categories and there are many regions of overlap where

multiple types of pumps in the same category and even in

different categories would be suitable. Since every pump

application is unique, each of the factors that influence the

pump selection must be considered in detail.

One fact that must always be remembered: A pump does not

create pressure, it only provides flow. Pressure is a just an

indication of the amount of resistance to flow.

Você também pode gostar

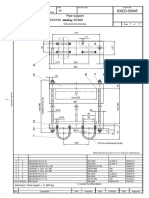

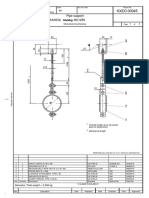

- KXEO-00045: CSC010A 25/460 Pipe SupportDocumento1 páginaKXEO-00045: CSC010A 25/460 Pipe SupportfacebookshopAinda não há avaliações

- HAX053A 80/1250 Pipe Support: KXEO-00045Documento1 páginaHAX053A 80/1250 Pipe Support: KXEO-00045facebookshopAinda não há avaliações

- Un 3790-31 PDFDocumento9 páginasUn 3790-31 PDFfacebookshopAinda não há avaliações

- Pressure Vessel Design CalculationsDocumento127 páginasPressure Vessel Design Calculationsajayghosh314086% (22)

- Un 3790-39Documento8 páginasUn 3790-39facebookshopAinda não há avaliações

- Stainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Documento5 páginasStainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Utada HikaruAinda não há avaliações

- Un 3790-33Documento10 páginasUn 3790-33facebookshopAinda não há avaliações

- Un 3790-44Documento8 páginasUn 3790-44facebookshopAinda não há avaliações

- Un 3790-41Documento14 páginasUn 3790-41facebookshopAinda não há avaliações

- Un 3790-31 PDFDocumento9 páginasUn 3790-31 PDFfacebookshopAinda não há avaliações

- Pde Pip G00 Ec 0137 000 00 DPP 1Documento3 páginasPde Pip G00 Ec 0137 000 00 DPP 1facebookshopAinda não há avaliações

- 1.standard Drawing R01 PDFDocumento1.690 páginas1.standard Drawing R01 PDFfacebookshopAinda não há avaliações

- Process Piping Welding T-IDocumento188 páginasProcess Piping Welding T-IfacebookshopAinda não há avaliações

- Metric Properties of Structural Shapes - AISCDocumento52 páginasMetric Properties of Structural Shapes - AISCalmeteck100% (7)

- Practical Piping CurseDocumento46 páginasPractical Piping Cursemsaad2100% (1)

- Prediction of Standard Pipe PressureDocumento5 páginasPrediction of Standard Pipe PressurefacebookshopAinda não há avaliações

- Piping Training CourseDocumento446 páginasPiping Training CoursefacebookshopAinda não há avaliações

- Procedures of Plant Layout N Piping-RILDocumento123 páginasProcedures of Plant Layout N Piping-RILfacebookshopAinda não há avaliações

- Piping SpecificationsDocumento10 páginasPiping SpecificationssmithallenAinda não há avaliações

- A - Piping Joint HandbookDocumento161 páginasA - Piping Joint HandbookCharles Tauk100% (30)

- Piping and Pipe Support SystemsDocumento178 páginasPiping and Pipe Support Systemssaisssms9116Ainda não há avaliações

- A - Piping Joint HandbookDocumento161 páginasA - Piping Joint HandbookCharles Tauk100% (30)

- Maximum Piping Operating PressureDocumento8 páginasMaximum Piping Operating PressurefacebookshopAinda não há avaliações

- Piping DesignDocumento122 páginasPiping Designfacebookshop100% (9)

- Pipeline BasicsDocumento12 páginasPipeline Basicsgerrydl100% (2)

- SAE Flanges PDFDocumento55 páginasSAE Flanges PDFG.SWAMI100% (2)

- Piping Application GuideDocumento36 páginasPiping Application GuidefacebookshopAinda não há avaliações

- Part 1 Piping SystemsDocumento22 páginasPart 1 Piping SystemsfacebookshopAinda não há avaliações

- General Piping and ValvesDocumento184 páginasGeneral Piping and Valvesfacebookshop100% (2)

- Flange TypesDocumento1 páginaFlange TypesHadi UtomoAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Nuclear Engineering Question BankDocumento5 páginasNuclear Engineering Question Bankaerochandru.87Ainda não há avaliações

- Laplace TableDocumento2 páginasLaplace TableosmanfıratAinda não há avaliações

- ElectricityDocumento25 páginasElectricityWeb BooksAinda não há avaliações

- Silt Load On GatesDocumento2 páginasSilt Load On GatesWaleed HassanAinda não há avaliações

- Elect Machine Total 2012Documento22 páginasElect Machine Total 2012NGOUNEAinda não há avaliações

- Task #5 (Hermo)Documento4 páginasTask #5 (Hermo)KATHLEEN MAE HERMOAinda não há avaliações

- Hertz Hgs 3 20 ManuelDocumento69 páginasHertz Hgs 3 20 Manueligor_sandulenkoAinda não há avaliações

- Calculations For IB ChemistryDocumento16 páginasCalculations For IB Chemistryanthor100% (3)

- Math 53 Samplex FinalsDocumento16 páginasMath 53 Samplex Finalskate_acamaAinda não há avaliações

- PhET - States of Matter in Html5Documento3 páginasPhET - States of Matter in Html5Anonymous 52Z8ZFkvAinda não há avaliações

- Vacuum, General Relativity: PHY100 The Nature of The Physical WorldDocumento21 páginasVacuum, General Relativity: PHY100 The Nature of The Physical WorldJacecosmozAinda não há avaliações

- Torque and Equilibrium (40 charactersDocumento2 páginasTorque and Equilibrium (40 charactersEndai DesuAinda não há avaliações

- Computational Chem 6Documento152 páginasComputational Chem 6Dr. Partha Sarathi SenguptaAinda não há avaliações

- The Preparation of Magnetic Nanoparticles For Applications in BiomedicineDocumento17 páginasThe Preparation of Magnetic Nanoparticles For Applications in BiomedicineMadavat Prem Pai LópezAinda não há avaliações

- Eqmod Alignment ModelsDocumento31 páginasEqmod Alignment Modelsastroman2011Ainda não há avaliações

- Chemistry Code No. 1/2 Set: 3 Time Allowed: 3 Hours Maximum Marks: 100 General InstructionsDocumento5 páginasChemistry Code No. 1/2 Set: 3 Time Allowed: 3 Hours Maximum Marks: 100 General InstructionsShalini KumariAinda não há avaliações

- IrDocumento13 páginasIrumesh123patilAinda não há avaliações

- UntitledDocumento3 páginasUntitledFarah EssidAinda não há avaliações

- 5-1 13 3/8" Surface Casing DesignDocumento10 páginas5-1 13 3/8" Surface Casing Designeng20072007Ainda não há avaliações

- Class XII Physics Exam Revision SheetDocumento4 páginasClass XII Physics Exam Revision SheetYogesh ChauhanAinda não há avaliações

- CCIP Footfall Induced VibrationDocumento84 páginasCCIP Footfall Induced VibrationjorgenkrabAinda não há avaliações

- Thermodynamics FundamentalsDocumento84 páginasThermodynamics FundamentalsKC Paguinto100% (1)

- Universe in Nutshell Hawking ReviewDocumento3 páginasUniverse in Nutshell Hawking ReviewVladica Barjaktarovic100% (1)

- Aqa 84031 W MS Jun13 PDFDocumento18 páginasAqa 84031 W MS Jun13 PDFdadajee420Ainda não há avaliações

- Partial Differential Equation MCQ For M.Sc. From T. AmaranatjDocumento10 páginasPartial Differential Equation MCQ For M.Sc. From T. AmaranatjSanket K Mohare100% (5)

- Unit 2Documento3 páginasUnit 2V V Satyanarayana PasupuletiAinda não há avaliações

- Otc18895 Flow Induced Pulsations in RisersDocumento5 páginasOtc18895 Flow Induced Pulsations in Risershamadani100% (1)

- Influence of Size Ion On The Stability of Chloroplumbates PDFDocumento7 páginasInfluence of Size Ion On The Stability of Chloroplumbates PDFUriel VázquezAinda não há avaliações

- CH 19Documento85 páginasCH 19Dan McAinda não há avaliações

- Heat exchanger specification sheetDocumento2 páginasHeat exchanger specification sheetDycka Anugerah PuryantoroAinda não há avaliações