Escolar Documentos

Profissional Documentos

Cultura Documentos

3 A Sanitary Standards Quick Reference Guide

Enviado por

fitiran0 notas0% acharam este documento útil (0 voto)

446 visualizações98 páginas3-A Sanitary Standards and Accepted Practices are copyrighted and cannot be distributed without authorization. This list has been created as a quick guide reference of the current 3-a Standards and Accepted Practices. Though an effort has been made to ensure the accuracy of this reference list, it is not guaranteed, and should always be verified with the latest 3-a standards.

Descrição original:

Título original

3 a Sanitary Standards Quick Reference Guide

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documento3-A Sanitary Standards and Accepted Practices are copyrighted and cannot be distributed without authorization. This list has been created as a quick guide reference of the current 3-a Standards and Accepted Practices. Though an effort has been made to ensure the accuracy of this reference list, it is not guaranteed, and should always be verified with the latest 3-a standards.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

446 visualizações98 páginas3 A Sanitary Standards Quick Reference Guide

Enviado por

fitiran3-A Sanitary Standards and Accepted Practices are copyrighted and cannot be distributed without authorization. This list has been created as a quick guide reference of the current 3-a Standards and Accepted Practices. Though an effort has been made to ensure the accuracy of this reference list, it is not guaranteed, and should always be verified with the latest 3-a standards.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 98

3-A Sanitary Standards

Quick Reference of the

3-A Sanitary Standards & Accepted Practices

List Date: January 4, 2013

3-A Std & Practices List with Document Scopes Page 1 of 98 J anuary 4,2013

IMPORTANT NOTES & DISCLAIMER

Disclaimer

This list has been created as a quick guide reference of the current 3-A Sanitary

Standards and Accepted Practices. It is not intended to replace, override or contradict the

actual copyrighted standards and accepted practices. Though an effort has been made to

ensure the accuracy of this reference list, it is not guaranteed, and should always be

verified with the latest 3-A Sanitary Standards and Accepted Practices.

Notes

This reference list was created J anuary 4, 2013, using the 3-A Sanitary Standards

and Accepted Practices as they were currently published in December 2012. The

Pharmaceutical P3-A standards are also included.

References for each standard include the cross reference 3-A Standards &

Accepted Practices

Other references may also be referenced in the Standards and Accepted Practices

but are not listed in this quick guide in all cases. Please verify all the references in

the applicable Standards and Accepted Practices.

3-A Sanitary Standards & Accepted Practices are copyrighted and cannot be

distributed without authorization. See www.3-a.org

3-A Std & Practices List with Document Scopes Page 2 of 98 J anuary 4,2013

Contents

Disclaimer ........................................................................................................................... 2

Notes ................................................................................................................................... 2

01-08 Storage Tanks ........................................................................................................... 7

02-11 Centrifugal and Positive Rotary Pumps.................................................................... 8

04-05 Homogenizers and Reciprocating Pumps ................................................................. 8

05-15 Stainless Steel Automotive Transportation Tanks for Bulk Delivery and Farm

Pick-Up Service ................................................................................................................ 11

10-04 Filters Using Single Service Filter Media .............................................................. 12

11-09 Plate Type Heat Exchangers ................................................................................... 12

12-07 Tubular Heat Exchangers ....................................................................................... 14

13-11 Farm Milk Cooling and Holding Tanks ................................................................. 15

16-05 Milk and Milk Products Evaporators and Vacuum Pans ........................................ 16

17-11 Formers, Fillers, and Sealers of Containers for Fluid Milk and Fluid Milk Products

........................................................................................................................................... 17

18-03 Multiple-Use Rubber and Rubber-Like Materials Used as Product Contact Surfaces

in Dairy Equipment ........................................................................................................... 18

19-07 Batch and Continuous Freezers for Ice Cream, Ices and Similarly Frozen Dairy

Foods ................................................................................................................................. 19

20-27 Multiple-Use Plastic Materials ............................................................................... 21

21-01 Centrifugal Separators and Clarifiers ..................................................................... 22

22-08 Silo-Type Storage Tanks for Milk and Milk Products ........................................... 23

23-06 Equipment for Packaging Viscous Product ............................................................ 24

24-03 Non-Coil Type Batch Pasteurizers for Milk and Milk Products ............................ 26

25-03 Non-Coil Type Batch Processors ........................................................................... 27

26-05 Sifters for Dry Products ......................................................................................... 28

27-06 Equipment for Packaging Dry Milk and Dry Milk Products ................................ 29

28-04 Flow Meters for Milk and Milk Products ............................................................... 30

29-03 Air Eliminators ...................................................................................................... 30

3-A Std & Practices List with Document Scopes Page 3 of 98 J anuary 4,2013

30-01 Farm Milk Storage Tanks ...................................................................................... 32

31-06 Scraped Surface Heat Exchangers ......................................................................... 33

32-02 Uninsulated Tanks for Milk and Milk Products .................................................... 33

33-02 Polished Metal Tubing for Milk and Milk Products ............................................... 35

34-02 Portable Bins for Dry Milk and Dry Milk Products .............................................. 35

35-04 Blending Equipment .............................................................................................. 36

36-01 Inline Rotor-Stator Mixers..................................................................................... 37

38-00 Cottage Cheese Vats .............................................................................................. 37

39-01 Pneumatic Conveyors for Dry Milk and Dry Milk Products ................................ 38

40-04 Bag Collectors ....................................................................................................... 39

41-03 Mechanical Conveyors for Dry Products ............................................................... 41

42-01 In-Line Strainers for Milk and Milk Products, Number ......................................... 41

44-03 Diaphragm Pumps ................................................................................................. 42

45-02 Crossflow Membrane Modules ............................................................................. 43

46-03 Refractometers and Energy Absorbing Optical Sensors for Milk and Milk

Products............................................................................................................................. 43

49-01 Air Driven Sonic Horns for Dry Products ............................................................. 44

50-01 Level Sensing Devices for Dry Products ................................................................ 45

51-01 Plug-Type Valves for Milk and Milk Products ..................................................... 45

52-02 Plastic Plug-Type Valves for Milk and Milk Products.......................................... 46

53-06 Compression-Type Valves .................................................................................... 47

54-02 Diaphragm-Type Valves for Milk and Milk Products........................................... 47

55-02 Boot Seal Type Valves .......................................................................................... 48

56-00 Inlet and Outlet Leak-Protector Plug-Type Valves for Milk and Milk Products .. 50

57-02 Disc-Type Valves .................................................................................................. 51

58-01 Vacuum Breakers and Check Valves for Milk and Milk Products ....................... 52

59-00 Automatic Positive Displacement Samplers for Fluid Milk and Fluid Milk

Products............................................................................................................................. 53

60-00 Milk and Milk Products Rupture Discs ................................................................. 54

61-01 Steam Injection Heaters for Milk and Milk Products ............................................ 54

62-02 Hose Assemblies for Milk and Milk Products........................................................ 55

3-A Std & Practices List with Document Scopes Page 4 of 98 J anuary 4,2013

63-03 Sanitary Fittings ..................................................................................................... 57

64-00 Pressure Reducing and Back Pressure Regulating Valves for Milk and Milk

Products............................................................................................................................. 58

65-01 Sight and/or Light Windows and Sight Indicators in Contact with Product ......... 58

68-00 Ball-Type Valves for Milk and Milk Products ...................................................... 60

70-01 Italian-Type Pasta Filata Style Cheese Cookers .................................................... 60

71-01 Italian-Type Pasta Filata Style Cheese Moulders ................................................. 61

72-01 Italian-Type Pasta Filata Style Moulded Cheese Chillers ..................................... 62

73-01 Shear Mixers, Mixers, and Agitators ..................................................................... 63

74-05 Sensors and Sensor Fittings and Connections ....................................................... 64

75-01 Belt-Type Feeders.................................................................................................. 66

78-01 Spray Cleaning Devices Intended to Remain in Place ........................................... 68

81-00 Auger-Type Feeders .............................................................................................. 69

82-00 Pulsation Dampening Devices ............................................................................... 70

83-00 Enclosed Cheese Vats and Tables ......................................................................... 70

84-02 Personnel Access Ports for Wet Applications ....................................................... 71

85-02 Double-Seat Mixproof Valves ............................................................................... 72

87-00 Mechanical Strainers .............................................................................................. 72

88-00 Machine Leveling Feet and Supports .................................................................... 73

95-00 Transportation Tank Vents .................................................................................... 74

101-00 Pipeline Product Recovery Equipment ................................................................ 76

603-07 Sanitary Construction, Installation, Testing and Operation of High-Temperature

Short-Time and Higher-Heat Shorter-Time Pasteurizer Systems ..................................... 80

604-05 Supplying Air Under Pressure in Contact With Milk, Milk Products and Product

Contact Surfaces ............................................................................................................... 81

605-04 Permanently Installed Product and Solution Pipelines and Cleaning Systems

Used in Milk and Milk Product Processing Plants ........................................................... 82

606-05 Design, Fabrication, and Installation of Milking and Milk Handling Equipment 83

607-05 Spray Drying Systems .......................................................................................... 84

608-02 Instantizing Systems ............................................................................................ 86

609-03 A Method of Producing Culinary Steam ............................................................. 87

3-A Std & Practices List with Document Scopes Page 5 of 98 J anuary 4,2013

610-02 Sanitary Construction, Installation, and Cleaning of Cross Flow Membrane

Processing Systems ........................................................................................................... 87

611-00 Farm Milk Cooling and Storage Systems ............................................................ 90

612-00 Plant Environmental Air Quality ......................................................................... 91

E-600 Egg Breaking and Separating Machines ............................................................... 92

E-1500 Shell Egg Washers .............................................................................................. 93

P3-A-001 Pharmaceutical General Glossary .................................................................... 93

P3-A-002 Materials for Use in Process Equipment and Systems ..................................... 94

3-A Std & Practices List with Document Scopes Page 6 of 98 J anuary 4,2013

01-08 Storage Tanks

Title: 3-ASanitary Standards for Storage Tanks, Number 01-08

Date: Effective November 20, 2001.

Scope: A1 These standards cover the sanitary aspects of storage tanks for milk

and milk products.

A2 In order to conform to these 3-A Sanitary Standards, storage tanks

shall comply with the following design, material, and fabrication

criteria.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

51- Plug-Type Valves for Milk and Milk Products

52- Plastic Plug-Type Valves for Milk and Milk Products

53- Compression-Type Valves

54- Diaphragm-Type Valves for Milk and Milk Products

56- Inlet and Outlet Leak-Protector Plug-Type Valves for Milk and

Milk Products

57- Disc-Type Valves

58- Vacuum Breakers and Check Valves for Milk and Milk Products

59- Automatic Positive Displacement Samplers for Fluid Milk and

Fluid Milk Products

63- Sanitary Fittings

74- Sensors and Sensor Fittings and Connections

73- Shear Mixers, Mixers, and Agitators

65- Sight and/or Light Windows and Sight Indicators in Contact with

Product

33- Polished Metal Tubing for Milk and Milk Products

85- Double-Seat Mixproof Valves

3-A Accepted Practice for:

604- Supplying Air Under Pressure in Contact With Milk, Milk

Products and Product Contact Surfaces

3-A Std & Practices List with Document Scopes Page 7 of 98 J anuary 4,2013

02-11 Centrifugal and Positi ve Rotary Pumps

Title: 3-A Sanitary Standards for Centrifugal and Positive Rotary Pumps,

Number 02-11

Date: Effective J uly 14, 2012

Scope: A1 These standards cover the sanitary aspects of centrifugal and

positive rotary pumps for milk and milk products.

A2 In order to conform to these 3 A Sanitary Standards, centrifugal

and positive rotary pumps shall comply with the following design,

materials, and fabrication criteria

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

63- Sanitary Fittings

04-05 Homogenizers and Reciprocating Pumps

Title: 3-ASanitary Standards for Homogenizers and Reciprocating Pumps,

Number 04-05

Date: Effective J une 15, 2012

Scope: A1 This 3-A Sanitary Standard covers the sanitary aspects of

homogenizers and reciprocating pumps, and their integral ancillary

components, for milk, milk products and other liquid food

products. Product enters the homogenizer or reciprocating pump at

the product inlet and exits at the product outlet.

A2 This 3-A Sanitary Standard does not include drum-type pumps.

A3 In order to conform to this 3 A Sanitary Standard, homogenizers

and reciprocating pumps shall conform to the following criteria for

design, materials of construction, fabrication techniques and

installation, as appropriate, and the current revisions or editions of

all referenced documents cited herein.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials

20- Multiple-Use Plastic Materials

3-A Std & Practices List with Document Scopes Page 8 of 98 J anuary 4,2013

33- Metal Tubing

42- In-Line Strainers

53- Compression-Type Valves

63- Sanitary Fittings

74- Sensors and Sensor Fittings and Connections Used on Equipment

82- Pulsation Dampening Devices

88- Machine Leveling Feet and Supports

603- Sanitary Construction, Installation, Testing, and Operation of

High-Temperature Short-Time and Higher-Heat Shorter-Time

Pasteurizer Systems

604- Supplying Air Under Pressure in Contact with Product or Product

Contact Surfaces

609- Method of Producing Steam of Culinary Quality

External

References:

1. American Society of Mechanical Engineers (ASME) B46.1

Surface Texture Waviness and Lay. Available from the American

Society of Mechanical Engineers, Three Park Ave., New York, NY

10016-5990, Phone: (212) 705-7722 or at http://www.asme.org

2. National Primary Drinking Water Regulation of the Environmental

Protection Agency (EPA), The Code of Federal Regulations

(CFR), Title 40, Parts 141, 142, and 143. For sale by the

Superintendent of Documents, U.S. Government Printing Office,

Washington, D.C. 20402, Phone: (202) 512-1800 or the EPA web

site at: http://water.epa.gov/drink/contaminants/index.cfm

3. Grade A Pasteurized Milk Ordinance, available from:

www.fda.gov/food/foodsafety/product-

specificinformation/milksafety/default.htm

4. AWS/ANSI D18.1 Specification for Welding of Austenitic

Stainless Steel Tube and Pipe Systems in Sanitary (Hygienic)

Applications.

AWS D18.2 Guide to Weld Discoloration Levels on Inside of

Austenitic Stainless Steel Tube (ANSI Approved)

AWS D18.3/D18.3M Specification for Welding of Tanks,

Vessels, and Other Equipment in Sanitary (Hygienic) Applications

(ANSI Approved)

Published by American Welding Society, 550 N.W. LeJ eune Rd.,

Miami FL, Phone: (800) 443-3953, www.aws.org

3-A Std & Practices List with Document Scopes Page 9 of 98 J anuary 4,2013

5. Advanced Materials and Processes, Volume 137(1), Coatings and

Coating Practices by H. Herman, Surface Modification by F. A.

Smidt. ASM International, Materials Park, OH 44073, Phone:

(216) 338-5151, Internet http://asminternational.org

6. AMS-S-13165, Shot Peening of Metal Parts. SAE International,

400 Commonwealth Dr., Warrendale, PA 15096-0001, Internet:

http://www.sae.org

7. SAE AMS 2406, Chromium Plating (Electrodeposited). SAE-AMS

QQ-N-290A, Nickel Plating (Electrodeposited). SAE

International, 400 Commonwealth Dr., Warrendale, PA 15096-

0001, Internet: http://www.sae.org

8. AIST Stainless Steels: A Steel Products Manual, Association for

Iron & Steel Technology, 186 Thorn Hill Road, Warrendale, PA

15086, Phone: (724) 814 3000, Internet: www.aist.org

9. Steel Casting Handbook, Supplement 2, Steel Founders Society of

America, 780 McArdle Dr., Unit G, Crystal Lake, IL 60014,

Phone: (815) 455-8240, Fax: (815) 455-8241, Internet:

www.sfsa.org

10. MIL-C-26074E. Military Specification: Coatings, Electroless

Nickel Requirements For. Standardization, Document Automation

& Production Service (Department of Navy), 700 Robbins Avenue,

Building 4, Section D, Philadelphia, PA 19111-5094, Phone:

(215) 697-2179, Fax: (215) 697-1462.

11. The Code of Federal Regulations (CFR), Title 21, Parts 175

Indirect Food Additives: Adhesives and Components of Coatings.

For sale by the Superintendent of Documents, U.S. Government

Printing Office, Washington, D.C. 20402, Phone: (202) 512-1800,

Internet: http://www.gpoaccess.gov/cfr/index.html

12. Machinery's Handbook, published by Industrial Press Inc., 200

Madison Avenue, New York, NY 10157, Phone: (888) 528-7852,

Internet: http://new.industrialpress.com

13. Aerospace Standard (AS) 568, Aerospace Size Standards for O-

rings, published by SAE, 400 Commonwealth Drive, Warrendale,

PA 15086, Phone: (724)-776-4841, Internet: http://www.sae.org

14. ISO 3601-1:2002: Fluid Power Systems, Sealing Devices O-

Rings Part 1: Inside diameters, cross-sections, tolerances and

size identification code, The International Organization for

3-A Std & Practices List with Document Scopes Page 10 of 98 J anuary 4,2013

Standardization (ISO), 1 ch. de la Voie-Creuse, Postale 56, CH -

1211, Geneva 20, Switzerland, Phone: +41-22-749-01-11, Internet:

www.iso.org

15. ASTM specifications for Cast Grades A351/A351M, A743/A743M

and A744/A744M. Available from ASTM, 100 Barr Harbor

Drive, West Conshohocken, PA 19428-2959, Phone: (610) 832-

9500. www.astm.org/standard/index.shtml

05-15 Stainless Steel Automotive Transportation Tanks

for Bulk Deli very and Farm Pick-Up Service

Title: 3-ASanitary Standards for Stainless Steel Automotive Transportation

Tanks for Bulk Delivery and Farm Pick-Up Service, Number 05-15

Date: Effective November 24, 2002

Scope: A1 These standards cover the sanitary aspects of automotive

transportation tanks for milk, fluid milk products, and other liquid

comestible products.

A2 In order to conform to these 3-A Sanitary Standards, transportation

tanks shall comply with the following design, material and

fabrication criteria

References: 3-A Sanitary Standard for:

02- Centrifugal and Positive Rotary Pumps

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

33- Polished Metal Tubing for Milk and Milk Products

51- Plug-Type Valves for Milk and Milk Products

53- Compression-Type Valves

57- Disc-Type Valves

62- Hose Assemblies for Milk and Milk Products

63- Sanitary Fittings

68- Ball-Type Valves for Milk and Milk Products

74- Sensors and Sensor Fittings and Connections

3-A Accepted Practice for:

604- Supplying Air Under Pressure in Contact With Milk, Milk

Products and Product Contact Surfaces

605- Permanently Installed Product and Solution Pipelines and Cleaning

Systems Used in Milk and Milk Product Processing Plants

3-A Std & Practices List with Document Scopes Page 11 of 98 J anuary 4,2013

3-A Sanitary Standards referenced which have been discontinued

55- Boot Seal-Type Valves for Milk and Milk Products

66- Caged-Ball Valves for Milk and Milk Products

10-04 Filters Using Single Service Filter Media

Title: 3-ASanitary Standards for Filters Using Single Service Filter Media,

Number 10-04

Date: Effective November 12, 2000

Scope: A1 These standards cover sanitary aspects of enclosed filtration

equipment that uses single service filter media for filtering milk

and milk products.

A2 In order to conform to these 3-A Sanitary Standards, filters shall

comply with the following design, material, and fabrication

criteria.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

63- Sanitary Fittings

11-09 Plate Type Heat Exchangers

Title: 3-ASanitary Standards for Plate Type Heat Exchangers, Number 11-08

Date: Effective: August 1, 2010

Scope: A1. This standard covers the sanitary aspects of plate type heat

exchangers beginning with the inlet fittings for product(s) and for

heat exchange media and ending with the outlet fittings for

product(s) and for heat exchange media. This standard include the

frame and/or support components for holding the heat exchange

plates and the means for manual or mechanical opening and

closing of the plate pack assembly.

A2 In order to conform to this 3-A Sanitary Standard, plate heat

exchangers shall conform to the following criteria for design,

3-A Std & Practices List with Document Scopes Page 12 of 98 J anuary 4,2013

materials of construction, fabrication techniques and installation, as

appropriate, and the current revisions or editions of all referenced

documents cited herein in Section B.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-like Materials

20- Multiple-Use Plastic Materials

63- Sanitary Fittings

33- Metal Tubing

88- Machine Leveling Feet and Supports

External

References:

1. AIST Steel Products Manual, Stainless & Heat Resisting Steels,

Table 2-1. Association for Iron & Steel Technology (AIST), 410

Commonwealth Drive, Warrendale, PA 15086, Phone: (412) 776-

1535. www.AIST.org

2. Steel Casting Handbook, Supplement 2, 1999. Available from

Steel Founders Society of America, 780 McArdle Dr., Unit G,

Crystal Lake, IL 60014, Phone: (815) 455-8240, Fax: (815) 455-

8241, www.sfsa.org.

3. MIL-C-26074E. Military Specification: Coatings, Electroless

Nickel Requirements For. Standardization, Document Automation

& Production Service (Department of Navy), 700 Robbins Avenue,

Building 4, Section D, Philadelphia, PA 19111-5094, Phone:

(215)697-2179, Fax: (215) 697-1462.

4. ASTM specifications for Cast Grades A351/A351M, A743/A743M

and A744/A744M. Available from ASTM, 100 Barr Harbor

Drive, West Conshohocken, PA 19428-1959, Phone: (610) 832-

9500. www.astm.org/standard/index.shtml

5. ASTM specifications for Wrought Grades A276, A582, and A666.

Available from ASTM, 100 Barr Harbor Drive, West

Conshohocken, PA 19428-2959, Phone: (610) 832-9500.

www.astm.org/standard/index.shtml

6. (ANSI)/American Society of Mechanical Engineers (ASME)

B46.1 Surface Texture Waviness and Lay. Available from the

American Society of Mechanical Engineers, 345 East 47th Street,

New York, NY 10017-2392, Phone: (212) 705-7722.

7. EHEDG Doc. 35 Welding of Stainless Steel Tubing in the Food

Industry. European Hygienic Engineering & Design Group.

Published by EHEDG. www.ehedg.org

8. The Code of Federal Regulations (CFR), Title 21, Parts 175

Indirect Food Additives: Adhesives and Components of Coatings.

3-A Std & Practices List with Document Scopes Page 13 of 98 J anuary 4,2013

For sale by the Superintendent of Documents, U.S. Government

Printing Office, Washington, D.C. 20402, Phone: (202) 512-1800

or at http://gpoacess.gov/cfr/index.html.

9. GAR C-9 Cast Microfinish Comparator. Available from Gar

Electroforming Division, Electroformers Inc., 11 Augusta Drive,

Commerce Park, PO Box 340, Danbury, CT 06813-0340, Phone:

(203) 744-4300.

10. Advanced Materials and Processes, Volume 137(1), Coatings and

Coating Practices by H. Herman, Surface Modification by F. A.

Smidt. ASM International, Materials Park, OH 44073, Phone:

(216) 338-5151.

12-07 Tubular Heat Exchangers

Title: 3-ASanitary Standards for Tubular Heat Exchangers, Number 12-07

Date: Adopted November 16, 2003

Scope: A1 These standards cover the sanitary aspects of tubular heat

exchangers without agitators. Tubular heat exchangers may have

tube cross-sectional profile modifications or removable devices for

promotion of desired flow characteristics. The standards do not

cover high-pressure (greater than 250 psig or 1724 kPa product

pressure) tubular heat exchangers which require special tubing

and/or fittings.

A2 In order to conform to these 3-A Sanitary Standards, tubular heat

exchangers shall conform to the following design, material, and

fabrication criteria.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

63- Sanitary Fittings

33- Polished Metal Tubing for Milk and Milk Products

74- Sensors and Sensor Fittings and Connections

3-A Accepted Practice for:

604- Supplying Air Under Pressure in Contact With Milk, Milk

Products and Product Contact Surfaces

605- Permanently Installed Product and Solution Pipelines and Cleaning

3-A Std & Practices List with Document Scopes Page 14 of 98 J anuary 4,2013

Systems Used in Milk and Milk Product Processing Plants

13-11 Farm Milk Cooling and Holding Tanks

Title: 3-ASanitary Standards for Farm Milk Cooling and Holding Tanks,

Number 13-11

Date: Effective: J uly 23, 2012

Scope: A1 This standard covers the sanitary aspects of tanks in which bulk

milk is cooled and stored on dairy farms.

A2 Tanks made in conformance to these standards shall provide a

means for cooling the milk.

A3 The milk tank will consist of the following components: Lining,

jacket and rail, personnel access openings and covers, outlet valve,

vent, agitation, refrigeration, measuring device and internal

solution piping.

A3.1 Other components may include: external solution piping, cleaning

controls, temperature indication thermometer, recording

thermometer, and weather protective cover and sanitary seals for

agitator.

A4 In order to conform to these 3-A Sanitary Standards, farm milk

cooling and holding tanks shall conform to the following design,

material, fabrication, and cooling criteria.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

33- Polished Metal Tubing for Milk and Milk Products

57- Disc-Type Valves

78- Spray Cleaning Devices Intended to Remain in Place

73- Shear Mixers, Mixers and Agitators

74- Sensors and Sensor Fittings and Connections

65- Sight and/or Light Windows and Sight Indicators in Contact with

Product

3-A Accepted Practice for:

604- Supplying Air Under Pressure in Contact With Milk, Milk

Products and Product Contact Surfaces

3-A Std & Practices List with Document Scopes Page 15 of 98 J anuary 4,2013

16-05 Milk and Milk Products Evaporators and Vacuum

Pans

Title: 3-ASanitary Standards for Milk and Milk Products Evaporators and

Vacuum Pans, Number 16-05

Date: Reaffirmed August 24, 1997

Scope: A1 These standards cover the sanitary aspects of evaporators and

vacuum pans used for milk and milk products.

A2 In order to conform to these 3-A Sanitary Standards, evaporators

and vacuum pans shall comply with the following design, material,

and fabrication criteria.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

11- Plate Type Heat Exchangers

12- Tubular Heat Exchangers

31- Scraped Surface Heat Exchangers

33- Polished Metal Tubing for Milk and Milk Products

51- Plug-Type Valves for Milk and Milk Products

52- Plastic Plug-Type Valves for Milk and Milk Products

63- Sanitary Fittings

58- Vacuum Breakers and Check Valves for Milk and Milk Products

74- Sensors and Sensor Fittings and Connections

68- Ball-Type Valves for Milk and Milk Products

59- Automatic Positive Displacement Samplers for Fluid Milk and

Fluid Milk Products

3-A Accepted Practice for:

605- Permanently Installed Product and Solution Pipelines and Cleaning

Systems Used in Milk and Milk Product Processing Plants

603- Sanitary Construction, Installation, Testing, and Operation of

High-Temperature Short-Time and Higher-Heat Shorter-Time

Pasteurizer Systems

3-A Sanitary Standards referenced which have been discontinued

66- Caged-Ball Valves for Milk and Milk Products

3-A Std & Practices List with Document Scopes Page 16 of 98 J anuary 4,2013

17-11 Formers, Fillers, and Sealers of Containers for

Fluid Milk and Fluid Milk Products

Title: 3-ASanitary Standards for Formers, Fillers, and Sealers of Containers

for Fluid Milk and Fluid Milk Products, Number 17-11

Date: Effective November 19, 2012

Scope: A1 These standards cover the sanitary aspects of unitized equipment for

forming, filling, and sealing containers for fluid milk and fluid

milk products. The equipment shall perform one or more of the

following functions: 1) forming the container, 2) applying and

sealing a supplementary fitment or device, 3) filling the container

and 4) sealing, including capping if part of the unitized equipment,

the container. The equipment shall start at the points where the

product, utilities (air, water, steam, cleaning chemicals, etc.),

container, container blank, or container material first enters the

unitized equipment. The equipment shall end where the formed,

filled, and/or sealed container exits the equipment.

A2 These standards do not pertain to the container, to free-standing

container forming equipment or to other equipment such as

labelers, printers, daters, cappers, applicators of supplementary

fitments or devices or wrappers not furnished as part of the

unitized equipment, nor shall it apply to fillers of viscous products,

such as frozen desserts, cottage cheese, cultured yogurt, sour

cream, whipped butter, cream cheese, and other similar viscous

dairy products.

A3 In order to conform to these 3-A Sanitary Standards, formers,

fillers, and sealers of containers shall comply with the following

design, material, and fabrication criteria.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

28- Flow Meters for Milk and Milk Products

33- Polished Metal Tubing for Milk and Milk Products

02- Centrifugal and Positive Rotary Pumps

04- Homogenizers and Reciprocating Pumps

44- Diaphragm Pumps

51- Plug-Type Valves for Milk and Milk Products

52- Plastic Plug-Type Valves for Milk and Milk Products

3-A Std & Practices List with Document Scopes Page 17 of 98 J anuary 4,2013

53- Compression-Type Valves

54- Diaphragm-Type Valves for Milk and Milk Products

59- Automatic Positive Displacement Samplers for Fluid Milk and

Fluid Milk Products

60- Milk and Milk Products Rupture Discs

74- Sensors and Sensor Fittings and Connections

64- Pressure Reducing and Back Pressure Regulating Valves for Milk

and Milk Products

65- Sight and/or Light Windows and Sight Indicators in Contact with

Product

62- Hose Assemblies for Milk and Milk Products

63- Sanitary Fittings

3-A Accepted Practice for:

604- Supplying Air Under Pressure in Contact With Milk, Milk

Products and Product Contact Surfaces

609- A Method of Producing Culinary Steam

3-A Sanitary Standards referenced which have been discontinued

55- Boot Seal-Type Valves for Milk and Milk Products

18-03 Multiple-Use Rubber and Rubber-Like Materials

Used as Product Contact Surfaces in Dairy Equipment

Title: 3-A Sanitary Standards for Multiple-Use Rubber and Rubber-Like

Materials Used as Product Contact Surfaces in Dairy Equipment, Number

18-03

Date: Effective August 21, 1999

Scope: A1 These sanitary standards cover the material and serviceability

requirements of rubber and rubber-like materials intended for

multiple-use as product contact surfaces or solution contact

surfaces in the production, processing and handling of milk or milk

products. Test procedures and criteria are also provided for rubber

and rubber-like materials as a means of determining their

acceptance as to their ability to be cleaned and to receive effective

bactericidal treatment or steam sterilization and to maintain their

essential properties in these accelerated use-simulating conditions .

These standards are not meant to cover design and fabrication

criteria for individual rubber or rubber-like components because

such criteria are provided for in other 3-A Sanitary Standards and

3-A Std & Practices List with Document Scopes Page 18 of 98 J anuary 4,2013

3-A Accepted Practices, nor are these standards intended to cover

RTV silicone adhesives or sealants.

A2 In order to conform with these 3-A Standards, multiple-use rubber

and rubber-like materials shall comply with the following material,

original physical properties and serviceability requirements.

References: 3-A Sanitary Standard for:

19-07 Batch and Continuous Freezers for Ice Cream,

Ices and Similarly Frozen Dairy Foods

Title: 3-A Sanitary Standards for Batch and Continuous Freezers for Ice

Cream, Ices and Similarly Frozen Dairy Foods, Number 19-07

Date: Effective December 1, 2008

Scope: A1 These standards cover the sanitary aspects of batch and continuous

freezers for ice cream, sherbets, sorbets, ices, and other similarly-

frozen foods and equipment integral therewith, including pumps,

equipment for incorporating air or introducing flavoring material

into the product and mix supply tanks attached to and made as a

part of the freezer. These standards do not cover equipment

designed for the freezing of soft-serve type ice cream, ices, and

similarly-frozen products which are served to the consumer

without further hardening.

A2 In order to conform to these 3-A Sanitary Standards, batch and

continuous freezers for ice cream, sherbets, sorbets, ices, and other

similarly frozen foods shall conform to the following design,

material, fabrication criteria and the applicable documents

referenced herein.

References: 3-A Sanitary Standard for:

02- Centrifugal and Positive Rotary Pumps

04- Homogenizers and Reciprocating Pumps

18- Multiple-Use Rubber and Rubber-Like Materials

20- Multiple-Use Plastic Materials

28- Flow Meters

33- Polished Metal Tubing

58- Vacuum Breakers and Check Valves

63- Sanitary Fittings

3-A Std & Practices List with Document Scopes Page 19 of 98 J anuary 4,2013

74- Sensors and Sensor Fittings and Connections Used on Equipment

88- Machine Leveling Feet and Supports

3-A Accepted Practice for:

604- Supplying Air Under Pressure in Contact With Milk, Milk

Products and Product Contact Surfaces

External

References:

1. Advanced Materials and Processes, Volume 137(1), Coatings and

Coating Practices by H. Herman, Surface Modification by F. A.

Smidt, p. 61. ASM International, Materials Park, OH 44073 (216)

338-5151.

2. AMS-S-13165, Shot Peening of Metal Parts. Society of

Automotive Engineers (AWS), Commonwealth Dr., Warrendale

PA 15096-0001.

3. SAE-AMS-QQ-C-320, Chromium Plating (Electrodeposited).

SAE-AMS QQ-N-290A, Nickel Plating (Electrodeposited). Society

of Automotive Engineers (AWS), 400 Commonwealth Dr.,

Warrendale, PA 15096- 0001.

4. AISI Steel Products Manual, Stainless & Heat Resisting Steels,

November 1990, Table 2-1, pp. 17-20. Available from the

American Iron and Steel Society, 410 Commonwealth Drive,

Warrendale, PA 15086 (412-776-1535).

5. Steel Founders Society of America, 780 McArdle Dr., Unit G,

Crystal Lake, IL 60014, Phone: (815) 455-8240, Fax: (815) 455-

8241, Internet: www.sfsa.org .

6. ASTM specifications for Cast Grades A351/A351M, A743/A743M

and A744/A744M. Available from ASTM, 100 Barr Harbor Drive,

West Conshohocken, PA 19428-2959, Phone: (610) 832-9500.

7. ASTM specifications for Wrought Grades A-276, A-582, and A-

666. Available from ASTM, 100 Barr Harbor Drive, West

Conshohocken, PA 19428-2959, Phone: (610) 832-9500.

8. (ANSI)/American Society of Mechanical Engineers (ASME)

B46.1 Surface Texture. Available from ASME, 345 East 47th

Street, New York, NY 10017-2392 (212-705-7722).

9. The Code of Federal Regulations (CFR), Title 21, Parts 175

Indirect Food Additives: Adhesives and Components of Coatings.

For sale by the Superintendent of Documents, U.S. Government

Printing Office, Washington, D.C. 20402, (202) 512-1800.

3-A Std & Practices List with Document Scopes Page 20 of 98 J anuary 4,2013

10. ASHRAE test 52.2-1999 method of testing general ventilation air-

cleaning devices for removal efficiency by particle size. Available

from American Society of Heating, Refrigeration and Air

Conditioning Engineers, 1791 Tullie Circle, N.E., Atlanta, GA

30329 Phone: 404-636-8400.

11. ISO 14644-1 designating standard classes of air particulate

cleanliness and specifies methods for verifying air cleanliness

classifications. Available from The International Organization for

Standardization (ISO), 1 Rue de Varembe, Case Postale 58, CH 1

1211, Geneva, Switzerland, Phone: +41-22-734-1240.

12. Machinery's Handbook, published by Industrial Press Inc., 200

Madison Avenue, New York, NY 10157, Phone: (888) 528-7852.

13. Aerospace Standard (AS) 568, Aerospace Size Standards for O-

rings, published by SAE, 400 Commonwealth Drive, Warrendale,

PA 15086. Phone: (412) 776-4970.

14. AWS/ANSI D18.1 Specification for Welding of Austenitic

Stainless Steel Tube and Pipe Systems in Sanitary (Hygienic)

Applications. Published by American Welding Society, 550 N.W.

LeJ eune Rd., Miami FL, Phone: (800) 443-3953, www.aws.org.

15. EHEDG Doc. 9 Welding Stainless Steel to Meet Hygienic

Requirements. European Hygienic Engineering & Design Group.

Published by EHEDG, www.ehedg.org

16. ISO 3601-1: The International Organization for Standardization

(ISO), 1 Rue de Varembe, Case Postale 58, CH 1 1211, Geneva,

Switzerland. Phone: +41-22-734-1240.

20-27 Multiple-Use Plastic Materials

Title: 3-ASanitary Standards for Multiple-Use Plastic Materials, Number 20-

27

Date: Effective: J uly 7, 2011

Scope: A1 These sanitary standards cover the material requirements of

plastics for multiple-use as product contact and/or cleaning

solution contact surfaces in equipment for production, processing,

and handling of milk and milk product(s). Test criteria are

provided for plastics as a means of determining their acceptance as

3-A Std & Practices List with Document Scopes Page 21 of 98 J anuary 4,2013

to their ability to be cleaned and to receive effective bactericidal

treatment and to maintain their essential functional properties and

surface finish in accelerated use-simulating tests . These standards

do not apply to plastics for single service application nor plastics

which are of rubber or rubber-like origin resulting from chemical

or thermal vulcanization or curing. These standards are also not

meant to cover design and fabrication criteria for individual plastic

components, because such criteria are provided for in other 3-A

Sanitary Standards and 3-A Accepted Practices.

A2 In order to conform to these 3-A Sanitary Standards, multiple-use

plastics shall comply with the following material, fabrication of

test specimens as described in Section D3 herein, and cleanability

standards.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

21-01 Centrifugal Separators and Clarifiers

Title: 3-A Sanitary Standards for Centrifugal Separators and Clarifiers,

Number 21-01

Date: Effective: November 13, 2006

Scope: A1 These Standards cover the sanitary aspects of centrifugal

separators or clarifiers used to separate fractions of milk or milk

products or other liquid food products or to centrifugally remove

dense phase material from products. This machine starts at the

product inlet(s) and terminates at the product outlet(s) and the

nonproduct discharge(s), if included.

These Standards do not cover cyclonic types of separators,

decanters, basket centrifuges and other types of devices and the

spacers (caulks) for separator or clarifier discs and their attachment

to the discs. (See Appendix M.)

A2 In order to conform to these 3-A Sanitary Standards, centrifugal

separators or clarifiers shall comply with the following design,

material, and fabrication criteria and the applicable documents

referenced herein.

References: 3-A Sanitary Standard for:

3-A Std & Practices List with Document Scopes Page 22 of 98 J anuary 4,2013

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

33- Polished Metal Tubing for Milk and Milk Products

63- Sanitary Fittings

74- Sensors and Sensor Fittings and Connections

65- Sight and/or Light Windows and Sight Indicators in Contact with

Product

3-A Accepted Practice for:

605- Permanently Installed Product and Solution Pipelines and Cleaning

Systems Used in Milk and Milk Product Processing Plants

22-08 Silo-Type Storage Tanks for Milk and Milk

Products

Title: 3-ASanitary Standards for Silo-Type Storage Tanks for Milk and Milk

Products, Number 22-08

Date: Adopted: November 21, 2004

Scope: A1 These standards cover the sanitary aspects of silo-type storage

tanks for milk and milk products used at dairy processing plants.

These standards are not intended to cover silo-type tanks used on

dairy farms.

A2 In order to conform to these 3-A Sanitary Standards, silo-type

storage tanks shall conform to the following design, material,

fabrication and refrigeration criteria

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

33- Polished Metal Tubing for Milk and Milk Products

73- Shear Mixers, Mixers, and Agitators

74- Sensors and Sensor Fittings and Connections

56- Inlet and Outlet Leak-Protector Plug-Type Valves for Milk and

Milk Products

57- Disc-Type Valves

60- Milk and Milk Products Rupture Discs

63- Sanitary Fittings

51- Plug-Type Valves for Milk and Milk Products

3-A Std & Practices List with Document Scopes Page 23 of 98 J anuary 4,2013

52- Plastic Plug-Type Valves for Milk and Milk Products

53- Compression-Type Valves

54- Diaphragm-Type Valves for Milk and Milk Products

3-A Accepted Practice for:

604- Supplying Air Under Pressure in Contact With Milk, Milk

Products and Product Contact Surfaces

605- Permanently Installed Product and Solution Pipelines and Cleaning

Systems Used in Milk and Milk Product Processing Plants

3-A Sanitary Standards referenced which have been discontinued

55- Boot Seal-Type Valves for Milk and Milk Products

23-06 Equipment for Packaging Viscous Product

Title: 3-ASanitary Standards for Equipment for Packaging Viscous Products,

Number 23-06

Date: Effective: November 19, 2012

Scope: A1 These standards cover the sanitary aspects of unitized equipment

for holding, opening, forming, dispensing, filling, closing, sealing,

or capping containers for viscous products, or wrapping viscous

products, and all parts essential to these functions. The equipment

shall perform one or more of the following functions:

1. Holding the container preparatory to further processing

2. Opening the container

3. Forming the container

4. Dispensing a preformed container

5. Applying and sealing a supplementary fitment

6. Other processing equipment, as defined herein

7. Filling the container

8. Closing the container

9. Sealing the container

10. Capping the container

11. Wrapping the container

12. Applying a tamper-evident security seal.

The equipment shall start at the point(s) where the product,

container, container blank, container material or wrapping material

first enters the equipment. The equipment shall end where the

packaged product exits the unitized equipment.

A2 These standards do not pertain to the container, to free-standing

3-A Std & Practices List with Document Scopes Page 24 of 98 J anuary 4,2013

container forming equipment or to other equipment such as

labelers, printers, daters, cappers, applicators of supplementary

fitments or devices or wrappers not furnished as part of the

unitized equipment, nor shall it apply to fillers of nonviscous

products.

A3 In order to conform to these 3-A Sanitary Standards, equipment for

packaging viscous products shall conform to the following design,

material, and fabrication criteria and the applicable documents

referenced herein.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

33- Polished Metal Tubing for Milk and Milk Products

65- Sight and/or Light Windows and Sight Indicators in Contact with

Product

60- Milk and Milk Products Rupture Discs

63- Sanitary Fittings

51- Plug-Type Valves for Milk and Milk Products

53- Compression-Type Valves

54- Diaphragm-Type Valves for Milk and Milk Products

02- Centrifugal and Positive Rotary Pumps

04- Homogenizers and Reciprocating Pumps

28- Flow Meters for Milk and Milk Products

46- Refractometers and Energy Absorbing Optical Sensors for Milk

and Milk Products

58- Vacuum Breakers and Check Valves for Milk and Milk Products

68- Ball-Type Valves for Milk and Milk Products

74- Sensors and Sensor Fittings and Connections

52- Plastic Plug-Type Valves for Milk and Milk Products

62- Hose Assemblies for Milk and Milk Products

3-A Accepted Practice for:

604- Supplying Air Under Pressure in Contact With Milk, Milk

Products and Product Contact Surfaces

605- Permanently Installed Product and Solution Pipelines and Cleaning

Systems Used in Milk and Milk Product Processing Plants

609- A Method of Producing Culinary Steam

3-A Sanitary Standards referenced which have been discontinued

66- Caged-Ball Valves for Milk and Milk Products

3-A Std & Practices List with Document Scopes Page 25 of 98 J anuary 4,2013

24-03 Non-Coil Type Batch Pasteurizers for Milk and Milk

Products

Title: 3-ASanitary Standards for Non-Coil Type Batch Pasteurizers for Milk

and Milk Products, Number 24-03

Date: Effective J uly 16, 2010

Scope: A1 This standard covers the sanitary aspect of non-coil type batch

pasteurizers used to pasteurize milk, fluid milk products, or other

fluid food products and includes those appurtenances necessary to

meet pasteurization requirements. This Standard shall be deemed

inclusive of the points where the product enters and exits the

noncoil type batch pasteurizer.

A2 In order to conform to this 3-A Sanitary Standard, non-coil type

batch pasteurizers shall conform to the following criteria for

design, materials of construction, fabrication techniques and

installation, as appropriate, and the current revisions or editions of

all referenced documents cited herein.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials

20- Multiple-Use Plastic Materials

33- Polished Metal Tubing

56- Inlet and Outlet Leak-Protector Plug-Type Valves

63- Sanitary Fittings

65- Sight and/or Light Windows and Sight Indicators

73- Shear Mixers, Mixers and Agitators

74- Sensors and Sensor Fittings and Connections Used on Equipment

78- Spray Devices to Remain in Place

84- Personnel Access Port for Wet Applications

88- Machine Leveling Feet and Supports

3-A Accepted Practice for:

604- Supplying Air Under Pressure in Contact with Product, and

Product Contact Surfaces

609- Accepted Practice for Culinary Steam

External

References:

1. AIST Steel Products Manual, Stainless & Heat Resisting Steels,

Table 2-1. Association for Iron & Steel Technology (AIST), 410

Commonwealth Drive, Warrendale, PA 15086, Phone: (412) 776-

1535. www.AIST.org

2. Steel Founders Society of America, 780 McArdle Dr., Unit G,

3-A Std & Practices List with Document Scopes Page 26 of 98 J anuary 4,2013

Crystal Lake, IL

60014, Phone: (815) 455-8240, Fax: (815) 455-8241,

Internet: www.sfsa.org

3. ASTM specifications for Cast Grades A351/A351M, A743/A743M

and A744/A744M. Available from ASTM, 100 Barr Harbor Drive,

West Conshohocken, PA 19428-2959, Phone: (610) 832-9500.

4. AWS/ANSI D18.1 Specification for Welding of Austenitic

Stainless Steel Tubeand Pipe Systems in Sanitary (Hygienic)

Applications.

AWS D18.2 Guide to Weld Discoloration Levels on Inside of

Austenitic Stainless Steel Tube (ANSI Approved)

AWS D18.3/D18.3M - Specification for Welding of Tanks, Vessels,

and Other Equipment in Sanitary (Hygienic) Applications (ANSI

Approved) Published by American Welding Society, 550 N.W.

LeJ eune Rd., Miami FL, Phone: (800) 443-3953, www.aws.org.

5. EHEDG Doc. 9 Welding Stainless Steel to Meet Hygienic

Requirements. European Hygienic Engineering & Design Group.

Published by EHEDG, www.ehedg.org

6. Grade A Pasteurized Milk Ordinance,

http://www.cfsan.fda.gov/~ear/pmo03toc.html.

7. The Code of Federal Regulations (CFR), Title 21, Parts 175

Indirect Food Additives: Adhesives and Components of Coatings.

For sale by the Superintendent of Documents, U.S. Government

Printing Office, Washington, D.C. 20402, Phone: (202) 512-1800

or at http://www.gpoaccess.gov/cfr/index.html.

8. Aerospace Standard (AS) 568, Aerospace Size Standards for O-

rings, published by SAE, 400 Commonwealth Drive, Warrendale,

PA 15086, Phone: (724)-776-4841.

9. ISO 3601-1: The International Organization for Standardization

(ISO), 1 Rue de Varembe, Case Postale 58, CH 1 1211, Geneva,

Switzerland, Phone: +41-22-734-1240.

25-03 Non-Coil Type Batch Processors

Title: 3-ASanitary Standards for Non-Coil Type Batch Processors, Number

25-03

3-A Std & Practices List with Document Scopes Page 27 of 98 J anuary 4,2013

Date: Effective November 24, 2002

Scope: A1 These standards cover sanitary aspects of non-coil type batch

processors used to heat, cool, or process milk, fluid milk products,

or other fluid comestibles. Batch processors may be either of the

atmospheric or closed type. The latter may be operated at

pressures from below to above that of the atmosphere.

A2 In order to conform to these 3-A Sanitary Standards, non-coil type

batch processors shall conform to the following design, material,

and fabrication criteria.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

33- Polished Metal Tubing for Milk and Milk Products

78- Spray Cleaning Devices Intended to Remain in Place

60- Milk and Milk Products Rupture Discs

63- Sanitary Fittings

65- Sight and/or Light Windows and Sight Indicators in Contact with

Product

73- Shear Mixers, Mixers, and Agitators

51- Plug-Type Valves for Milk and Milk Products

52- Plastic Plug-Type Valves for Milk and Milk Products

53- Compression-Type Valves

54- Diaphragm-Type Valves for Milk and Milk Products

56- Inlet and Outlet Leak-Protector Plug-Type Valves for Milk and

Milk Products

57- Disc-Type Valves

58- Vacuum Breakers and Check Valves for Milk and Milk Products

74- Sensors and Sensor Fittings and Connections

3-A Sanitary Standards referenced which have been discontinued

55- Boot Seal-Type Valves for Milk and Milk Products

26-05 Sifters for Dry Products

Title: 3-ASanitary Standards for Sifters for Dry Products, Number 26-05

Date: Effective: April 26, 2007

Scope: A1 These standards cover the sanitary aspects of sifters used for

processing dry products beginning at, as appropriate, the inlets for

3-A Std & Practices List with Document Scopes Page 28 of 98 J anuary 4,2013

products, cleaning solutions, processing air and terminating at the

outlets for product, processing air, cleaning solutions or rejected

material.

A2 In order to conform to these 3 A Sanitary Standards, sifting

equipment shall comply with the following design, material, and

fabrication criteria.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

65- Sight and/or Light Windows and Sight Indicators in Contact with

Product

62- Hose Assemblies for Milk and Milk Products

63- Sanitary Fittings

27-06 Equipment for Packaging Dry Milk and Dry Milk

Products

Title: 3-ASanitary Standards for Equipment for Packaging Dry Milk and Dry

Milk Products, Number 27-06

Date: Effective May 7, 2010

Scope: A1 These standards cover the sanitary aspects of equipment for

performing the functions of holding, forming, dispensing, filling,

weighing, deaerating, closing, and/or sealing containers, and all

parts which are essential to these functions when they are

performed as an integral part of the packaging operation. These

standards do not pertain to the container nor to a duct(s) which is

not a part of the packaging equipment.

A2 In order to conform to these 3-A Sanitary Standards, equipment for

packaging dry milk and dry milk products shall conform to the

following design, material, and fabrication criteria and the

applicable documents referenced herein.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

3-A Std & Practices List with Document Scopes Page 29 of 98 J anuary 4,2013

63- Sanitary Fittings

3-A Accepted Practice for:

604- Supplying Air Under Pressure in Contact With Milk, Milk

Products and Product Contact Surfaces

28-04 Flow Meters for Milk and Milk Products

Title: 3-ASanitary Standards for Flow Meters for Milk and Milk Products,

Number 28-04

Date: Effective J anuary 26, 2009

Scope: A1 These standards cover the sanitary aspects of flow meters for milk

and milk products and include that portion of any device integral

with the meter such as strainers, temperature sensors and density

sensors, which is in contact with the flowing product. It does not

pertain to meters designed to measure the milk from an individual

milking animal.

A2 In order to conform to these 3 A Sanitary Standards, flow meters

shall comply with the following design, material, and fabrication

criteria

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

63- Sanitary Fittings

33- Polished Metal Tubing for Milk and Milk Products

29-03 Air Eliminators

Title: 3-ASanitary Standards for Air Eliminators, Number 29-03

Date: Effective August 22, 2011

Scope: A1 This 3-A Sanitary Standard covers the sanitary aspects of air

eliminators that vent air removed from product directly to the

atmosphere and does not apply to devices using vacuum to remove

air. Product and air enter the air eliminator at the inlet connection,

3-A Std & Practices List with Document Scopes Page 30 of 98 J anuary 4,2013

product exits at the outlet connection and air exits at the air vent.

A2 In order to conform to this 3-A Sanitary Standard, air eliminators

shall conform to the following criteria for design, materials of

construction, fabrication techniques and installation, as

appropriate, and the current revisions or editions of all referenced

documents cited herein.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-like Materials

20- Multiple-Use Plastic Materials

33- Metal Tubing

58- Vacuum Breakers and Check Valves

63- Sanitary Fittings

65- Sight and/or Light Windows and Sight Indicators in Contact with

Product

74- Sensors and Sensor Fittings and Connections Used on Equipment

78- Spray Cleaning Devices Intended to Remain in Place

88- Machine Leveling Feet and Supports

External

References:

1. (ANSI)/American Society of Mechanical Engineers (ASME) B46.1

- Surface Texture Waviness and Lay. Available from the American

Society of Mechanical Engineers, 345 East 47th Street, New York,

NY 10017-2392, Phone: (212) 705-7722. http://webstore.ansi.org

2. AIST Steel Products Manual, Stainless & Heat Resisting Steels,

Table 2-1. Association for Iron & Steel Technology (AIST), 410

Commonwealth Drive, Warrendale, PA 15086, Phone: (412) 776-

1535. www.AIST.org

3. Steel Casting Handbook, Supplement 2, 1999, Steel Founders

Society of America, 780 McArdle Dr., Unit G, Crystal Lake, IL

60014, Phone: (815) 455-8240, Fax: (815) 455-8241, Internet:

www.sfsa.org

4. The Code of Federal Regulations (CFR), Title 21, Parts 175

Indirect Food Additives: Adhesives and Components of Coatings.

For sale by the Superintendent of Documents, U.S. Government

Printing Office, Washington, D.C. 20402, Phone: (202) 512-1800

or at http://www.gpoaccess.gov/cfr/index.html

5. AWS/ANSI D18.1 Specification for Welding of Austenitic

Stainless Steel Tube and Pipe Systems in Sanitary (Hygienic)

Applications. Published by American Welding Society, 550 N.W.

LeJ eune Rd., Miami FL, Phone: (800) 443-3953, www.aws.org

3-A Std & Practices List with Document Scopes Page 31 of 98 J anuary 4,2013

6. EHEDG Doc. 9 Welding Stainless Steel to Meet Hygienic

Requirements. European Hygienic Engineering & Design Group.

Published by EHEDG, www.ehedg.org

7. Aerospace Standard (AS) 568, published by SAE, 400

Commonwealth Drive, Warrendale, PA 15086, Phone: (412) 776-

4970.

8. ISO 3601-1:2002: Fluid Power Systems, Sealing Devices O-

Rings Part 1: Inside diameters, cross-sections, tolerances and

size identification code, The International Organization for

Standardization (ISO), 1 ch. de la Voie-Creuse, Postale 56, CH -

1211, Geneva 20, Switzerland, Phone: +41-22-749-01-11.

www.iso.org

9. ASTM specifications for Cast Grades A351/A351M, A743/A743M

and A744/A744M. Available from ASTM, 100 Barr Harbor Drive,

West Conshohocken, PA 19428-2959, Phone: (610) 832-9500.

www.astm.org/standard/index.shtml

10. ASTM specifications for Wrought Grades A-276, A-582, and A-

666. Available from ASTM, 100 Barr Harbor Drive, West

Conshohocken, PA 19428-2959, Phone: (610) 832-9500.

www.astm.org/standard/index.shtml

30-01 Farm Milk Storage Tanks

Title: 3-ASanitary Standards for Farm Milk Storage Tanks, Number 30-01

Date: Effective September 9, 1984

Scope: A1 These standards cover the sanitary aspects of tanks in which bulk

milk is stored on dairy farms. They do not pertain to storage tanks

nor to silo type tanks for milk and milk products used in dairy

processing plants nor do they pertain to farm milk cooling and

holding tanks.

A2 Tanks made in conformance to these standards will prevent a

significant increase in the temperature of the milk stored in the

tank by the insulation or by the combination of the insulation and

refrigeration. These tanks will not provide the means for cooling

the milk.

A3 In order to conform with these 3-A Sanitary Standards, farm milk

storage tanks shall comply with the following design, material and

3-A Std & Practices List with Document Scopes Page 32 of 98 J anuary 4,2013

fabrication criteria.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

63- Sanitary Fittings

74- Sensors and Sensor Fittings and Connections

3-A Accepted Practice for:

604- Supplying Air Under Pressure in Contact With Milk, Milk

Products and Product Contact Surfaces

31-06 Scraped Surface Heat Exchangers

Title: 3-ASanitary Standards for Scraped Surface Heat Exchangers, Number

31-06

Date: Effective: September 24, 2010

Scope: A1 These standards cover the sanitary aspects of scraped surface heat

exchangers for adding heat to, or removing heat from products.

These standards do not pertain to freezers for ice cream, ices and

similarly frozen dairy foods nor to batch processors.

A2 In order to conform to these 3-A Sanitary Standards, scraped

surface heat exchangers shall conform to the following design,

material and fabrication criteria

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

63- Sanitary Fittings

33- Polished Metal Tubing for Milk and Milk Products

74- Sensors and Sensor Fittings and Connections

19- Batch and Continuous Freesers for Ice Cream, Ices and Similarly

Frozen Dairy Foods

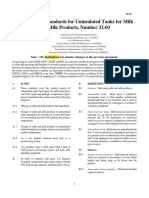

32-02 Uninsulated Tanks for Milk and Milk Products

3-A Std & Practices List with Document Scopes Page 33 of 98 J anuary 4,2013

Title: 3-A Sanitary Standards for Uninsulated Tanks for Milk and Milk

Products, Number 32-02

Date: Effective August 20, 1994

Scope: A1 These standards cover the sanitary aspects of un-insulated tanks,

both open top and closed types, and both single and multiple

compartment types, that are intended to be used for one of the

following purposes:

A1.1 Mixing of milk and milk products and ingredients.

A1.2 Storage of milk and milk products in uninsulated tanks

intended to be located in a room in which the air

surrounding the tank will maintain the product temperature.

A1.3 Storage of milk and milk products in uninsulated tanks

having heat exchange surfaces to maintain the product

temperature.

A1.4 As a raw product constant level tank in a pasteurizing

system.

A1.5 As a product surge or feed tank within a milk or milk

products processing system, and farm milk handling

equipment.

A2 In order to conform with these 3-A Sanitary Standards, uninsulated

tanks shall comply with the following design, material, and

fabrication criteria.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

63- Sanitary Fittings

33- Polished Metal Tubing for Milk and Milk Products

74- Sensors and Sensor Fittings and Connections

51- Plug-Type Valves for Milk and Milk Products

52- Plastic Plug-Type Valves for Milk and Milk Products

53- Compression-Type Valves

54- Diaphragm-Type Valves for Milk and Milk Products

56- Inlet and Outlet Leak-Protector Plug-Type Valves for Milk and

Milk Products

57- Disc-Type Valves

3-A Std & Practices List with Document Scopes Page 34 of 98 J anuary 4,2013

3-A Accepted Practice for:

604- Supplying Air Under Pressure in Contact With Milk, Milk

Products and Product Contact Surfaces

3-A Sanitary Standards referenced which have been discontinued

55- Boot Seal-Type Valves for Milk and Milk Products

33-02 Polished Metal Tubing for Milk and Milk Products

Title: 3-ASanitary Standards for Polished Metal Tubing for Milk and Milk

Products, Number 33-02

Date: Effective September 11, 2009

Scope: A1 This standard covers the sanitary aspects of metal tubing used to

convey milk and milk products. This standard does not apply to the

assembly of metal tubing into further fabricated forms or systems.

A2 In order to conform to this 3-A Sanitary Standard, metal tubing

shall conform to the following criteria for materials of

construction, fabrication techniques, and the current revisions or

editions of all referenced documents cited herein.

References: 3-A Sanitary Standard for:

34-02 Portable Bins for Dry Milk and Dry Milk Products

Title: 3-ASanitary Standards for Portable Bins for Dry Milk and Dry Milk

Products, Number 34-02

Date: Effective September 28, 1992

Scope: A1 These standards cover the sanitary aspects of portable bins for

storage, transportation and handling of dry milk and dry milk

products in bulk. They do not pertain to (1) stationary bins, (2)

bins (tanks) installed on automotive highway equipment, or (3)

piping and appurtenances that are not attached to the bin.

A2 In order to conform with these 3 A Sanitary Standards, dry milk

bins shall comply with the following design, material, and

fabrication criteria, and the applicable documents referenced

3-A Std & Practices List with Document Scopes Page 35 of 98 J anuary 4,2013

herein.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials Used as Product

Contact Surfaces in Dairy Equipment

20- Multiple-Use Plastic Materials

63- Sanitary Fittings

74- Sensors and Sensor Fittings and Connections

35-04 Blending Equipment

Title: 3-ASanitary Standards for Blending Equipment, Number 35-04

Date: Effective: August 8, 2011

Scope: A1 These standards cover the sanitary aspects of blending equipment

used for combining and/or mixing either wet or dry products and

includes any component equipment which shall conform to their

respective 3-A Sanitary Standards.

A1.1 The blending equipment begins at the entrance to the hopper or

infeed pipe connection(s) and ends at the exit pipe fitting and

includes all equipment in between.

A2 In order to conform to these 3-A Sanitary Standards, blending

equipment shall conform to the following design, material and

fabrication criteria

References: 3-A Sanitary Standards for:

02- Centrifugal and Positive Rotary Pumps

18- Multiple-Use Rubber and Rubber-Like Materials

20- Multiple-Use Plastic Materials

32- Uninsulated Tanks

33- Polished Metal Tubing

36- In-Line Rotor-Stator Mixers

51- Plug-Type Valves

52- Plastic Plug-Type Valves

53- Compression-Type Valves

54- Diaphragm-Type Valves

55- Boot Seal-Type Valves

57- Tank Outlet Valves

58- Vacuum Breakers and Check Valves

62- Hose Assemblies

63- Sanitary Fittings

3-A Std & Practices List with Document Scopes Page 36 of 98 J anuary 4,2013

65- Sight and/or Light Windows and Sight Indicators

73- Shear Mixers, Mixers, and Agitators

74- Sensors and Sensor Fittings and Connections Used on Equipment

78- Spray Devices to Remain in Place

81- Auger-Type Feeders

3-A Accepted Practices for:

605- Permanently Installed Product and Solution Pipelines and Cleaning

Systems

36-01 Inline Rotor-Stator Mixers

Title: 3-ASanitary Standards for Inline Rotor-Stator Mixers Number 36-01

Date: Adopted November 16, 2003

Scope: A1 These standards cover the sanitary aspects of inline devices which

use a combination of a rotor and a stator to effect mixing and size

reductions for liquids, slurries, and liquid-gas mixtures.

A1.1 The rotor-stator mixer begins at the infeed pipe connection(s) and

ends at the exit pipe fitting and includes all equipment in between.

A2 In order to conform to the 3-A Sanitary Standards, rotor-stator

inline mixers, (Referred hereinafter as inline mixers) shall

conform to the following design, material and fabrication criteria

and the applicable documents referenced herein.

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials

20- Multiple-Use Plastic Materials

63- Sanitary Fittings

74- Sensors and Sensor Fittings and Connections Used on Equipment

38-00 Cottage Cheese Vats

Title: 3-ASanitary Standards for Cottage Cheese Vats, Number 38-00

Date: Effective August 1, 1980

Scope: A1 These standards cover the sanitary aspects of open top-type vats

3-A Std & Practices List with Document Scopes Page 37 of 98 J anuary 4,2013

used in the batch production of cottage cheese curd.

A2 In order to conform with these 3-A Sanitary Standards, cottage

cheese vats shall comply with the following design, material and

fabrication criteria

References: 3-A Sanitary Standard for:

18- Multiple-Use Rubber and Rubber-Like Materials

20- Multiple-Use Plastic Materials

63- Sanitary Fittings

39-01 Pneumatic Conveyors for Dry Milk and Dry Milk

Products

Title: 3-ASanitary Standards for Pneumatic Conveyors for Dry Milk and Dry

Milk Products, Number 39-01

Date: Adopted November 16, 2003

Scope: A1 These standards cover the sanitary aspects of equipment used in

systems solely for the pneumatic conveying of dry milk, dry milk

products, or other dry comestibles utilizing air flow which is

caused by either a pressure or vacuum differential. These

standards are not intended to cover pneumatic conveying

equipment or systems that are an integral part of a spray drying or

instantizing system unless specifically referenced for that purpose

in the applicable 3-A Sanitary Standard or 3-A Accepted Practice.

The equipment begins at the point at which product enters the

conveyor and ends at the point(s) where product is discharged from

the conveyor. With respect to air, the equipment begins at the

point where conveying air leaves the final filter and ends at the

entrance of the air/product separator equipment. These standards

also include any required product accumulation, conditioning and

metering equipment which are located before product introduction