Escolar Documentos

Profissional Documentos

Cultura Documentos

Hinge Design Guide

Enviado por

hshewyDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Hinge Design Guide

Enviado por

hshewyDireitos autorais:

Formatos disponíveis

Hinge Design Guidelines

Consider The Overall Design Because exposed hinges are visible

Consider how much flexibility there is on the outside of the product,

TEN FACTORS FOR in the design of the door and frame.

Requirements such as gasket sealing

aesthetics may be a factor. Take care to

ensure the design of the external hinge

SPECIFYING HINGES and aesthetic constraints can help

determine the best hinge options for an

blends well with the application. Also,

evaluate the risk of users hitting or

application. Often door and frame snagging the hinge if it protrudes too

designs can be modified to suit a far off the door.

readily available hinge, keeping overall

Incorporating hinges early into costs down. Door And Frame Configuration

designs helps keep costs down Both concealed and external hinges

and options open. Concealed Versus Externally can require specific door and frame

Mounted Hinges configurations, requiring different ways

Concealed or of mounting. When selecting an

internal hinges Axial externally mounted

mount on the In-line Radial hinge, determine

interior part of the Hinge whether your door

ore and more, designers

M

door and frame. and frame

consider fasteners, latches They provide a configuration calls for

and similar hardware early in clean outer panel an in-line hinge or an

design, but leave hinges until and improve offset hinge.

the last minute. Although many security by

engineers face shortened design eliminating attack Opening Angle

cycles, considering hinges late in a points for vandals. If Many applications today

design cycle may severely limit some using a concealed require hands-free access

options. This can compromise the hinge, consider the — the ability to keep the

design, forcing nonstandard parts into amount of internal door open without

products while increasing costs and protrusion. someone holding it. If this is

reducing performance. Designing For example, with the case, think about using a

hinges into an application can be easy, electronic hinge with a built-in detent feature

especially when keeping the following enclosures, inside to hold the door open at a preset

considerations in mind. space is limited angle, or an adjustable-

Offset

because of Hinge Axial friction feature that lets the

How Much Load Will The numerous internally user tighten or free-up the

Hinges Bear? mounted door swing. Both of these

Strength requirements play a major components. Also, hinge styles eliminate

role in any design. In specifying hinges, concealed hinges secondary mechanical

crucial considerations include not only may re-strict access supports like gas struts or

the weight of the door, but all possible and cause other door stays.

external sources of load. Think about issues, namely Radial Detent and friction hinges

dynamic loading - will equipment be installing and hiding are two products in one —

mounted on the door? More the mounting the hinge and the door

importantly, will people hang on the hardware. These stay. They also reduce the

open door? hinges work with number of parts

Manufacturing and installation specific door and purchased and stocked,

variations normally result in unequal frame cut down on installation time

load distribution among the hinges. configurations, so by installing one product, and

Keep in mind that as the ratio of the product and mounting options lower overall cost.

door width to height increases, the should be designed with them in mind. Most detent hinges come with preset

stresses becomes more severe. Exposed or external hinges are opening angles such as 80°, 120°, and

Determining strength requirements mounted on the exterior of the door 170°. Many also provide a negative

means considering the total applied and frame. They solve the problem of detent angle (such as –5°), which lets

load from all sources. limited interior space, offer greater the hinge go slightly past center when

For maximum strength, place the strength than concealed hinges, and closed, holds the door securely against

hinges as far apart as possible on the can allow for a greater door-opening the frame, and reduces vibration. some

longest edge of the door. Depending angle. They are also easier to fit to an cases, this eliminates a latch. Detent

upon the design, use a closer hinge application any time in the design hinges are recommended for small,

spacing to stiffen the door or to ensure process, and are more universal — one lightweight applications.

sealing against a gasket. hinge design can often be used for a

variety of applications.

1 1-866-378-7550 (Toll Free) w w w. a l l e g i s c o r p . c o m

Hinge Design Guidelines

Removability/ Access To

The Interior

If a user or service technician

requires full access to the interior of

the cabinet or enclosure, removable

hinges may be the answer. Removable

hinges are also valuable if the product

ships unassembled or if the door and

frame are manufactured in different

locations. Lift-off hinges or hinges with

retractable pins are easy to remove.

Lift-off hinges let the door be

removed in a single motion without

using tools. Simply lift it off the hinge

pins mounted to the frame. The door is

replaced by lowering it back over the

hinge pins. Both hands remain free to

maneuver the door.

A pin-style hinge offers easy lift-off door removal and replacement. The lift-off feature

Hinges with retractable pins allow provides unrestricted access inside an enclosure, cabinet, or storage space.

removal of the door without lifting the

door. To remove, retract the hinge pins

and pull the door straight off. To ensures selecting the best hinge for an and stainless steel hinges withstand

replace the door, align the two halves application, saving time and money in wide temperature variations.

of the hinge and extend the hinge pins, the certification process to bring the Engineering plastics and stainless steel

locking the door back into place. product to market. offer corrosion resistance. Plastics

Hinges with pins reduce noise and vibration.

that remain Installation Method Factors such as strength, corrosion

permanently Think about manufacturing tolerances and UV resistance, weight, and

attached to in the design and installation process, aesthetics influence hinge selection.

the leaf especially where aligning the hinges

won’t let the on the door and frame are Aesthetics

pins drop concerned. Slotted holes To optimize overall quality and cost

out or get may help compensate for effectiveness, balance performance

lost. manufacturing needs with aesthetic judgment. Large,

Retractable variations. Also, external hinges give an impression of

hinge pins are a understand where great strength. Concealed hinges

better choice if the in the remove appearance concerns. To

hinge axis is not manufacturing enhance an application’s design, most

guaranteed to remain process the plastic and powder-coated hinges are

vertical and steady. hinge is installed. easily customized to meet color

Determine if the leaves will be specifications.

Industry Specifications assembled to the door and frame at the Some hinges include snap-on covers

Choosing a hinge can depend on same time or in different locations and that conceal mounting hardware, giving

where the final product will ultimately assembled later. Mounting methods them a more polished appearance.

be used. When designing the product include screws, studs, rivets, welds, Mounting hardware can also be

and selecting hinges, consider any and adhesives. Also, determine concealed by installing the hinge from

regulations or specifications required. clearance for any tools needed for the back side of the door or frame.

For example, hinges used on outdoor installation, as well as the hardware

enclosures housing electronic itself.

equipment may be required to meet

NEMA and IP standards. In the food- Materials

equipment industry, NSF certification In evaluating materials, consider

imposes stringent guidlines on potential environmental conditions and

materials and design. the end use of an application.

Hinges can be certified to meet a Temperature range, chemical exposure,

specification as is, or the specification UV radiation, and moisture conditions

may require evaluation of the complete influence hinge material selection.

system. Choose a hinge capable of Hinges come in a variety of materials

meeting all product standards. such as steel, stainless steel, die-cast

Understanding industry requirements zinc, and engineering plastics. Steel

1-866-378-7550 (Toll Free) w w w. a l l e g i s c o r p . c o m 2

Hinge Design Guidelines

How Strong A Hinge Is Needed?

Consider These Factors:

1. How much does the door weigh?

To determine the weight of a door, multiply the volume by

the density of the door material. For a simple rectangular

door, this equates to length X width X height X density.

Better still, if a sample of the door is available, put it on a

scale.

2. Where is the center of gravity of the door?

For a uniform thickness door, the center of gravity (Cg) will

lie in the exact center of the door. Unfortunately, most

doors aren’t uniform. If a sample of the door is available,

here’s a hands-on method to determine the Cg, regardless Considerations At A Glance:

of the door shape:

10 Questions To Ask

a. Hang the door from one corner so it can pivot freely. When Designing A Hinge

b. Attach a plumb line to the pivot so the line hangs freely. 1. How much load must the hinge withstand?

(A chalk line is ideal for this). Determine the size and weight of the door, along with

attachments.

c. Mark the line on the door.

2. How do hinges fit in the overall design?

d. Repeat steps a through c twice more, hanging the door Designing the hinge in early may allow use of an available

from a different corner each time. hinge.

e. All three lines should cross at the same point, which is

the Cg of the door. 3. How much space can you afford inside or outside the

enclosure?

3. What other loads will be applied? Think about concealed versus externally mounted hinges.

Consider the weight of components that might be

fastened to the door. Will electronics or cooling equipment 4. How do you plan to mount or access the door?

be mounted on the door? Are there hooks or handles to Door and frame configurations play a critical role here.

hang something on? Also, keep in mind the unintended

uses of the door: Will people use the door to support their 5. How far must the door open?

weight as they stand up? Might someone sit or climb on Detent and friction hinges allow the door to remain open

the door? Is load applied by wind or a moving object? Are without secondary mechanical supports for hands-free

forces generated by compressing a gasket or from access.

pressure within the enclosure?

6. Is removing the door a requirement?

4. Whenever possible, test the hinge in the application. Lift-off hinges offer fast door removal for quick and

Theoretically, the vertical load on a door will be distributed complete access to the interior of the cabinet.

evenly among the hinges. In practice, however, variations

in mounting and build tolerances often mean that one 7. What specifications (environmental, sanitation, etc.) must

hinge takes the brunt of the load. Testing the final product the hinge and enclosure meet?

is always recommended. Many hinges are already certified to meet various industry

standard specifications.

8. How will the hinge be installed?

Consider the manufacturing and installation process

carefully.

9. Do you need to meet specific material requirements?

Think about environmental conditions the end product

may face.

10. How large a role do aesthetics play in the design?

Balance performance needs with aesthetic judgment.

3 1-866-378-7550 (Toll Free) w w w. a l l e g i s c o r p . c o m

Hinge Design Guidelines

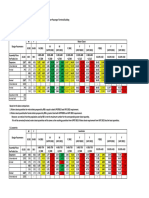

Calculating The Amount Of Hinge Operation Illustration

Force Each Hinge Bears

The following examples show a basic calculation for Vertical d2

F ext

determining the amount of force acting on each hinge. Axis R axial

These calculations assume uniform distribution of load

R radial

among all the hinges. In practice, however, manufacturing

Cg

variations and build tolerances often mean that one hinge

will bear most of the load. Apply adequate safety factors dhinge

and test the hinge in the final application. F door

1. For a door with a vertical axis, using two hinges:

d1 Horizontal

A. Calculate the axial load (Raxial): add the forces dhinge Axis

generated by the door and components attached to it d1

(Fdoor) to the external force applied to the door (Fext) R axial

and divide by 2: R radial 1 R radial 2

Raxial = (Fdoor + Fext) / 2 Cg

B. Calculate the radial load (Rradial): multiply the forces

generated by the door and attachments (Fdoor) by the

distance from the hinge to the center of gravity of the F door

door (d1).

Detent

Then multiply the external force applied to the door

d2

(Fext) by the distance from the hinge to an external load

on the door (d2). Add these two values and divide by Cg

d1

the distance between the hinges (dhinge):

T resist

Rradial = [(Fdoor • d1) + (Fext • d2)] / dhinge

F door

2. For a door with a horizontal axis, using two hinges:

A. The axial load (Raxial) = 0 Tdoor = d1 • cos( 0 ) • Fdoor

B. Calculate the radial load (Rradial) of each hinge:

1. Multiply the forces generated by the door and This is the minimum torque required to hold the door

attachments (Fdoor) by the difference between the in position with no external load.

distance between the hinges (dhinge) and the B. Calculate the total torque required to overcome all

distance from the hinge to the center of gravity of hinges on the door (Tresist): multiply the number of

the door (d1). Then divide by the distance between hinges per door (n) by the torque required to

the hinges (dhinge): overcome the detent or frictional force of the hinge

(Thinge).

Rradial 1 = Fdoor • (dhinge – d1) / (dhinge)

Tresist = n • Thinge

2. Multiply the forces generated by the door and

attachments (Fdoor) by the distance from the hinge Choose the number and type of hinges such that the

to the center of gravity of the door (d1) and divide total torque required to overcome all hinges on the door

by the distance between the hinges (dhinge): (Tresist) is greater than the torque generated by the door

forces (Tdoor).

Rradial 2 = Fdoor • d1 / (dhinge) C. To calculate the external force applied to the door,

subtract the torque generated by (Fdoor) from the

3. How to calculate the torque required for detent or total torque required to overcome all hinges on the

friction hinges on a door with horizontal axis: door (Tresist). Then divide by the distance from the

hinge to an external load on the door (d2):

A. To find the torque (Tdoor) generated by all the forces

acting on the door and attachments: multiply the Fext = (Tresist – Tdoor) / d2

distance from the hinge to the center of gravity of the

door (d1) by cos( 0 ) and by the forces generated by Fext represents the external force required to

the door and attachments (Fdoor): overcome the hinge torque and move the door from

the position 0.

1-866-378-7550 (Toll Free) w w w. a l l e g i s c o r p . c o m 4

Você também pode gostar

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNo EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersAinda não há avaliações

- Structural GlassDocumento1 páginaStructural GlassBoy BangusAinda não há avaliações

- 2015 SolidWorks - WeldmentsDocumento19 páginas2015 SolidWorks - WeldmentsKiran Kumar KondapalliAinda não há avaliações

- Reactions As Per The ModelDocumento2 páginasReactions As Per The Modelwaweng22Ainda não há avaliações

- Anchor Bolt Design of Channel Pinned ConnectionDocumento42 páginasAnchor Bolt Design of Channel Pinned Connectionprasanth bhadranAinda não há avaliações

- Astmc864 05Documento11 páginasAstmc864 05pandey0080% (1)

- Project Description PDFDocumento10 páginasProject Description PDFAS V Kamesh100% (1)

- Metric FastenersDocumento26 páginasMetric FastenersvijayjaghanAinda não há avaliações

- Design Purlin - As 4600Documento8 páginasDesign Purlin - As 4600trung1983Ainda não há avaliações

- Lindapter PDFDocumento76 páginasLindapter PDFYsmael Steel TeklaAinda não há avaliações

- Monorail CalculationDocumento10 páginasMonorail CalculationMiftakhu ZaimAinda não há avaliações

- Davit Anchor Calculation PDFDocumento14 páginasDavit Anchor Calculation PDFRiyas RafiAinda não há avaliações

- Training Manual RAM Ans STAAD-1Documento13 páginasTraining Manual RAM Ans STAAD-1tigersronnieAinda não há avaliações

- Acrow Load TablesDocumento1 páginaAcrow Load Tableskj55Ainda não há avaliações

- Structural Glass Barrier GuidelinesDocumento4 páginasStructural Glass Barrier GuidelinesSiYing LaiAinda não há avaliações

- Honeycomb Beam & Panel Calculations XLV1 - 2Documento29 páginasHoneycomb Beam & Panel Calculations XLV1 - 2Krishant Krishant Krishant0% (1)

- Steel Member Design - Sample Calculation (AS4100)Documento5 páginasSteel Member Design - Sample Calculation (AS4100)Tiam MarapeAinda não há avaliações

- Mcnichols Master Catalog PDFDocumento60 páginasMcnichols Master Catalog PDFing_julio_siviraAinda não há avaliações

- MAS Modular Assembly System 7.1Documento156 páginasMAS Modular Assembly System 7.1ANVAinda não há avaliações

- Scaffold Basic PartsDocumento57 páginasScaffold Basic PartsSn Carbonel100% (1)

- HeliCoil CatalogueDocumento34 páginasHeliCoil Cataloguejarv7910Ainda não há avaliações

- 1 How To Activate The LinkDocumento6 páginas1 How To Activate The LinkThinh Vipro100% (1)

- Inventor Project Frame Generator Guide enDocumento16 páginasInventor Project Frame Generator Guide enHajrah SitiAinda não há avaliações

- Fortress Timber & Metal SDS Screws 2017 WebDocumento36 páginasFortress Timber & Metal SDS Screws 2017 WebGabriel MacedoAinda não há avaliações

- Sds Screw DesignDocumento3 páginasSds Screw DesignvtalexAinda não há avaliações

- Maryland MetricsDocumento19 páginasMaryland MetricsKurt VaughnAinda não há avaliações

- Carport DesignDocumento6 páginasCarport DesignTuroyAinda não há avaliações

- Anchor BoltDocumento4 páginasAnchor BoltAhmed Shaban0% (1)

- Cad Standards ManualDocumento38 páginasCad Standards Manuala1c2d3Ainda não há avaliações

- Sample Calculations To Australian Standard AS1170 For Design Loads For A Post To A Barrier PDFDocumento24 páginasSample Calculations To Australian Standard AS1170 For Design Loads For A Post To A Barrier PDFRommel Angelo KirongAinda não há avaliações

- Dathan Tool and Gauge HandbookDocumento32 páginasDathan Tool and Gauge HandbooksamirkaminskyAinda não há avaliações

- Roof SheetingDocumento6 páginasRoof SheetingGaner DaliAinda não há avaliações

- 1657Documento29 páginas1657TrisonAinda não há avaliações

- Week 5 - Project 3 - Ilogic Part 2 PDFDocumento22 páginasWeek 5 - Project 3 - Ilogic Part 2 PDFKhairun NisaAinda não há avaliações

- Driveworks - Product ConfiguratorDocumento16 páginasDriveworks - Product ConfiguratorjayakumarAinda não há avaliações

- Standard Series Limits Size-Unified and American Screw Threads PDFDocumento19 páginasStandard Series Limits Size-Unified and American Screw Threads PDFrefaeAinda não há avaliações

- Purlins: Rails Eaves Beams AccessoriesDocumento48 páginasPurlins: Rails Eaves Beams AccessoriesRam AravindAinda não há avaliações

- K-Factor Sheet MetalDocumento3 páginasK-Factor Sheet MetalkawalhayerAinda não há avaliações

- Aluminum Welding DefectDocumento8 páginasAluminum Welding DefectriessanandaAinda não há avaliações

- FastenersDocumento28 páginasFastenersthulasi_krishnaAinda não há avaliações

- METSEC Purlins SystemsDocumento84 páginasMETSEC Purlins SystemsIvan KlyuchkaAinda não há avaliações

- Inch Series Dowel Pins: Mechanical PropertiesDocumento2 páginasInch Series Dowel Pins: Mechanical PropertieswilliaqAinda não há avaliações

- Design Calculation For L ClampDocumento7 páginasDesign Calculation For L Clampwaseq911Ainda não há avaliações

- Tutorial - STAAD - Pro Link: 1 How To Activate The LinkDocumento19 páginasTutorial - STAAD - Pro Link: 1 How To Activate The LinkDass MAinda não há avaliações

- Strand 7 TutorialDocumento25 páginasStrand 7 TutorialmohanumaAinda não há avaliações

- Neral Notes On Engineering Hardware - FastenersDocumento45 páginasNeral Notes On Engineering Hardware - Fastenersbrotaccristian100% (1)

- Autodesk Inventor Ilogic Basic TutorialDocumento33 páginasAutodesk Inventor Ilogic Basic TutorialJW100% (2)

- Autodesk Inventor - VBA-api pt2Documento7 páginasAutodesk Inventor - VBA-api pt2Ndianabasi Udonkang0% (1)

- STEPOC 150dpiDocumento6 páginasSTEPOC 150dpinick8081Ainda não há avaliações

- Autocad Command Reference GuideDocumento1.322 páginasAutocad Command Reference GuideujalaAinda não há avaliações

- ABS - Application of Ergonomics To Marine SystemsDocumento222 páginasABS - Application of Ergonomics To Marine SystemsJDPNetoAinda não há avaliações

- Manual CompletoDocumento442 páginasManual CompletoManuel Rodrigo Cortés VásquezAinda não há avaliações

- DriveWorks Solo Design Automation For SolidWorks TrainingDocumento138 páginasDriveWorks Solo Design Automation For SolidWorks TrainingKoen Bidlot100% (1)

- Kisssoft Tut 005 E ShaftanalysisDocumento11 páginasKisssoft Tut 005 E ShaftanalysisBeytullah AcarAinda não há avaliações

- Bolts Design Strength Tables EN 1993-1-8Documento2 páginasBolts Design Strength Tables EN 1993-1-8ValentinAinda não há avaliações

- Doors, Windows and Glazing: Superstructure (Excluding Roofs)Documento8 páginasDoors, Windows and Glazing: Superstructure (Excluding Roofs)Joni StulicAinda não há avaliações

- HW02 CSMT Hinge.r9.pdrDocumento6 páginasHW02 CSMT Hinge.r9.pdrAndrew LiebermannAinda não há avaliações

- Preventive Maintenance Belts PDFDocumento6 páginasPreventive Maintenance Belts PDFrezeiba_74Ainda não há avaliações

- 1preventive Maintenance Belts PDFDocumento6 páginas1preventive Maintenance Belts PDFrezeiba_74Ainda não há avaliações

- 1 s2.0 S2665917422000757 Main PDFDocumento10 páginas1 s2.0 S2665917422000757 Main PDFAbhishek SantraAinda não há avaliações

- 07-11-23 PL Fixture Count ComparisonDocumento2 páginas07-11-23 PL Fixture Count ComparisonJovenal TuplanoAinda não há avaliações

- TXV Training DeckDocumento32 páginasTXV Training DeckJak JoniAinda não há avaliações

- OLTP To OLAP COnversionDocumento39 páginasOLTP To OLAP COnversionAmit SharmaAinda não há avaliações

- Unit 1 Assignment in ResearchDocumento3 páginasUnit 1 Assignment in ResearchJovzAinda não há avaliações

- Glunz Service Manual For ProcessorDocumento164 páginasGlunz Service Manual For ProcessorEd Chambley100% (1)

- DevlistDocumento8 páginasDevlistcolossusanirudhAinda não há avaliações

- Cyber Law IntroductionDocumento4 páginasCyber Law IntroductionVENKAT SAinda não há avaliações

- Hackathons: A Guide OnDocumento13 páginasHackathons: A Guide OndhjfbfsbjfAinda não há avaliações

- Computer Science Textbook Solutions - 27Documento31 páginasComputer Science Textbook Solutions - 27acc-expertAinda não há avaliações

- EdgeX Foundry A Microservice Approach To IoT Edge Computing Jim WhiteDocumento33 páginasEdgeX Foundry A Microservice Approach To IoT Edge Computing Jim WhiteJagadeesh JAinda não há avaliações

- Information Security Thesis ExamplesDocumento5 páginasInformation Security Thesis Examplesafkololop100% (2)

- CC ZG522 Ec-2r First Sem 2023-2024Documento12 páginasCC ZG522 Ec-2r First Sem 2023-20242023mt03587Ainda não há avaliações

- Series G - 200 Oi ManualDocumento26 páginasSeries G - 200 Oi ManualRonald Chacón QuirósAinda não há avaliações

- Data Sheet c78-720918Documento46 páginasData Sheet c78-720918bluesir2000Ainda não há avaliações

- Workshop Manual Engine Man D 0836 Le PDFDocumento144 páginasWorkshop Manual Engine Man D 0836 Le PDFSecret6480% (5)

- Thesis FypDocumento47 páginasThesis FypMohd AymanAinda não há avaliações

- My ProjectDocumento21 páginasMy ProjectSam SachanAinda não há avaliações

- Security SIMATIC Controller V30 enDocumento34 páginasSecurity SIMATIC Controller V30 enDavid PelechanoAinda não há avaliações

- Bill of Quantities: 1,327,636.37 75 CD Item No. Description Qty Unit Unit Price Amount (Pesos)Documento1 páginaBill of Quantities: 1,327,636.37 75 CD Item No. Description Qty Unit Unit Price Amount (Pesos)Lon OdiAinda não há avaliações

- Stakeholder AnalysisDocumento2 páginasStakeholder AnalysisKen Lee0% (1)

- 169-179techno Enhanced Lan LearningDocumento258 páginas169-179techno Enhanced Lan LearningAbebayehu YohannesAinda não há avaliações

- MATLAB Workshop:Basics of Simulation: September 2019 Mrs.T.KanimozhiDocumento53 páginasMATLAB Workshop:Basics of Simulation: September 2019 Mrs.T.KanimozhiKani MozhiAinda não há avaliações

- BIA108S Assessment2 PaperB v2Documento7 páginasBIA108S Assessment2 PaperB v2IsulaAinda não há avaliações

- Lzlabs Software Defined Mainframe Product Data SheetDocumento4 páginasLzlabs Software Defined Mainframe Product Data Sheet20446Ainda não há avaliações

- Introduction To Orthogonal Polynomials PDFDocumento30 páginasIntroduction To Orthogonal Polynomials PDFJose SotoAinda não há avaliações

- WING Broschuere enDocumento4 páginasWING Broschuere enT ParkerAinda não há avaliações

- ALL TEST PRO 7 Brochure English LRDocumento4 páginasALL TEST PRO 7 Brochure English LRMuhammad Tahir AbbasAinda não há avaliações

- Ab Ipbox 55Hd: HDTV Linux ReceiverDocumento8 páginasAb Ipbox 55Hd: HDTV Linux ReceiverAlexander WieseAinda não há avaliações

- Boundary SecurityDocumento18 páginasBoundary SecurityShame BopeAinda não há avaliações