Escolar Documentos

Profissional Documentos

Cultura Documentos

Structural Analysis & Design (Investigation)

Enviado por

klynchelleDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Structural Analysis & Design (Investigation)

Enviado por

klynchelleDireitos autorais:

Formatos disponíveis

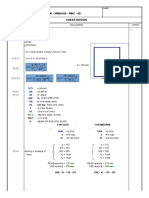

DESIGN OF BEAM

BEAM 1

FIXED ENF MOMENT BEAM STIFFNESS (k)

M

AB

= -60.083 M

BA

= 60.083 K

AB

= 1/10

M

BC

= -38.453 M

CB

= 38.453 K

BC

= 1/8

M

CD

= -38.453 M

DC

= 38.453 K

CD

= 1/8

M

DE

= -38.453 M

ED

= 38.453 K

DE

= 1/8

M

EF

= -38.453 M

FE

= 38.453 K

EF

= 1/8

DISTRIBUTION FACTOR

DF

AB

= - (fixed end)

DF

BA

= 0.50

DF

BC

= 0.50

DF

CB

= 0.50

DF

CD

= 0.50

DF

DC

= 0.50

DF

DE

= 0.50

DF

ED

= 0.50

DF

EF

= 0.50

DF

EF

= - (fixed end)

AB BA BC CB CD

DF - 0.500 0.500 0.500 0.500

FEM -60.083 60.083 -38.453 38.453 -38.453

1st - 10.815 10.815 - 0.000

COM 5.408 - 0.000 5.407 0.000

2nd - - 0.000 2.704 2.704

COM - - 1.352 - 0.000

3rd - 0.676 0.676 - 0.000

COM 0.338 - 0.000 0.338 0.338

4th - - 0.000 0.338 0.338

COM - - 0.169 - 0.000

5.746 71.574 13.011 47.240 3.380

AB BA BC CB CD

DF 0 0.50 0.50 0.50 0.50

FEM ############ ############ ############ ############ ############

1st 0 ############ ############ ############ ############

COM -72781021.416 0 99753389.246 -72777495.545 #REF!

MOMENT DISTRIBUTION METHOD (WEIGHT OF BEAM)

MOMENT DISTRIBUTION METHOD (DUE TO LOADS)

2nd 0 49877902.788 49875486.458 #REF! #REF!

COM 24938951.394 0 #REF! 24937743.229 #REF!

3rd 0 #REF! #REF! #REF! #REF!

COM #REF! 0 #REF! #REF! #REF!

4th #REF! #REF! #REF! #REF! #REF!

COM #REF! #REF! #REF! #REF! #REF!

#REF! #REF! #REF! #REF! #REF!

#REF! #REF!

SECTION 350 600

EI I = 6,300,000,000.00

EI

EI

EI

EI

DC DE ED EF FE

0.500 0.500 0.500 0.500 -

38.453 -38.453 38.453 -38.453 38.453

- 0.000 - 0.000 -

- 0.000 - 0.000 -

- 0.000 - 0.000 -

1.352 0.000 - 0.000 -

0.676 0.000 - 0.000 -

- 0.000 - 0.000 -

- 0.000 - 0.000 -

0.169 0.000 - 0.000 -

40.650 0.000 38.453 0.000 38.453

DC

#REF!

############

#REF!

99753389.246

MOMENT DISTRIBUTION METHOD (WEIGHT OF BEAM)

MOMENT DISTRIBUTION METHOD (DUE TO LOADS)

#REF!

#REF!

#REF!

#REF!

#REF!

#REF!

#REF!

PROJECT : THE NEW BLUE WAVE

LOCATION : MACAPAGAL BLVD., PASAY CITY

SUBJECT : STRUCTURAL DESIGN and ANALYSIS

DESIGN and ANALYSIS OF SLAB (S - 1)

* DESIGN CRITERIA

f'c = 27.65 MPa 4,000 psi

fy = 276.46 MPa 40,000 psi

SPAN

L = 15.00 m

S = 4.00 m

* DESIGN LOADING

A. REINFORCED CONCRETE : 23.55 kN/m

3

B. DEAD LOAD

* TOPPING : 1.20

kN/m

2

25 psf

* CEILING : 0.24 kN/m

2

5 psf

* PARTITION : 0.96

kN/m

2

20 psf

* 4" CHB WALL : - kN/m

2

* 6" CHB WALL : - kN/m

2

* CONCRETE SLAB (6") : 3.60

kN/m

2

75 psf

* ROOF TRUSS : -

kN/m

2

* CEMENT TILE ROOFING : -

kN/m

2

Note:

ASSUME FLOOR FINISH : - kN/m

2

CERAMIC TILE 25 mm MORTAR : - kN/m

2

TOTAL DEAD LOAD : 6.00 kN/m

2

125 psf

C. LIVE LOAD

* ROOF : -

kN/m

2

* FLOORS : 4.80

kN/m

2

100 psf

* BALCONY : - kN/m

2

TOTAL LIVE LOAD : 4.80 kN/m

2

100 psf

* DESIGN ANALYSIS

1.0 ACI SPECIFICATION

CODE:

* If m = s/L < 0.50 ONE - WAY SLAB

* If m = s/L > 0.50 TWO - WAY SLAB

L = 15.00

S = 4.00

S

L

m = 0.27

SINCE

m = 0.27 < 0.50 therefore ONE - WAY SLAB

2.0 MINIMUM THICKNESS

L fy

28 700

H = say

3.0 ULTIMATE LOAD

W

u

=

1.2 DL + 1.6 LL

W

u

=

4.0 ULTIMATE MOMENT (coefficient method)

* NEGATIVE MOMENT (@ continuous side)

W

u

L

n

2

11

Mu = 21.631 kN-m

* POSTIVE MOMENT (@ midspan)

m =

H = ( 0.4 + ) 1000

113.56 mm 150.00 mm

14.872 kN/m

Mu =

m

m

W

u

L

n

2

16

Mu = 14.872 kN-m

5.0 REINFORCING STEEL BAR and SPACING

* NEGATIVE MOMENT (@ continuous side)

Mu =

M

U

= f'

c

b d

2

(1 - 0.59 )

ASSUMPTIONS:

b = 1.0 m strip

d =

H - cover - 1/2 d

bar

cover = 20.00 mm

d =

1

= 1.63635

2

= 0.05856

1

fc'

2

fc'

fy fy

1

= 0.16364

2

= 0.00586

1.4

fy

min = 0.00506

max =

0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max =

0.75

b

max = 0.03710

ACI CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00586 >

min = 0.00506

<

max = 0.03710

SINCE

min

<

<

max

THEREFORE USE = 0.00586

STEEL AREA (MAINBARS)

As =

b d

As

=

726.19

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

* POSITIVE MOMENT (@ midspan)

Mu =

M

U

= f'

c

b d

2

(1 - 0.59 )

min =

b

S =

155.74 mm

450 mm

100 mm

2

=

Mu =

21.631 kN/m

124.00 mm

1 =

0.85

1

155 mm O.C.

155.74 mm 155 mm O.C.

155 mm O.C.

14.872 kN/m

=

(fc') (600)

fy (600 + fy)

1 = 1.65511

2

= 0.03981

1

fc'

2

fc'

fy fy

1

=

0.16551

2

=

0.00398

1.4

fy

min = 0.00506

max =

0.75

b

1

= 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max =

0.75

b

max = 0.03710

ACI CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00398 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA (MAINBARS)

As

min =

min

b d

As

min = 627.93

mm

2

SPACING

1 =

2

min =

b = 0.85

1

(fc') (600)

=

fy (600 + fy)

A

b

(1000) Note: use 12 mm mainbars

A

s min

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

6.0 TEMPERATURE BARS

As

t = 0.002 b h

As

t = 300.00

mm

2

SPACING

A

b

(1000) Note: use 10 mm temperature bars

A

s min

S = say

7.0 SUMMARY

THICKNESS : 150.00 mm

COVER : 20.00 mm

REBARS

MAINBARS : 12 mm mainbars

SPACING

SHORT SPAN

TOP :

BOT :

LONG SPAN

TEMPERATURE BARS : 10 mm mainbars

TOP : say

BOT : say

S =

261.80 mm 260 mm O.C.

DISC. END MIDSPAN

180 mm 0 mm

155 mm 180 mm

180.11 mm

S =

180 mm O.C.

450 mm

100 mm

261.80 mm 260 mm O.C.

261.80 mm 260 mm O.C.

180.11 mm 180 mm O.C.

180 mm O.C.

CONT. END

180 mm

155 mm

PROJECT : TROPICANA GARDEN CITY

LOCATION : SUMULONG AVENUE, BRGY. STO. NINO, MARIKINA CITY

SUBJECT : STRUCTURAL DESIGN and ANALYSIS

DESIGN and ANALYSIS OF SLAB (S - 1)

* DESIGN CRITERIA

f'c = 27.65 MPa 4,000 psi

fy = 276.46 MPa 40,000 psi

SPAN

L = 9.76 m

S = 5.12 m

* DESIGN LOADING

A. REINFORCED CONCRETE : 23.55 kN/m

3

B. DEAD LOAD

* TOPPING : 2.40 kN/m

2

50 psf

* CEILING : 0.24 kN/m

2

5 psf

* PARTITION : - kN/m

2

* 4" CHB WALL : - kN/m

2

* 6" CHB WALL : - kN/m

2

* CONCRETE SLAB (6") : 3.60 kN/m

2

75 psf

* ROOF TRUSS : - kN/m

2

* CEMENT TILE ROOFING : - kN/m

2

* MEACHANICAL/ ELECTRICAL

AHU : - kN/m

2

Note:

ASSUME FLOOR FINISH : - kN/m

2

CERAMIC TILE 25 mm MORTAR : - kN/m

2

TOTAL DEAD LOAD : 6.24 kN/m

2

130 psf

C. LIVE LOAD

* ROOF : - kN/m

2

* FLOORS : 4.80 kN/m

2

100 psf

* BALCONY : - kN/m

2

TOTAL LIVE LOAD : 4.80 kN/m

2

100 psf

* DESIGN ANALYSIS

1.0 ACI SPECIFICATION

CODE:

* If m = s/L < 0.50 ONE - WAY SLAB

* If m = s/L > 0.50 TWO - WAY SLAB

L = 9.76

S = 5.12

S

L

m = 0.525

SINCE

m = 0.525 > 0.50 therefore TWO - WAY SLAB

2.0 MINIMUM THICKNESS

perimeter

180

H = say

3.0 ULTIMATE LOAD

W

u

=

1.2 DL + 1.6 LL

W

u

=

W

u dead load

=

(DEAD LOAD)

W

u live load

=

(LIVE LOAD)

m

m

m =

H = ( 1000 )

165.33 mm 150.00 mm

15.159 kN/m

7.484 kN/m

7.676 kN/m

4.0 ULTIMATE MOMENT (coefficient method)

m = 0.525

Note:

indicates continuous edge, fixed at support

indicates discontinuous edge, torsion is negligible

A.) @ SHORT SPAN s = 5.12 m B.) @ LONG SPAN L = 9.76 m

* NEGATIVE MOMENT (@ continuous side) * NEGATIVE MOMENT (@ continuous side)

0.55 - 0 0.55 - 0.028

0.525 -

C

S neg 0.525 -

C

L neg

0.50 - 0 0.50 - 0.022

C

S neg =

- C

L neg =

0.02495

Mu

s = C

S neg

W

u

s

2

Mu

L =

Mu

s = Mu

L =

* POSITIVE MOMENT (@ midspan) * POSITIVE MOMENT (@ midspan)

DEAD LOAD DEAD LOAD

0.55 - 0.071 0.55 - 0.009

0.525 - C

s DL 0.525 - C

L DL

0.50 - 0.08 0.50 - 0.007

C

s DL =

0.07557 C

L DL =

0.00798

Mu

s DL = C

s DL

Wu

DL

s

2

Mu

L DL =

Mu

s DL = Mu

L DL =

LIVE LOAD LIVE LOAD

0.55 - 0.080 0.55 - 0.009

0.525 - C

s LL 0.525 - C

L LL

0.50 - 0.088 0.50 - 0.007

C

s LL

= 0.08407 C

L LL = 0.00798

Mu

s LL = C

s LL

Wu

LL

s

2

Mu

L LL =

Mu

s LL = Mu

L LL =

TOTAL (+) Mu

s = TOTAL (+) Mu

L =

* MOMENT (@ discontinuous side) * MOMENT (@ discontinuous side)

Mu

s = 1/3 (+Mu

s

) Mu

L = 1/3 (+Mu

L

)

Mu

s = Mu

L =

5.0 REINFORCING STEEL BAR and SPACING

5.1 A.) ALONG SHORT SPAN

* NEGATIVE MOMENT (@ continuous side)

Mu

s =

M

U

= f'

c

b d

2

(1 - 0.59 )

ASSUMPTIONS:

b = 1.0 m strip

d =

H - cover - 1/2 d

b

cover = 20.00 mm

d =

1 = 1.69492

2 = 0.00000

1

fc'

2

fc'

fy fy

C

L DL

Wu

DL

L

2

14.826 kN/m 5.691 kN/m

31.741 kN/m 11.529 kN/m

10.580 kN/m

C

L neg

W

u

L

2

0.000 kN-m 36.030 kN/m

CASE 3

S

L

124.00 mm

C

L LL

WuL

L

L

2

16.915 kN/m 5.837 kN/m

0.000 kN/m

0.000 kN/m

1 =

2 =

1

= 0.16949

2

= -

1.4

fy

min = 0.00506

max =

0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max =

0.75

b

max =

0.03710

ACI CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= - <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA (MAINBARS)

As

min =

min

b d

As

min = 627.93

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

* POSITIVE MOMENT (@ midspan)

(+) Mu

s =

M

U

= f'

c

b d

2

(1 - 0.59 )

1 = 1.60743

2 = 0.08748

1

fc'

2

fc'

fy fy

1

= 0.16074

2

= 0.00875

1.4

fy

min = 0.00506

max =

0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max =

0.75

b

max =

0.03710

ACI CODE:

IF

min

< <

max USE

fy (600 + fy)

S =

180.11 mm 180 mm O.C.

450 mm

100 mm

b = 0.85

1

(fc') (600)

fy (600 + fy)

31.741 kN/m

180.11 mm 180 mm O.C.

180 mm O.C.

1 =

2 =

min =

min =

b = 0.85

1

(fc') (600)

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00875 >

min = 0.00506

<

max = 0.03710

SINCE

min

<

<

max

THEREFORE USE = 0.00875

STEEL AREA (MAINBARS)

As

min =

min

b d

As

min = 1,084.76

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s min

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

5.2 B.) ALONG LONG DIRECTION

* NEGATIVE MOMENT (@ continuous side)

Mu

L =

Mu

L

= f'

c

b d

2

(1 - 0.59 )

ASSUMPTIONS:

b = 1.0 m strip

d' =

H - cover - d

b

- 1/2 d

b

cover = 20.00 mm

d' = 112.00 mm

1 = 1.57032

2 = 0.12460

1

fc'

2

fc'

fy fy

1

= 0.15703

2

= 0.01246

1.4

fy

min = 0.00506

max =

0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max =

0.75

b

max = 0.03710

ACI CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.01246 >

min = 0.00506

<

max = 0.03710

SINCE

min

<

<

max

THEREFORE USE = 0.01246

STEEL AREA (MAINBARS)

As

min =

min

b d

fy (600 + fy)

1 =

2 =

min =

b = 0.85

1

(fc') (600)

S =

104.26 mm 100 mm O.C.

450 mm

100 mm

104.26 mm 100 mm O.C.

100 mm O.C.

36.030 kN/m

As

min = 1,395.49

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

* POSITIVE MOMENT (@ midspan)

(+) Mu

L =

M

U

= f'

c

b d

2

(1 - 0.59 )

1 = 1.65714

2 = 0.03778

1

fc'

2

fc'

fy fy

1

= 0.16571

2

= 0.00378

1.4

fy

min = 0.00506

max =

0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max =

0.75

b

max = 0.03710

ACI CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00378 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA (MAINBARS)

As

min =

min

b d

As

min = 567.16

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

* MOMENT (@ discontinuous side)

S = 3 S

@ midspan

S =

190 mm O.C.

190 mm O.C.

570 mm O.C.

=

min =

b = 0.85

1

(fc') (600)

fy (600 + fy)

S =

81.04 mm 100 mm O.C.

450 mm

100 mm

S =

199.41 mm 190 mm O.C.

450 mm

100 mm

199.41 mm

1 =

81.04 mm 100 mm O.C.

100 mm O.C.

11.529 kN/m

2

ACI CODE:

S <

S = > 500 mm ; ok

6.0 SUMMARY

THICKNESS : 150.00 mm

COVER : 20.00 mm

REBARS

MAINBARS : 12 mm mainbars

SPACING

SHORT SPAN

TOP :

BOT :

LONG SPAN

TOP :

BOT : 300 mm 100 mm 190 mm

180 mm 100 mm 180 mm

DISC. END MIDSPAN CONT. END

300 mm 190 mm 100 mm

450 mm

570 mm O.C.

DISC. END CONT. END

100 mm 180 mm 100 mm

MIDSPAN

PROJECT : THE NEW BLUE WAVE

LOCATION : MACAPAGAL BLVD., PASAY CITY

SUBJECT : STRUCTURAL DESIGN and ANALYSIS

DESIGN and ANALYSIS OF SLAB (S - 3)

* DESIGN CRITERIA

f'c = 27.65 MPa 4,000 psi

fy = 276.46 MPa 40,000 psi

SPAN

L = 5.35 m

S = 2.94 m

* DESIGN LOADING

A. REINFORCED CONCRETE : 23.55 kN/m

3

B. DEAD LOAD

* TOPPING : 1.20 kN/m

2

25 psf

* CEILING : 0.24 kN/m

2

5 psf

* PARTITION : 0.96 kN/m

2

20 psf

* 4" CHB WALL : - kN/m

2

* 6" CHB WALL : - kN/m

2

* CONCRETE SLAB (6") : 3.60 kN/m

2

75 psf

* ROOF TRUSS : - kN/m

2

* CEMENT TILE ROOFING : - kN/m

2

* MEACHANICAL/ ELECTRICAL

AHU : - kN/m

2

Note:

ASSUME FLOOR FINISH : - kN/m

2

CERAMIC TILE 25 mm MORTAR : - kN/m

2

TOTAL DEAD LOAD : 6.00 kN/m

2

125 psf

C. LIVE LOAD

* ROOF : - kN/m

2

* FLOORS : 4.80 kN/m

2

100 psf

* BALCONY : - kN/m

2

TOTAL LIVE LOAD : 4.80 kN/m

2

100 psf

* DESIGN ANALYSIS

1.0 ACI SPECIFICATION

CODE:

* If m = s/L < 0.50 ONE - WAY SLAB

* If m = s/L > 0.50 TWO - WAY SLAB

L = 5.35

S = 2.94

S

L

m = 0.549

SINCE

m = 0.549 > 0.50 therefore TWO - WAY SLAB

2.0 MINIMUM THICKNESS

perimeter

180

H = say

3.0 ULTIMATE LOAD

W

u

=

1.2 DL + 1.6 LL

W

u

=

W

u dead load

=

(DEAD LOAD)

W

u live load

=

(LIVE LOAD)

4.0 ULTIMATE MOMENT (coefficient method)

m = 0.549

Note:

indicates continuous edge, fixed at support

indicates discontinuous edge, torsion is negligible

A.) @ SHORT SPAN s = 2.94 m B.) @ LONG SPAN L = 5.35 m

* NEGATIVE MOMENT (@ continuous side) * NEGATIVE MOMENT (@ continuous side)

7.196 kN/m

7.676 kN/m

CASE 9

m

m

m =

S

L

H = ( 1000 )

92.06 mm 150.00 mm

14.872 kN/m

0.55 - 0.086 0.55 - 0.005

0.549 -

C

S neg 0.549 -

C

L neg

0.50 - 0.088 0.50 - 0.003

C

S neg = 0.08606 C

L neg = 0.00494

Mu

s = C

S neg

W

u

s

2

Mu

L =

Mu

s = Mu

L =

* POSITIVE MOMENT (@ midspan) * POSITIVE MOMENT (@ midspan)

DEAD LOAD DEAD LOAD

0.55 - 0.037 0.55 - 0.003

0.549 - C

s DL 0.549 - C

L DL

0.50 - 0.038 0.50 - 0.002

C

s DL = 0.03703 C

L DL = 0.00297

Mu

s DL = C

s DL

Wu

DL

s

2

Mu

L DL =

Mu

s DL = Mu

L DL =

LIVE LOAD LIVE LOAD

0.55 - 0.063 0.55 - 0.006

0.549 - C

s LL 0.549 - C

L LL

0.50 - 0.067 0.50 - 0.004

C

s LL

= 0.06311 C

L LL = 0.00594

Mu

s LL = C

s LL

Wu

LL

s

2

Mu

L LL =

Mu

s LL = Mu

L LL =

TOTAL (+) Mu

s = TOTAL (+) Mu

L =

* MOMENT (@ discontinuous side) * MOMENT (@ discontinuous side)

Mu

s = 1/3 (+Mu

s

) Mu

L = 1/3 (+Mu

L

)

Mu

s = Mu

L =

5.0 REINFORCING STEEL BAR and SPACING

A.) ALONG SHORT SPAN

* NEGATIVE MOMENT (@ continuous side)

Mu

s =

M

U = f'

c

b d

2

(1 - 0.59 )

ASSUMPTIONS:

b = 1.0 m strip

d = H - cover - 1/2 d

b

cover = 20.00 mm

d =

1 = 1.66559

2 = 0.02932

1

fc'

2

fc'

fy fy

1 = 0.16656

2 = 0.00293

1.4

fy

min = 0.00506

max = 0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max = 0.75

b

max = 0.03710

ACI CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00293 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA (MAINBARS)

1 = =

min =

b = 0.85

1

(fc') (600)

fy (600 + fy)

11.024 kN/m

124.00 mm

C

L LL

WuL

L

L

2

4.173 kN/m 1.306 kN/m

6.468 kN/m 1.918 kN/m

0.000 kN/m 0.639 kN/m

C

L neg

W

u

L

2

11.024 kN-m 2.104 kN/m

C

L DL

Wu

DL

L

2

2.295 kN/m 0.612 kN/m

As

min =

min

b d

As

min = 627.93

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

* POSITIVE MOMENT (@ midspan)

(+) Mu

s =

M

U = f'

c

b d

2

(1 - 0.59 )

1 = 1.67784

2 = 0.01708

1

fc'

2

fc'

fy fy

1 = 0.16778

2 = 0.00171

1.4

fy

min = 0.00506

max = 0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max = 0.75

b

max = 0.03710

ACI CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00171 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA (MAINBARS)

As

min =

min

b d

As

min = 627.93

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s min

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

B.) ALONG LONG DIRECTION

* NEGATIVE MOMENT (@ continuous side)

Mu

L =

Mu

L =

f'

c

b d

2

(1 - 0.59 )

ASSUMPTIONS:

b = 1.0 m strip

d' = H - cover - d

b

- 1/2 d

b

cover = 20.00 mm

180.11 mm 180 mm O.C.

180 mm O.C.

2.104 kN/m

S =

180.11 mm 180 mm O.C.

450 mm

100 mm

100 mm

S =

180.11 mm 180 mm O.C.

450 mm

180.11 mm 180 mm O.C.

180 mm O.C.

6.468 kN/m

1 =

2 =

min =

b = 0.85

1

(fc') (600)

fy (600 + fy)

d' = 112.00 mm

1 = 1.68815

2 = 0.00677

1

fc'

2

fc'

fy fy

1 = 0.16881

2 = 0.00068

1.4

fy

min = 0.00506

max = 0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max = 0.75

b

max = 0.03710

ACI CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00068 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA (MAINBARS)

As

min =

min

b d

As

min = 567.16

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

2 =

min

199.41 mm 190 mm O.C.

450 mm

100 mm

199.41 mm 190 mm O.C.

=

b = 0.85

1

(fc') (600)

1 =

fy (600 + fy)

S =

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

* POSITIVE MOMENT (@ midspan)

(+) Mu

L =

M

U = f'

c

b d

2

(1 - 0.59 )

1 = 1.68875

2 = 0.00617

1

fc'

2

fc'

fy fy

1 = 0.16887

2 = 0.00062

1.4

fy

min = 0.00506

max = 0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max = 0.75

b

max = 0.03710

ACI CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00062 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA (MAINBARS)

As

min =

min

b d

As

min = 567.16

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

* MOMENT (@ discontinuous side)

S = 3 S

@ midspan

S =

ACI CODE:

S <

S = > 500 mm ; ok

6.0 SUMMARY

THICKNESS : 150.00 mm

COVER : 20.00 mm

REBARS

MAINBARS : 12 mm mainbars

SPACING

SHORT SPAN

TOP :

BOT :

LONG SPAN

TOP :

BOT :

=

min =

b = 0.85

1

(fc') (600)

fy (600 + fy)

1 =

2

190 mm O.C.

1.918 kN/m

S =

199.41 mm

450 mm

100 mm

199.41 mm 190 mm O.C.

190 mm O.C.

570 mm O.C.

190 mm O.C.

450 mm

570 mm O.C.

DISC. END MIDSPAN CONT. END

300 mm 180 mm 180 mm

300 mm 180 mm 180 mm

DISC. END MIDSPAN CONT. END

300 mm 190 mm 190 mm

300 mm 190 mm 190 mm

PROJECT : TROPICANA GARDEN CITY

LOCATION : SUMULONG AVENUE, BRGY. STO. NINO, MARIKINA CITY

SUBJECT : STRUCTURAL DESIGN and ANALYSIS

DESIGN and ANALYSIS OF SLAB (S - 2)

* DESIGN CRITERIA

f'c = 27.65 MPa 4,000 psi

fy = 276.46 MPa 40,000 psi

SPAN

L = 5.09 m

S = 4.72 m

* DESIGN LOADING

A. REINFORCED CONCRETE : 23.55 kN/m

3

B. DEAD LOAD

* TOPPING : 2.40 kN/m

2

50 psf

* CEILING : 0.24 kN/m

2

5 psf

* PARTITION : - kN/m

2

* 4" CHB WALL : - kN/m

2

* 6" CHB WALL : - kN/m

2

* CONCRETE SLAB (5") : 3.60 kN/m

2

75.0 psf

* ROOF TRUSS : - kN/m

2

* CEMENT TILE ROOFING : - kN/m

2

* MEACHANICAL/ ELECTRICAL

AHU : - kN/m

2

Note:

ASSUME FLOOR FINISH : - kN/m

2

CERAMIC TILE 25 mm MORTAR : - kN/m

2

TOTAL DEAD LOAD : 6.24 kN/m

2

130.0 psf

C. LIVE LOAD

* ROOF : - kN/m

2

* FLOORS : 4.80 kN/m

2

100 psf

* BALCONY : - kN/m

2

TOTAL LIVE LOAD : 4.80 kN/m

2

100 psf

* DESIGN ANALYSIS

1.0 ACI SPECIFICATION

CODE:

* If m = s/L < 0.50 ONE - WAY SLAB

* If m = s/L > 0.50 TWO - WAY SLAB

L = 5.09

S = 4.72

S

L

m = 0.927

SINCE

m = 0.927 > 0.50 therefore TWO - WAY SLAB

2.0 MINIMUM THICKNESS

perimeter

180

H = try

3.0 ULTIMATE LOAD

W

u

=

1.2 DL + 1.6 LL

W

u

=

W

u dead load

=

(DEAD LOAD)

W

u live load

=

(LIVE LOAD)

m

m

m =

H = ( 1000 )

109.00 mm 150.00 mm

15.159 kN/m

7.484 kN/m

7.676 kN/m

4.0 ULTIMATE MOMENT (coefficient method)

m = 0.927

Note:

indicates continuous edge, fixed at support

indicates discontinuous edge, torsion is negligible

A.) @ SHORT SPAN s = 4.72 m B.) @ LONG SPAN L = 5.09 m

* NEGATIVE MOMENT (@ continuous side) * NEGATIVE MOMENT (@ continuous side)

0.95 - 0.074 0.95 - 0

0.927 -

C

S neg 0.927 -

C

L neg

0.90 - 0.080 0.90 - 0

C

S neg =

0.07672 C

L neg =

-

Mu

s = C

S neg

W

u

s

2

Mu

L =

Mu

s = Mu

L =

* POSITIVE MOMENT (@ midspan) * POSITIVE MOMENT (@ midspan)

DEAD LOAD DEAD LOAD

0.95 - 0.028 0.95 - 0.015

0.927 - C

s DL 0.927 - C

L DL

0.90 - 0.029 0.90 - 0.013

C

s DL =

0.02845 C

L DL =

0.01409

Mu

s DL = C

s DL

Wu

DL

s

2

Mu

L DL =

Mu

s DL = Mu

L DL =

LIVE LOAD LIVE LOAD

0.95 - 0.034 0.95 - 0.024

0.927 - C

s LL 0.927 - C

L LL

0.90 - 0.037 0.90 - 0.021

C

s LL

= 0.03536 C

L LL = 0.02264

Mu

s LL = C

s LL

Wu

LL

s

2

Mu

L LL =

Mu

s LL = Mu

L LL =

TOTAL (+) Mu

s = TOTAL (+) Mu

L =

* MOMENT (@ discontinuous side) * MOMENT (@ discontinuous side)

Mu

s = 1/3 (+Mu

s

) Mu

L = 1/3 (+Mu

L

)

Mu

s = Mu

L =

5.0 REINFORCING STEEL BAR and SPACING

5.1 A.) ALONG SHORT SPAN

* NEGATIVE MOMENT (@ continuous side)

Mu

s =

M

U

= f'

c

b d

2

(1 - 0.59 )

ASSUMPTIONS:

b = 1.0 m strip

d =

H - cover - 1/2 d

b

cover = 20.00 mm

d =

1 = 1.62424

2 = 0.07067

1

fc'

2

fc'

fy fy

S

L

C

L neg

W

u

L

2

25.911 kN-m 0.000 kN-m

C

L DL

Wu

DL

L

2

4.744 kN-m 2.732 kN-m

CASE 5

25.911 kN-m

124.00 mm

C

L LL

WuL

L

L

2

6.047 kN-m 4.502 kN-m

10.791 kN-m 7.234 kN-m

0.000 kN-m 2.411 kN-m

=

1 =

2

1

= 0.16242

2

= 0.00707

1.4

fy

min = 0.00506

max =

0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max =

0.75

b

max = 0.03710

ACI CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00707 >

min = 0.00506

<

max = 0.03710

SINCE

min

<

<

max

THEREFORE USE = 0.00707

STEEL AREA (MAINBARS)

As =

b d

As

=

876.37

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

* POSITIVE MOMENT (@ midspan)

(+) Mu

s =

M

U

= f'

c

b d

2

(1 - 0.59 )

1 = 1.66622

2 = 0.02869

1

fc'

2

fc'

fy fy

1

= 0.16662

2

= 0.00287

1.4

fy

min = 0.00506

max =

0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max =

0.75

b

max = 0.03710

ACI CODE:

IF

min

< <

max USE

min =

b = 0.85

1

(fc') (600)

125 mm O.C.

125 mm O.C.

10.791 kN-m

fy (600 + fy)

S =

129.05 mm 125 mm O.C.

450 mm

100 mm

129.05 mm

b = 0.85

1

(fc') (600)

fy (600 + fy)

1 =

2 =

min =

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00287 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE = 0.00506

STEEL AREA (MAINBARS)

As =

b d

As

=

627.93

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s min

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

5.2 B.) ALONG LONG DIRECTION

* NEGATIVE MOMENT (@ continuous side)

Mu

L =

Mu

L

= f'

c

b d

2

(1 - 0.59 )

ASSUMPTIONS:

b = 1.0 m strip

d' =

H - cover - d

b

- 1/2 d

b

cover = 20.00 mm

d' = 112.00 mm

1 = 1.69492

2 = 0.00000

1

fc'

2

fc'

fy fy

1

= 0.16949

2

= -

1.4

fy

min = 0.00506

max =

0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max =

0.75

b

max = 0.03710

ACI CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= - <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA (MAINBARS)

As

min =

min

b d

180.11 mm 175 mm O.C.

175 mm O.C.

0.000 kN/m

S =

180.11 mm 175 mm O.C.

450 mm

100 mm

=

min =

b = 0.85

1

(fc') (600)

1 =

2

fy (600 + fy)

As

min = 567.16

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

* POSITIVE MOMENT (@ midspan)

(+) Mu

L =

M

U

= f'

c

b d

2

(1 - 0.59 )

1 = 1.67141

2 = 0.02350

1

fc'

2

fc'

fy fy

1

= 0.16714

2

= 0.00235

1.4

fy

min = 0.00506

max =

0.75

b

1 = 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b = 0.04946

max =

0.75

b

max = 0.03710

ACI CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00235 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA (MAINBARS)

As

min =

min

b d

As

min = 567.16

mm

2

SPACING

A

b

(1000) Note: use 12 mm mainbars

A

s

S = say

ACI CODE:

S < 3H

<

S = say < 450 mm ; ok

< 450 mm ; ok

> 100 mm ; ok

Therefore S =

* MOMENT (@ discontinuous side)

S = 3 S

@ midspan

S =

195 mm O.C.

195 mm O.C.

7.234 kN/m

S =

199.41 mm 195 mm O.C.

450 mm

100 mm

199.41 mm

(fc') (600)

fy (600 + fy)

1 =

2 =

min =

S =

199.41 mm 195 mm O.C.

450 mm

100 mm

b = 0.85

1

199.41 mm 195 mm O.C.

195 mm O.C.

585 mm O.C.

ACI CODE:

S <

S = > 500 mm ; ok

6.0 SUMMARY

THICKNESS : 150.00 mm

COVER : 20.00 mm

REBARS

MAINBARS : 12 mm mainbars

SPACING

SHORT SPAN

TOP :

BOT :

LONG SPAN

TOP :

BOT :

DISC. END MIDSPAN CONT. END

125 mm 175 mm 125 mm

450 mm

585 mm O.C.

300 mm 195 mm 195 mm

300 mm 195 mm 195 mm

175 mm 125 mm 175 mm

DISC. END MIDSPAN CONT. END

DESIGN and ANALYSIS OF BEAM (B - 1C)

ANALYSIS FOR BENDING

* DESIGN CRITERIA

f'c = 27.65 MPa 4,000 psi

fy = 276.46 MPa 40,000 psi

LENGTH (L) = 9.76

LENGTH (s) = 5.12

* DESIGN LOADING

A. REINFORCED CONCRETE : 23.55

kN/m

3

B. DEAD LOAD

* TOPPING : 2.40

kN/m

2

50 psf

* CEILING : 0.24 kN/m

2

5 psf

* PARTITION : - kN/m

2

* 4" CHB WALL : - kN/m

2

* 6" CHB WALL : - kN/m

2

* CONCRETE SLAB (6") : 3.60 kN/m

2

75 psf

* ROOF TRUSS : -

kN/m

2

* CEMENT TILE ROOFING : -

kN/m

2

Note:

ASSUME FLOOR FINISH : -

kN/m

2

CERAMIC TILE 25 mm MORTAR : -

kN/m

2

TOTAL DEAD LOAD : 6.24 kN/m

2

130 psf

C. LIVE LOAD

* ROOF : - kN/m

2

* FLOORS : 4.80 kN/m

2

100 psf

* BALCONY : - kN/m

2

TOTAL LIVE LOAD : 4.80 kN/m

2

100 psf

* DESIGN ANALYSIS

1.0 ULTIMATE LOAD

W

u

=

1.2 DL + 1.6 LL

W

u

= 15.16

* LOAD TRANSFER

@ LONG DIRECTION

P s

6

Wu =

@ SHORT DIRECTION

P s

6

Wu =

CONSIDER LONG DIRECTION

TRIAL SECTION 300 x 500

wt. of beam

=

W

u TOTAL

=

2.0 ULTIMATE MOMENT

* NEGATIVE MOMENT

W

u

L

2

11

M

U

=

* POSITIVE MOMENT

W

u

L

2

16

M

U

= 235.090 kN-m

4.239 kN/m

39.487 kN/m

m

25.872 kN/m

341.949 kN-m

2

m

kN/m

2

35.248 kN/m

M

U

WEIGHT OF BEAM

=

M

U =

Wu = 2

Wu = (3 - (s/L)

2

* TOTAL REACTIONS

R

TA

= R

TB =

R

TA

= R

TB =

3.0 REINFORCING STEEL BARS

ASSUME:

= 0.90 bending

d = say 430 mm

b = 300 mm

h = d + cover

cover = 60 mm

* NEGATIVE MOMENT

M

U

=

M

U

= f'c b d

2

(1-0.59 )

1 = 1.39359

2 = 0.30132

1

fc'

2

fc'

fy fy

1

= 0.13936

2

= 0.03013

1.4

fy

min

= 0.00506

max

= 0.75

b f'c (600)

fy (600 + fy)

1

= 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b

=

max

= 0.75

b

max

=

min = 0.00506

max = 0.03710

CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.03013 >

min = 0.00506

<

max = 0.03710

SINCE

min

<

<

max

THEREFORE USE = 0.03013

STEEL AREA

As =

b d

As =

mm

2

No. OF BARS

As Note: use 20 mm BARS

A

b

N = 12.37 say 13 20 mm BARS

SPACING OF MAINBARS

S = 4.00 mm < 25.00 mm Use bundled bars

* POSITIVE MOMENT

341.95 kN-m

R

T(A-B) due to loads

+ R

T(A-B) due to wt of beam

192.697 kN

b

=

3,887.09

427.50 mm

N =

=

1 = =

0.85

1

0.04946

0.03710

min

M

U

=

M

U

= f'c b d

2

(1-0.59 )

1 = 0.78226

2 = 0.21774

1

fc'

2

fc'

fy fy

1

= 0.07823

2

= 0.02177

1.4

fy

min

= 0.00506

max

= 0.75

b f'c (600)

fy (600 + fy)

1

= 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b

=

max

= 0.75

b

max

=

min = 0.00506

max = 0.03710

CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.02177 >

min = 0.00506

<

max = 0.03710

SINCE

min

<

<

max

THEREFORE USE = 0.02177

STEEL AREA

As =

b d

As =

mm

2

No. OF BARS

As Note: use 20 mm BARS

A

b

N = 8.94 say 9 20 mm BARS

SPACING OF MAINBARS

S = 14.00 mm < 25.00 mm Use bundled bars

CHECK ADEQUACY 300 x 500

M

U

= f'c b d

2

(1-0.59 )

d = say 430 mm

@ NEGATIVE MOMENT

C = T

0.85 f'c a b = As fy

a =

M

U

=

As fy (d - a/2))

M

U

=

> SAFE 342.17 kN-m 341.95 kN-m

2,808.90

N =

152.43 mm

427.50 mm

b

= 0.85

1

0.04946

=

min =

1 =

235.09 kN-m

0.03710

@ POSITIVE MOMENT

C = T

0.85 f'c a b = As fy

a =

M

U

=

As fy (d - a/2))

M

U

=

> SAFE

6.0 SUMMARY

BEAM DIMENSION : 300 x 500

COVER : 60.00 mm

REBARS

MAINBARS : 20 mm mainbars

TOP :

BOT :

110.15 mm

262.04 kN-m 235.09 kN-m

DISC. END MIDSPAN

9

13

9

- 9

- 13

CONT. END

@ LEFT @ RIGHT

13

PROJECT : THE NEW BLUE WAVE

LOCATION : MACAPAGAL BLVD., PASAY CITY

SUBJECT : STRUCTURAL DESIGN and ANALYSIS

DESIGN and ANALYSIS OF BEAM (2B - 1B)

ANALYSIS FOR SHEARING

1.0 WEB REINFORCEMENT

FACTORED SHEAR

W

u

L

2

V

u =

FACTORED SHEAR

R

T =

SHEAR STRENGTH

= 0.75

V

C =

1/6 f'c b d

CODE

IF V

u

> V

c ; STIRRUPS ARE NECESSARY

IF V

u

< V

c BUT V

u

> 1/2 V

c

b

w

s

3 fy

S = d / 2 or 600 mm (WHICHEVER IS SMALLER)

IF V

u

< 1/2 V

c ; STIRRUPS ARE NOT NECESSARY

V

C =

1/6 f'c b d

V

C =

V

c =

Vu

Vs = -14.41 kN

CHECK CODE:

V

u = 73.98 kN

V

c

= 84.79 kN

1/2 V

c

= 42.39 kN

V

u

= 73.98 kN < V

c

= 84.79 kN

> 1/2 V

c

= 42.39 kN

Therefore STIRRUPS ARE NEEDED

MAXIMUM SPACING TO PROVIDE MINIMUM Av FOR STIRRUPS

b

w

s

3 fy

S = d /2 or 600 mm (WHICHEVER IS SMALLER)

Av fy d

Vs

A

V

= mm

2

Note: use 12 mm TIES

Av fy d

Vs

S

1

= say

Vs = - Vc

113.05 kN

84.79 kN

(MINIMUM AREA IF STIRRUPS) =

73.978 kN

192.697 kN

S =

-933.05 mm -950.00 mm

= V

u

A

V

S

A

V

=

=

113.10

S

= d /2 or 600 mm

S

2

=

=

Therefore use S = (use smaller value)

WEB REINFORCEMENT DETAILS

5.0 DEVELOPMENT LENGTH

fy

t

e

1.7 f'c

t

= 1.0

e

= 1.0

s

= 1.0

= 1.0

c

b

= 30.00 mm (one half of c. to c. spacing of bars)

L

d = say 620.00 mm

40 A

tr

sn

A

tr

= mm

2

n = 13 bars

SPACING OF MAINBARS

S 25.33 mm > 25 mm ; Therefore ok

40 A

tr

sn

k

tr

= 0.0

4,084.07

215.00 mm

(d

b

)

(d

b

)

k

tr =

fy

t

s

1.1 f'c ((c

b

+ k

tr

)/ d

b

)

fy

t

s

k

tr =

L

d =

L

d =

-950.00 mm

L

d = (d

b

) (25 mm bars and larger)

618.59 mm

600.00 mm

L

d =

CHECK CODE:

(c

b

+ k

tr

)/ d

b

= 1.50 < 2.50

Mu =

Mu

Mn =

Mn = Mn

1

+ Mn

2

Mn

1 =

Mn

2 =

STEEL AREA

COMPRESSION BARS

Mn

1 = As

1

fy (d - a/2)

Mn

2 = As

2

fy (d - d')

As

1 =

b d

As

1 =

mm

2

Checking if Compression Steel Yields

As

1

fy

0.85 f'c b

a =

a

1

c =

(d - c)

c

'

s

= #REF!

fy

Es

'

s

= #REF! # 0.001 #REF!

Mn

2

fy (d - d')

As'

req'd

= mm

2

No. of COMPRESSION BARS

As'

req'd

Note: use 28 mm BARS

A

b

N = #REF! say #REF! 28 mm BARS

#REF!

'

s = 0.003

c = =

As'

req'd

=

0.00138

#REF!

=

= As

2

1.1 f'c ((c

b

+ k

tr

)/ d

b

)

= 0.85

Mn =

#REF!

a

#REF!

c =

1

(d

b

)

N

=

1

c

#REF!

#REF!

#REF!

#REF!

=

637.33 mm

L

d =

Checking of bar spacing

S = 14.67 mm > 25 mm spacing is OK

TENSION BARS

Mn

1 = As

1

fy (d - a/2)

Mn

1

fy (d - a/2)

As

1

= mm

2

As = As

1

+ As

2

As'

req'd

= As

2

= mm

2

As = mm

2

No. of TENSION BARS

As Note: use 28 mm BARS

A

b

N = #REF! say #REF! 28 mm BARS

6.0 DEVELOPMENT LENGTH

L

d

= l

db

x applicable modification factor

BUT NOT LESS THAN 300 mm

DEVELOPMENT LENGTH IN TENSION

0.02 Ab fy

fc'

MODIFICATION FACTOR

CODE: CONDITIONS

* Bars not included in the conditions (m = 1.4)

0.02 Ab fy

fc'

l

db

= 244.35 mm SAY 200.00 mm

L

d

= l

db

x modification factor

L

d

=

244.35 mm SAY 200.00 mm

CHECK CODE:

0.02 Ab fy

fc'

0.06 d

b

fy = 265.41 mm

l

db

= 200.00 mm > 218.38 mm THEREFORE USE MINIMUM l

db

L

d

=

371.57 mm SAY 310.00 mm

DEVELOPMENT LENGTH IN COMPRESSION

#REF!

#REF!

N =

As

1 =

#REF!

l

db

=

BUT NOT LESS THAN 0.06

d

b

fy

l

db

=

BUT NOT LESS THAN 0.06

d

b

fy

l

db

=

0.24 db fy

fc'

MODIFICATION FACTOR

CODE: CONDITIONS

* Excess reinforcement. Reinforcement more than that

required by analysis

As required

As provided

m= #REF!

0.24 db fy

fc'

l

db

= 233.34 mm

L

d

= l

db

x modification factor

L

d

=

#REF! mm SAY 30.00 mm

CHECK CODE:

0.24 db fy

fc'

0.04 d

b

fy = 176.94

m

m

l

db

= 190.00 mm > 145.59 mm THEREFORE OK!

L

d

=

#REF! mm SAY 30.00 mm

7.0 STANDARD HOOKS AND SPLICES

HOOKS

100 d

b

fc'

l

dh

= l

hb

x applicable modification factor

; NOT LESS THAN 8 d

b

AND

NOT LESS THAN 150 mm

l

hb

=

57.87 mm

MODIFICATION FACTOR

CODE:

1. fy = 227.48 Mpa l

hb

x (fy/415)

l

dh

= mm

2. l

hb

x 0.70 l

hb

= mm

3. A

s

required l

hb

= # mm

A

s

provided

CODE:

l

dh

> 8 d

b

> 150 mm

l

dh

= 42.37 mm < 128.00 mm , 150.00 mm

l

dh

= 54.11 mm < 128.00 mm , 150.00 mm

l

dh

= 18.70 mm < 128.00 mm , 150.00 mm

THEREFORE USE l

dh

= 128.00 mm

SPLICES

* TENSION

CODE:

CLASS A SPLICE: - - - - - - 1.0 L

d

CLASS B SPLICE: - - - - - - 1.3 L

d

l

db

=

l

db

=

m

=

BUT NOT LESS THAN 0.04

d

b

fy

l

hb

=

l

db

=

BUT NOT LESS THAN 0.04

d

b

fy

L

d

= #REF! mm

Lap splices of deformed bars and deformed wire in tension shall be Class B splices

except that Class A splices are allowed when:

(a) The area of reinforcement provided is at least twice that required by analysis over

the entire length of the splice, and

(b) One-half or less of the total reinforcement is spliced within the required lap

strength

(a) A

s

required = 113.10 mm

2

(b) Lap strength: 415 Mpa

THEREFORE SPLICE IS CLASS B

SPLICE = #REF! mm SAY 30.00 mm

* COMPRESSION

CODE:

1. L

d

> 0.07 fy d

b

; fy = 415 Mpa or less

2. L

d

> (0.13 fy - 24)d

b

fy > 415 Mpa

fy = 415.00 Mpa

L

d

= #REF! mm

0.07 fy d

b

= 309.64 mm

THEREFORE SPLICE = #REF! mm SAY 30.00 mm

DESIGN and ANALYSIS OF BEAM (B - 6)

ANALYSIS FOR BENDING

* DESIGN CRITERIA

f'c = 27.65 MPa 4,000 psi

fy = 276.46 MPa 40,000 psi

LENGTH (L) = 9.76

LENGTH (s) = 5.12

* DESIGN LOADING

A. REINFORCED CONCRETE : 23.55

kN/m

3

B. DEAD LOAD

* TOPPING : 2.40

kN/m

2

50 psf

* CEILING : 0.24 kN/m

2

5 psf

* PARTITION : - kN/m

2

* 4" CHB WALL : - kN/m

2

* 6" CHB WALL : - kN/m

2

* CONCRETE SLAB (6") : 3.60 kN/m

2

75 psf

* ROOF TRUSS : -

kN/m

2

* CEMENT TILE ROOFING : -

kN/m

2

Note:

ASSUME FLOOR FINISH : -

kN/m

2

CERAMIC TILE 25 mm MORTAR : -

kN/m

2

TOTAL DEAD LOAD : 6.24 kN/m

2

130 psf

C. LIVE LOAD

* ROOF : - kN/m

2

* FLOORS : 4.80 kN/m

2

100 psf

* BALCONY : - kN/m

2

TOTAL LIVE LOAD : 4.80 kN/m

2

100 psf

* DESIGN ANALYSIS

1.0 ULTIMATE LOAD

W

u

=

1.2 DL + 1.6 LL

W

u

= 15.16

* LOAD TRANSFER

@ LONG DIRECTION

P s

6

Wu =

@ SHORT DIRECTION

P s

6

Wu =

CONSIDER LONG DIRECTION

TRIAL SECTION 300 x 500

wt. of beam

=

W

u TOTAL

=

2.0 ULTIMATE MOMENT

* NEGATIVE MOMENT

W

u

L

2

16

M

U

=

* POSITIVE MOMENT

W

u

L

2

14

M

U

=

* TOTAL REACTIONS

2

35.248 kN/m

m

m

kN/m

2

Wu = (3 - (s/L)

2

Wu = 2

WEIGHT OF BEAM

4.239 kN/m

30.111 kN/m

M

U =

49.334 kN-m

M

U =

56.382 kN-m

25.872 kN/m

R

TA

= R

TB =

R

TA

= R

TB =

3.0 REINFORCING STEEL BARS

ASSUME:

= 0.90 bending

d = say 430 mm

b = 300 mm

h = d + cover

cover = 60 mm

* NEGATIVE MOMENT

M

U

=

M

U

= f'c b d

2

(1-0.59 )

1 = 1.65838

2 = 0.03653

1

fc'

2

fc'

fy fy

1

= 0.16584

2

= 0.00365

1.4

fy

min = 0.00506

max = 0.75

b f'c (600)

fy (600 + fy)

1

= 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b

=

max

= 0.75

b

max

=

min = 0.00506

max = 0.03710

CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00365 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA

As

min =

min

b d

As

min =

mm

2

No. OF BARS

As Note: use 20 mm BARS

A

b

N = 2.08 say 3 20 mm BARS

SPACING OF MAINBARS

S = 48.00 mm > 25.00 mm Therefore ok

77.084 kN

R

T(A-B) due to loads

+ R

T(A-B) due to wt of beam

427.50 mm

49.33 kN-m

1 = =

min =

b

= 0.85

1

0.04946

2

0.03710

653.25

N =

* POSITIVE MOMENT

M

U

=

M

U

= f'c b d

2

(1-0.59 )

1 = 0.95733

2 = 0.04267

1

fc'

2

fc'

fy fy

1

= 0.09573

2

= 0.00427

1.4

fy

min = 0.00506

max

= 0.75

b

f'c (600)

fy (600 + fy)

1

= 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b

=

max

= 0.75

b

max

=

min = 0.00506

max = 0.03710

CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00427 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA

As

min =

min

b d

As

min =

mm

2

No. OF BARS

As Note: use 20 mm BARS

A

b

N = 2.08 say 3 20 mm BARS

SPACING OF MAINBARS

S = 48.00 mm > 25.00 mm Therefore ok

CHECK ADEQUACY 300 x 500

M

U

= f'c b d

2

(1-0.59 )

d = say 430 mm

@ NEGATIVE MOMENT

C = T

0.85 f'c a b = As fy

a =

M

U

=

As fy (d - a/2))

M

U

=

> SAFE

56.38 kN-m

1 =

25.62 mm

=

min =

b

= 0.85

1

0.04946

2

0.03710

653.25

N =

427.50 mm

67.81 kN-m 49.33 kN-m

@ POSITIVE MOMENT

C = T

0.85 f'c a b = As fy

a =

M

U

=

As fy (d - a/2))

M

U

=

> SAFE

6.0 SUMMARY

BEAM DIMENSION : 300 x 500

COVER : 60.00 mm

REBARS

MAINBARS : 20 mm mainbars

TOP :

BOT :

DISC. END MIDSPAN

CONT. END

@ LEFT @ RIGHT

25.62 mm

67.81 kN-m 56.38 kN-m

3 3 - -

3 3 - -

CONT. END

@ RIGHT

-

-

DESIGN and ANALYSIS OF BEAM (B - 1D)

ANALYSIS FOR BENDING

* DESIGN CRITERIA

f'c = 27.65 MPa 4,000 psi

fy = 276.46 MPa 40,000 psi

LENGTH (L) = 5.09

LENGTH (s) = 4.72

* DESIGN LOADING

A. REINFORCED CONCRETE : 23.55

kN/m

3

B. DEAD LOAD

* TOPPING : 2.40

kN/m

2

50 psf

* CEILING : 0.24 kN/m

2

5 psf

* PARTITION : - kN/m

2

* 4" CHB WALL : - kN/m

2

* 6" CHB WALL : - kN/m

2

* CONCRETE SLAB (6") : 3.60 kN/m

2

75 psf

* ROOF TRUSS : -

kN/m

2

* CEMENT TILE ROOFING : -

kN/m

2

Note:

ASSUME FLOOR FINISH : -

kN/m

2

CERAMIC TILE 25 mm MORTAR : -

kN/m

2

TOTAL DEAD LOAD : 6.24 kN/m

2

130 psf

C. LIVE LOAD

* ROOF : - kN/m

2

* FLOORS : 4.80 kN/m

2

100 psf

* BALCONY : - kN/m

2

TOTAL LIVE LOAD : 4.80 kN/m

2

100 psf

* DESIGN ANALYSIS

1.0 ULTIMATE LOAD

W

u

=

1.2 DL + 1.6 LL

W

u

= 15.16

* LOAD TRANSFER

@ LONG DIRECTION

P s

6

Wu =

@ SHORT DIRECTION

P s

6

Wu =

CONSIDER LONG DIRECTION

TRIAL SECTION 300 x 500

wt. of beam

=

W

u TOTAL

=

2.0 ULTIMATE MOMENT

* NEGATIVE MOMENT

W

u

L

2

11

M

U

=

* POSITIVE MOMENT

W

u

L

2

16

M

U

=

* TOTAL REACTIONS

2

25.521 kN/m

m

m

kN/m

2

Wu = (3 - (s/L)

2

Wu = 2

WEIGHT OF BEAM

4.239 kN/m

28.090 kN/m

M

U =

56.890 kN-m

M

U =

39.112 kN-m

23.851 kN/m

R

TA

= R

TB =

R

TA

= R

TB =

3.0 REINFORCING STEEL BARS

ASSUME:

= 0.90 bending

d = say 430 mm

b = 300 mm

h = d + cover

cover = 60 mm

* NEGATIVE MOMENT

M

U

=

M

U

= f'c b d

2

(1-0.59 )

1 = 1.65264

2 = 0.04227

1

fc'

2

fc'

fy fy

1

= 0.16526

2

= 0.00423

1.4

fy

min = 0.00506

max = 0.75

b f'c (600)

fy (600 + fy)

1

= 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b

=

max

= 0.75

b

max

=

min = 0.00506

max = 0.03710

CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00423 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA

As

min =

min

b d

As

min =

mm

2

No. OF BARS

As Note: use 20 mm BARS

A

b

N = 2.08 say 3 20 mm BARS

SPACING OF MAINBARS

S = 48.00 mm > 25.00 mm Therefore ok

* POSITIVE MOMENT

M

U

=

M

U

= f'c b d

2

(1-0.59 )

66.292 kN

R

T(A-B) due to loads

+ R

T(A-B) due to wt of beam

427.50 mm

56.89 kN-m

1 = =

min =

b

= 0.85

1

0.04946

2

0.03710

653.25

N =

39.11 kN-m

1 = 0.97081

2 = 0.02919

1

fc'

2

fc'

fy fy

1

= 0.09708

2

= 0.00292

1.4

fy

min = 0.00506

max

= 0.75

b

f'c (600)

fy (600 + fy)

1

= 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b

=

max

= 0.75

b

max

=

min = 0.00506

max = 0.03710

CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00292 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA

As

min =

min

b d

As

min =

mm

2

No. OF BARS

As Note: use 20 mm BARS

A

b

N = 2.08 say 3 20 mm BARS

SPACING OF MAINBARS

S = 48.00 mm > 25.00 mm Therefore ok

CHECK ADEQUACY 300 x 500

M

U

= f'c b d

2

(1-0.59 )

d = say 430 mm

@ NEGATIVE MOMENT

C = T

0.85 f'c a b = As fy

a =

M

U

=

As fy (d - a/2))

M

U

=

> SAFE

@ POSITIVE MOMENT

C = T

0.85 f'c a b = As fy

a =

M

U

=

As fy (d - a/2))

M

U

=

> SAFE

1 =

25.62 mm

=

min =

b

= 0.85

1

0.04946

2

0.03710

653.25

N =

427.50 mm

67.81 kN-m 56.89 kN-m

25.62 mm

67.81 kN-m 39.11 kN-m

6.0 SUMMARY

BEAM DIMENSION : 300 x 500

COVER : 60.00 mm

REBARS

MAINBARS : 20 mm mainbars

TOP :

BOT :

DISC. END MIDSPAN

CONT. END

@ LEFT @ RIGHT

- 3 3 3

- 3 3 3

CONT. END

@ RIGHT

3

3

DESIGN and ANALYSIS OF ROOF BEAM (RB - 1C)

ANALYSIS FOR BENDING

* DESIGN CRITERIA

f'c = 27.65 MPa 4,000 psi

fy = 276.46 MPa 40,000 psi

LENGTH (L) = 9.76

LENGTH (s) = 5.12

* DESIGN LOADING

A. REINFORCED CONCRETE : 23.55

kN/m

3

B. DEAD LOAD

* TOPPING : -

kN/m

2

* CEILING : 0.24 kN/m

2

5 psf

* PARTITION : - kN/m

2

* 4" CHB WALL : - kN/m

2

* 6" CHB WALL : - kN/m

2

* CONCRETE SLAB (6") : - kN/m

2

* ROOF TRUSS : 1.44

kN/m

2

30 psf

* CEMENT TILE ROOFING : -

kN/m

2

Note:

ASSUME FLOOR FINISH : -

kN/m

2

CERAMIC TILE 25 mm MORTAR : -

kN/m

2

TOTAL DEAD LOAD : 1.68 kN/m

2

35 psf

C. LIVE LOAD

* ROOF : 0.77 kN/m

2

16 psf

* FLOORS : - kN/m

2

* BALCONY : - kN/m

2

TOTAL LIVE LOAD : 0.77 kN/m

2

16 psf

* DESIGN ANALYSIS

1.0 ULTIMATE LOAD

W

u

=

1.2 DL + 1.6 LL

W

u

= 3.24

* LOAD TRANSFER

@ LONG DIRECTION

P s

6

Wu =

@ SHORT DIRECTION

P s

6

Wu =

CONSIDER LONG DIRECTION

TRIAL SECTION 300 x 500

wt. of beam

=

W

u TOTAL

=

2.0 ULTIMATE MOMENT

* NEGATIVE MOMENT

W

u

L

2

11

M

U

=

* POSITIVE MOMENT

W

u

L

2

16

M

U

=

* TOTAL REACTIONS

WEIGHT OF BEAM

4.239 kN/m

11.779 kN/m

M

U =

102.007 kN-m

M

U =

70.130 kN-m

5.535 kN/m

Wu = (3 - (s/L)

2

Wu = 2

2

7.540 kN/m

m

m

kN/m

2

R

TA

= R

TB =

R

TA

= R

TB =

3.0 REINFORCING STEEL BARS

ASSUME:

= 0.90 bending

d = say 430 mm

b = 300 mm

h = d + cover

cover = 60 mm

* NEGATIVE MOMENT

M

U

=

M

U

= f'c b d

2

(1-0.59 )

1 = 1.61747

2 = 0.07745

1

fc'

2

fc'

fy fy

1

= 0.16175

2

= 0.00774

1.4

fy

min = 0.00506

max = 0.75

b f'c (600)

fy (600 + fy)

1

= 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b

=

max

= 0.75

b

max

=

min = 0.00506

max = 0.03710

CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00774 >

min = 0.00506

<

max = 0.03710

SINCE

min

<

<

max

THEREFORE USE = 0.00774

STEEL AREA

As

min =

min

b d

As

min =

mm

2

No. OF BARS

As Note: use 20 mm BARS

A

b

N = 3.18 say 4 20 mm BARS

SPACING OF MAINBARS

S = 25.33 mm > 25.00 mm Therefore ok

* POSITIVE MOMENT

M

U

=

M

U

= f'c b d

2

(1-0.59 )

=

min =

b

= 0.85

1

0.04946

2

0.03710

999.06

N =

70.13 kN-m

1 =

427.50 mm

102.007 kN-m

30.155 kN

R

T(A-B) due to loads

+ R

T(A-B) due to wt of beam

1 = 0.94631

2 = 0.05369

1

fc'

2

fc'

fy fy

1

= 0.09463

2

= 0.00537

1.4

fy

min = 0.00506

max

= 0.75

b

f'c (600)

fy (600 + fy)

1

= 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b

=

max

= 0.75

b

max

=

min = 0.00506

max = 0.03710

CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00537 >

min = 0.00506

<

max = 0.03710

SINCE

min

<

<

max

THEREFORE USE = 0.00537

STEEL AREA

As

min =

min

b d

As

min =

mm

2

No. OF BARS

As Note: use 20 mm BARS

A

b

N = 2.20 say 3 20 mm BARS

SPACING OF MAINBARS

S = 48.00 mm > 25.00 mm Therefore ok

CHECK ADEQUACY 300 x 500

M

U

= f'c b d

2

(1-0.59 )

d = say 430 mm

@ NEGATIVE MOMENT

C = T

0.85 f'c a b = As fy

a =

M

U

=

As fy (d - a/2))

M

U

=

> SAFE

@ POSITIVE MOMENT

C = T

0.85 f'c a b = As fy

a =

M

U

=

As fy (d - a/2))

M

U

=

> SAFE

102.02 kN-m 102.01 kN-m

27.16 mm

71.77 kN-m 70.13 kN-m

39.18 mm

=

min =

b

= 0.85

1

0.04946

2

0.03710

692.66

N =

427.50 mm

1 =

6.0 SUMMARY

BEAM DIMENSION : 300 x 500

COVER : 60.00 mm

REBARS

MAINBARS : 20 mm mainbars

TOP :

BOT :

- 3 4 4

- 4 3 3

DISC. END MIDSPAN

CONT. END

@ LEFT @ RIGHT

4

3

CONT. END

@ RIGHT

DESIGN and ANALYSIS OF ROOF BEAM (RB - 6)

ANALYSIS FOR BENDING

* DESIGN CRITERIA

f'c = 27.65 MPa 4,000 psi

fy = 276.46 MPa 40,000 psi

LENGTH (L) = 9.76

LENGTH (s) = 5.12

* DESIGN LOADING

A. REINFORCED CONCRETE : 23.55

kN/m

3

B. DEAD LOAD

* TOPPING : -

kN/m

2

* CEILING : 0.24 kN/m

2

5 psf

* PARTITION : - kN/m

2

* 4" CHB WALL : - kN/m

2

* 6" CHB WALL : - kN/m

2

* CONCRETE SLAB (6") : - kN/m

2

* ROOF TRUSS : 1.44

kN/m

2

30 psf

* CEMENT TILE ROOFING : -

kN/m

2

Note:

ASSUME FLOOR FINISH : -

kN/m

2

CERAMIC TILE 25 mm MORTAR : -

kN/m

2

TOTAL DEAD LOAD : 1.68 kN/m

2

35 psf

C. LIVE LOAD

* ROOF : 0.77 kN/m

2

16 psf

* FLOORS : - kN/m

2

* BALCONY : - kN/m

2

TOTAL LIVE LOAD : 0.77 kN/m

2

16 psf

* DESIGN ANALYSIS

1.0 ULTIMATE LOAD

W

u

=

1.2 DL + 1.6 LL

W

u

= 3.24

* LOAD TRANSFER

@ LONG DIRECTION

P s

6

Wu =

@ SHORT DIRECTION

P s

6

Wu =

CONSIDER LONG DIRECTION

TRIAL SECTION 300 x 500

wt. of beam

=

W

u TOTAL

=

2.0 ULTIMATE MOMENT

* NEGATIVE MOMENT

W

u

L

2

16

M

U

=

* POSITIVE MOMENT

W

u

L

2

14

M

U

=

* TOTAL REACTIONS

WEIGHT OF BEAM

4.239 kN/m

9.774 kN/m

M

U =

16.013 kN-m

M

U =

18.301 kN-m

5.535 kN/m

Wu = (3 - (s/L)

2

Wu = 2

2

7.540 kN/m

m

m

kN/m

2

R

TA

= R

TB =

R

TA

= R

TB =

3.0 REINFORCING STEEL BARS

ASSUME:

= 0.90 bending

d = say 430 mm

b = 300 mm

h = d + cover

cover = 60 mm

* NEGATIVE MOMENT

M

U

=

M

U

= f'c b d

2

(1-0.59 )

1 = 1.68323

2 = 0.01168

1

fc'

2

fc'

fy fy

1

= 0.16832

2

= 0.00117

1.4

fy

min = 0.00506

max = 0.75

b f'c (600)

fy (600 + fy)

1

= 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b

=

max

= 0.75

b

max

=

min = 0.00506

max = 0.03710

CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00117 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA

As

min =

min

b d

As

min =

mm

2

No. OF BARS

As Note: use 20 mm BARS

A

b

N = 2.08 say 3 20 mm BARS

SPACING OF MAINBARS

S = 48.00 mm > 25.00 mm Therefore ok

* POSITIVE MOMENT

M

U

=

M

U

= f'c b d

2

(1-0.59 )

=

min =

b

= 0.85

1

0.04946

2

0.03710

653.25

N =

18.30 kN-m

1 =

427.50 mm

16.01 kN-m

25.021 kN

R

T(A-B) due to loads

+ R

T(A-B) due to wt of beam

1 = 0.98656

2 = 0.01344

1

fc'

2

fc'

fy fy

1

= 0.09866

2

= 0.00134

1.4

fy

min = 0.00506

max

= 0.75

b

f'c (600)

fy (600 + fy)

1

= 0.85 if fc' 30 MPa

if fc' > 30 MPa, 1 = 0.85 - 0.008 (fc' - 30)

but not less than 0.65

b

=

max

= 0.75

b

max

=

min = 0.00506

max = 0.03710

CODE:

IF

min

< <

max USE

IF >

max INCREASE DEPTH OF SLAB

IF <

min

USE

min

= 0.00134 <

min = 0.00506

<

max = 0.03710

SINCE

min

>

<

max

THEREFORE USE

min = 0.00506

STEEL AREA

As

min =

min

b d

As

min =

mm

2

No. OF BARS

As Note: use 20 mm BARS

A

b

N = 2.08 say 3 20 mm BARS

SPACING OF MAINBARS

S = 48.00 mm > 25.00 mm Therefore ok

CHECK ADEQUACY 300 x 500

M

U

= f'c b d

2

(1-0.59 )

d = say 430 mm

@ NEGATIVE MOMENT

C = T

0.85 f'c a b = As fy

a =

M

U

=

As fy (d - a/2))

M

U

=

> SAFE

@ POSITIVE MOMENT

C = T

0.85 f'c a b = As fy

a =

M

U

=

As fy (d - a/2))

M

U

=

> SAFE

67.81 kN-m 16.01 kN-m

25.62 mm

67.81 kN-m 18.30 kN-m

25.62 mm

=

min =

b

= 0.85

1

0.04946

2

0.03710

653.25

N =

427.50 mm

1 =

6.0 SUMMARY

BEAM DIMENSION : 300 x 500

COVER : 60.00 mm

REBARS

MAINBARS : 20 mm mainbars

TOP :

BOT :

3 3 - -

3 3 - -

DISC. END MIDSPAN

CONT. END

@ LEFT @ RIGHT

-

-

CONT. END

@ RIGHT

DESIGN and ANALYSIS OF ROOF BEAM (RB - 1D)

ANALYSIS FOR BENDING

* DESIGN CRITERIA

f'c = 27.65 MPa 4,000 psi

fy = 276.46 MPa 40,000 psi

LENGTH (L) = 5.09

LENGTH (s) = 4.72

* DESIGN LOADING

A. REINFORCED CONCRETE : 23.55

kN/m

3

B. DEAD LOAD

* TOPPING : -

kN/m

2

* CEILING : 0.24 kN/m

2

5 psf

* PARTITION : - kN/m

2

* 4" CHB WALL : - kN/m

2

* 6" CHB WALL : - kN/m

2

* CONCRETE SLAB (6") : - kN/m

2

* ROOF TRUSS : 1.44

kN/m

2

30 psf

* CEMENT TILE ROOFING : -

kN/m

2

Note:

ASSUME FLOOR FINISH : -

kN/m

2

CERAMIC TILE 25 mm MORTAR : -

kN/m

2

TOTAL DEAD LOAD : 1.68 kN/m

2

35 psf

C. LIVE LOAD

* ROOF : 0.77 kN/m

2

16 psf

* FLOORS : - kN/m

2

* BALCONY : - kN/m

2

TOTAL LIVE LOAD : 0.77 kN/m

2

16 psf

* DESIGN ANALYSIS

1.0 ULTIMATE LOAD

W

u

=

1.2 DL + 1.6 LL

W

u

= 3.24

* LOAD TRANSFER

@ LONG DIRECTION

P s

6

Wu =

@ SHORT DIRECTION

P s

6

Wu =

CONSIDER LONG DIRECTION

TRIAL SECTION 300 x 500

wt. of beam

=

W

u TOTAL

=

2.0 ULTIMATE MOMENT

* NEGATIVE MOMENT

W

u

L

2

16

M

U

=

* POSITIVE MOMENT

W

u

L

2

14

M

U

=

* TOTAL REACTIONS

WEIGHT OF BEAM

4.239 kN/m

9.341 kN/m

M

U =

13.007 kN-m

M

U =

14.865 kN-m

5.102 kN/m

Wu = (3 - (s/L)

2

Wu = 2

2

5.460 kN/m

m

m

kN/m

2

R

TA

= R