Escolar Documentos

Profissional Documentos

Cultura Documentos

TC120 PWM/PFM Step-Down Combination Regulator/Controller: Features General Description

Enviado por

Rijal SaifurTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

TC120 PWM/PFM Step-Down Combination Regulator/Controller: Features General Description

Enviado por

Rijal SaifurDireitos autorais:

Formatos disponíveis

TC120-1 7/18/00

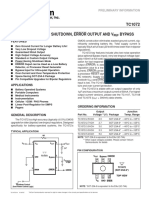

TC120

2001 Microchip Technology Inc. DS21365A

PWM/PFM Step-Down Combination Regulator/Controller

FEATURES

I Internal Switching Transistor Supports 600mA

Output Current

I External Switching Transistor Control for Output

Currents of 2A+

I 300 KHz Oscillator Frequency Supports Small

Inductor Size

I Short Circuit Protection

I Built-In Undervoltage Lockout

I High (95%, Typ) Efficiency

I Automatic Switchover to Current-Saving PFM

Mode at Low Output Loads

I Automatic Output Capacitor Discharge While in

Shutdown

I Programmable Soft-Start Time

I Power-Saving Shutdown Mode

I Small 8-Pin SOP Package

TYPICAL APPLICATIONS

I Portable Test Equipment

I Local Logic Supplies

I Portable Audio Systems

I Portable Scanners

I Palmtops

I Electronic Organizers

GENERAL DESCRIPTION

TC120 is a 300 KHz PFM/PWM step-down (Buck)

DC/DC regulator/controller combination for use in systems

operating from two or more cells, or in line-powered applica-

tions. It uses PWM as the primary modulation scheme, but

automatically converts to PFM at low output loads for greater

efficiency. It requires only an external inductor, Schottky

diode, and two capacitors to implement a step-down con-

verter having a maximum output current of 600 mA (V

IN

=5V,

V

OUT

= 3.3V). An external switching transistor (P-channel

MOSFET) can be added to increase output current capabil-

ity to support output loads of 2A or more.

The TC120 consumes only 55A (max) of supply cur-

rent (V

OUT

= 3.3V) and can be placed in shutdown mode by

bringing the shutdown input (SHDN) low. During shutdown,

the regulator is disabled, supply current is reduced to 2.5

A(max), and V

OUT

is internally pulled to ground, discharg-

ing the output capacitor. Normal operation resumes when

SHDN is brought high. Other features include a built-in

undervoltage lockout (UVLO), an externally programmable

soft start time, and output short circuit protection. The TC120

operates from a maximum input voltage of 10V and is

available in a low-profile 8-Pin SOP package.

TYPICAL APPLICATION

PIN CONFIGURATION

ORDERING INFORMATION

Part No. Output Package Temperature

Voltage (V) Range

TC120303EHA 3.0 8-Pin SOP 40C to +85C

TC120333EHA 3.3 8-Pin SOP 40C to +85C

TC120503EHA 5.0 8-Pin SOP 40C to +85C

TC120

VIN

EXTW

CPC

SHDN/SS

LX

EXT

GND

SENSE

47 F/16V

Tantalum

CSS

4.7 nF

IN5817

L1

22 H

VOUT = 3V

VIN = 5V

COUT

47 F/10V

Tantalum

5V to 3.0V, 500 mA Step-Down Converter

1

2

3

4

8

7

6

5

TC120

8-Pin SOP

EXTW

CPC

SHDN/SS

V

IN

GND

EXT

SENSE

L

X

2

PWM/PTM Step-Down Combination

Regulator/Controller

TC120

TC120-1 7/18/00

2001 Microchip Technology Inc. DS21365A

ABSOLUTE MAXIMUM RATINGS*

Power Supply Voltage (V

IN

) ....................... 0.3V to +12V

Voltage on V

OUT

Pin................................... 0.3V to +12V

Voltage on LX, Boost Pins ...... (V

IN

12V) to (V

IN

+ 0.3V)

Voltage on EXT1, EXT2, SHDN Pins

................................................ (0.3V) to (V

IN

+ 0.3V)

L

X

Pin Current ........................................................700mA

EXT1, EXT2 Pin Current ........................................ 50mA

Continuous Power Dissipation .............................. 300mW

ELECTRICAL CHARACTERISTICS: (Test Circuit of Figure 1, T

A

= 25C, V

IN

=V

R

x 1.2, Note 1, unless other-wise noted)

Symbol Parameter Test Conditions Min Typ Max Unit

V

OUT

Output Voltage V

R

= 3.0, I

OUT

=120mA (Note 1) V

R

x 0.975 V

R

0.5% V

R

x 1.025 V

V

R

= 3.3, I

OUT

=132mA

V

R

= 5.0, I

OUT

=200mA

V

IN

Input Voltage 1.8 10 V

I

OUT(MAX)

Maximum Output Current V

OUT

= 3.0V 500 mA

V

OUT

= 3.3V 600

V

OUT

= 5.0V 600

I

IN

Supply Current V

IN

= V

R

x 1.05, V

OUT

= 3.0V 52 82 A

No Load V

OUT

= 3.3V 55 86

V

OUT

= 5.0V 71 110

I

SHDN

Shutdown Supply Current (Note 2), 1.5 2.5 A

No Load, SHDN = 0V

I

LX

LX Pin Leakage Current Measured at EXT 1 Pin (Note 2) 2 A

No Load, SHDN = 0V 1.5 2.5

R

DSON(LX)

LX Pin ON Resistance V

OUT

= V

R

x 0.9 (Note 2) V

OUT

= 3.0V 0.69 0.94

V

LX

= V

IN

0.2V, 10 V

OUT

= 3.3V 0.64 0.85

Resistor from L

X

to V

IN

, V

OUT

= 5.0V 0.44 0.58

SHDN = V

IN

R

EXTH

EXT1, EXT2 (Note 2); V

OUT

= 3.0V 38 52

On Resistance to V

IN

SHDN = V

IH

; EXT1 and V

OUT

= 3.3V 35 47

EXT 2 connected to V

OUT

= 5.0V 24 32

200 load, V

EXT1

=

V

EXT2

= (V

IN

0.4V);

V

OUT

= V

IN

R

EXTL

EXT1, EXT2 (Note 2); V

OUT

= 3.0V 31 41

On Resistance to GND SHDN = V

IH

; EXT1 and V

OUT

= 3.3V 29 37

EXT2 pulled up through V

OUT

= 5.0V 20 26

a series resistance of

200 to a voltage such

that VEXT1, 2 = 0.4V

f

OSC

Oscillator Frequency Measured at EXT1 Pin, V

IN

= V

OUT

+0.3V, 255 300 345 KHz

I

OUT

= 20mA, (Note 3)

D

PWM

Maximum PWM Duty Cycle 100 %

D

PFM

PFM Duty Cycle No Load 15 25 35 %

Efficiency V

IN

> V

R

x 1.2 95 %

Operating Temperature (T

C

) ...................... 40C to 85C

Storage Temperature (T

STG

) .................... 40C to 150C

*Static-sensitive device. Unused devices must be stored in conductive

material. Protect devices from static discharge and static fields. Stresses

above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. These are stress ratings only and functional

operation of the device at these or any other conditions above those

indicated in the operational sections of the specifications is not implied.

Exposure to Absolute Maximum Rating Conditions for extended periods

may affect device reliability.

3

TC120

PWM/PTM Step-Down Combination

Regulator/Controller

TC120-1 7/18/00 2001 Microchip Technology Inc. DS21365A

ELECTRICAL CHARACTERISTICS: (Test Circuit of Figure 1, T

A

= 25C, V

IN

=V

R

x 1.2, Note 1, unless other-wise noted)

Symbol Parameter Test Conditions Min Typ Max Unit

V

UVLO

Minimum Operating Voltage V

OUT

= V

R

x 0.9 (Note 2), SHDN = V

IN

0.9 1.8 V

Measured with internal transistor in OFF

state and V

IN

falling.

V

IH

SHDN Input Logic High (Note 2), V

OUT

= 0V 0.65 V

Threshold Voltage

V

IL

SHDN Input Logic Low (Note 2), V

OUT

= 0V 0.2 V

Threshold Voltage

t

PRO

Short Circuit Protection (Note 2) Time from V

OUT

= 0V to 3 5 8 msec

Response Time SHDN = V

IL

t

SS

Soft Start Time 6 10 16 msec

Notes: 1. V

R

is the factory-programmed output voltage setting.

2. No external components connected, except C

SS

.

3. While operating in PWM Mode.

PIN DESCRIPTION

Pin Number Name Description

1 V

IN

Unregulated Supply Input.

2 EXTW Extended External Switching Transistor Drive Output. This output follows the timing on the

EXT output with an additional 100nsec blanking time on both the leading and trailing edges.

That is, this output transitions from high-to-low 100nsec prior to the same transition on EXT;

and transitions low-to-high 100nsec after the same transition on EXT; resulting in a longer

external switch ON time. (See Operation as a Regulator Controller for more information).

3 CPC Charge Pump Capacitor Input. An inverting charge pump is formed by attaching a capacitor

and diode to this input (please see Improving High Load Efficiency In Regulator

Operating Mode section).

4 SHDN/SS Shutdown and Soft-Start Control Input. A soft start capacitor of 100pF (min) must be

connected to this input. The soft start capacitor is charged by an internal 1A current source

that gently ramps the TC120 into service. Shutdown control is best implemented with an

external open collector (or open drain) switch. The TC120 enters shutdown when this input is

low. During shutdown, the regulator is disabled, and supply current is reduced to less than

2.5 A. Normal operation is restored when this input is open-circuited, and allowed to float

high. Please see SHDN/SS section for details.

5 SENSE Voltage Sense Input. This input must be connected to the output voltage node at the

physical location that requires the tightest voltage regulation.

6 GND Ground Terminal.

7 EXT External Switching Transistor Drive Output. This output connects directly to the gate of an

external P-channel MOSFET for applications requiring output currents greater than 600mA.

The timing of this output exactly matches that of the gate drive for the internal P-channel

transistor. This output can drive a maximum capacitance of 1000 pF. (See Operation as a

Regulator Controller for more information).

8 L

X

Inductor Terminal. This pin is connected to the drain of the internal P-channel switching

transistor. If the TC120 is operated as a regulator (i.e. using the internal switch); the inductor

must be connected between this pin and the SENSE pin.

4

PWM/PTM Step-Down Combination

Regulator/Controller

TC120

TC120-1 7/18/00

2001 Microchip Technology Inc. DS21365A

DETAILED DESCRIPTION

The TC120 can be operated as an integrated step-down

regulator (using the internal switching transistor); or as a

step-down regulator controller (using an external switching

transistor). When operating as an integrated regulator, the

only required external components are a Shottky diode,

inductor and an output capacitor. Operating in this configu-

ration, the TC120 is capable of supporting output load

currents to a maximum of 600 mA with operating efficiencies

above 85%. (Efficiencies at high loads can be further im-

proved by using the on-board charge pump circuit to pull the

gate of the internal switching transistor below ground for the

lowest possible ON resistance. For more information, see

Improving High Load Efficiency in Regulator Operating

Mode section).

Higher output currents are achieved by operating the

TC120 with an external P-Channel switching transistor

(Controller mode). In this operating configuration, the maxi-

mum output current is determined primarily by the ON

resistance of the P-Channel switch and the series resis-

tance of the inductor.

Inductor Selection

Selecting the proper inductor value is a trade-off be-

tween physical size and power conversion requirements.

Lower value inductors cost less, but result in higher ripple

current and core losses. They are also more prone to

saturate since the coil current ramps faster and could

overshoot the desired peak value. This not only reduces

efficiency, but could also cause the current rating of the

external components to be exceeded. Larger inductor val-

ues reduce both ripple current and core losses, but are

larger in physical size and tend to increase the start-up time

slightly. A 22 H inductor is the best overall compromise and

is recommended for use with the TC120. For highest effi-

ciency, use inductors with a low DC resistance (less than 20

m). To minimize radiated noise, consider using a toroid,

pot core or shielded-bobbin inductor.

Input Bypass Capacitor

Using an input bypass capacitor reduces peak current

transients drawn from the input supply, and reduces the

switching noise generated by the regulator. The source

impedance of the input supply determines the size of the

capacitor that should be used.

Output Capacitor

The effective series resistance of the output capacitor

directly affects the amplitude of the output voltage ripple.

(The product of the peak inductor current and the ESR

determines output ripple amplitude.) Therefore, a capacitor

with the lowest possible ESR should be selected. Smaller

capacitors are acceptable for light loads or in applications

where ripple is not a concern. A 47 F Tantalum capacitor is

recommended for most applications. The Sprague 595D

series of tantalum capacitors are amongst the smallest of all

low ESR surface mount capacitors available. Table 1 lists

suggested component numbers and manufacturers.

Catch Diode

The high operating frequency of the TC120 requires a

high-speed diode. Schottky diodes such as the MA737 or

1N5817 through 1N5823 (and the equivalent surface mount

versions) are recommended. Select a diode whose average

current rating is greater than the peak inductor current; and

whose voltage rating is higher than V

IN(MAX)

.

Improving High Load Efficiency in Regulator

Operating Mode

If the TC120 is operated at high output loads most (or all)

of the time, efficiency can be improved with the addition of

two components. Ordinarily, the voltage swing on the gate

of the internal P-Channel transistor is from ground to V

IN

. By

adding a capacitor and diode as shown in Figure 3, an

inverting charge pump is formed, enabling the internal gate

voltage to swing from a negative voltage to +V

IN

. This

increased drive lowers the R

DS(ON)

of the internal transistor,

improving efficiency at high output currents. Care must be

taken to ensure the voltage measured between V

IN

and CPC

does not exceed an absolute value of 10V. While this is not

a problem at values of V

IN

at (or below) 5V, higher V

IN

values

will require the addition of a clamping mechanism (such as

a Zener diode) to limit the voltage as described. While this

technique improves efficiency at high output loads, it is at the

expense of low load efficiency because energy is expended

charging and discharging the charge pump capacitor. This

technique is therefore not recommended for applications

that operate the TC120 at low output currents for extended

time periods. If unused, CPC must be grounded.

Figure 1. Test Circuit

TC120xx03

VIN

EXTW

CPC

SHDN/SS

LX

EXT

GND

SENSE

47 F/10V

Tantalum

CSS

4.7 nF

IN5817

L1

22 H

VOUT VIN

COUT

47 F/10V

Tantalum

5

TC120

PWM/PTM Step-Down Combination

Regulator/Controller

TC120-1 7/18/00 2001 Microchip Technology Inc. DS21365A

Low Power Shutdown Mode/Soft Start Input

The SHDN/SS input acts as both the shutdown control

and the node for the external soft start capacitor, which is

charged by an internal 1 A current source. A value of 4700

pF (100 pF minimum) is recommended for the soft start

capacitor. IFailure to do this may cause large overshoot

voltages and/or large inrush currents resulting in possible

instability. The TC120 enters a low power shutdown mode

when SHDN/SS is brought low. While in shutdown, the

oscillator is disabled and the output discharge switch is

turned on, discharging the output capacitor. Figure 4 shows

the recommended interface circuits to the SHDN/SS input.

As shown, the SHDN/SS input should be controlled using an

open collector (or open drain) device, such that the SHDN/

SS input is grounded for shutdown mode, and open-cir-

cuited for normal operation (Figure 5a). If a CMOS device is

used to control shutdown (Figure 5b), the value of R1 and

C

SS

should be chosen such that the voltage on SHDN/SS

rises from ground to 0.65V in 1.5 msec (Figure 6).

If shutdown is not used, C

SS

must still be connected as

shown i n Fi gures 5c and 5d. SHDN/SS may

be pulled up with a resistor (Figure 5c) as long as the values

of R

SS

and C

SS

provide the approximate charging

characteristic on power up shown in Figure 6. C

SS

only may

also be connected as shown in Figure 5d with C

SS

chosen

at 4700 pF (minimum 100 pF).

Undervoltage Lockout (UVLO)

The TC120 is disabled whenever V

IN

is below the

undervoltage lockout threshold. This threshold is equal to

the guaranteed minimum operating voltage for the TC120

(i.e. 2.2V). When UVLO is active, the TC120 is completely

disabled.

Short Circuit Protection

Upon detection of an output short circuit condition, the

TC120 reduces the PWM duty cycle to a minimum value

using its internal protection timer. The sequence of events is

as follows: when an output voltage decrease to near zero is

detected (as the result of an overload), the internal (5 msec)

protection timer is started. If the output voltage has not

recovered to nominal value prior to the expiration of the

protection timer, the TC120 is momentarily shut down by

dedicated, internal circuitry. Immediately following this ac-

tion, the soft start sequence is engaged in an attempt to re-

start the TC120. If the output short circuit is removed, normal

operation is automatically restored. If the short circuit is still

present, the timed self-shutdown sequence described above

is repeated.

Operation as a Regulator Controller

External Switching Transistor Selection

EXT is a complimentary output with a maximum ON

resistances of 32 to V

DD

when high and 26 to ground

when low, at V

OUT

= 5V. It is designed to directly drive a P-

channel MOSFET (Figure 7). The P-channel MOSFET

selection is determined mainly by the on-resistance, gate-

source threshold and gate charge requirements. Also, the

drain-to-source and gate-to-source breakdown voltage rat-

ings must be greater than V

IN(MAX)

. The total gate charge

specification should be less than 100 nC for best efficiency.

The MOSFET must be capable of handling the required

peak inductor current, and should have a very low on-

resistance at that current. For example, a Si9430 MOSFET

has a drain-to-source rating of 20V, and a typical on-

resistance r

DS(ON)

of 0.07 at 2A, with V

GS

= 4.5V. (EXTW

(Figure 8) may be gated with external circuitry to add

blanking, or as an auxiliary timing signal.) Table A lists

suppliers of external components recommended for use

with the TC120.

Board Layout Guidelines

As with all inductive switching regulators, the TC120

generates fast switching waveforms, which radiate noise.

Interconnecting lead lengths should be minimized to keep

stray capacitance, trace resistance and radiated noise as

low as possible. In addition, the GND pin, input bypass

capacitor and output filter capacitor ground leads should be

connected to a single point. The input capacitor should be

placed as close to power and ground pins of the TC120 as

possible. The length of the EXT trace must also be kept as

short as possible.

6

PWM/PTM Step-Down Combination

Regulator/Controller

TC120

TC120-1 7/18/00

2001 Microchip Technology Inc. DS21365A

Figure 2. TC120 Typical Application

Figure 3. TC120 with Added Components for Improved Efficiency at High Output Currents

TC120xx03

V

IN

EXTW

CPC

SHDN/SS

L

X

EXT

GND

SENSE

C

IN

D1

L1

V

OUT V

IN

C

OUT

C

SS

4.7 nF

TC120xx03

VIN

EXTW

CPC

SHDN/SS

LX

EXT

GND

SENSE

D1

IN5817

a) For VIN 5V

CP

2200 pF

Ceramic

TC120xx03

VIN

EXTW

CPC

SHDN/SS

LX

EXT

GND

SENSE

D1

IN5817

b) For VIN > 5V

CP

2200 pF

Ceramic

10V

Zener

Diode

VIN 5V VIN > 5V

7

TC120

PWM/PTM Step-Down Combination

Regulator/Controller

TC120-1 7/18/00 2001 Microchip Technology Inc. DS21365A

2

IN5817

2N2222A

47K

EXTW NC

SHUTDOWN

CONTROL

J1

J4

CHARGE PUMP

10V

ZENER

3

4

TC120

1 8

5

6

7

V

IN

47F

16V

Tantalum

22H

47F

10V

V

IN

UI

V

IN

V

IN

V

OUT

EXT

W

CSS

4700pF

2200pF

IN5817

SWITCHING

TRANSISTOR

J2

CPC

SENSE

GND

EXT

LX

IN OUT

INT EXT

SHDN/SS

J3

CHARGE

PUMP

P-Channel

Mosfet

C3

C1

D1

D2

Q1

Q2

D3

L1

C2

R1

TC120 Demo Board

The TC120 DEMO allows the user to quickly prototype

TC120-based circuits. The TC120 DEMO consists of a

printed circuit board and TC120. The Schottky diodes, zener

diode, input capacitor, output capacitor, charge pump ca-

pacitor, external P-channel FET switch, NPN transistor (for

shutdown), soft-start capacitor (C

SS

), and 22H inductor

may be selected by the design engineer utilizing the compo-

nent selection criteria previously discussed as well as the

suggested components in Table 1. The circuit schematic

appears in Figure 4.

Jumper block J1 controls shutdown by: 1) connecting

to V

IN

to shut down the TC120 (NOTE: the TC120s soft-start

feature is disabled in this mode), or 2) connecting to Ground

to enable the TC120. Capacitor C

SS

allows the TC120 to

power on in a soft-start mode. Connecting jumper block J2

to INT disables the gate drive to the external P-channel

MOSFET and the TC120s internal switching transistor is

used to control the output. The internal transistor of the

TC120 can be used for output loads up to 600 mA. Connect-

ing J2 to EXT and J3 to OUT (NOTE: Both of these

connections are required to drive the external P-chan-

nel FET) allows the user to enable the gate drive to the

external P-channel MOSFET to drive higher current output

loads (up to 2 amps).

Connecting jumper block J3 to IN enables an inverting

charge pump (via external components D2 and C3) in the

TC120 that improves the efficiency of the device at higher

loads when the internal switch of the TC120 is used (for

loads up to 600 mA). An inverting charge pump is formed in

this configuration which increases the internal transistors

gate voltage (from a negative voltage to VIN) to lower the ON

resistance of the internal switching transistor. Connecting

jumper block J4 to EXTW allows for an extended external

gate drive to the P-channel FET (see Figure 8). In this

mode, the FET will turn on about 100 nsec earlier and remain

on about 100 nsec later than int he normal external switching

mode.

Figure 4. DEMO Board Schematic

8

PWM/PTM Step-Down Combination

Regulator/Controller

TC120

TC120-1 7/18/00

2001 Microchip Technology Inc. DS21365A

Figure 5. Shutdown Control Circuits

SHDN/SS

TC120xx03

CSS

SHDN/SS

TC120xx03

CSS

SHDN/SS

TC120xx03

CSS

4.7 nF

SHDN/SS

TC120xx03

RSS

VIN

SHDN

ON

OFF

SHDN

ON

OFF

47K

2N2222

C

SS

4.7 nF

R1

VIN

CMOS

Gate

a) Using an Open Collector Device b) Using a Complementary Output Device

c) Shutdown Not Used with Pull-Up d) Shutdown Not Used No Pull-Up

The Table below summarizes the jumper connections

for different modes of operation of the TC120.

MODE J1 J2 J3 J4

Shutdown V

IN

Internal Switching without Inverting Charge Pump GROUND INT OPEN OPEN

Internal Switching with Inverting Charge Pump GROUND INT IN OPEN

Normal External Switching (Via EXT) GROUND EXT OUT OPEN

Extended External Switching (Via EXT

W

) GROUND EXT OPEN EXTW

9

TC120

PWM/PTM Step-Down Combination

Regulator/Controller

TC120-1 7/18/00 2001 Microchip Technology Inc. DS21365A

Figure 6. Soft Start Timing Figure 7. Using External Transistor Switch

Figure 8. External (EXT) and Extended External (EXTW) Switching Transistor Drive Output

OFF

ON

0.65V

0V

1.5 msec

SHDN/SS

Shutdown

Signal

X

EXT

EXTW

100 nsec 100 nsec

TC120xx03

VIN

EXTW

CPC

SHDN/SS

LX

EXT

GND

SENSE

CSS

4.7 nF

IN5817

L1

22 H

VOUT

VIN

CIN

47 F

Tantalum

COUT

47 F

Tantalum

10

PWM/PTM Step-Down Combination

Regulator/Controller

TC120

TC120-1 7/18/00

2001 Microchip Technology Inc. DS21365A

Table 1. Suggested Components and Manufacturers

Type Inductors Capacitors Diodes Transistors

Surface Mount Sumida AVX Motorola Silconix

CD54 Series TPS Series MBRS340T3 Little Foot MOSFET Series

CDRH Series

Sprague NiHon Zetex FZT749

Coilcraft 595D Series NSQ Series PNP Bipolar Transistor

DO Series

Matsushita Toshiba 2SA1213 PNP

MA737 Transistor

Miniature Sumida Sanyo IRC

Through Hole RCH Series OS-CON Series OAR Series

Standard Coilcraft Nichicon Motorola

Through-Hole PCH Series PL Series TMOS Power MOSFETs

United Chemi-Con

LXF Series

TAPING DIAGRAM

PIN 1

PIN 1

Component Taping Orientation for 8-Pin SOP

User Direction of Feed User Direction of Feed

Standard Reel Component Orientation

for 713 or TR Suffix Device

Reverse Reel Component Orientation

for 723 or RT Suffix Device

W = Width

of Carrier

Tape

P = Pitch

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

8-Pin SOP 12 mm 8.0 mm 1000 7 in

Carrier Tape, Reel Size, and Number of Components Per Reel

11

TC120

PWM/PTM Step-Down Combination

Regulator/Controller

TC120-1 7/18/00 2001 Microchip Technology Inc. DS21365A

PACKAGE DIMENSIONS

Dimensions: inches (mm)

8-Pin SOP

.181 (4.60)

.165 (4.20)

.217 (5.50)

.193 (4.90)

.069 (1.75)

.055 (1.40)

.008 (0.20)

.000 (0.00)

.020 (0.50)

.012 (0.30)

.256 (6.50)

.232 (5.90)

PIN 1

.010 (0.25)

.004 (0.10)

.018 (0.45)

.014 (0.35)

8 MAX.

.051 (1.30)

.049 (1.24)

12

PWM/PTM Step-Down Combination

Regulator/Controller

TC120

TC120-1 7/18/00

2001 Microchip Technology Inc. DS21365A

Information contained in this publication regarding device applications and the like is intended through suggestion only and may be superseded by

updates. It is your responsibility to ensure that your application meets with your specifications. No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect to the accuracy or use of such information, or infringement of patents or other intellectual

property rights arising from such use or otherwise. Use of Microchips products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, except as maybe explicitly expressed herein, under any intellec-

tual property rights. The Microchip logo and name are registered trademarks of Microchip Technology Inc. in the U.S.A. and other countries. All rights

reserved. All other trademarks mentioned herein are the property of their respective companies.

All rights reserved. 2001 Microchip Technology Incorporated. Printed in the USA. 1/01 Printed on recycled paper.

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Rocky Mountain

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-7456

Atlanta

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640-0307

Austin

Analog Product Sales

8303 MoPac Expressway North

Suite A-201

Austin, TX 78759

Tel: 512-345-2030 Fax: 512-345-6085

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692-3848 Fax: 978-692-3821

Boston

Analog Product Sales

Unit A-8-1 Millbrook Tarry Condominium

97 Lowell Road

Concord, MA 01742

Tel: 978-371-6400 Fax: 978-371-0050

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818-7423 Fax: 972-818-2924

Dayton

Two Prestige Place, Suite 130

Miamisburg, OH 45342

Tel: 937-291-1654 Fax: 937-291-9175

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263-1338

Mountain View

Analog Product Sales

1300 Terra Bella Avenue

Mountain View, CA 94043-1836

Tel: 650-968-9241 Fax: 650-967-1590

New York

150 Motor Parkway, Suite 202

Hauppauge, NY 11788

Tel: 631-273-5305 Fax: 631-273-5335

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Canada

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

China - Beijing

Microchip Technology Beijing Office

Unit 915

New China Hong Kong Manhattan Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85282100 Fax: 86-10-85282104

China - Shanghai

Microchip Technology Shanghai Office

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-6275-5700 Fax: 86-21-6275-5060

Hong Kong

Microchip Asia Pacific

RM 2101, Tower 2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401-1200 Fax: 852-2401-3431

India

Microchip Technology Inc.

India Liaison Office

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, OShaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Microchip Technology Intl. Inc.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea

Tel: 82-2-554-7200 Fax: 82-2-558-5934

ASIA/PACIFIC (continued)

Singapore

Microchip Technology Singapore Pte Ltd.

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-334-8870 Fax: 65-334-8850

Taiwan

Microchip Technology Taiwan

11F-3, No. 207

Tung Hua North Road

Taipei, 105, Taiwan

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

Australia

Microchip Technology Australia Pty Ltd

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

Denmark

Microchip Technology Denmark ApS

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45 4420 9895 Fax: 45 4420 9910

France

Arizona Microchip Technology SARL

Parc dActivite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Germany

Arizona Microchip Technology GmbH

Gustav-Heinemann Ring 125

D-81739 Munich, Germany

Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Germany

Analog Product Sales

Lochhamer Strasse 13

D-82152 Martinsried, Germany

Tel: 49-89-895650-0 Fax: 49-89-895650-22

Italy

Arizona Microchip Technology SRL

Centro Direzionale Colleoni

Palazzo Taurus 1 V. Le Colleoni 1

20041 Agrate Brianza

Milan, Italy

Tel: 39-039-65791-1 Fax: 39-039-6899883

United Kingdom

Arizona Microchip Technology Ltd.

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshire, England RG41 5TU

Tel: 44 118 921 5869 Fax: 44-118 921-5820

01/09/01

WORLDWIDE SALES AND SERVICE

Você também pode gostar

- Analog Circuit Design Volume Three: Design Note CollectionNo EverandAnalog Circuit Design Volume Three: Design Note CollectionNota: 3 de 5 estrelas3/5 (2)

- TCK101G, TCK102G: 1A Load Switch IC With Slew Rate Control DriverDocumento12 páginasTCK101G, TCK102G: 1A Load Switch IC With Slew Rate Control DriverLuis OliveiraAinda não há avaliações

- TC1072 50ma Cmos Ldo With Shutdown, Error Output and V BypassDocumento12 páginasTC1072 50ma Cmos Ldo With Shutdown, Error Output and V BypassΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣAinda não há avaliações

- Bit3193g PDFDocumento10 páginasBit3193g PDFh.keulder1480Ainda não há avaliações

- Dual Half Bridge Driver: Multipower BCD TechnologyDocumento9 páginasDual Half Bridge Driver: Multipower BCD TechnologyDan EsentherAinda não há avaliações

- LMD 18200Documento14 páginasLMD 18200Itzamary Romero SosaAinda não há avaliações

- RSP 3000 SpecDocumento6 páginasRSP 3000 SpecGrigoriu CodrutaAinda não há avaliações

- Mach Cong Suat Cau H - Lmd18200Documento14 páginasMach Cong Suat Cau H - Lmd18200hieuhuech1Ainda não há avaliações

- LMD18201 3A, 55V H-Bridge: Literature Number: SNVS092CDocumento14 páginasLMD18201 3A, 55V H-Bridge: Literature Number: SNVS092CIrfan AbbasiAinda não há avaliações

- Line Regulator Controller: Features General DescriptionDocumento16 páginasLine Regulator Controller: Features General DescriptionfuzulibabaAinda não há avaliações

- TSM 101Documento15 páginasTSM 101thiemncAinda não há avaliações

- Features General Description: Advanced Dual PWM and Dual Linear Power ControllerDocumento13 páginasFeatures General Description: Advanced Dual PWM and Dual Linear Power ControllerbehzadAinda não há avaliações

- Fan 6961Documento13 páginasFan 6961Ariel NavarreteAinda não há avaliações

- L4972ADocumento23 páginasL4972ARICHIHOTS2Ainda não há avaliações

- LB 11961Documento7 páginasLB 11961Ayala Eduardo La San RamonAinda não há avaliações

- Ltc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching RegulatorsDocumento28 páginasLtc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching Regulatorscatsoithahuong84Ainda não há avaliações

- IC 3842 para FonteDocumento8 páginasIC 3842 para FonteTomNedscAinda não há avaliações

- ZXSC410 420Documento12 páginasZXSC410 420Catalin TirtanAinda não há avaliações

- 3000W Single Output Power Supply: SeriesDocumento7 páginas3000W Single Output Power Supply: SeriesAlexander PekarovskiyAinda não há avaliações

- Thb7128 InstructionsDocumento9 páginasThb7128 InstructionsanhxcoAinda não há avaliações

- Linear Technology LTC3728EG28400Documento37 páginasLinear Technology LTC3728EG28400Rickz2k8Ainda não há avaliações

- A 2918 SW Data SheetDocumento8 páginasA 2918 SW Data SheetGustavo LunaAinda não há avaliações

- 5101 Motor DriverDocumento11 páginas5101 Motor DriverMoise CristinaAinda não há avaliações

- LTC 7138Documento24 páginasLTC 7138MallickarjunaAinda não há avaliações

- PT4115EDocumento18 páginasPT4115Edragom2Ainda não há avaliações

- LMD18201 3A, 55V H-Bridge: General DescriptionDocumento8 páginasLMD18201 3A, 55V H-Bridge: General DescriptionNairo FilhoAinda não há avaliações

- DatasheetDocumento13 páginasDatasheetadixadrianAinda não há avaliações

- FaDocumento20 páginasFaVishwanath ShervegarAinda não há avaliações

- Uc3842b 3843BDocumento10 páginasUc3842b 3843Bbob75Ainda não há avaliações

- SG 3524Documento10 páginasSG 3524Akhlaque ShamsiAinda não há avaliações

- Datasheet PJ494Documento11 páginasDatasheet PJ494Achmad Rifdatul HisanAinda não há avaliações

- Aerosemi: Features ApplicationsDocumento9 páginasAerosemi: Features Applicationsttnaing100% (1)

- PT4115 89eDocumento15 páginasPT4115 89eAnonymous aDAfzvAinda não há avaliações

- PWM Control 1A Step-Down Converter Data Sheet: TM Technology IncDocumento12 páginasPWM Control 1A Step-Down Converter Data Sheet: TM Technology IncselocaAinda não há avaliações

- Ncl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsDocumento10 páginasNcl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsKhúc Hành QuânAinda não há avaliações

- Green Mode PWM Controller Ap384XgDocumento13 páginasGreen Mode PWM Controller Ap384XgbaphometabaddonAinda não há avaliações

- Data SheetDocumento10 páginasData SheetselocaAinda não há avaliações

- 500 Ma Synchronous Buck Regulator, + 300 Ma LDO With Power-Good OutputDocumento30 páginas500 Ma Synchronous Buck Regulator, + 300 Ma LDO With Power-Good OutputppanagosAinda não há avaliações

- Wide Input Voltage 3.0 A Step Down Regulator: Features and Benefits DescriptionDocumento10 páginasWide Input Voltage 3.0 A Step Down Regulator: Features and Benefits Descriptioncdan99Ainda não há avaliações

- FAN7602B Green Current-Mode PWM Controller: Features DescriptionDocumento17 páginasFAN7602B Green Current-Mode PWM Controller: Features DescriptionNichole RollinsAinda não há avaliações

- Uc2577 AdjDocumento14 páginasUc2577 AdjChandranoola RajuAinda não há avaliações

- Ltc1871ems (LTSX, Frntoluz Welch Allyn)Documento36 páginasLtc1871ems (LTSX, Frntoluz Welch Allyn)RICHIHOTS2Ainda não há avaliações

- XX3842 Series FunctionDocumento7 páginasXX3842 Series FunctionbernabethAinda não há avaliações

- SG3525A Pulse Width Modulator Control Circuit: 1% and The ErrorDocumento10 páginasSG3525A Pulse Width Modulator Control Circuit: 1% and The ErrorJayesh SuryavanshiAinda não há avaliações

- Miniature, Low-Voltage, Precision Step-Down Controller: General Description - FeaturesDocumento20 páginasMiniature, Low-Voltage, Precision Step-Down Controller: General Description - Featurescatsoithahuong84Ainda não há avaliações

- High Efficiency Low-Side N-Channel Controller For Switching RegulatorsDocumento33 páginasHigh Efficiency Low-Side N-Channel Controller For Switching Regulatorssoft4gsmAinda não há avaliações

- Dual Quick-PWM Step-Down Controller With Low-Power LDO and RTC Regulator For MAIN SuppliesDocumento24 páginasDual Quick-PWM Step-Down Controller With Low-Power LDO and RTC Regulator For MAIN SuppliesReklama BielskoAinda não há avaliações

- NCP349 Positive Overvoltage Protection Controller With Internal Low R Nmos FetDocumento12 páginasNCP349 Positive Overvoltage Protection Controller With Internal Low R Nmos Fetjmathew_984887Ainda não há avaliações

- Solare DatasheetDocumento25 páginasSolare Datasheetfb1145Ainda não há avaliações

- LM2852 Synchronous BuckDocumento14 páginasLM2852 Synchronous BuckAndrew CavanaughAinda não há avaliações

- STCC05-B: Home Appliance Control CircuitDocumento13 páginasSTCC05-B: Home Appliance Control Circuitsvhanu4010Ainda não há avaliações

- DatasheetDocumento15 páginasDatasheetUngureanu VasileAinda não há avaliações

- 34063A Dc-To-Dc Converter Control Circuits: Features Functional Block DiagramDocumento3 páginas34063A Dc-To-Dc Converter Control Circuits: Features Functional Block DiagramJuanito Naxito Jebus ArjonaAinda não há avaliações

- D Escriptio: S FeatureDocumento8 páginasD Escriptio: S Featurevsc2012Ainda não há avaliações

- Microstepping DMOS Driver With Translator: Description Features and BenefitsDocumento18 páginasMicrostepping DMOS Driver With Translator: Description Features and BenefitsSaid BoubkerAinda não há avaliações

- Tea 2262Documento9 páginasTea 2262Pablo RiseAinda não há avaliações

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Ainda não há avaliações

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1No EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Nota: 2.5 de 5 estrelas2.5/5 (3)

- 1SBN010040R1122 Ca5 22m Auxiliary Contact BlockDocumento3 páginas1SBN010040R1122 Ca5 22m Auxiliary Contact BlockRijal SaifurAinda não há avaliações

- Sump Pump WiringDocumento1 páginaSump Pump WiringRijal SaifurAinda não há avaliações

- UltraxperiaDocumento1 páginaUltraxperiaRijal SaifurAinda não há avaliações

- Umur BearingDocumento1 páginaUmur BearingRijal SaifurAinda não há avaliações

- Instanaous AdalahDocumento4 páginasInstanaous AdalahRijal SaifurAinda não há avaliações

- Data Sheet At8535Documento22 páginasData Sheet At8535priyoAinda não há avaliações

- BC 184Documento3 páginasBC 184Rijal SaifurAinda não há avaliações

- Active PFC Dari WikipediaDocumento1 páginaActive PFC Dari WikipediaRijal SaifurAinda não há avaliações

- Tisyh: UyniiaiflsDocumento1 páginaTisyh: UyniiaiflsRijal SaifurAinda não há avaliações

- 12 Electricity and Magnetisium - 1Documento33 páginas12 Electricity and Magnetisium - 1Harsh GuptaAinda não há avaliações

- SR2/SR3 Series: 3-Phase, Detachable/Integrated Heatsink Type SSRDocumento8 páginasSR2/SR3 Series: 3-Phase, Detachable/Integrated Heatsink Type SSRaldo peñaAinda não há avaliações

- GM24-SR Damper Actuator 30 NMDocumento1 páginaGM24-SR Damper Actuator 30 NMMatias ZarateAinda não há avaliações

- Case Study Ifa 2000 France Uk HVDC Transmission LinkDocumento4 páginasCase Study Ifa 2000 France Uk HVDC Transmission LinkTetianaAinda não há avaliações

- Belden 4-0 95mm DatashetDocumento3 páginasBelden 4-0 95mm DatashetMiroslaw LabudaAinda não há avaliações

- HPV 600 AC Elevator Drive: Technical ManualDocumento172 páginasHPV 600 AC Elevator Drive: Technical ManualShadi MattarAinda não há avaliações

- Sonic Bomb Alarm Clock User ManualDocumento5 páginasSonic Bomb Alarm Clock User ManualZariab KhanAinda não há avaliações

- KXFL403EXDocumento272 páginasKXFL403EXasdref100% (1)

- EcoGo 1.1 17-11-15Documento31 páginasEcoGo 1.1 17-11-15prasadAinda não há avaliações

- Raytek ManualDocumento45 páginasRaytek ManualAdiel Ceballos0% (1)

- Icom OPC-478PIXDocumento27 páginasIcom OPC-478PIXBram HtbaratAinda não há avaliações

- Mobile SubstationsDocumento12 páginasMobile Substationsengineer_2009Ainda não há avaliações

- PANASONIC Panasonic TH-L32X10M Chassis KM02 Service Manual PDFDocumento130 páginasPANASONIC Panasonic TH-L32X10M Chassis KM02 Service Manual PDFAbhiAinda não há avaliações

- Data Sheet MUR 1520, MUR 1560Documento3 páginasData Sheet MUR 1520, MUR 1560Rifadi ArdiansyahAinda não há avaliações

- PME Pneumatic cylinders-DATA SheetDocumento2 páginasPME Pneumatic cylinders-DATA SheetGopal HegdeAinda não há avaliações

- IEC - TR - 61641 - 2008 - FR - EN.pdf-đã chuyển đổiDocumento11 páginasIEC - TR - 61641 - 2008 - FR - EN.pdf-đã chuyển đổiĐông Á ĐiệnAinda não há avaliações

- The Sproutie MK II HF Regen Receiver - Dave Richards AA7EEDocumento81 páginasThe Sproutie MK II HF Regen Receiver - Dave Richards AA7EEdetroit_me25530% (1)

- Selec - 900VPR 2 280 520V - Op380 V0... Op PDFDocumento4 páginasSelec - 900VPR 2 280 520V - Op380 V0... Op PDFsushil kumarAinda não há avaliações

- 8.03 Fall 2004 Problem Set 2 SolutionsDocumento15 páginas8.03 Fall 2004 Problem Set 2 SolutionseviroyerAinda não há avaliações

- Harmonic Analysis of Separately Excited DC Motor Drives Fed by Single Phase Controlled Rectifier and PWM RectifierDocumento112 páginasHarmonic Analysis of Separately Excited DC Motor Drives Fed by Single Phase Controlled Rectifier and PWM RectifierGautam Umapathy0% (1)

- Vacuum Drying Oven Model ADP200/300: First EditionDocumento36 páginasVacuum Drying Oven Model ADP200/300: First EditionMartin Fco EncinasAinda não há avaliações

- Dkg-307 Automatic Mains Failure Unit: Canbus and Mpu VersionsDocumento54 páginasDkg-307 Automatic Mains Failure Unit: Canbus and Mpu VersionsMohammed Bouziane100% (1)

- Stamford PE-734-B Generator Data With DVRDocumento81 páginasStamford PE-734-B Generator Data With DVRSerg MarushkoAinda não há avaliações

- Photoelectric LabDocumento5 páginasPhotoelectric LabNajma BelvanaAinda não há avaliações

- StopWatt ReviewsDocumento5 páginasStopWatt Reviewspatriciacarlton1Ainda não há avaliações

- Intro To Electronic Comm - Part2Documento21 páginasIntro To Electronic Comm - Part2Wawan NazriAinda não há avaliações

- MCT I 1415343544 Sales enDocumento14 páginasMCT I 1415343544 Sales enpisemude2706Ainda não há avaliações

- Advanced Power Electronics Corp.: AP72T02GH/JDocumento6 páginasAdvanced Power Electronics Corp.: AP72T02GH/JFrancisco MataAinda não há avaliações

- General Residential Service: Puerto Rico Electric Power AuthorityDocumento76 páginasGeneral Residential Service: Puerto Rico Electric Power AuthorityMonica DiazAinda não há avaliações

- QUCS ProcedureDocumento559 páginasQUCS ProcedureSailaja DatlaAinda não há avaliações