Escolar Documentos

Profissional Documentos

Cultura Documentos

Effects of Operational Parameters of Spiral in Mica-Feldspar

Enviado por

Manishankar Panda0 notas0% acharam este documento útil (0 voto)

29 visualizações5 páginasEffects of several operating parameters on the separation efficiency of mica from feldspar by spiral concentrator were investigated. Best results were obtained with feed solid content of 15% by weight for the particle size fraction of 2212z74 mm.

Descrição original:

Título original

Effects of Operational Parameters of Spiral in Mica-feldspar

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoEffects of several operating parameters on the separation efficiency of mica from feldspar by spiral concentrator were investigated. Best results were obtained with feed solid content of 15% by weight for the particle size fraction of 2212z74 mm.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

29 visualizações5 páginasEffects of Operational Parameters of Spiral in Mica-Feldspar

Enviado por

Manishankar PandaEffects of several operating parameters on the separation efficiency of mica from feldspar by spiral concentrator were investigated. Best results were obtained with feed solid content of 15% by weight for the particle size fraction of 2212z74 mm.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 5

Effects of operational parameters of spiral

concentrator on micafeldspar separation

O. Y. Gulsoy and M. Kademli

In the present study, effects of several operating parameters on the separation efficiency of mica

from feldspar by spiral concentrator were investigated. For this purpose, an albite ore containing

mica was treated in a full scale Reichert spiral (model HG7) under various test conditions. During

the study, particle size distribution, solid contents of the feed, feedrate and splitter position were

changed. It was observed that in a spiral concentrator mica could be separated from feldspar

owing to its laminar morphology. Accordingly, it was found that particle size and solid contents

had significant effect on the separation. Best results were obtained with feed solid content of 15%

by weight for the particle size fraction of 2212z74 mm. In line with this, Fe

2

O

3

content, which was

0

.

71% in the feed, decreased to 0

.

07% in concentrate.

Keywords: Feldspar, Mica, Spiral concentrator, Gravity separation

Introduction

Mica is one of the main impurities in feldspar used in

ceramic and glass industries. It contains iron, which

causes colouring in ceramic and glass. Titanium is also a

colouring impurity in feldspar. The sources of titanium

in feldspar are rutile, sphene and ilmenite as well as

biotite, in some cases depending on displacement of

titanium with other metals in the crystal lattice.

1

Flotation is usually applied to remove the colouring

impurities from feldspar ore. However, otation may

cause some environmental problems because of the use

of some chemicals. Also, mica and oxide minerals

require different otation steps and some additional

processes are required between the steps in order to

remove the reactant from the mineral surfaces and to

carry out reconditioning.

26

The specic gravities of feldspar and mica minerals

are approximately 2

.

65 and 2

.

73

.

4 respectively. As

mentioned by Iverson, the difference between their

specic gravities is not enough to achieve efcient

separation of these minerals with gravity methods.

7

Coarse mica grains are nearly equidimensional and

spherical. However, in ne sizes the platy character of

the mica minerals is revealed. This physical character-

istic of the mineral has been responsible for its

separation by gravity from feldspar. This distinguishing

property of ne mica particles was rst reported by

Iverson.

7

In his study, Iverson managed to separate mica

from feldspar by tabling. Later, Adair et al. also showed

the possibility of concentration of mica in a Humphrey

spiral.

8

Therefore, gravity methods are considered as an

alternative method to otation.

The purpose of the present study was to investigate

the separation characteristics of mica in a Reichert spiral

and to determine the effects of operating parameters,

such as particle size distribution, feed solid contents,

feedrate and splitter position, on the separation ef-

ciency. Industrial scale equipment was used in the

present study, therefore the results can be applied to

the industry directly. A model HG7 Reichert spiral was

used because of its availability and because preliminary

experiments showed potential for good separations.

Material and method

The tests were carried out in an industrial scale Reichert

spiral (HG7). The equipment was operated in a closed

circuit, including a tank and a pump. There were two

splitters at the equipment discharge. The position of the

outer splitter was not suitable to control product

streams owing to the occurrence of a big gap largely

free of particles between the tailing and the concentrate

streams during the tests (Fig. 1). Therefore this splitter

was xed for all conditions in the main series of tests.

The position of the inner splitter was adjusted to 1/4, 1/2

and 3/4 of the maximum opening (16 mm, L). Samples

were taken simultaneously of primary and secondary

concentrates and tailings during the tests (Fig. 1). Before

each test, the system was discharged, cleaned and then

operated in a manner appropriate to the new feed and

solid contents. Sampling time was measured by a digital

chronometer in each test. Samples were dried and

weighted. Therefore, owrates of each stream could be

calculated.

Pulp owrates studied were 1, 1

.

5 and 2 L s

21

, and

pulp solid contents for these owrates were 15, 20 and

25 wt-%. The solid owrates calculated according to

these test conditions are given in Table 2.

Fe

2

O

3

removal recovery was calculated from 12R,

where, R is Fe

2

O

3

recovery in concentrate, which is

Hacettepe University, Department of Mining Engineering, Beytepe

Campus, Ankara, Turkey

*Corresponding author, email ogulsoy@hacettepe.edu.tr

2006 Institute of Materials, Minerals and Mining and The AusIMM

Published by Maney on behalf of the Institute and The AusIMM

Received 17 March 2005; accepted 19 July 2005

80 DOI 10.1179/174328506X99907

Mineral Processing and Extractive

Metallurgy (Trans. Inst. Min. Metall. C) 2006 VOL 115 NO 2

calculated from equation (1)

R~

Cc

Ff

(1)

where C is the owrate of concentrate (t h

21

), F is

the owrate of feed (t h

21

), c is the Fe

2

O

3

grade of

concentrate (%) and f is the Fe

2

O

3

grade of feed (%).

Firing at 1200uC is a quick test method to control the

quality of feldspar samples. Some impurities change the

colour of the ring buttons. Titanium gives pinkish

colours and iron is the source of the grey colours. The

density of the colours is directly related to the amount of

the impurities.

Because the main source of titanium in the ore was

generally rutile and sphene, a signicant decrease in

titanium content might not be expected. However, the

titanium presented especially in the crystal lattices of the

biotite was removed by the separation of mica, and this

had the potential to result in a slight decrease in titanium

content.

Results

In the present study, the effects of operational para-

meters on the separation efciency of mica in a spiral

concentrator were investigated for a wide range of

feedrate values, which were varied between 0

.

6 and

2

.

1 t h

21

. This range stayed within normal industrial

operational limits of the equipment.

At the beginning of the tests, primary and secondary

concentrates and tailing were obtained as shown in

Fig. 1, and Fe

2

O

3

grades of the concentrates were

determined by chemical assaying. A comparison of

Fe

2

O

3

grades of primary and secondary concentrates for

all test conditions is given in Fig. 2. As can be seen from

Fig. 2, there is no meaningful difference between the

primary and secondary concentrates, and a regression

analysis yields an intercept very close to zero and a slope

close to 1. In addition a paired t test showed that there

was a negligible difference between the primary and

secondary concentrates at the 99

.

9% level of probability.

It was therefore apparent that dividing the concentrate

as primary and secondary was not necessary. Therefore,

only one set of concentrate data representing the average

characteristics of the two concentrates and one set of

tailing data were used in the evaluation of the effect of

ow and percentage of solids, and there was no need to

take a middling stream using a second splitter in the

separation process. This enables the process to be used

and controlled easily at the plant level.

The major part of water in the feed accumulated at the

outside of the separation surface carrying most of the

platy mica with it. The feldspar particles moved

predominantly to the inner part of the surface forming

a natural gap between concentrate and tailing streams.

Because of this the outer splitter was not very effective in

controlling the concentrate quality. During the separa-

tion the outer splitter was roughly adjusted by visual

judgement of the best position. The effects of inner

splitter setting on the Fe

2

O

3

grade of the concentrate for

each test condition are given in Table 3. As can be seen

from Table 3, Fe

2

O

3

grade of the concentrate increases

slightly by sliding the splitter to the outside position.

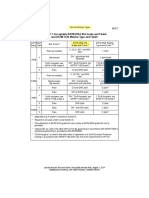

Table 2 Solid feedrates calculated for each test

condition

Pulp flowrate,

L s

21

Solid content,

wt-%

Solid flowrate,

t h

21

1 15 0

.

596

20 0

.

822

25 1

.

065

1

.

5 15 0

.

894

20 1

.

233

25 1

.

598

2 15 1

.

192

20 1

.

644

25 2

.

130

2 Comparison of Fe

2

O

3

grades of primary and secondary

concentrates

1 View of spiral discharge

Table 1 Chemical compositions of spiral feed and slime (74 mm) fractions

Size fraction, mm Content, (slime, 74 mm), wt-% Fe

2

O

3

content (slime, 74 mm), % Fe

2

O

3

content (feed), %

2850z74 4

.

20 0

.

03 0

.

74

2600z74 5

.

28 0

.

06 0

.

74

2425z74 7

.

10 0

.

07 0

.

76

2300z74 8

.

54 0

.

08 0

.

77

2212z74 10

.

25 0

.

12 0

.

78

Gulsoy and Kademli Effects of operational parameters on micafeldspar separation

Mineral Processing and Extractive Metallurgy (Trans. Inst. Min. Metall. C) 2006 VOL 115 NO 2 81

However, this did not affect the percentage of solids and

owrate of concentrate signicantly.

The minimum and maximum operating owrates

were determined according to the specications of the

Reichert spiral (HG7) used in the tests. Thus, three

different owrates, 1, 1

.

5 and 2 L s

2-1

, were selected and

the tests were performed at these owrates with three

different solid contents that were 15, 20 and 25 wt-%.

The effects of owrate on Fe

2

O

3

grade of concentrate,

Fe

2

O

3

removal and mass recovery were investigated for

each feed size. The relationships for 15, 20 and 25% solid

contents are shown in Figs. 35 respectively with

owrate as the parameter and for each of the owrates

in Figs. 68 with the percentage of solids as the

parameter.

Discussion

It can be seen from Figs. 38 that the particle size

distribution is the most effective parameter in the

separation. As explained above, the coarse mica grains

are nearly equidimensional, and the difference in specic

gravity is not enough to make the separation of these

minerals possible. However, the platy character of the

smaller mica particles made the separation of mica from

feldspar possible at ne particle sizes. This situation is

not related to the differences in the degree of liberation,

because mica was in the form of liberated particles even

in the coarse fractions.

Fe

2

O

3

grade of the concentrate, Fe

2

O

3

removal and

recovery to feldspar were directly related to the change

in maximum particle size. An increase in the particle size

increased Fe

2

O

3

grade of the concentrate and decreased

the Fe

2

O

3

removal. The mass recovery decreased slightly

with ner particle size, because the amount of particles

carried by water to the tailings stream increased. This

behaviour was observed at all owrates and feed solid

contents.

Figures 35 show that increasing the owrate to the

spiral generally caused an increase in the Fe

2

O

3

grade of

Table 3 Effect of inner splitter setting on Fe

2

O

3

grades of concentrates at different test conditions

Feed top

size, mm

Splitter

setting

Fe

2

O

3

grade, %

1 L s

21

pulp flowrate 1

.

5 L s

21

pulp flowrate 2 L s

21

pulp flowrate

15%

solids

20%

solids

25%

solids

15%

solids

20%

solids

25%

solids

15%

solids

20%

solids

25%

solids

212 1/4 L 0

.

065 0

.

101 0

.

157 0

.

070 0

.

102 0

.

169 0

.

078 0

.

110 0

.

210

1/2 L 0

.

068 0

.

109 0

.

169 0

.

071 0

.

111 0

.

181 0

.

082 0

.

109 0

.

217

3/4 L 0

.

068 0

.

118 0

.

179 0

.

079 0

.

110 0

.

179 0

.

090 0

.

130 0

.

241

300 1/4 L 0

.

095 0

.

188 0

.

238 0

.

138 0

.

209 0

.

251 0

.

154 0

.

199 0

.

288

1/2 L 0

.

105 0

.

191 0

.

259 0

.

142 0

.

219 0

.

268 0

.

158 0

.

248 0

.

299

3/4 L 0

.

118 0

.

202 0

.

270 0

.

152 0

.

228 0

.

279 0

.

169 0

.

259 0

.

311

425 1/4 L 0

.

293 0

.

398 0

.

478 0

.

319 0

.

413 0

.

498 0

.

379 0

.

449 0

.

518

1/2 L 0

.

293 0

.

410 0

.

498 0

.

329 0

.

440 0

.

511 0

.

397 0

.

461 0

.

532

3/4 L 0

.

298 0

.

423 0

.

509 0

.

338 0

.

458 0

.

527 0

.

411 0

.

479 0

.

547

600 1/4 L 0

.

610 0

.

759 0

.

839 0

.

699 0

.

788 0

.

830 0

.

757 0

.

800 0

.

821

1/2 L 0

.

627 0

.

778 0

.

841 0

.

717 0

.

799 0

.

840 0

.

768 0

.

820 0

.

821

3/4 L 0

.

659 0

.

791 0

.

841 0

.

738 0

.

817 0

.

831 0

.

778 0

.

817 0

.

837

850 1/4 L 0

.

844 0

.

849 0

.

852 0

.

851 0

.

852 0

.

858 0

.

839 0

.

849 0

.

849

1/2 L 0

.

848 0

.

849 0

.

852 0

.

838 0

.

851 0

.

848 0

.

842 0

.

842 0

.

859

3/4 L 0

.

842 0

.

838 0

.

842 0

.

839 0

.

851 0

.

840 0

.

841 0

.

851 0

.

859

3 Variations in Fe

2

O

3

grade of concentrate, Fe

2

O

3

removal (dashes) and mass recovery (dot) as function

of feed top size for different owrate at 15% solids

4 Variations in Fe

2

O

3

grade of concentrate, Fe

2

O

3

removal (dashes) and mass recovery (dot) as function

of feed top size for different owrate at 20% solids

Gulsoy and Kademli Effects of operational parameters on micafeldspar separation

82 Mineral Processing and Extractive Metallurgy (Trans. Inst. Min. Metall. C) 2006 VOL 115 NO 2

the concentrate and a drop in the Fe

2

O

3

removal.

However, the effect of the increase in the owrate on

separation was small when compared with the effects of

other variables. There was virtually no owrate effect

for a top particle size of 850 mm and very little for

200 mm. The negative effect of the owrate on the

separation was progressively less evident with increasing

percentage of solids in the feed so that it was almost

negligible for 25% solids.

The effects of feed solid contents on Fe

2

O

3

grade of

concentrates, Fe

2

O

3

removal and mass recovery are

given in Figs. 68. These gures show that regardless of

feedrate, increasing percentage of solids in the feed

increased the Fe

2

O

3

grade of concentrate and decreased

percentage of Fe

2

O

3

removal except for the feed top size

of 850 mm. Also, reducing the separation efciency

increases in the solid contents slightly reduced the

amount of concentrate. This occurred at all spiral

feedrates.

Conclusions

In the present study, the effects of the process variables

such as particle size distribution, per cent solids in the

feed, splitter position and owrate on mica separation

were examined. The results revealed that the maximum

particle size had an extreme effect on separation efci-

ency. Separation was not possible when the maximum

particle size was 850 or 600 mm. The separation

efciency of mica increased as the particle size distribu-

tion got ner, and the most suitable maximum size was

212 mm when Fe

2

O

3

content of the concentrate was

reduced from 0

.

70 to 0

.

07% with 93% removal of Fe

2

O

3

and mass recovery of y70%. This iron content met the

specications required by the glass industry. Firing

buttons with a pale pink colour conrmed this result. It

appeared that particle size needed to be reduced to

2212 mm, in order to ensure that the mica was in a platy

form which had the desired distinctive behaviour on the

spiral surface.

6 Variations in Fe

2

O

3

grade of concentrate, Fe

2

O

3

removal (dashes) and mass recovery (dot) as function

of feed top size for solid content at owrate of 1 L s

21

5 Variations in Fe

2

O

3

grade of concentrate, Fe

2

O

3

removal (dashes) and mass recovery (dot) as function

of feed top size for different owrate at 25% solids

7 Variations in Fe

2

O

3

grade of concentrate, Fe

2

O

3

removal (dashes) and mass recovery (dot) as function

of feed top size for solid content at owrate of

1

.

5 L s

21

8 Variations in Fe

2

O

3

grade of concentrate, Fe

2

O

3

removal (dashes) and mass recovery (dot) as function

of feed top size for solid content at owrate of 2 L s

21

Gulsoy and Kademli Effects of operational parameters on micafeldspar separation

Mineral Processing and Extractive Metallurgy (Trans. Inst. Min. Metall. C) 2006 VOL 115 NO 2 83

Although the effect on separation efciency of

owrate and percentage of solids in feed was less

pronounced than that of particle size, increasing

owrates or percentage of solids signicantly reduced

the separation efciency. Only concentrate obtained

with the minimum owrate (1 L s

21

) and minimum per

cent solids (15%) met the desired specication corre-

sponding to a solid feedrate of y0

.

6 t h

21

.

The position of the outer splitter was important in this

separation. Serendipitously it was in the ideal position

and the small changes in the position of the splitter

available did not affect the separation efciency

signicantly. A wide feldspar band on the inner surface

of spiral and a mica ow close to the outer wall were

formed. Therefore, the separation between feldspar and

mica minerals was sharp, and an absence of a middling

stream provided important advantages in control of the

separation.

To be effective separation with spirals required

removing material by screening which would tend to

report to the micaeous tailing stream and be lost to

concentrate. As mica was prone to accumulate in coarse

screen fractions, the mica and therefore iron contents of

the nes were much lower than the coarse fractions. The

iron content of the 274 mm fraction was sufciently low

for it to be used directly in industry.

Because concentrate could be produced with iron

content within the limits required by the glass industry,

titanium minerals could be removed by otation to

produce a nal concentrate with suitable iron and

titanium contents as required by the ceramic industry.

Therefore, one of two standard stages of otation can be

avoided by spiral separation.

Acknowledgement

The authors would like to thank A. S . C ine-Akmaden

for its contributions to supplying the samples used in the

present study.

References

1. I. Bayraktar, S. Ersayin and O. Y. Gulsoy: in Innovations in

mineral and coal processing, (ed. S. Atak et al.), 315318; 1998,

Rotterdam, Balkema.

2. A. AKAR: in Progress in mineral processing technology,

(ed. H. Demirel and S. Ersayn), 243249; 1994, Rotterdam,

Balkema.

3. I. Bayraktar, S. Ersayin, O. Y. Gulsoy, Z. Ekmekci and N. M. Can:

Temel seramik ve cam hammaddelerimizdeki (feldispat, kuvars ve

kaolin) kalite sorunlar ve co zu m o nerileri, Proc. 3rd Industrial

Mineral Symp., Izmir, Turkey, 1999, 2233.

4. I. Bayraktar, O. Y. Gulsoy, N. M. Can and E. C. Orhan:

Feldispatlarn zenginlestirilmesi, Proc. 4th Industrial Mineral

Symp., Izmir, Turkey, 2002, 97105.

5. M. S. Celik, I. Can and R. H. Eren: Miner. Eng., 1998, 12, 1201

1208.

6. M. S. Celik, B. Pehlivanoglu, A. Aslanbas and R. Asmatulu:

Miner. Metall. Process., 2001, 18, 101105.

7. H. G. Iverson: Eng. Min. J., 1932, April, 227229.

8. R. Adair, W. T McDaniel and W. R. Hudspeth: Min. Eng., 1951, 3,

252254.

Gulsoy and Kademli Effects of operational parameters on micafeldspar separation

84 Mineral Processing and Extractive Metallurgy (Trans. Inst. Min. Metall. C) 2006 VOL 115 NO 2

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Astm A781 2020 PDFDocumento11 páginasAstm A781 2020 PDFCristhian Camilo Quiroga Walteros100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- GOLDEN DAWN 2 9 Alchemical SephirothDocumento2 páginasGOLDEN DAWN 2 9 Alchemical SephirothF_RC67% (3)

- PSD CEU 180Sept11-Corrosion PDFDocumento17 páginasPSD CEU 180Sept11-Corrosion PDFSam ChoiAinda não há avaliações

- Atlas Aluminium Datasheet 3003 Rev Oct 2013Documento3 páginasAtlas Aluminium Datasheet 3003 Rev Oct 2013PrakashAinda não há avaliações

- ASTM B151 Copper-Nickel-Zinc Alloy (Nickel Silver) and Copper-Nickel Rod and BarDocumento2 páginasASTM B151 Copper-Nickel-Zinc Alloy (Nickel Silver) and Copper-Nickel Rod and BarAmanda Ariesta ApriliaAinda não há avaliações

- C95500 ASTM - Nickel Aluminum BronzeDocumento2 páginasC95500 ASTM - Nickel Aluminum BronzethuykvAinda não há avaliações

- Effect of Metal Coupling On Rusting of Iron: Chemistry Project FileDocumento14 páginasEffect of Metal Coupling On Rusting of Iron: Chemistry Project FilePrashant Pandey100% (3)

- Flue Gas DesulfurisationDocumento22 páginasFlue Gas DesulfurisationManishankar PandaAinda não há avaliações

- Modeling and Optimization of Multi Gravity Separator To Produce Celestite ConcentrateDocumento7 páginasModeling and Optimization of Multi Gravity Separator To Produce Celestite ConcentrateManishankar PandaAinda não há avaliações

- Application of Response Surface Methodology and Central Composite RotatableDocumento7 páginasApplication of Response Surface Methodology and Central Composite RotatableManishankar PandaAinda não há avaliações

- Cyber SocietyDocumento1 páginaCyber SocietyManishankar PandaAinda não há avaliações

- EN DX51D - 1.0226 - SteelNumber - Chemical Composition, Equivalent, PropertiesDocumento2 páginasEN DX51D - 1.0226 - SteelNumber - Chemical Composition, Equivalent, PropertiesliusfAinda não há avaliações

- Astm A743 A743m - 12Documento6 páginasAstm A743 A743m - 12Joshua ZantoyAinda não há avaliações

- Difference Between Alloy and Composite Word FinalDocumento2 páginasDifference Between Alloy and Composite Word FinalMehedi HasanAinda não há avaliações

- Gold Pyrite OresDocumento1 páginaGold Pyrite OresSilver Rio CarangcarangAinda não há avaliações

- RCSC Table 2.1 Nut and Washer TypesDocumento1 páginaRCSC Table 2.1 Nut and Washer TypesAdam JonesAinda não há avaliações

- BHMC News v9n4 Radium Hill LimestoneDocumento8 páginasBHMC News v9n4 Radium Hill LimestoneobamaAinda não há avaliações

- BIWDocumento12 páginasBIWSatyawan KaleAinda não há avaliações

- Ores in Ladakh and KarnatakaDocumento3 páginasOres in Ladakh and KarnatakashashwatthegamerytAinda não há avaliações

- Physical Properties of MineralsDocumento7 páginasPhysical Properties of MineralsRizette PaloganAinda não há avaliações

- Corrosion of Surgical Instruments: Standard Test Method ForDocumento3 páginasCorrosion of Surgical Instruments: Standard Test Method ForArmoghan SajidAinda não há avaliações

- Steel For Mechanical Work at High Velocity With Removal of ChipsDocumento6 páginasSteel For Mechanical Work at High Velocity With Removal of ChipsSuresh ShindeAinda não há avaliações

- Tooling by Design - Shaving and Burnishing Guidelines - MetalForming MagazineDocumento2 páginasTooling by Design - Shaving and Burnishing Guidelines - MetalForming MagazineSIMONEAinda não há avaliações

- Steel Grade: Material Data SheetDocumento7 páginasSteel Grade: Material Data Sheetispat_jagadeeshAinda não há avaliações

- Stainless Steels: Martensitic: of Steels Metallurgy of SteelsDocumento7 páginasStainless Steels: Martensitic: of Steels Metallurgy of SteelsGhazal NanaaAinda não há avaliações

- TDS - Mulcoa - 47 - Rev 1Documento1 páginaTDS - Mulcoa - 47 - Rev 1유유재하Ainda não há avaliações

- WC515 Why Welds CrackDocumento1 páginaWC515 Why Welds CrackOscar Montana Perez RochaAinda não há avaliações

- SERIES 2100 Bridge BearingsDocumento4 páginasSERIES 2100 Bridge Bearingskhx2Ainda não há avaliações

- Astm A490Documento7 páginasAstm A490vu hungAinda não há avaliações

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Documento2 páginasProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajAinda não há avaliações

- ME8491 - Unit1 PDFDocumento44 páginasME8491 - Unit1 PDFSenthilkumar SivasankaranAinda não há avaliações

- Strictly For Private Circulation Amongst Members OnlyDocumento3 páginasStrictly For Private Circulation Amongst Members OnlyMohammed KhorakiwalaAinda não há avaliações

- Amp MPDocumento7 páginasAmp MPSujal RaijadeAinda não há avaliações

- Thesis FypDocumento47 páginasThesis FypMohd AymanAinda não há avaliações