Escolar Documentos

Profissional Documentos

Cultura Documentos

1399 LPKF Stencillaser G 6080

Enviado por

rrebollar0 notas0% acharam este documento útil (0 voto)

45 visualizações8 páginasThe new LPKF StencilLaser G 6080 improves the stencil business with a comprehensive feature set. It cuts materials from 20 to 1,000 um (0. To 40 mil) with highest precision at unparalleled speed. The system features easy access architecture, state-of-the-art fume extraction and simplified material handling.

Descrição original:

Título original

1399 Lpkf Stencillaser g 6080

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThe new LPKF StencilLaser G 6080 improves the stencil business with a comprehensive feature set. It cuts materials from 20 to 1,000 um (0. To 40 mil) with highest precision at unparalleled speed. The system features easy access architecture, state-of-the-art fume extraction and simplified material handling.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

45 visualizações8 páginas1399 LPKF Stencillaser G 6080

Enviado por

rrebollarThe new LPKF StencilLaser G 6080 improves the stencil business with a comprehensive feature set. It cuts materials from 20 to 1,000 um (0. To 40 mil) with highest precision at unparalleled speed. The system features easy access architecture, state-of-the-art fume extraction and simplified material handling.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 8

The Most Efcient SMT Solder Paste Stencil Cutter Available

LPKF StencilLaser G 6080

2 % cost savings on cutting gas

1

100 % cost savings on chiller operation

2

100 % time savings on post process inspection

3

= produce more stencils per day for less

See for yourself: Ask our sales team for help calculating your individual cost savings.

1

when using oxygen for cutting gas,

2

no external chiller required,

3

when using real-time process control function.

100 % assured LPKF quality!

Optimum Results

Exact geometries for each and

every stencil aperture are essential

to achieving perfect printing results.

The LPKF StencilLaser G 6080 cuts

materials from 20 to 1,000 m

(0.8 to 40 mil) with highest precision

at unparalleled speed.

150 x 66.7 m 300 x 33.3 m 700 x 14.3 m

Accurate geometries. Smooth, vertical sidewalls

By specically combining customers in-depth process

knowledge with quality assurance tools and in-house

mico-machining expertise, LPKF helps increase

efciency and effectiveness beyond expectation.

The new LPKF StencilLaser G 6080 improves the stencil

business with a comprehensive feature set, resulting in:

increased overall performance

reduced ownership costs

simplied operation

integrated quality control

maximum up-time

maximum production exibility

The LPKF StencilLaser G 6080 helps LPKF customers

stay ahead of the competition by utilizing the industrys

most advanced technology. Purchasing a StencilLaser

G 6080 adds greater exibility, faster reaction cycles

and a higher throughput to your portfolio.

Engineered for Safety

All LPKF StencilLaser systems are compliant with

Class 1 laser safety guidelines. They feature easy

access architecture, state-of-the art fume extraction

and simplied material handling. The systems meet

or exceed the most stringent industry regulations and

recommendations for a safe work environment and

environmentally-friendly production.

Worldwide Customer Support

LPKF maintains a global service staff with hubs located

around the world. The experienced and well-trained

service personnel provide the most reliable support

structure in the industry. Furthermore LPKFs service staff

can remotely service your system from anywhere in the

world.

Financing Options

LPKF partners with industry leading nancial specialists to

offer custom nancing options. These tailored packages are

designed to t a variety of cash ow needs and produce an

even quicker return on investment.

Innovation Drives Revenue

The StencilLaser G 6080 represents everything LPKF is renowned for: Worldwide leadership

in designing highly sophisticated products, inspired by customers. The second generation

StencilLaser G 6080 is designed to rapidly produce assured quality at minimum cost.

Top Performance, Top Prots

LPKFs well-known carbon ber gantry

technology was revised to yield even

higher performance. The heart of the

StencilLaser G 6080 is dened by an LPKF designed

motion system. All of the parts in this system work

together like high-end clockwork, providing maximum

precision and performance. This improved dynamic

design results in impressive benets:

Higher throughput through optimized motion control

Enhanced stiffness of the gantry system to maintain

accuracy

Minimal preventative maintenance requirements

The StencilLaser G 6080 handles different speeds

and cutting parameters, depending on the pattern.

The EasyEdit software is rich in features and

allows users to assign specic cutting parameters

to various groups of apertures automatically.

Best in class:

Cutting performance

Cost-performance ratio

Cutting quality

Process monitoring

An Easy Way to Perfect Stencils

Using the LPKF StencilLaser G 6080 is simple. Select

a frame from the customized library, load the stencil,

select the cutting job and push start. Easy to understand

touch-screen menus guide the operator. A multi-level user

architecture of the machine operation software allows

extensive customization for managers and administrators,

without compromising safe and simple operation.

LPKFs EasyEdit software is the most

powerful stencil editor on the industry.

It streamlines the customization process by

applying modications in aperture shape and

dimensions either globally or individually. EasyEdit features

include:

One-click aperture modication

Full scalability of aperture dimensions

Custom libraries for automated aperture modications

Special cutting routines

One-click data matrix code or barcode generation for

stencil marking

Maximum Efciency Benets

Having out-performed every commercially available laser system used in stencil production for the last years

LPKF continues to expand its innovation. Focusing R&D efforts on the highly dynamic motion systems allowed us

to improve the StencilLaser G 6080s cutting throughput by 20 % compared to its predecessor. This combination

of heightened performance and cutting quality with increased system uptime directly adds greater exibility,

higher throughput and faster delivery.

LPKF StencilLaser G 6080

Fast Setup: Loose Foils and Framed Stencils

The LPKF StencilLaser G 6080 automatically adjusts to

t stencil size up to 740 x 1,000 mm (29.1 x 39.4).

Loose metal sheets can be cut in a reusable clamping

and stretching frame that does not require any tools

to load and mount of the material. The StencilLaser G

6080 does not require any adaptors to handle sheets

and stencils of various sizes.

The latest feature in LPKF StencilLaser

systems is their capability to be integrated

into an automatic handling process. The

StencilLaser G 6080 is equipped with a

handling interface according to SMEMA standard, enabling

the system to be connected to any auto-loading device.

The automatic width adjustment allows the operation of

a mix of stencil frames and even loose sheets without

requiring any changeover or process stoppage.

Assured Quality

The fully automatic loading routine assures stencils

remain at the optimal focal point. This feature enables

the system to cut or engrave stencils from both sides.

Manual calibration is not required.

Easy Rework

The integrated LPKF vision system allows stencils to

be re-worked with easy setup and high accuracy.

The new LPKF Real-Time Process

Control (patent pending) monitors the

cutting process for every aperture. If

an undesired cutting result is detected,

the LPKF Real-Time Process Control automatically

optimizes the cutting parameters without wasting

production time. This real-time process is signicantly

faster than a post-process visual scan. This feature

allows skipping a tedious and time consuming post-

process inspection of a stencil.

The G 6080s reliable production schedule and assured

quality control is a highly desirable benet for every

solder paste stencil production. 100 % quality does not

have to be an illusion any longer. The LPKF StencilLaser

G 6080 makes it a reality.

Designed for 24/7 Use

The LPKF StencilLaser G 6080 is designed for

permanent and professional use with minimal

maintenance requirements. In addition the following

features help to save money.

The proven LPKF LongLife ber laser

technology is now even more efcient,

featuring 100 % air-cooling. This reduces

the systems total power consumption by

about 30 % while eliminating service and maintenance

downtime for any external chiller system.

The StencilLaser G 6080 can use either

compressed air or oxygen for cutting

gas. In fact, it can even be operated with

two different cutting gases in the same

job. The selection of the gas type, as well as pressure

adjustment and monitoring is done fully automatic.

The setup is cutting tool dependent, allowing the

operator to use the most appropriate gas type for

the job at hand. As part of the parameter set, cutting

gas is controlled for every single aperture type. This

feature helps saving cost on more expensive cutting

gases, such as oxygen, while also delivering the highest

possible cutting quality where it really counts.

Micromachining Capability

The LPKF StencilLaser G 6080 offers power and efciencies well-suited to a variety of applications.

In addition to the ever-growing stencil market, micromachining of mechanical parts is another lucrative

application for the LPKF StencilLaser G 6080 system. The system is capable of cutting metal sheets up

to 1,000 m (40 mil) thick with superior precision.

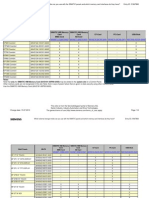

Reference layout A:

Stainless steel, 150 m (6 mil) thick

Number of apertures: 14,157

Speed: Up to 23,400 apertures per

hour

Reference layout B:

Stainless steel, 100 m (4 mil) thick

Number of apertures: 11,676

Speed: Up to 30,200 apertures per

hour

Reference layout C:

Stainless steel, 40 m (1.6 mil) thick

Number of apertures: 18,000

Speed: Up to 51,200 apertures per

hour

Fast Fact Reference Layouts

L

P

K

F

A

G

,

1

0

0

0

5

4

1

3

-

2

1

0

8

1

3

-

E

N

P

i

c

t

u

r

e

s

m

a

y

s

h

o

w

o

p

t

i

o

n

a

l

e

q

u

i

p

m

e

n

t

.

w

w

w

.

j

e

n

k

o

-

s

t

e

r

n

b

e

r

g

.

d

e

LPKF Laser & Electronics AG, LPKF reserves the right to modify the specications and other product information without giving notice. Systems and products supplied by LPKF and its subsidiaries

are covered by valid or pending US and other foreign patents. Product names are only used for identication and could be trademarks or registered brand names of the companies involved.

LPKF Laser & Electronics AG sells and markets

products and provides support in more than

50 countries. Find your local representative at

www.lpkf.com.

Worldwide (LPKF Headquarters)

LPKF Laser & Electronics AG Osteriede 7 30827 Garbsen Germany

Phone +49 (5131) 7095-0 Fax +49 (5131) 7095-90 info@lpkf.com

www.lpkf.com

North / Central America

LPKF Laser & Electronics North America

Phone +1 (503) 454-4200 Fax +1 (503) 682-7151 sales@lpkfusa.com

www.lpkfusa.com

China

LPKF Tianjin Co., Ltd.

Phone +86 (22) 2378-5318 Fax +86 (22) 2378-5398 sales@lpkf.cn

www.lpkf.cn

Hong Kong

LPKF Laser & Electronics (Hong Kong) Ltd.

Phone +852-2545-4005 Fax +852-2545-4006 hongkong@lpkf.com

www.lpkf.com

Japan

LPKF Laser & Electronics K.K. Japan

Phone +81 (0) 45 650 1622 Fax +81 (0) 45 650 1624 info.japan@lpkf.com

www.lpkf.com

Technical Data: StencilLaser G 6080

Speed Please refer to: Fast fact reference layouts

Cutting range (X/Y) 600 mm x 800 mm (23.6 x 31.5)

Maximum frame size (X/Y) 740 mm x 1,000 mm x 40 mm (29.1 x 39.4 x 1.6)

Maximum loose sheet size (X/Y) 650 mm x 850 mm (25.6 x 33.5)

Material thickness Up to 1 mm (0.04)

Laser repetition rate Max. 45 kHz

Axial precision 2 m

Right-angle precision 4 angular seconds

Repeatability 2 m

Power consumption Max. 2,800 VA over all

Dimension system (W x H x D) 1,530 mm x 1,920 mm x 1,625 mm (61 x 75 x 64)

Weight Less than 2,000 kg (4,400 lbs)

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Datasheet PDFDocumento34 páginasDatasheet PDFYounes Ez-zaydyAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Tb6560 PDFDocumento1 páginaTb6560 PDFrrebollarAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Datasheet LS14250 Lithium Batery (Li-SOCl2)Documento2 páginasDatasheet LS14250 Lithium Batery (Li-SOCl2)RafaelAyresGonçalvesAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- 1864228Documento2 páginas1864228rrebollarAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- MODEL TL-5101: Memory BackupDocumento2 páginasMODEL TL-5101: Memory BackuprrebollarAinda não há avaliações

- Datasheet-TB6560 3axis Stepper Motor Driver: Sunwind Electronics Company LTDDocumento6 páginasDatasheet-TB6560 3axis Stepper Motor Driver: Sunwind Electronics Company LTDAdelAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- AC Axial Fans: Max. M /HDocumento3 páginasAC Axial Fans: Max. M /HrrebollarAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Lithium Battery Cross ReferenceDocumento2 páginasLithium Battery Cross ReferencerrebollarAinda não há avaliações

- MODEL TL-5101: Memory BackupDocumento2 páginasMODEL TL-5101: Memory BackuprrebollarAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- 2071 In001 - en PDocumento20 páginas2071 In001 - en PrrebollarAinda não há avaliações

- Tsxplp01 TSX 37Documento1 páginaTsxplp01 TSX 37rrebollarAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Lithium Battery Cross ReferenceDocumento2 páginasLithium Battery Cross ReferencerrebollarAinda não há avaliações

- Datasheet LS14250 Lithium Batery (Li-SOCl2)Documento2 páginasDatasheet LS14250 Lithium Batery (Li-SOCl2)RafaelAyresGonçalvesAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- ABB Drives ACS580 Manual 2017Documento278 páginasABB Drives ACS580 Manual 2017rrebollarAinda não há avaliações

- e 02Documento96 páginase 02rrebollarAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Abb VFD Acs550 01Documento320 páginasAbb VFD Acs550 01Anil SankhlaAinda não há avaliações

- Electronic Control: TumblerDocumento71 páginasElectronic Control: TumblerrrebollarAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Alj Quick Guides EDC Dryer Controls 120V / 24V Changing Price (Manually)Documento2 páginasAlj Quick Guides EDC Dryer Controls 120V / 24V Changing Price (Manually)rrebollarAinda não há avaliações

- Control Valve ICSDocumento72 páginasControl Valve ICSrrebollarAinda não há avaliações

- Electronic Control: TumblerDocumento71 páginasElectronic Control: TumblerrrebollarAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Alj Quick Guides EDC Dryer Controls 120V / 24V Changing Price (Manually)Documento2 páginasAlj Quick Guides EDC Dryer Controls 120V / 24V Changing Price (Manually)rrebollarAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Delta VFD-M ManualDocumento173 páginasDelta VFD-M Manualpanait_a,alexandru100% (1)

- 520 qs001 - en eDocumento36 páginas520 qs001 - en errebollarAinda não há avaliações

- e 02Documento96 páginase 02rrebollarAinda não há avaliações

- Brochure Panels en PDFDocumento17 páginasBrochure Panels en PDFrrebollarAinda não há avaliações

- Simatic Hmi Memory Card MMC-Card Simatic Hmi Memory Card SD-Card CF-Card PC-Card USB-Stick MLFB Comfort PanelsDocumento8 páginasSimatic Hmi Memory Card MMC-Card Simatic Hmi Memory Card SD-Card CF-Card PC-Card USB-Stick MLFB Comfort PanelsrrebollarAinda não há avaliações

- RKW Progspecs PDFDocumento7 páginasRKW Progspecs PDFrrebollarAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- General Purpose 6-Pin Phototransistor Optocouplers: 4N25 4N26 4N27 4N28 4N35 4N36 4N37 H11A1 H11A2 H11A3 H11A4 H11A5Documento12 páginasGeneral Purpose 6-Pin Phototransistor Optocouplers: 4N25 4N26 4N27 4N28 4N35 4N36 4N37 H11A1 H11A2 H11A3 H11A4 H11A5rrebollarAinda não há avaliações

- Technical Data Sheet Permatex Rear Window Defogger Tab AdhesiveDocumento1 páginaTechnical Data Sheet Permatex Rear Window Defogger Tab AdhesiverrebollarAinda não há avaliações

- Kepco Gives You Zero-Up Programmability in An Affordable Power ModuleDocumento6 páginasKepco Gives You Zero-Up Programmability in An Affordable Power ModulerrebollarAinda não há avaliações

- Aires Acond ToshibaDocumento72 páginasAires Acond Toshibarabino_rojoAinda não há avaliações

- Samsung Sustainability Reports 2014Documento69 páginasSamsung Sustainability Reports 2014nicholasdeleoncircaAinda não há avaliações

- Circuit Symbols of Electronic Components - HomeDocumento9 páginasCircuit Symbols of Electronic Components - Homesef_razumanAinda não há avaliações

- Waterproof and Cleanroom Luminaires PDFDocumento13 páginasWaterproof and Cleanroom Luminaires PDFdwi wahyu sugiartoAinda não há avaliações

- Bateria Leoch 100ahDocumento2 páginasBateria Leoch 100ahAlba Car MarAinda não há avaliações

- Instruction Manual For CheckweigherDocumento54 páginasInstruction Manual For Checkweigheralesia delgadoAinda não há avaliações

- JJRC H6C User ManualDocumento7 páginasJJRC H6C User ManualManuelAinda não há avaliações

- Bom Uss1Documento15 páginasBom Uss1superthambiAinda não há avaliações

- SKANDIX Pricelist Saab 900 (-1993)Documento451 páginasSKANDIX Pricelist Saab 900 (-1993)AAinda não há avaliações

- CMOS-MEMS SensorDocumento16 páginasCMOS-MEMS SensorFaresAinda não há avaliações

- DRV134 PDFDocumento20 páginasDRV134 PDFLesseigne Marie-ClaireAinda não há avaliações

- La-A998p R01 Szso40 PDFDocumento58 páginasLa-A998p R01 Szso40 PDFJoselo LópezAinda não há avaliações

- Iit LectureDocumento38 páginasIit LectureNIshantAinda não há avaliações

- DEPT. of Computer Science Engineering SRM IST, Kattankulathur - 603 203Documento5 páginasDEPT. of Computer Science Engineering SRM IST, Kattankulathur - 603 203nielabh GireyAinda não há avaliações

- Dual JK Negative Edge-Triggered Flip-Flop SN54/74LS114A: Low Power SchottkyDocumento4 páginasDual JK Negative Edge-Triggered Flip-Flop SN54/74LS114A: Low Power Schottkydistrict19Ainda não há avaliações

- VNA2180 ReviewDocumento8 páginasVNA2180 ReviewRamot M HutabaratAinda não há avaliações

- Scratch KeyDocumento7 páginasScratch KeyJUAN CADILLO LEONAinda não há avaliações

- 4-2.0L Gasoline EngineDocumento187 páginas4-2.0L Gasoline EngineMarco Antonio Tomaylla Huamani100% (1)

- Digital Lab ManualDocumento87 páginasDigital Lab ManualKALAIMATHIAinda não há avaliações

- Intelligent Alcohol Detection System For CarDocumento4 páginasIntelligent Alcohol Detection System For CarNoslen Alois EstradaAinda não há avaliações

- Asus N550jk E-ManualDocumento140 páginasAsus N550jk E-Manualzlaja3011Ainda não há avaliações

- Mitutoyo - Mikroskopy Pomiarowe TM Seria - E14013 - 2015Documento4 páginasMitutoyo - Mikroskopy Pomiarowe TM Seria - E14013 - 2015D.T.Ainda não há avaliações

- Complete Note On Solar Panel InstallationDocumento3 páginasComplete Note On Solar Panel InstallationtowfiqeeeAinda não há avaliações

- Topic 7.3 - The Structure of MatterDocumento57 páginasTopic 7.3 - The Structure of MatterPaul Amezquita100% (2)

- Resume Doudoulekata TebungagiDocumento5 páginasResume Doudoulekata TebungagiDouglas TebungagiAinda não há avaliações

- User Guide For Adjustable Delay Timer Relay 12V & 24V 10ADocumento2 páginasUser Guide For Adjustable Delay Timer Relay 12V & 24V 10AThai TaAinda não há avaliações

- Aoc 152v Tsum16akDocumento49 páginasAoc 152v Tsum16akedyAinda não há avaliações

- Impedance in Audio Lundahl TransformerDocumento6 páginasImpedance in Audio Lundahl TransformerVũThậpAinda não há avaliações

- Samsung LED Repair ManualDocumento79 páginasSamsung LED Repair ManualStephen Boyce83% (12)