Escolar Documentos

Profissional Documentos

Cultura Documentos

Lifting Lug Design Thuwal

Enviado por

narutothunderjet2160 notas0% acharam este documento útil (0 voto)

1K visualizações80 páginasCCS X

Título original

lifting lug design Thuwal.xls

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

XLS, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoCCS X

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato XLS, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

1K visualizações80 páginasLifting Lug Design Thuwal

Enviado por

narutothunderjet216CCS X

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato XLS, PDF, TXT ou leia online no Scribd

Você está na página 1de 80

NESMA HAVATEK

Project Name : Lifting Beam

10

DESIGN OF LIFTING LUG

INPUT

Thickness t= 0.9843 inches

Diameter of hole d= 1.85 inches

Dimension a a= 1.45 inches

Dimension e e= 1.9685 inches

Ultimate steel strength F

u

= 58 ksi

Yeild strength

F

y

=

36 ksi

Geometric Guidelines:

Rule 1: OK

Rule 2: OK

Evaluation based on Failure Mode:

Failure Mode 1:

This failure mode involves tension failure on both sides of the hole.

Ultimate tensile load P

u

=2.a.t.F

u

165.55926 kips

Factor of safety FS= 5

P

w1

=P

u

/FS P

w1

= 33.112 kips

Failure Mode 2:

diameter of pin d

pin

= 1.35 inches

P

w2

=0.9.F

y

.t.d

pin

/1.8 P

w2

= 23.918 kips

Failure Mode 3:

P

w3

=2x0.4.F

y

.e.t/1.8 P

w3

= 31.002 kips

Failure Mode 4:

P

w4

=1.67x0.67F

y

.e

2

.t/1.8d P

w4

= 46.137 kips

Failure Mode 5:

Rule 3: OK

There are some geometric guidelines to be considered as recommended in

Ref 1. They will be called Rule 1 and Rule 2.

Rule 3: The thickness of lug is greater than or equal to 0.5 inches

This Failure mode involves bearing failure at the pin/lifting lug interface. Often

the pin diameter is much less than the hole diameter. Let us assume a pin

diameter 1/2" less than the hole diameter. Using a bearing stress of 0.9F

y

,

and a "factor" of 1.8

This Failure mode involves shear failure as the pin tries to push out a block of

steel through the edge of the lug plate. The shear area is twice the cross-

sectional area beyond the hole for the pin.

This failure mode involves tensile failure as the pin tries to push out of a block

of steel through the edge of the lug plate. Assume a block of steel 0.8d in

length.

This failure mode involves the out-of-plane buckling failure of the lug. Per Ref.

1, this failure is prevented by ensuring a minimum thickness of lug of 0.5

inches and 0.25 times the hloe diameter d. These are refered to as Rule 3 and

Rule 4 here.

Rule 1: The dimension "a" must be greater than or equal to half the hole

diameter, d.

Rule 2: The dimension "e" must be greater than or equal to 0.67 times the

hole diameter, d

a

e

Page 1

NESMA HAVATEK

Project Name : Lifting Beam

10

Rule 4: OK

AISC Code Checks per Section D3.2:

Requirement 1:

A

1

=t.e 1.93759455 in2

A

2

=2.a.t 2.85447 in2

Compare A1 and A2 A

1

>=2/3xA

2

Reduced dimension 'a' a

eff

= 1.45 inches

Requirement 2:

4xt>a

a

eff

1.45 inches

Requirement 3:

d>1.25.a

Reduced dimension 'a' a

eff

= 1.45 inches

Tensile capacity based on these 3 requirements

Use minimum a

eff

a

eff

1.45 inches

P

w5

=2.aeffx0.45.Fy.t/1.8 P

w5

25.690 kips

Weld between Lug and Base Plate:

This requirement states that the diameter of the pin hole shall not be less than 1.25 times

distance from the edge of pin hole to the edge of plate 'a'.

OK

This is typically the weakest link in the overhead lifting lug, due to off-set loading. In general,

the lug is rarely directly over the item to be rigged. Conservatively, let us assume that the off-

set is a maximum of 45 degrees in the plane of the lug and 20 degress normal to the plane

of the lug. The additional loads due to off-set can be determined by statics to be as follows:

This requirement states that the distance transverse to the axis of a pin-connected plate

from the edge of the pin hole to the edge of the member, that is dimension 'a' shall not

exceed 4 times the thickness at the pin hole.

OK

Rule 4: The thickness is greater than or equal to 0.25 times the hole diameter

The D3.2 section of AISC code has three separate geometry checks that can be applied to

the lifting lug. If these requirements are not met, a smaller value for "a" should be used for

the calculation of tensile capacity.

This requirement states that the minimum net area beyond the pin hole, parallel to the axis

of the member (A

1

), shall not be less than 2/3 of the net area across the pin hole (A

2

).

OK

Page 2

NESMA HAVATEK

Project Name : Lifting Beam

10

Load W= 16600 lbs

Length of weld along lug thickness t

w

= 2 inches

Lever arm l= 4.252 inches

Length of weld along lug width w= 7.6 inches

a 45 deg

b 20 deg

tan a 1

tan b 0.363970234

f

max

(for 3/8 inch weld) 1694 lbs/in

f

1

4467.086089 lbs

f

2

314.6825984 lbs

f

3

864.5833333 lbs

Resultant of f

1

, f

2

and f

3

4560.853824 lbs

Difference resultant and f

max

2866.853824 lbs Ref. 3

P

w6

= 16.600 kips

Lug Base Material:

Load W= 8283.176018 lbs

f

max

=0.75.Fy/1.8 f

max

= 15 kips

Lug width l

w

=2.a+d 4.75 inches

f

1

28000.19786 lbs

Difference between f

1

and f

max

13000.19786

The analysis is similar to the weld above except that there is no interaction

between tension and shear. The capacity is based on the maximum tensile

stress at the base of the lug.

In order to find P

w6

, the difference between the resultant and f

max

should be zero. To get this, go to Tools

menu and click on Goal Seek. You will get the following window. Fill in as shown below and click OK

This is typically the weakest link in the overhead lifting lug, due to off-set loading. In general,

the lug is rarely directly over the item to be rigged. Conservatively, let us assume that the off-

set is a maximum of 45 degrees in the plane of the lug and 20 degress normal to the plane

of the lug. The additional loads due to off-set can be determined by statics to be as follows:

From Table 3.24 of Steel Handbook,

for 3/8 inche weld factored shear

resistance is 5710 lbs/in. Divided by a

factor of safety of 1.8 we get 1694

lbs/in. (Ref. 4)

W

W tan a

a deg

W

W tan b

b deg

Page 3

NESMA HAVATEK

Project Name : Lifting Beam

10

P

w7

8.283 kips

CONCLUSION:

P

w1

= 33.112 kips

P

w2

= 23.918 kips

P

w3

= 31.002 kips

P

w4

= 46.137 kips

P

w5

= 25.690 kips

P

w6

= 16.600 kips

P

w7

=

8.283 kips

Capacity will be minimum of these 8.283 kips CAPACITY

References:

1. David T. Ricker, "Design and Construction of Lifting Beams", Engineering Journal, 4th Quarter, 1991.

2. AISC Manual of steel Construction (ASD), 9th edition, 1989.

3. Omer Blodgett, "Design of Welded Structures", 1966.

4. CISC Handbook of Steel Construction, 1997.

Notes:

1. As discussed in Ref. 1, using a factor of 1.8 on AISC allowables results in a factor of safety of 5 for A36 steel. This

is in line with ASME B30.20 which required a design factor of 3 on yield strength and ANSI N14.6 which requires a

design factor of 3 on yield strength and 5 on ultimate strength. This is also in line with the load ratings for other

components of the lifting assembly such as slings, shackles, etc.

If additional capacity is desired, the angles a and b can be restricted as needed to increase the capcity of

the lug.

In order to find P

w7

, the difference between f

1

and f

max

should be zero. To get this, go to Tools menu and

click on Goal Seek. You will get the following window. Fill in as shown below and click OK

Page 4

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 5

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 6

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 7

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 8

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 9

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 10

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 11

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 12

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 13

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 14

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 15

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 16

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 17

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 18

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 19

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 20

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 21

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 22

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 23

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 24

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 25

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 26

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 27

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 28

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 29

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 30

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 31

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 32

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 33

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 34

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 35

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 36

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 37

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 38

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 39

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 40

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 41

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 42

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 43

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 44

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 45

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 46

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 47

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 48

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 49

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 50

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 51

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 52

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 53

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 54

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 55

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 56

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 57

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 58

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 59

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 60

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 61

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 62

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 63

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 64

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 65

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 66

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 67

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 68

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 69

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 70

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 71

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 72

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 73

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 74

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 75

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 76

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 77

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 78

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 79

NESMA HAVATEK

Project Name : Lifting Beam

10

Page 80

Você também pode gostar

- Fe Report of Base SkidDocumento16 páginasFe Report of Base SkidpawanAinda não há avaliações

- Lifting Lug DesignDocumento18 páginasLifting Lug DesignRui Salvador0% (1)

- Lifting Lug DesignDocumento6 páginasLifting Lug DesignmaniaxpdfAinda não há avaliações

- Simply Support Beam. Centre LoadDocumento7 páginasSimply Support Beam. Centre LoadjhsompuraAinda não há avaliações

- Latest Lifting LugDocumento8 páginasLatest Lifting Lugjagannadha varmaAinda não há avaliações

- Tailing LugDocumento12 páginasTailing LuguvarajmecheriAinda não há avaliações

- Calculation Lifting LugDocumento4 páginasCalculation Lifting Lugelang purbayaAinda não há avaliações

- Pad Eye Design CalculationDocumento7 páginasPad Eye Design CalculationLưu Xuân0% (1)

- 6a Padeye Aisc 360 2005Documento6 páginas6a Padeye Aisc 360 2005mjlazoAinda não há avaliações

- Sfex Pad Eyes Calculations 35T - 32MMDocumento1 páginaSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaAinda não há avaliações

- Pveng: Pressure Vessel Engineering LTDDocumento5 páginasPveng: Pressure Vessel Engineering LTDBruno TrujilloAinda não há avaliações

- Lifting Lug CapacityDocumento1 páginaLifting Lug CapacityfutzbubbleAinda não há avaliações

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADocumento1 página2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanAinda não há avaliações

- #754 v-3103 Spreader & Lifting 60 DegreeDocumento12 páginas#754 v-3103 Spreader & Lifting 60 DegreeHafizi HZnumismatic100% (1)

- Spreader Bar3 - L.9 M-CertificationDocumento10 páginasSpreader Bar3 - L.9 M-CertificationsiagiandobahAinda não há avaliações

- Monorail DesignDocumento24 páginasMonorail DesignBolarinwadeAinda não há avaliações

- Platform Cleat CalculationDocumento1 páginaPlatform Cleat Calculationmiteshpatel191Ainda não há avaliações

- Welded Connection 1Documento2 páginasWelded Connection 1engineeringyusufAinda não há avaliações

- Most Applications, F.S. 5.0) : Calculation ReferenceDocumento5 páginasMost Applications, F.S. 5.0) : Calculation ReferenceParthibanAinda não há avaliações

- Calculation of Lifting ForcesDocumento9 páginasCalculation of Lifting ForcesprantikduarahAinda não há avaliações

- Bolted Moment Connection 2x2Documento22 páginasBolted Moment Connection 2x2Немања Караклајић100% (1)

- Revised Pedestal CalculationsDocumento2 páginasRevised Pedestal Calculationsvikash kumarAinda não há avaliações

- Calculation Pipe Clamp 10 BarDocumento13 páginasCalculation Pipe Clamp 10 BarDica Rasyid MaulidhaniAinda não há avaliações

- Lifting Lug AnalysisDocumento3 páginasLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Cdo CalcDocumento3 páginasCdo CalcJeric FarinAinda não há avaliações

- Lifting Lug Load Capacity Vs Crack Length CalculationDocumento26 páginasLifting Lug Load Capacity Vs Crack Length CalculationRajneesh Pratap SinghAinda não há avaliações

- Heat ExchangersDocumento30 páginasHeat ExchangersvpjagannaathAinda não há avaliações

- Padeye .5MT CHKDocumento12 páginasPadeye .5MT CHKDhanraj VasanthAinda não há avaliações

- Lug For SkidDocumento12 páginasLug For Skidsurefooted1Ainda não há avaliações

- Spreader BeamDocumento7 páginasSpreader BeamAnonymous sfkedkymAinda não há avaliações

- Lifting Calculation REV ADocumento1 páginaLifting Calculation REV APohn Myint HanAinda não há avaliações

- Design of Pad Eye Using Check PlatesDocumento3 páginasDesign of Pad Eye Using Check Plateshyoung65Ainda não há avaliações

- Pin Design AISCDocumento3 páginasPin Design AISCFernando SimaAinda não há avaliações

- 1st Stage Lifting & Transportation AX 010915Documento95 páginas1st Stage Lifting & Transportation AX 010915Fauzan Rusmayadi ReharderAinda não há avaliações

- LIFTING LUG Weld Check KGDocumento4 páginasLIFTING LUG Weld Check KGjoerijiAinda não há avaliações

- Lifting Lug CalculationDocumento2 páginasLifting Lug CalculationAnonymous sfkedkymAinda não há avaliações

- Lifting Lug CalculationDocumento4 páginasLifting Lug CalculationLokesh PatelAinda não há avaliações

- Pin Connected Tension MemberDocumento2 páginasPin Connected Tension MemberAUNGPSAinda não há avaliações

- Calculation For Lifting Lug On Channel Shell: Provided Thickness Is More Than Required ThicknessDocumento6 páginasCalculation For Lifting Lug On Channel Shell: Provided Thickness Is More Than Required ThicknessErin JohnsonAinda não há avaliações

- Aisc 34Documento4 páginasAisc 34AlaaBadwyAinda não há avaliações

- Lifting Lug Weld DesignR1aDocumento1 páginaLifting Lug Weld DesignR1aJohnclaude ChamandiAinda não há avaliações

- Padeye Design: Project: Prepared By: Client: Date: 14-May-20 CaseDocumento7 páginasPadeye Design: Project: Prepared By: Client: Date: 14-May-20 CaseFian ArdiyanaAinda não há avaliações

- Sample Section Modulas CalculationDocumento18 páginasSample Section Modulas CalculationShamik ChowdhuryAinda não há avaliações

- Leaflet Swing Beam Spreader PDFDocumento1 páginaLeaflet Swing Beam Spreader PDFGhyd ArtiagaAinda não há avaliações

- Bolt Patterns: Exhaust StackDocumento8 páginasBolt Patterns: Exhaust Stackmdelacua2Ainda não há avaliações

- Shear Strength Calculation For Lifting Lug For Plate FlippingDocumento16 páginasShear Strength Calculation For Lifting Lug For Plate FlippingKarthikeyan VisvakAinda não há avaliações

- Lifting Lug CalculationDocumento7 páginasLifting Lug CalculationErin JohnsonAinda não há avaliações

- Trunnion 6 TonDocumento3 páginasTrunnion 6 TonEngr Khurram Jaan RamayAinda não há avaliações

- Gantry Girder DesignDocumento6 páginasGantry Girder DesignpandianAinda não há avaliações

- Curved - Monorail - As Per Is 800Documento2 páginasCurved - Monorail - As Per Is 800dsanandaAinda não há avaliações

- Design Calculation LiftingDocumento19 páginasDesign Calculation LiftingAbu Al Sayyid100% (1)

- Beam DesignDocumento6 páginasBeam DesignrustamriyadiAinda não há avaliações

- Pad Eye New ReleaseDocumento10 páginasPad Eye New ReleaseRaza AidanAinda não há avaliações

- Lifting Lug DesignDocumento7 páginasLifting Lug DesignJens SøndergaardAinda não há avaliações

- Lifting Lug CalculationDocumento8 páginasLifting Lug CalculationLathesh JanarthananAinda não há avaliações

- Bottom LugDocumento7 páginasBottom LugAjiri IvoviAinda não há avaliações

- Lifting Lug DesignDocumento7 páginasLifting Lug DesignadammzjinAinda não há avaliações

- Lifting Lug DesignDocumento7 páginasLifting Lug Designnitinphadtare100% (1)

- Sheave Manual SMDocumento8 páginasSheave Manual SMLutfi IsmailAinda não há avaliações

- Orbital Tube Welding PDFDocumento7 páginasOrbital Tube Welding PDFnarutothunderjet216100% (1)

- Anak 'Child',作者:Freddie Aguilar, 1978 ANAK (Original song & lyrics in Filipino)Documento1 páginaAnak 'Child',作者:Freddie Aguilar, 1978 ANAK (Original song & lyrics in Filipino)narutothunderjet216Ainda não há avaliações

- Riser GuideDocumento120 páginasRiser GuideAndrea ZuritaAinda não há avaliações

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocumento4 páginasSummary ISO TR 15608 Metallic Materials Grouping SystemV SwamiAinda não há avaliações

- Welders, CWI Inspectors, Instructors Now You Can Design Your Inspection Tool KitDocumento2 páginasWelders, CWI Inspectors, Instructors Now You Can Design Your Inspection Tool Kitcamelod555Ainda não há avaliações

- Bargarefg4re Gra H5 Gtve5t3 54g Eth W54 Hnt4 6 Twry45y2 46 U5 264 4Documento1 páginaBargarefg4re Gra H5 Gtve5t3 54g Eth W54 Hnt4 6 Twry45y2 46 U5 264 4narutothunderjet216Ainda não há avaliações

- Echnical Ulletin: Cmnsi P S CrmoDocumento1 páginaEchnical Ulletin: Cmnsi P S Crmonarutothunderjet216Ainda não há avaliações

- Report of Lifting Beam DesignDocumento5 páginasReport of Lifting Beam Designnarutothunderjet216100% (1)

- How To Take A Weld Test (UAWT)Documento4 páginasHow To Take A Weld Test (UAWT)narutothunderjet216Ainda não há avaliações

- Boxfile LabelDocumento2 páginasBoxfile Labelnarutothunderjet216Ainda não há avaliações

- Word 9Documento1 páginaWord 9narutothunderjet216Ainda não há avaliações

- BrochupdfDocumento24 páginasBrochupdfnarutothunderjet216Ainda não há avaliações

- Aaadoc 1Documento1 páginaAaadoc 1narutothunderjet216Ainda não há avaliações

- ,mhlfp765 8t76jye 34t3rbtshd 65trhs6wDocumento1 página,mhlfp765 8t76jye 34t3rbtshd 65trhs6wnarutothunderjet216Ainda não há avaliações

- Star Very GoodDocumento8 páginasStar Very Goodnarutothunderjet216Ainda não há avaliações

- EquationcscxDocumento1 páginaEquationcscxnarutothunderjet216Ainda não há avaliações

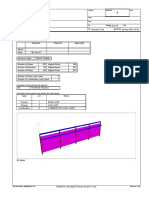

- Beam Design ThuwalDocumento5 páginasBeam Design Thuwalnarutothunderjet216Ainda não há avaliações

- AWS WPQR WPS FormularioDocumento1 páginaAWS WPQR WPS FormularioAntonio RuscittoAinda não há avaliações

- Welding Performance QualificationDocumento5 páginasWelding Performance Qualificationnarutothunderjet216Ainda não há avaliações

- STEEL PIPE For Automatic Sprinkler SystemsDocumento51 páginasSTEEL PIPE For Automatic Sprinkler Systemsnarutothunderjet216Ainda não há avaliações

- Welder Qualification PDFDocumento7 páginasWelder Qualification PDFnarutothunderjet216Ainda não há avaliações

- Welder Qualification (ALL CODES)Documento3 páginasWelder Qualification (ALL CODES)narutothunderjet216Ainda não há avaliações

- AWS Welding Performance Qualification StandardDocumento12 páginasAWS Welding Performance Qualification Standardnarutothunderjet216Ainda não há avaliações

- Piping Class Summary - OSBL PDFDocumento2 páginasPiping Class Summary - OSBL PDFnarutothunderjet216100% (1)

- Painting Specification - 11 11 16Documento13 páginasPainting Specification - 11 11 16narutothunderjet216Ainda não há avaliações

- A106 A672 A53 API5L ComparisonDocumento4 páginasA106 A672 A53 API5L Comparisonkyashkumar100% (10)

- S275JRDocumento1 páginaS275JRShahzad QamarAinda não há avaliações

- Insulation PDFDocumento10 páginasInsulation PDFnarutothunderjet216100% (1)

- Piping Class Summary - CM2Documento1 páginaPiping Class Summary - CM2narutothunderjet216100% (1)

- SMAW 10 - Q1 - W2 - Mod2Documento16 páginasSMAW 10 - Q1 - W2 - Mod2Romeo Dela RosaAinda não há avaliações

- SF AERO Skills Map Aircraft Maintenance Track PDFDocumento50 páginasSF AERO Skills Map Aircraft Maintenance Track PDFrehannstAinda não há avaliações

- 26 - Improved Forged Crankshaft Performance Utilizing Deep RollingDocumento23 páginas26 - Improved Forged Crankshaft Performance Utilizing Deep RollingandypressAinda não há avaliações

- Kyletsai Aero ResumeDocumento2 páginasKyletsai Aero ResumeKyle TsaiAinda não há avaliações

- Fatigue Under Mean ConditionsDocumento6 páginasFatigue Under Mean Conditionsrizzo8Ainda não há avaliações

- ICE Student Chapter PaperworkDocumento11 páginasICE Student Chapter PaperworkMoh BayoAinda não há avaliações

- 1 First Fence StaadDocumento8 páginas1 First Fence StaadSiva JaseAinda não há avaliações

- Tremix Flooring PDFDocumento4 páginasTremix Flooring PDFdinkad29Ainda não há avaliações

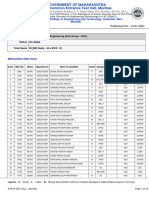

- 3175 - M.G.M.'s College of Engineering and Technology, Kamothe, Navi MumbaiDocumento20 páginas3175 - M.G.M.'s College of Engineering and Technology, Kamothe, Navi MumbaiPrashant ChouguleAinda não há avaliações

- Different Approaches in Modeling of RC Shear Wall: A ReviewDocumento15 páginasDifferent Approaches in Modeling of RC Shear Wall: A Reviewrahimmulla100% (2)

- Ibrahim Alquraishi's CVDocumento1 páginaIbrahim Alquraishi's CVAnonymous Mz5S9Mn6bAinda não há avaliações

- Readme 14 PDFDocumento25 páginasReadme 14 PDFVenomKarmaAinda não há avaliações

- Terms of ReferenceDocumento5 páginasTerms of ReferenceSetemi 'sherlock' ObatokiAinda não há avaliações

- Business PlanDocumento105 páginasBusiness PlanmarinelascribdAinda não há avaliações

- CCN144 Studio 5000 Logix Designer Level 4 Kinetix 6500 (CIP) ProgrammingDocumento2 páginasCCN144 Studio 5000 Logix Designer Level 4 Kinetix 6500 (CIP) Programmingبلال حسينيAinda não há avaliações

- Durham Uni H1K609: New and Renewable EnergyDocumento7 páginasDurham Uni H1K609: New and Renewable Energysy4nAinda não há avaliações

- Shock & Vibration Handbook (1) - 8 PDFDocumento1 páginaShock & Vibration Handbook (1) - 8 PDFjohnaustin1Ainda não há avaliações

- SDLG E6350hDocumento1 páginaSDLG E6350hrizqin ilmanAinda não há avaliações

- DiffEq SyllabusDocumento16 páginasDiffEq SyllabusFrendick LegaspiAinda não há avaliações

- CE 632 Design of Prestressed ConcreteDocumento1 páginaCE 632 Design of Prestressed ConcretemuhammadAinda não há avaliações

- FACTS Edited by SongDocumento523 páginasFACTS Edited by Songdejan9267% (3)

- Lesson Plan in Science Perpetuation of Life I. Learning ObjectivesDocumento3 páginasLesson Plan in Science Perpetuation of Life I. Learning ObjectivesRachel Lorenzo SaldoAinda não há avaliações

- National Bioeconomy Blueprint USADocumento6 páginasNational Bioeconomy Blueprint USAJulieta SeifertAinda não há avaliações

- PLTW - Computer Integrated Manufacturing - 2017Documento2 páginasPLTW - Computer Integrated Manufacturing - 2017Eduardo OrnelasAinda não há avaliações

- JL-93-July-August Guidelines For The Use of Epoxy-Coated Strand PDFDocumento7 páginasJL-93-July-August Guidelines For The Use of Epoxy-Coated Strand PDFDeris BagusAinda não há avaliações

- Enebi Water Supply TalkoffDocumento101 páginasEnebi Water Supply TalkoffMiko AbiAinda não há avaliações

- 530.1R-05 Specification For Masonry Structures and CommentaryDocumento1 página530.1R-05 Specification For Masonry Structures and CommentaryCenteno NelsonAinda não há avaliações

- HVDS BasicDocumento67 páginasHVDS Basicjothipriyad100% (1)

- Understanding of The ScopeDocumento2 páginasUnderstanding of The ScopeSijo JoyAinda não há avaliações

- 6 SheetpileDocumento2 páginas6 SheetpileIwan Dirgantara100% (2)