Escolar Documentos

Profissional Documentos

Cultura Documentos

P&G steam piping safety plan

Enviado por

sacbalo0 notas0% acharam este documento útil (0 voto)

36 visualizações6 páginas1. The document outlines a safety plan for a contractor installing 5" steam piping at a Procter & Gamble plant in Ibadan, Nigeria.

2. The work is scheduled to take place from May 2014 to June 2014 and will involve fabricating and installing pipes, as well as non-destructive testing and hydrostatic testing.

3. The safety plan details the risks associated with each task and the control measures required to mitigate those risks, such as using proper personal protective equipment, restricting access to work areas, and ensuring only qualified personnel perform specialized tasks.

Descrição original:

Título original

Almadina Safety Paln

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documento1. The document outlines a safety plan for a contractor installing 5" steam piping at a Procter & Gamble plant in Ibadan, Nigeria.

2. The work is scheduled to take place from May 2014 to June 2014 and will involve fabricating and installing pipes, as well as non-destructive testing and hydrostatic testing.

3. The safety plan details the risks associated with each task and the control measures required to mitigate those risks, such as using proper personal protective equipment, restricting access to work areas, and ensuring only qualified personnel perform specialized tasks.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

36 visualizações6 páginasP&G steam piping safety plan

Enviado por

sacbalo1. The document outlines a safety plan for a contractor installing 5" steam piping at a Procter & Gamble plant in Ibadan, Nigeria.

2. The work is scheduled to take place from May 2014 to June 2014 and will involve fabricating and installing pipes, as well as non-destructive testing and hydrostatic testing.

3. The safety plan details the risks associated with each task and the control measures required to mitigate those risks, such as using proper personal protective equipment, restricting access to work areas, and ensuring only qualified personnel perform specialized tasks.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 6

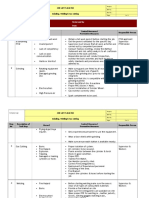

Health Safety & Environment

Procter & Gamble, Ibadan Plant

CONTRACTOR: ALMADINA ENGINEERING

SAFETY PLAN FOR STEAM PIPINGS @ LEVEL AT F&HC

Background: Fabrication and installation of 5 steam piping.

Work Supervision and Duration

1. Work is proposed to start May. 2014 8am to 6pm daily.

2. Supervision will be done by mechanical construction manager when the job is going on.

Work Description:

Mobilizing of tools and equipments to site/lay down area

Barricading of the site with caution tape.

Erecting scaffold for pipes installation

Marking & Taking pipes measurement for fabrication of pipes.

Fabricating and painting of pipes in the lay down area

Installation of fabricated pipes.

Dye Penetrate examination ( NDT)

Hydrostatics testing

Open hole on the cladding

Housekeeping and exit site

Site clearance

Work Supervision and Duration

The contractors, due to their eligibility are familiar with the scope of the work. Prefabrication will be done in lay

down area. Work will be supervised by mechanical construction manager on site. All equipment will be checked by

P & G safety personnel and approved prior to the personnels usage.

Additional Consideration

1. There will be a housekeeping programme to clear the site before and after work is completed.

2. The following basic PPEs must be used by the contractor while doing the job; safety shoe, hard hat, hand

glove, other PPE will be as per task performed and must be inspected before use.

3. The area of work will be properly barricaded with caution tape.

4. P&G approved disciplinary action / matrix will be implemented on any personnel / contractor found violating

safety rules.

5. ALMADINA ENGINEERING will be given in a documented warning where same staff is observed to violate

same expectations more than once.

6. Any life threatening behavior will lead to an immediate dismissal of the affected individual from site.

7. First aid box would be provided and first aiders to be on alert, for immediate administration of first aid

before transport to hospital.

Alignments:

HSE OFFICER P&G WORK SUPERVISOR CONTRACTOR

RISK ASSESSMENT FOR STEAM PIPINGS @ LEVEL AT F&HC.

S/N Work RISK POSSIBLE CAUSES CONTROL MEASURES

1. Mobilizing to

site/lay down

area

Vehicle hit, collision,

Cuts, bruise,

Driver not keeping to speed limit,

unlicensed driver driving, when

offloading materials,

Only licensed driver

should drive vehicle,

driver should keep to

speed P&G Speed

limit(10km/hr), Wear

cotton gloves, and

good safety shoes

when offloading.

Adequate supervision.

2. Barricading of

the site with

caution tape

Unauthorized persons

accessing work area

No visible administrative control in

place: e.g. safety signs

Barricade work area

with caution tape, use

sign posts for direction

changes

3 Erecting

scaffold for

pipes

installation

Cuts/bruise, head

injuries, back pain,

impact/hit, fall from

height, object drop,

collision.

Bad tools, wrong use of tools,

Inexperienced technician, Sharp Cutting

tools. Improperly secured materials when

lifting to height. Falling of the pipes

when lifting. Throwing & dropping of

tools/materials from height, Worker not

using the necessary PPEs (hand gloves,

body harness, helmet and lanyard &

anchorage properly), worker

carelessness/horseplay,

Obtain a scaffold

erection permit

Only qualified

technician should erect

scaffolds.

Secure pipes with rope

when lifting.

The technician is not

working under the

influence of alcohol or

medication (perceive

breathe).

The material (scaffold

pipes and platform

materials etc.) are

properly secured

before lifting.

Obtain scaffold

approval green tag

after erection & hang

on scaffold prior to use.

Worker should use the

necessary PPEs (hand

gloves, body harness,

helmet and lanyard &

anchorage properly);

Adequate supervision.

4 Marking &

Taking pipes

measurement

for fabrication

of pipes.

Cuts, bruise, fall from

height, slip, head bump,

hearing discomfort,

falling object, collision

with equipment,

Sharp/ rough objects & surfaces, poor

access to height, wet floor, noise from

boiler & compressor, Fixed equipment

on the floor,

Access heights with

inspected and

approved scaffold/ A-

ladder, clean floor of

wet substance, Wear

necessary PPEs ( cotton

hand gloves, coverall,

safety boot, hard hat),

ensure adequate

lighting in work area

5. Fabricating and Thermal burns, Cuts Hot metal, flying sparks, infrared Obtain a hot-work

painting of

pipes in the lay

down area

&bruise, electric shock,

trip & fall, Fire outbreak,

Eye irritations/strain,

headache/fatigue,

respiratory problems,

hearing discomfort,

head injuries, back pain,

object drop, Paint splash

& spill, skin irritation,

dizziness, fatigue,

radiation, Cutting/grinding disc fly-off &

shatter, inferior & damaged discs,

grinding machine without guard,

damaged electric cables, trailing cables,

Combustible and flammable materials

(liq, vap), Flying chips from

grinding/cutting materials, metal fume

& dusts, horseplay, over exposure of

workers, noise, bad tools, wrong use of

tools, exposed cable wires, poor/wrong

power connections, workers not using

the right PPES

permit

Only qualified welders

&fitters should perform

the task.

Inspect & approve all

equipment/tools

before use. Welding

surfaces should be

fireproof/ non

combustible, Ensure

work area is free of

combustible &

flammable

materials(liq, vap)

Correct use of PPEs

(leather gloves, safety

boots, hardhats,

coverall, face shield &

goggle, Ear/plugs, nose

mask), Functional fire

extinguisher present at

hot work area,

Standby Fire watch

Ensure the

oxyacetylene

cylinders/apparatuses

are in good conditions

& proper settings(

hose, valves, arrestors,

etc)

Workers rest per shift

as @ when due,

workers should use the

right PPES correctly

always (safety boot,

cotton& leather gloves

hand gloves, nose

mask, hard hat, safety

goggles, nose mask).

Adequate supervision.

No lone-worker is

allowed

6 Installation &

welding of

fabricated pipes

& supports.

Thermal burns, Cuts

&bruise, electric shock,

trip & fall, Fire outbreak,

Eye irritations/strain,

headache/fatigue,

respiratory problems,

hearing discomfort,

head injuries, back pain,

object drop,

Hot metal, flying sparks, infrared

radiation, Cutting/grinding disc fly-off &

shatter, inferior & damaged discs,

grinding machine without guard,

damaged electric cables, trailing cables,

Combustible and flammable materials

(liq, vap), Flying chips from

grinding/cutting materials, metal fume

& dusts, horseplay, over exposure of

workers, noise, bad tools, wrong use of

tools, exposed cable wires, poor/wrong

power connections, workers not using

the right PPES

Obtain a hot-work

permit

Only qualified welders

& fitters should

perform the task.

Inspect & approve all

equipment/tools

before use. Welding

surfaces should be

fireproof/ non

combustible, Ensure

work area is free of

combustible &

flammable

materials(liq, vap)

Correct use of PPEs

(leather gloves, safety

boots, hardhats,

coverall, face shield &

goggle, Ear /plugs),

Functional fire

extinguisher must be

present at hot work

area, Standby Fire

watch

Ensure the

oxyacetylene

cylinders/apparatuses

are in good conditions

& proper settings(

hose, valves, arrestors,

etc)

Workers rest per shift

as @ when due,

workers should use the

right PPES correctly

always (safety boot,

cotton& leather gloves

hand gloves, nose

mask, hard hat, safety

goggles). Adequate

supervision.

No lone-worker is

allowed

7. Tie-in of newly

constructed

steam line into

the crusher

Steam line explosion,

burns, steam water

spills, Thermal burns,

Cuts &bruise, electric

shock, trip & fall, Fire

outbreak, Eye

irritations/strain,

headache/fatigue,

respiratory problems,

hearing discomfort,

head injuries, back pain,

object drop,

Hot water splash, flying sparks, infrared

radiation, Cutting/grinding disc fly-off &

shatter, inferior & damaged discs,

grinding machine without guard,

damaged electric cables, trailing cables,

Combustible and flammable materials

(liq, vap), Flying chips from

grinding/cutting materials, metal fume

& dusts, horseplay, over exposure of

workers, noise, bad tools, wrong use of

tools, exposed cable wires, poor/wrong

power connections, workers not using

the right PPES

Obtain line breaking

permit Obtain a hot-

work permit

Only qualified welders

& fitters should

perform the task.

Inspect & approve all

equipment/tools

before use. Welding

surfaces should be

fireproof/ non

combustible, Ensure

work area is free of

combustible &

flammable

materials(liq, vap)

Correct use of PPEs

(leather gloves, safety

boots, hardhats,

coverall, face shield &

goggle, Ear /plugs),

Functional fire

extinguisher must be

present at hot work

area, Standby Fire

watch

Ensure the

oxyacetylene

cylinders/apparatuses

are in good conditions

& proper settings(

hose, valves, arrestors,

etc)

Workers rest per shift

as @ when due,

workers should use the

right PPES correctly

always (safety boot,

cotton& leather gloves

hand gloves, nose

mask, hard hat, safety

goggles). Adequate

supervision.

No lone-worker is

allowed

8. Dye Penetrate

examination (

NDT)

Thermal burns, Cuts

&bruise, electric shock,

trip & fall, Fire outbreak,

Eye irritations/strain,

Flying chips from grinding/cutting

materials, metal fume & dusts,

horseplay, over exposure of workers,

noise, bad tools, wrong use of tools,

exposed cable wires, poor/wrong power

connections, workers not using the right

PPES

Competent personal

must handle NDT

inspection.

Correct use of PPEs

(leather gloves, safety

boots, hardhats,

coverall, face shield &

goggle, Ear /plugs),

Functional fire

extinguisher must be

present at hot work

area, Standby Fire

watch

8. Hydrostatics

testing

Flooding, slip, trip and

fall.

Busted water hose, porous / leakages on

the lines

Stand by housekeeper

to wipe off spill water

as the task progresses,

use appropriate tools

for the task

9. Open hole on

the cladding

sheet

Cuts/bruise, head

injuries, back pain,

impact/hit, fall from

height, object drop.

Bad tools, wrong use of tools,

Inexperienced technician, Sharp Cutting

tools. Improperly secured materials when

lowering from height. Worker not using

the necessary PPEs (hand gloves, body

harness, helmet carelessness/horseplay,

Only qualified

technician should

perform this task.

Secure cladding with

rope when lowering.

The technician is not

working under the

influence of alcohol or

medication (perceive

breathe).

Worker should use the

necessary PPEs (hand

gloves, body harness,

helmet and Adequate

supervision.

10. Housekeeping

and exit site

Cuts, bruise, dust

inhalation

Metal scraps, metal dust, dust particles, Ensure housekeeping is

on-going

Ensure cleaner wears

cotton gloves, nose

mask, safety shoes,

metal bin for hot iron

11. Site clearance

Vehicle hit, collision,

Cuts, bruise,

Driver not keeping to speed limit,

unlicensed driver driving, when

offloading materials,

Only licensed driver

should drive vehicle,

driver should keep to

speed limit(10km/hr),

Wear cotton gloves,

and good safety shoes

when offloading.

Adequate supervision.

ADDITIONAL CONSIDERATIONS:

1. Deploy this risk analysis to workers before starting the job.

2.) Toolbox Attendance sheet should be attached to the line breaking permit to be filled.

3.) Make provision for standby ambulance as contingency plan.

4.) All PPEs to be used must be inspected O.K. before use.

Alignments:

__________________ ____________________ ___________________

PROJECT MANAGER SITE HSE CONTRACTOR

Você também pode gostar

- Job Hazard Analysis For Desalination of First Effect RetubingDocumento7 páginasJob Hazard Analysis For Desalination of First Effect Retubingmc chesterAinda não há avaliações

- Haz Repair&MaintDocumento29 páginasHaz Repair&MaintSANJAY PANDYAAinda não há avaliações

- JOB SAFETY ANALYSIS FOR WATER TREATMENT FACILITIESDocumento8 páginasJOB SAFETY ANALYSIS FOR WATER TREATMENT FACILITIESAldrinAinda não há avaliações

- JHA Construction Workshop Air Liquide PhilippinesDocumento3 páginasJHA Construction Workshop Air Liquide Philippinesgerard_borbonAinda não há avaliações

- How Chin Engineering: Job Safety AnalysisDocumento5 páginasHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdAinda não há avaliações

- Aboveground Piping Installation Works 2016Documento7 páginasAboveground Piping Installation Works 2016Aldrin75% (4)

- Jsa For Weld and GrindingDocumento6 páginasJsa For Weld and GrindingTanzeel LiaqatAinda não há avaliações

- Risk Assessment Procedures ManualDocumento12 páginasRisk Assessment Procedures ManualTony Gallacher60% (5)

- OME553 Industrial Safety Engineering: (Open Elective)Documento47 páginasOME553 Industrial Safety Engineering: (Open Elective)Jana garan.s100% (1)

- Jsa For Lifting (Crane) 016Documento6 páginasJsa For Lifting (Crane) 016aliraza572270% (27)

- JSA For KAHSDocumento6 páginasJSA For KAHSFrancis Enriquez TanAinda não há avaliações

- Plumbing SafetyDocumento2 páginasPlumbing Safetyazizi_fadzli100% (1)

- JOB: Welding A Broken Bottle Lifter of A Maheu MachineDocumento4 páginasJOB: Welding A Broken Bottle Lifter of A Maheu MachinemunatsiAinda não há avaliações

- SAFE ERECTION OF ALL WORKSDocumento4 páginasSAFE ERECTION OF ALL WORKSsoubhagyaAinda não há avaliações

- Piling Safety PlanDocumento8 páginasPiling Safety PlanBalogun Isaac100% (1)

- Risk Assessment for Mechanical Work and Welding ProjectsDocumento7 páginasRisk Assessment for Mechanical Work and Welding ProjectsZeb KhanAinda não há avaliações

- How Chin Engineering: Job Safety AnalysisDocumento6 páginasHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdAinda não há avaliações

- JobSafetyAnalysisFM Mech TradesDocumento83 páginasJobSafetyAnalysisFM Mech TradestgvnayagamAinda não há avaliações

- Jsa Grinding Welding Gas CuttingDocumento3 páginasJsa Grinding Welding Gas CuttingRana Waseem Khan84% (75)

- JSA For PVC FlooringDocumento4 páginasJSA For PVC FlooringJavedAinda não há avaliações

- JSA FormDocumento6 páginasJSA FormAjeesh CochinAinda não há avaliações

- Jsa SKDocumento10 páginasJsa SKEngr Tahir UL Haq100% (2)

- BRIEFING ON HSE DM Water TankDocumento7 páginasBRIEFING ON HSE DM Water Tankssb goddaAinda não há avaliações

- JSA For Flue Gas Duct Height WorkDocumento4 páginasJSA For Flue Gas Duct Height Worksubhadipmanna8Ainda não há avaliações

- Angle Grinder SOPDocumento1 páginaAngle Grinder SOPNhypz Marcaida67% (3)

- JSA for Above Ground Piping WorkDocumento3 páginasJSA for Above Ground Piping WorkBhisamS SallehAinda não há avaliações

- Safety Do's & DontsDocumento13 páginasSafety Do's & DontsBrijgopal YadavAinda não há avaliações

- Risk Register: Hazards IdentifiedDocumento5 páginasRisk Register: Hazards IdentifiedthomasAinda não há avaliações

- Grounding System Jsa 2008Documento4 páginasGrounding System Jsa 2008Aldrin100% (5)

- S-PCM Meeting Minutes Insulation InstallDocumento5 páginasS-PCM Meeting Minutes Insulation Installsudeesh kumarAinda não há avaliações

- JHA FORM CompleteDocumento5 páginasJHA FORM Completeangelo177Ainda não há avaliações

- Checklist For High Risk Work - Hot WorkDocumento8 páginasChecklist For High Risk Work - Hot WorkSalsabilla Putri anggrainiAinda não há avaliações

- Gunmaster 400 - Mig - Gun - F 15 613 DDocumento36 páginasGunmaster 400 - Mig - Gun - F 15 613 DmekoxxxAinda não há avaliações

- Jsa Grinding Welding Gas CuttingDocumento3 páginasJsa Grinding Welding Gas CuttingQomarudin Comenk100% (2)

- Workshop Risk AssessmentDocumento7 páginasWorkshop Risk AssessmentJeganeswaran100% (1)

- PPEsDocumento11 páginasPPEsPrithivirajan CuddaloreAinda não há avaliações

- Belt & Orbital Sander PDFDocumento2 páginasBelt & Orbital Sander PDFcityofdarwingisAinda não há avaliações

- Grounding Rod Installation SafetyDocumento5 páginasGrounding Rod Installation SafetyHow Chin Engineering Sdn BhdAinda não há avaliações

- HSE ManualDocumento18 páginasHSE ManualMughees AliAinda não há avaliações

- Risk Assessment No. 41 WORKING IN MACHINERY SPACE Rev. 02 20Documento3 páginasRisk Assessment No. 41 WORKING IN MACHINERY SPACE Rev. 02 20Devi Ratna Pratiwi100% (3)

- Risk Assessment No. 39 WELDING IN GENERAL Rev. 02 20.03.09Documento2 páginasRisk Assessment No. 39 WELDING IN GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi100% (2)

- Job Safety Analysis Work SheetDocumento20 páginasJob Safety Analysis Work SheetBarkat Ullah50% (2)

- Appendix A-Job Safety Analysis FormDocumento3 páginasAppendix A-Job Safety Analysis Formjiks_i4uAinda não há avaliações

- Safety Abrasive WheelDocumento32 páginasSafety Abrasive WheelMohamed Hichem GuesmiAinda não há avaliações

- Ma'aden Ammonia Plant JSA for Painting WorkDocumento2 páginasMa'aden Ammonia Plant JSA for Painting WorkSantos Rex100% (1)

- Risk Assesment of Tank ConstructionDocumento4 páginasRisk Assesment of Tank ConstructionBalogun Isaac100% (4)

- United Mining Industries "Health Safety and Environment General Rules"Documento139 páginasUnited Mining Industries "Health Safety and Environment General Rules"Jakaria Al-MahmudAinda não há avaliações

- Arc Welding - JSADocumento6 páginasArc Welding - JSAdroffilcz27Ainda não há avaliações

- Pha ExcavationDocumento13 páginasPha ExcavationirshadAinda não há avaliações

- Hazard AnalysisDocumento82 páginasHazard AnalysisrickymmaAinda não há avaliações

- Osha Book PDFDocumento76 páginasOsha Book PDFTahir MasoodAinda não há avaliações

- Code: Mech 100.0 Risk Assessment - GrindingDocumento2 páginasCode: Mech 100.0 Risk Assessment - Grindingste23571Ainda não há avaliações

- Angle Grinder PDFDocumento2 páginasAngle Grinder PDFcityofdarwingisAinda não há avaliações

- Workplace Vocabulary for Esl Students: With Exercises and TestsNo EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsAinda não há avaliações

- The Construction Safety Guide: Injury and Illness Prevention through DesignNo EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignNota: 4 de 5 estrelas4/5 (6)

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsNo EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsNota: 3 de 5 estrelas3/5 (8)

- Ultimate Guide to Home Repair and Improvement, 3rd Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsNo EverandUltimate Guide to Home Repair and Improvement, 3rd Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsAinda não há avaliações

- Compress Receipt-6 20230615143642Documento1 páginaCompress Receipt-6 20230615143642sacbaloAinda não há avaliações

- Disciplinary Policy ProceduresDocumento3 páginasDisciplinary Policy ProceduressacbaloAinda não há avaliações

- Zircongeosystem and Engineering ServicesDocumento11 páginasZircongeosystem and Engineering ServicessacbaloAinda não há avaliações

- LicenseDocumento13 páginasLicenseMahes WarAinda não há avaliações

- Disc Nozzle Fan Dust Control Fan Riggs Safe - Work - Method - Statement - Template - SampleDocumento7 páginasDisc Nozzle Fan Dust Control Fan Riggs Safe - Work - Method - Statement - Template - SamplesacbaloAinda não há avaliações

- CORE FORMER FAN. RIGGS Safe - Work - Method - Statement - Template - SampleDocumento8 páginasCORE FORMER FAN. RIGGS Safe - Work - Method - Statement - Template - SamplesacbaloAinda não há avaliações

- MAKKO RIGGS Safe Work Method Statement Template SampleDocumento7 páginasMAKKO RIGGS Safe Work Method Statement Template SamplesacbaloAinda não há avaliações

- Working at Height: Learning Lite ModuleDocumento13 páginasWorking at Height: Learning Lite ModuleTri FebriyaniAinda não há avaliações

- DELUGE SYSTEM RIGGS Safe - Work - Method - Statement - Template - SampleDocumento6 páginasDELUGE SYSTEM RIGGS Safe - Work - Method - Statement - Template - SamplesacbaloAinda não há avaliações

- MS - Removal of Duct Pipes & Duct Control Process Vaccum ConveyorDocumento3 páginasMS - Removal of Duct Pipes & Duct Control Process Vaccum ConveyorsacbaloAinda não há avaliações

- Jan1 11kuharchik Handbook FinalDocumento21 páginasJan1 11kuharchik Handbook FinalsacbaloAinda não há avaliações

- MS - Removal of Railling On Top, Ladder, Doors, Body PanelsDocumento2 páginasMS - Removal of Railling On Top, Ladder, Doors, Body PanelssacbaloAinda não há avaliações

- 2377 s1512 Offshore Pipelines LRDocumento6 páginas2377 s1512 Offshore Pipelines LRsacbaloAinda não há avaliações

- Electrode Catalog 2009Documento56 páginasElectrode Catalog 2009Ismael Isaac Rios JoseAinda não há avaliações

- Mba Final Year ProjectDocumento86 páginasMba Final Year Projectmonica.dAinda não há avaliações

- Haefely Tdr-1150 SpecDocumento2 páginasHaefely Tdr-1150 SpecZain ArhamAinda não há avaliações

- General Biology 2 4 Quarter: Valerie Ross Pinlac Stem 11 GalileoDocumento18 páginasGeneral Biology 2 4 Quarter: Valerie Ross Pinlac Stem 11 GalileoInned NylAinda não há avaliações

- Quality of Work Life: The Determinants of Job Satisfaction and Job Retention Among Rns and OhpsDocumento22 páginasQuality of Work Life: The Determinants of Job Satisfaction and Job Retention Among Rns and OhpsMominah MayamAinda não há avaliações

- 6 Minute English Dealing With Mass UnemploymentDocumento5 páginas6 Minute English Dealing With Mass UnemploymentkateAinda não há avaliações

- ANSI/NETA ETT-2010 Standard for Certification of Electrical Testing TechniciansDocumento13 páginasANSI/NETA ETT-2010 Standard for Certification of Electrical Testing TechniciansPhillip BlackAinda não há avaliações

- Engineered Natural Fibre Composites For Oil and Gas Application: A ReviewDocumento25 páginasEngineered Natural Fibre Composites For Oil and Gas Application: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- Accounting Chapter 2 - Analyzing and Recording TransactionsDocumento72 páginasAccounting Chapter 2 - Analyzing and Recording Transactionsnicat100% (4)

- Medical Service in The European TheaterDocumento675 páginasMedical Service in The European TheaterBob Andrepont100% (4)

- CMT2210LC en V0.9 20170817Documento20 páginasCMT2210LC en V0.9 20170817Ta ToAinda não há avaliações

- Contoh Soalan 14Documento4 páginasContoh Soalan 14Rozaiya RamliAinda não há avaliações

- Asteroid IIIDocumento13 páginasAsteroid IIIlachimolala. kookieee97Ainda não há avaliações

- Novametrix 7100 - User ManualDocumento139 páginasNovametrix 7100 - User ManualNoe Carlos Liviapoma GironAinda não há avaliações

- Traders' QuestionnaireDocumento4 páginasTraders' QuestionnaireHans WinataAinda não há avaliações

- SIP5 7SJ82-85 V09.40 Manual C017-J en CompressedDocumento2.126 páginasSIP5 7SJ82-85 V09.40 Manual C017-J en CompressedMike VillarinoAinda não há avaliações

- EU Summit DR David Martin May 2023Documento6 páginasEU Summit DR David Martin May 2023MA-DocAinda não há avaliações

- Reactions of Carbonyl and Non-carbonyl Functional GroupsDocumento4 páginasReactions of Carbonyl and Non-carbonyl Functional GroupsKashif AliAinda não há avaliações

- Key theories and principles of motivationDocumento19 páginasKey theories and principles of motivationGrace SarteAinda não há avaliações

- Kiln Miscellaneous PDFDocumento69 páginasKiln Miscellaneous PDFAhmad NilAinda não há avaliações

- Saudi Health ExamDocumento90 páginasSaudi Health ExamJafar AP100% (2)

- Construction Health and Safety PolicyDocumento30 páginasConstruction Health and Safety PolicySamuel AntobamAinda não há avaliações

- Type 2 Diabetes - Term PaperDocumento10 páginasType 2 Diabetes - Term Paperapi-581991695Ainda não há avaliações

- Compounding With PhlojelDocumento29 páginasCompounding With PhlojelMichael SchreiberAinda não há avaliações

- A&D - mf50 Manual PDFDocumento74 páginasA&D - mf50 Manual PDFEdgardo AzurAinda não há avaliações

- 8 Firefighter Interview Questions and AnswersDocumento7 páginas8 Firefighter Interview Questions and AnswersMichael John Quintos100% (1)

- Programs That Work 3.1Documento460 páginasPrograms That Work 3.1watchabc100% (10)

- Rottne F18 Forwarder Cab Comfort and FunctionsDocumento8 páginasRottne F18 Forwarder Cab Comfort and Functionstystar_21Ainda não há avaliações

- Project Vestige PDFDocumento28 páginasProject Vestige PDFEunice PondevidaAinda não há avaliações

- Whats It Like To Live Without ElectricityDocumento7 páginasWhats It Like To Live Without ElectricityYazmin Rios100% (2)