Escolar Documentos

Profissional Documentos

Cultura Documentos

Crane Girder

Enviado por

Ralf SnellDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Crane Girder

Enviado por

Ralf SnellDireitos autorais:

Formatos disponíveis

4/28/2010 PCJohnson and JALaman 1

Singly Symmetric Combination Section Crane Girder Design Aids

by

Patrick C. Johnson

The Pennsylvania State University

University Park, PA 16802

and

Jeffrey A. Laman, Ph.D., P.E.

Associate Professor of Civil Engineering

The Pennsylvania State University

University Park, PA 16802

Abstract

Crane runway girders are distinguished by long unbraced lengths and biaxial bending.

Combination sections consisting of a W shape with a channel cap are typically efficient for these

conditions, but time consuming to design due to the iterative process required due to biaxial

bending and the complex stability equations provided in AISC (2005) specifications. This paper

presents developed Z

x

tables, flexural strength graphs, and introduces a trial section selection

method. Included herein are updated design charts to allow for fast and efficient analysis of the

typical combination sections provided in Table 1-19 of the AISC Steel Construction Manual.

Also presented is an overview of crane girder design procedures and an abbreviated design

example.

4/28/2010 PCJohnson and JALaman 2

Introduction

The design or evaluation procedure for combination sections a wide flange with a channel

cap is specified in Section F4 of the AISC Specification for Structural Steel Buildings (AISC,

2005), which covers singly symmetric I-shaped members bent about their major axis. Reversal

of the specified AISC evaluation process for direct design is not feasible; therefore design

becomes a matter of trial and error. The situation is compounded for a combination section that

supports x- and y-axis moments as in the case of a crane girder where Chapter H of the AISC

Specification must be applied. As a result, design aids are needed to streamline the design

process that facilitates rapid selection of the most economical combination section. This paper

updates a previously published paper by Laman (1996), presenting new design aids, formatted in

the style of familiar AISC tables and figures, including the basis by which the aids are developed

and a supporting example. Also presented is a method to determine the equivalent x-axis moment

required for beams subjected to biaxial moments.

There are available many texts and design aids that address the design of industrial buildings

with cranes, such as the design guide by Fisher (2004). While these sources explain the loading

and evaluation required for crane runway girders, they do not offer any systematic approach to

the selection of trial sections. The problems of a trial and error approach are further compounded

by the lack of design aids for quickly determining the capacity of the combination sections.

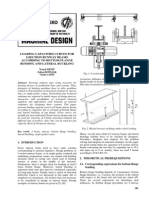

Crane Girder Design Basis

Crane girders are distinguished by long unbraced lengths and combined bending about the x-

and y-axis as well as torsion. For typical loading and spans, a wide flange section with a channel

cap normally provides an efficient cross section for the design. Historically, the assumption has

4/28/2010 PCJohnson and JALaman 3

been made that the channel and the wide flange top flange resist the horizontal loads and the

combination section resists the vertical load. This simplifies the analysis of the actual condition

and eliminates the need for an analysis of torsional effects on the combination section (Laman,

1996). Given the complexity of AISC (2005) design equations due to lateral torsional buckling

strength determination, design tables and graphs are needed to speed the process. Currently the

AISC Specification contains design tables and graphs to assist with wide flange and channel

design under lateral torsional buckling and serve as a model for the aids presented herein. Based

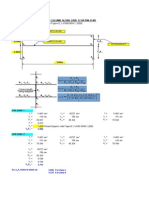

on AISC 2005 Ch F.4 and the flow chart of Figure 1, design aids presented in Table 2 and 3 and

Figures 2 and 3 have been developed. With the availability of these new design aids, a trial

section selection methodology is now possible and is presented here.

M

ueq

Method

Defining the ratio of M

nx

to M

ny

as a plastic section modulus ratio, ZR:

y

x

y y

y x

ny

nx

Z

Z

F Z

F Z

M

M

ZR = = = (1)

and observing that a nearly linear relationship between ZR and |M

nx

exists for each channel

section used as a cap, equation H1-1b can be rearranged into an explicit function for |M

nx

:

1 s +

ny

uy

nx

ux

M

M

M

M

| |

(2)

Now substituting ZR for the moment ratio into Equation (2)

1 s +

ZR

M

M

M

M

nx

uy

nx

ux

|

|

(3)

Rearranging Equation (3):

4/28/2010 PCJohnson and JALaman 4

( )( )

1 s +

nx

uy

nx

ux

M

M ZR

M

M

| |

(4)

Rearranging Equation (4):

( )( )

nx uy ux

M M ZR M | s + (5)

Equation (5) is an approximation based on an assumed linear relationship between ZR and M

nx

.

Because |M

nx

is not initially known, an equivalent moment, M

ueq

, is substituted for |M

n

in

Equation (5). Then ZR is replaced with the linear function of M

ueq

and solved for M

ueq

:

( )

uy ueq ux ueq

M M ZR M M + = (6)

Making the linear substitution for ZR into Equation (6):

( )

uy ueq ux ueq

M b mM M M + + = (7)

where the coefficients m and b represent the straight-line slope and intercept for the relationship.

Distributing terms:

uy uy ueq ux ueq

bM M mM M M + + = (8)

Collecting terms of Equation (8):

( )

uy ux ueq uy

bM M M mM + = 1 (9)

And solving for M

ueq

results in Equation (10):

uy

uy ux

ueq

mM

bM M

M

+

=

1

(10)

The derivation for ASD is similar and results in the following equation:

ay

ay ax

aeq

mM

bM M

M

5 . 1 1

+

= (11)

The coefficients m and b have been determined based on a regression analysis of all values

for applicable channel caps for spans in 10 ft. increments up to 100 ft and are provided in Table

4/28/2010 PCJohnson and JALaman 5

1. The resulting equivalent moment determined from Equation (10) (LRFD) or Equation (11)

(ASD) is then used to select a trial section from Z

x

tables presented in Table 2 (F

y

= 36 ksi) or

Table 3 (F

y

= 50 ksi) or from design graphs presented in Figures 1 and 2 to select a trial section.

For unbraced lengths greater than the limiting length for yielding (L

b

> L

p

), the strong axis

moment, M

ux

or M

ax

, should be divided by the buckling moment modification factor, C

b

, for a

more accurate selection.

ay

ay

b

ax

aeq

mM

bM

C

M

M

5 . 1 1

+

= (12)

uy

uy

b

ux

ueq

mM

bM

C

M

M

+

=

1

(13)

Table 1. b and m Values for Typical Combination Sections.

F

y

=

5

0

k

s

i

Channel

Cap

L

b

= 10' 20' 30' 40' 50' 60' 70' 80' 90' 100'

MC18x42.7

b 1.5 1.4 1.3 1.1 1.1 0.75 0.6 0.5 0.4 0.4

m*10

3

1.9 1.9 1.9 1.9 1.6 1.7 1.7 1.7 1.7 1.6

C15x33.9

b 1.1 1.0 0.9 0.9 0.8 0.6 0.5 0.4 0.4

m*10

3

3.0 3.0 3.0 2.8 2.6 2.5 2.5 2.5 2.3

C12x20.7

b 0.7 0.7 0.6 0.7 0.5 0.4 0.4 0.4

m*10 6.3 6.0 6.0 5.1 5.0 5.0 4.6 4.2

C10x15.3

b 0.2 0.2 0.2 0.1 0.2 0.1

m*10

3

13 12 12 11 11 11

F

y

=

3

6

k

s

i

Channel

Cap

L

b

= 10' 20' 30' 40' 50' 60' 70' 80' 90' 100'

MC18x42.7

b 1.4 1.5 1.4 1.3 1.3 1.1 0.85 0.7 0.6 0.5

m*10

3

2.7 2.6 2.6 2.6 2.5 2.3 2.3 2.3 2.3 2.4

C15x33.9

b 1.1 1.0 1.0 0.9 0.9 0.9 0.7 0.6 0.6 0.6

m*10

3

4.1 4.1 4.1 4.1 3.9 3.5 3.4 3.4 3.1 3.0

C12x20.7

b 0.7 0.7 0.7 0.7 0.7 0.5 0.5 0.5

m*10 8.4 8.4 8.0 8.0 7.3 7.3 6.7 6.2

C10x15.3

b 0.2 0.2 0.2 0.2 0.2 0.2

m*10

3

17 17 17 17 16 16

4/28/2010 PCJohnson and JALaman 6

M

ueq

is then used in the design graphs presented in Figure 2 (F

y

= 36 ksi) or Figure 3 (F

y

= 50 ksi)

to select a trial section. The use of these graphs is identical to the widely used and familiar Beam

Design Moment graphs already provided in Part 3 of the AISC Steel Manual (AISC, 2005).

Singly Symmetric Crane Girder Design Procedure

1. Determine deflection limits and stiffness requirements. Vertical deflection is typically

limited to

L

600

for light and medium cranes and

L

1000

for heavy cranes. Horizontal

deflection is typically limited to

L

400

for all cranes. I

x

is based on the full combination

section, while I

y

is based only on the channel and the top flange of the W shape.

2. Determine the applied loads including crane manufacturer specified maximum wheel loads,

rail weight, and runway girder weight. Maximum wheel loads are increased by 25% for cab

or remotely operated bridge cranes and 10% for pendant operated bridge cranes.

3. Calculate the x- and y-axis bending moments and shear forces, applying suitable load

combinations and determine the equivalent moment from Equation (10) or (11).

4. Using the equivalent moment, select a trial section from either or Figure 2 or 3 Table 2 or 3.

Long spans supporting light cranes are normally controlled by deflection, therefore trial

selection may be based on moment of inertia.

5. Evaluate the trial section for flexural and shear capacity based on AISC Specification

Chapter F.4 following the flowchart in Figure 1, Chapter G, and Chapter H. Flexural capacity

can also be determined quickly with the assistance of Table 2 or 3. M

ny

is calculated as the y-axis

plastic bending strength of the wide flange top flange and the channel for combination sections:

( )

y x

f f

y x flange top W ny

F Z

b t

F Z Z M

|

|

.

|

\

|

+ = + =

channel

2

channel

4

(14)

7. Check concentrated load criteria in Section J10 of the AISC Specification.

8. Evaluate fatigue provisions of AISC (2005) Appendix 3

4/28/2010 PCJohnson and JALaman 7

Example by LRFD Methods

Crane Capacity = 20 tons

Bridge Span = 70- 0

Cab operated

Bridge weight = 57.2 kips

Trolley weight = 10.6 kips

Max wheel load = 38.1 kips (no impact included)

Wheel spacing = 12- 0

Runway girder span = L

b

= 30- 0, F

y

= 50 ksi

1. Calculate the maximum factored moments and shears:

P

u

vert

per wheel = 55.2 kips (assuming = 1.6 for lifted and trolley weight)

P

u

horz

per wheel = 4.05 kips

w

u

(self weight of girder and rail) = 0.19 klf

M

ux

= 683 ft-kips, C

b

= 1.19

M

uy

= 39 ft-kips

V

uy

= 119 kips

V

ux

= 6.5 kips

2. Determine M

ueq

Expect a C1533.9 channel cap. From Table 1, with L

b

= 30- 0 and F

y

= 50 ksi get values

for b and m:

b = 0.9

m = 3.010

-3

( )

( )

( )( )

kips - ft 690

kips - ft 39 10 3 - 1

kips - ft 9 3 9 . 0

19 . 1

kips - ft 683

1

3 -

=

+

=

+

=

uy

uy

b

ux

ueq

mM

bM

C

M

M

3. Select first trial section:

From Figure 3, with M

ueq

= 690 ft-kips and L

b

= 30- 0, select a W2468 + C1533.9

M

px

= 967 kip-ft

L

p

= 10.2 ft

L

r

= 43.2 ft

I

x

= 2710 in

4

I

y

= 385 in

4

4. Evaluate M

cx

and M

cy

All of the sections listed in Table 1-19 of the Manual meet the compact web criteria in

Table B4.1, so the web plastification factors, R

pc

and R

pt

, are the ratio between the plastic

moment capacity and the compression and tension flange yield moments. Thus R

pc

M

yc

= M

p

and R

pt

M

yt

= M

p

, which can be substituted into the equations in F4 of the Specification.

4/28/2010 PCJohnson and JALaman 8

L

p

= 10.2 ft < L

b

= 30 ft < L

r

= 43.2 ft

( )

( )

( )( )

( )

( )

ft - kip 261

in. 12

ft 1

in. 8 . 50

4

in. 97 . 8 in. 585 . 0

ksi 50

4

ft - kip 967 ft - kip 974

ft - kip 967

ft 2 . 10 ft 2 . 43

ft 2 . 10 ft 30

in. 12

ft 1

in. 321 ksi 9 . 26 ( ft - kip 967 ft - kip 967 19 . 1

ksi 9 . 26 ksi 50

in. 321

in. 173

3

2

channel

2

channel

2

3

3

=

|

.

|

\

|

|

|

.

|

\

|

+ =

|

|

.

|

\

|

+ =

= + = =

s =

s

(

|

.

|

\

|

|

.

|

\

|

=

s

(

(

|

|

.

|

\

|

=

= = =

ny

ny

x

f f

y ny

x flange top y y y y ny

nx

nx

p

p r

p b

xc L p p b nx

y

xc

xt

L

M

M

Z

b t

F M

Z Z F Z F M

M

M

M

L L

L L

S F M M C M

F

S

S

F

5. Evaluate Chapter H interaction (Equation H1-1b)

( ) ( )

o.k. 0 . 1 951 .

0 . 1 166 . 0 785 . 0

0 . 1

ft - kip 61 2 9 . 0

ft - kip 9 3

ft - kip 67 9 9 . 0

ft - kip 683

0 . 1 0

0 . 1

2

s

s +

s +

s + +

s + +

ny

uy

nx

ux

cy

ry

cx

rx

c

r

M

M

M

M

M

M

M

M

P

P

| |

6. Calculating I

required

based on the maximum deflection

" 6 . 0

600

" 360

600

max vert

= = s A

L

therefore

4

in 3372 >

x

I

" 9 . 0

400

" 360

400

max vert

= = s A

L

therefore

4

in 140 >

y

I

The trial section does not meet deflection requirements, so try a W2784 + C1533.9:

7. Flexural Capacity

Using Table 3:

I

x

= 4050 in.

4

4/28/2010 PCJohnson and JALaman 9

|M

px

=1190 kip-ft

L

p

= 10.0 ft

L

r

= 40.1 ft

BF = 9.85 k

( ) | |

( )( ) | |

ft - kip 1190 ft - kip 1182

ft - kip 1190 ft 0 . 10 ft 0 . 30 k 85 . 9 ft - kip 1190 19 . 1

s =

s =

s =

nx

nx

p p b p b nx

M

M

M L L BF M C M

|

|

| | |

8. Evaluate Interaction (Equation H1-1b)

o.k. 0 . 1 . 733 . 0

0 . 1 155 . 0 578 . 0

0 . 1

ft - kip 251

ft - kip 9 3

ft - kip 182 1

ft - kip 683

0 . 1 0

0 . 1

2

s

s +

s +

s + +

s + +

ny

uy

nx

ux

cy

ry

cx

rx

c

r

M

M

M

M

M

M

M

M

P

P

| |

9. Check shear, concentrated loads, and fatigue criteria.

The vertical shear is assumed to be resisted by the web of the W shape and horizontal shear

is assumed to be resisted only by the web of the channel, so Tables 3-6, 3-8, and 3-9 of the

Manual can be used to quickly determine shear capacity.

4/28/2010 PCJohnson and JALaman 10

Select Trial

Combination Section

L

b

, C

b

, M

rx

, M

ry

L

b

< L

p

?

(F4-8)

F

L

: (F4-6a or F4-6b)

S

xc

: elastic section modulus w/r/t top flange

h

o

: distance between flange centriods

J = J

WF

+ J

C

L

b

< L

r

?

2

76 . 6 1 1 95 . 1 |

.

|

\

|

+ + =

J

h S

E

F

h S

J

F

E

r L

o xc L

o xc L

t r

y

t p

F

E

r L 1 . 1 = (F4-7)

rt : radius of gyration of flange

components and 1/3 web

NO

( )

yc pc

p r

p b

xc L yc pc yc pc b n

M R

L L

L L

S F M R M R C M s

(

(

|

|

.

|

\

|

=

| = 0.9, O = 1.67

YES

NO

(F4-2)

yc pc xc cr n

M R S F M s =

| = 0.9, O = 1.67

2

2

2

078 . 0 1

|

|

.

|

\

|

+

|

|

.

|

\

|

=

t

b

o xc

t

b

b

cr

r

L

h S

J

r

L

E C

F

t

(F4-3)

(F4-5)

YES

xc y pc yc pc n

S F R M R M s =

| = 0.9, O = 1.67

(F4-1)

yt pt n

M R M = (F4-14)

| = 0.9, O = 1.67

Figure 1. Flowchart of AISC Part 16, Chapter F.4 Evaluation Process

4/28/2010 PCJohnson and JALaman 11

Conclusion

A simplified design procedure is discussed for crane girders. An equivalent moment method

is presented for accurate selection of a combination section subjected to biaxial bending. Beam

design moment graphs are presented to allow rapid selection of trial sections and tables are

provided for efficient analysis of typical combination sections.

References

AISC, Steel Construction Manual, 13th Ed., American Institute of Steel Construction, Chicago,

IL, 2005.

Fisher, J.M., Design Guide No. 7 Industrial BuildingsRoofs to Anchor Rods, 2nd Ed., AISC,

Chicago, IL, 2004.

Laman, J.A., LRFD Crane Girder Design and Aids, Engineering Journal, AISC, Vol. 33, No.

4, 1996, pp. 153-158.

4/28/2010 PCJohnson and JALaman 12

Table 2. Z

x

Design Selection Table for Typical Combination Sections F

y

= 36 ksi.

4/28/2010 PCJohnson and JALaman 13

Table 3. Z

x

Design Selection Table for Typical Combination Sections F

y

= 50 ksi.

4/28/2010 PCJohnson and JALaman 14

Figure 2. Combination Section Design Moment Diagram F

y

= 36 ksi.

4/28/2010 PCJohnson and JALaman 15

Figure 3. Combination Section Design Moment Diagram F

y

= 36 ksi.

Você também pode gostar

- Rane Runway Beam Example: Crab Crane Bridge Buffer BeamDocumento27 páginasRane Runway Beam Example: Crab Crane Bridge Buffer BeamwearplayAinda não há avaliações

- Eurocode Verification of A Runway Beam Subject To Wheel Loads - Part 1Documento3 páginasEurocode Verification of A Runway Beam Subject To Wheel Loads - Part 1José Miguel BarataAinda não há avaliações

- 3) Initial Sizing of MembersDocumento5 páginas3) Initial Sizing of MembersKenAinda não há avaliações

- Runway Crane GirdersDocumento15 páginasRunway Crane GirdersFabio OkamotoAinda não há avaliações

- Design Tables For Steel GradesDocumento29 páginasDesign Tables For Steel Gradesdiego_is_onlineAinda não há avaliações

- Cranerunwaybeams 4ed bk180 PDFDocumento13 páginasCranerunwaybeams 4ed bk180 PDFMacAinda não há avaliações

- NCCI Initial Sizing of Vertical BracingDocumento8 páginasNCCI Initial Sizing of Vertical BracingCristian BlanaruAinda não há avaliações

- Crane Example EurocodesDocumento36 páginasCrane Example EurocodesKen SmithAinda não há avaliações

- Design of Unbraced Multi-Storey Steel FramesDocumento7 páginasDesign of Unbraced Multi-Storey Steel FramestaosyeAinda não há avaliações

- Brace Compression and Tension Capacity Design Charts As Per CSA S16 09 Rev1.5Documento44 páginasBrace Compression and Tension Capacity Design Charts As Per CSA S16 09 Rev1.5Antonio LópezAinda não há avaliações

- Design of Steel Beams To Aisc LRFD - 02Documento52 páginasDesign of Steel Beams To Aisc LRFD - 02ArchIEF Form (JASA ARSITEK)Ainda não há avaliações

- Analysis and Design of Substructures Limit State Design Balkema Proceedings and Monographs in Engineering Water and by Swami Saran 0415418445 PDFDocumento5 páginasAnalysis and Design of Substructures Limit State Design Balkema Proceedings and Monographs in Engineering Water and by Swami Saran 0415418445 PDFAmit ShuklaAinda não há avaliações

- Appendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)Documento10 páginasAppendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)sundarAinda não há avaliações

- Vertical Brace ConnectionsDocumento13 páginasVertical Brace ConnectionsAnkit GuptaAinda não há avaliações

- Crane Girder Design ProcedureDocumento18 páginasCrane Girder Design ProcedureBhadresh Shah0% (1)

- Çeşitli Bağlantı Tiplerinin HesabıDocumento63 páginasÇeşitli Bağlantı Tiplerinin HesabıblueswanAinda não há avaliações

- GantryDocumento7 páginasGantrysatydevsinghnegiAinda não há avaliações

- Procedure of Crane Girder Design: Presentation OnDocumento65 páginasProcedure of Crane Girder Design: Presentation OnShamik Ghosh100% (1)

- Answer All QuestionsDocumento8 páginasAnswer All Questionsbrownpepper30100% (1)

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDocumento6 páginasStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresAinda não há avaliações

- Example 2a: All-Round Fillet Weld Connection Between I Beam and Plate (Simple)Documento6 páginasExample 2a: All-Round Fillet Weld Connection Between I Beam and Plate (Simple)Imran SaikatAinda não há avaliações

- Design of TrussDocumento29 páginasDesign of Trussfrancis100% (1)

- Pin Connected Tension MemberDocumento2 páginasPin Connected Tension MemberAUNGPSAinda não há avaliações

- In-Plane Stability of Portal FramesDocumento222 páginasIn-Plane Stability of Portal Frameschoriya007Ainda não há avaliações

- AE21!06!01 - Steel Grating Load Class-D400Documento40 páginasAE21!06!01 - Steel Grating Load Class-D400nithya sudheeshAinda não há avaliações

- Crane Design Guide To BS 5950Documento1 páginaCrane Design Guide To BS 5950mark perezAinda não há avaliações

- Load Case, Load Combination, Modal Case Options. Choose The Load Case To Be DisplayedDocumento5 páginasLoad Case, Load Combination, Modal Case Options. Choose The Load Case To Be DisplayedLivia15Ainda não há avaliações

- Steel ConnectionsDocumento83 páginasSteel ConnectionsMEPAinda não há avaliações

- 4B4DC764AC39AFAD5D5F9C87B731618Documento12 páginas4B4DC764AC39AFAD5D5F9C87B731618Rama KrishnaAinda não há avaliações

- Guide For The Design of Crane-Supporting Steel Structures 2Documento128 páginasGuide For The Design of Crane-Supporting Steel Structures 2GogyAinda não há avaliações

- Structural Design Basic ReportDocumento4 páginasStructural Design Basic Reportvaidehisarathy1857Ainda não há avaliações

- Single Girder EOT Cranes (SG-EOT)Documento5 páginasSingle Girder EOT Cranes (SG-EOT)Nikhil PoriyaAinda não há avaliações

- Steel Connection DesignDocumento72 páginasSteel Connection DesignShams Abbas NaqviAinda não há avaliações

- Beam Column ConnectionDocumento2 páginasBeam Column ConnectionHAZIRACFS SURATAinda não há avaliações

- Crane Girder DesignDocumento6 páginasCrane Girder DesignAya Montes100% (3)

- Basic Introduction To FatigueDocumento13 páginasBasic Introduction To FatigueMariusz MilewskiAinda não há avaliações

- Crane GirderDocumento43 páginasCrane GirderAlma M. LaraAinda não há avaliações

- SFD Ec 3 2005Documento137 páginasSFD Ec 3 2005Fatih ÇELİKERAinda não há avaliações

- Steel Buildings: Ferenc PappDocumento29 páginasSteel Buildings: Ferenc PappThinn Thida HtayAinda não há avaliações

- Effective Length For Moment FrameDocumento5 páginasEffective Length For Moment FramenhulugallaAinda não há avaliações

- Bearing Capacity of Connected Parts With Slotted HolesDocumento50 páginasBearing Capacity of Connected Parts With Slotted Holesaomareltayeb100% (1)

- S&T Purlins & Girts Catalogue PDFDocumento36 páginasS&T Purlins & Girts Catalogue PDFNguyen Duc CuongAinda não há avaliações

- ModelingSCBF PDFDocumento28 páginasModelingSCBF PDFadnanraisahmedAinda não há avaliações

- Chimney Breast RemovalDocumento3 páginasChimney Breast Removaljason_barnes4097Ainda não há avaliações

- F1. SCT - SN-Steel Formwork Design - GTG BEAM FORMWORKDocumento32 páginasF1. SCT - SN-Steel Formwork Design - GTG BEAM FORMWORKshihabAinda não há avaliações

- Crane Wheel Load EccentricityDocumento2 páginasCrane Wheel Load Eccentricitypranit_rai0% (1)

- AD 334 - Tension Capacity of Bolts in Tapped Holes or When Nuts Are Not Fully EngagedDocumento2 páginasAD 334 - Tension Capacity of Bolts in Tapped Holes or When Nuts Are Not Fully Engagedsymon ellimacAinda não há avaliações

- Section Properties For Builtup and Unsymmetrical SectionsDocumento5 páginasSection Properties For Builtup and Unsymmetrical Sectionsdhamodharan24Ainda não há avaliações

- Thuat Ngu PEB PDFDocumento35 páginasThuat Ngu PEB PDFYami Yugi100% (1)

- AISC Crane Runway TipsDocumento25 páginasAISC Crane Runway Tipstpaterno77100% (10)

- CraneGirder PDFDocumento15 páginasCraneGirder PDFLeonardo WadaAinda não há avaliações

- Design of Crane Runway Beam With ChannelDocumento9 páginasDesign of Crane Runway Beam With Channellatyrniang100% (3)

- 181-186 For Web PDFDocumento6 páginas181-186 For Web PDFdiego.peinado8856100% (1)

- PCA Teoria-Rectangular Concrete TanksDocumento27 páginasPCA Teoria-Rectangular Concrete TanksAlberto Muñoz Vizcarra100% (3)

- PCI Journal Prestressed Poles JL 88 January February 3Documento23 páginasPCI Journal Prestressed Poles JL 88 January February 3nagenol100% (1)

- K Factors of Framed Columns Restrained by Tapered Girders in US Codes 1993Documento10 páginasK Factors of Framed Columns Restrained by Tapered Girders in US Codes 1993ciscoAinda não há avaliações

- A New Method To Design End Plate Moment ConnectionsDocumento31 páginasA New Method To Design End Plate Moment Connectionsjihu1170Ainda não há avaliações

- A New Approach For Design of Steel Beam-Columns Our A.Documento32 páginasA New Approach For Design of Steel Beam-Columns Our A.mbrown4382Ainda não há avaliações

- CIDECT DG3 For Rectangular Hollow Section Joints Static Loading PDFDocumento103 páginasCIDECT DG3 For Rectangular Hollow Section Joints Static Loading PDFJoel MooreAinda não há avaliações

- ACI Struct JRNL - Eval of Strut and Tie ModelDocumento6 páginasACI Struct JRNL - Eval of Strut and Tie ModelRalf SnellAinda não há avaliações

- Seismic Code Analysis of Buildings Without Locating Centers of RigidityDocumento18 páginasSeismic Code Analysis of Buildings Without Locating Centers of RigidityVSMS8678Ainda não há avaliações

- Linea de CedenciaDocumento175 páginasLinea de CedenciaKatherine Prado100% (1)

- Acrylics Secrets EbookDocumento93 páginasAcrylics Secrets Ebookkkant7895% (22)

- Frame Stability ExamplesDocumento21 páginasFrame Stability ExamplesRalf SnellAinda não há avaliações

- Reinforcing Steel in Slabs On Grade - tcm45-346883Documento3 páginasReinforcing Steel in Slabs On Grade - tcm45-346883Ralf SnellAinda não há avaliações

- Practical Analysis of Semi - Rigid FramesDocumento15 páginasPractical Analysis of Semi - Rigid FramesRalf SnellAinda não há avaliações

- Design of Crane Steel BeamsDocumento134 páginasDesign of Crane Steel Beamsshak54383% (6)

- Fatigue Strength of Fillet-Welded Transverse Stiffeners With UndercutsDocumento76 páginasFatigue Strength of Fillet-Welded Transverse Stiffeners With UndercutsWei ZhangAinda não há avaliações

- ARE YOU PROPERLY SPECIFYING MATERIALS? 1 of 3Documento4 páginasARE YOU PROPERLY SPECIFYING MATERIALS? 1 of 3vAinda não há avaliações

- Fiber Amounts in Foods PDFDocumento2 páginasFiber Amounts in Foods PDFRalf SnellAinda não há avaliações

- CivilBay Crane Load Crane Runway Beam Design 1.0.0 ManualDocumento112 páginasCivilBay Crane Load Crane Runway Beam Design 1.0.0 Manualwudongxiao3953100% (2)

- FINALadheredStoneVeneerGuide2010 000Documento15 páginasFINALadheredStoneVeneerGuide2010 000Ralf SnellAinda não há avaliações

- Savage 99sf PDFDocumento4 páginasSavage 99sf PDFRalf SnellAinda não há avaliações

- Dumbbell ConditioningDocumento2 páginasDumbbell ConditioningRalf SnellAinda não há avaliações

- ACI Legacy-SOG PaperDocumento9 páginasACI Legacy-SOG PaperRalf SnellAinda não há avaliações

- Tabata Tracksheet PDFDocumento1 páginaTabata Tracksheet PDFRalf SnellAinda não há avaliações

- Product and Engineering Manual: 8.0 AccessoriesDocumento29 páginasProduct and Engineering Manual: 8.0 AccessoriesRalf SnellAinda não há avaliações

- Templating MeasuringDocumento4 páginasTemplating MeasuringRalf SnellAinda não há avaliações

- TableA 1ListOfTypicalRepFoodsWithPercentages PDFDocumento13 páginasTableA 1ListOfTypicalRepFoodsWithPercentages PDFRalf SnellAinda não há avaliações

- Estimated Calorie Needs Per Day TableDocumento2 páginasEstimated Calorie Needs Per Day TableИндийскаяДевушкаAinda não há avaliações

- NewHandbookStandardReticlePatterns Ver8 NEWDocumento82 páginasNewHandbookStandardReticlePatterns Ver8 NEWronin70100% (8)

- Upper Body Exercises: Bench Press: Laying Down FlatDocumento12 páginasUpper Body Exercises: Bench Press: Laying Down FlatNaveen KumarAinda não há avaliações

- Nutrition 2Documento32 páginasNutrition 2Abdul Rasyid MusthafaAinda não há avaliações

- Book Data Fats That Heal Fats That KillDocumento5 páginasBook Data Fats That Heal Fats That Killnandoperu33% (3)

- Intensive Culture 00 Aqua RichDocumento234 páginasIntensive Culture 00 Aqua RichRalf SnellAinda não há avaliações

- American Examples 2007Documento388 páginasAmerican Examples 2007Eudo GonzalezAinda não há avaliações

- Modelling of Diaphrams in STAAD Pro PDFDocumento13 páginasModelling of Diaphrams in STAAD Pro PDFragalwarAinda não há avaliações

- Eastman Industries - BoqDocumento6 páginasEastman Industries - BoqcivilAinda não há avaliações

- 30 - EC210B - MCV, Válvula Lógica EmperradaDocumento4 páginas30 - EC210B - MCV, Válvula Lógica EmperradaAparecidaMarquesAinda não há avaliações

- SarfDocumento51 páginasSarfSantosh ThakurAinda não há avaliações

- (KG/M) (WM °C) / (Kcal H M °C) : Pipe InsulationDocumento3 páginas(KG/M) (WM °C) / (Kcal H M °C) : Pipe InsulationZaid Al RayesAinda não há avaliações

- Usg Iom PDFDocumento56 páginasUsg Iom PDFAnonymous 7xHNgoKE6eAinda não há avaliações

- Schedule of Accreditation United Kingdom Accreditation ServiceDocumento53 páginasSchedule of Accreditation United Kingdom Accreditation Servicegops1963Ainda não há avaliações

- Residential KitchenBathrooDocumento7 páginasResidential KitchenBathrooCarlos Daniel Ayala GonzalezAinda não há avaliações

- Dril-Flex® Structural Self-Drilling FastenersDocumento4 páginasDril-Flex® Structural Self-Drilling FastenersPaulAinda não há avaliações

- Analisa Struktur 4 Tugas 1 Linpro 2.7Documento10 páginasAnalisa Struktur 4 Tugas 1 Linpro 2.7Mohamad Taufiqul HakimAinda não há avaliações

- CE 315 Syllabus Spring 10 - Dr. AlhassanDocumento5 páginasCE 315 Syllabus Spring 10 - Dr. AlhassandraqbhattiAinda não há avaliações

- Gravity Wall Calculator TADocumento6 páginasGravity Wall Calculator TAAnonymous AXaLBO4y100% (1)

- Electrolux Hermetic Compressors - R600A LBP VOLTAGE 220-240/1/50Documento2 páginasElectrolux Hermetic Compressors - R600A LBP VOLTAGE 220-240/1/50Ahmed RedaAinda não há avaliações

- Ductal ConcreteDocumento13 páginasDuctal ConcreteAnand BabuAinda não há avaliações

- Brightray Alloy 35Documento2 páginasBrightray Alloy 35SANKET SINGHAinda não há avaliações

- SampleDocumento14 páginasSamplephan phucAinda não há avaliações

- Material Compliance-New DesignDocumento6 páginasMaterial Compliance-New DesignvtalexAinda não há avaliações

- Eton West Wing Residences at North Belton Communities Quezon CityDocumento20 páginasEton West Wing Residences at North Belton Communities Quezon CityEvelyn L. AguinaldoAinda não há avaliações

- G2593R9Documento21 páginasG2593R9TanaAinda não há avaliações

- Analisis de Fallas Ejes MeritorDocumento91 páginasAnalisis de Fallas Ejes MeritorJohan GomezAinda não há avaliações

- BILL OF MATERIALS & PARTIAL ACCOMPLISHMENTS To Date SummaryDocumento2 páginasBILL OF MATERIALS & PARTIAL ACCOMPLISHMENTS To Date Summaryjhune abadAinda não há avaliações

- Annexure - Bolt Torque CalculationDocumento4 páginasAnnexure - Bolt Torque CalculationDarshan PanchalAinda não há avaliações

- Wellhead For Oil and Gas WellDocumento49 páginasWellhead For Oil and Gas Wellerwan100% (3)

- HLX 5T TabancaDocumento137 páginasHLX 5T TabancaOzan SahinAinda não há avaliações

- SA Model Paper Solutions - III SemesterDocumento23 páginasSA Model Paper Solutions - III Semesterkotireddy.vaishnaviAinda não há avaliações

- TERRAM For Pipeline and UtilitiesDocumento20 páginasTERRAM For Pipeline and Utilitiessaneela bibiAinda não há avaliações

- Ductile Iron Pipe Iso en Standards E779dc24Documento24 páginasDuctile Iron Pipe Iso en Standards E779dc24David FergusonAinda não há avaliações

- PCINE Spec Sec-Precast Partial Depth Panel Guidelines 2nd EdDocumento12 páginasPCINE Spec Sec-Precast Partial Depth Panel Guidelines 2nd Edatman chanaAinda não há avaliações

- Precheck Before Light-Up: Drum Metal Temp. DiffDocumento12 páginasPrecheck Before Light-Up: Drum Metal Temp. DiffAhemadAinda não há avaliações

- American Standard Unified Inch Screw Thread Form DataDocumento2 páginasAmerican Standard Unified Inch Screw Thread Form DataVaibhav ShuklaAinda não há avaliações

- PM 293598 001 1800 PartsDocumento663 páginasPM 293598 001 1800 Partsgilberto isrrael roman saviñonAinda não há avaliações