Escolar Documentos

Profissional Documentos

Cultura Documentos

Cedar Raised Bed Construction-1

Enviado por

tbailey1111Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Cedar Raised Bed Construction-1

Enviado por

tbailey1111Direitos autorais:

Formatos disponíveis

CEDAR RAISED BED BOX CONSTRUCTION

All previous cedar raised bed box construction at DCI Homes were built using a simple

4x 8x 24.5 (Width x Length x Height) (24.5 Height = 7 2x4 High), joined at the

corners with 4x 4 x 23.75 (Cedar) pieces, using 2.5 inch #9 Deck Screws, Two screws

at the end of each board in a staggered pattern, countersunk into material for greater

strength.

MATERIALS

22 - 2x4x8 (Cedar)

These include 14 (8-foot) boards for the sides (7 per side), 7 (8-foot) boards cut

into 4-foot lengths for the ends, and one extra board for cutting 23.5 inch lengths

(4) to attach to inner sides and ends at center (vertically).

Preferable to have all exact lengths from lumberyard to reduce need for trimming

cuts (customarily 8-footers measure 3/8 to inch long)

If possible request or pick out lumber without too much bow or twist

1 - 4x4x 8 (Cedar)

This will be cut into 4 lengths of 23.75 inches for the corner braces.

168 - 2.5 inch #9 Deck Screws (Two Pounds?)

Check with hardware Guru to get approx. screw count per pound.

Tan color screws blend nicely with cedar if available

Square drive heads are preferable to Phillips-head, Combi-heads work too.

Pick up #9 size drill bit Using a rotatable drill-bit / drive-bit mechanism saves

time

TOOLS:

Some kind of saw chop saw, radial arm saw, circular saw, to cut lumber to

length

Saw horses with a 4x8 sheet of plywood make a nice work table

Drill Youll need a power drill. My 14-Volt Cordless works fine. Bring a power

cord if needed

As mentioned above, if you havent tried a quick release rotatable bit/drive set-up,

youre in for a treat. Get one, you wont be sorry. You will be pre-drilling all

holes as cedar has a tendency to split otherwise.

Carpenters Square, 16 x 24 works well; A 6-inch square for 4x4 alignment.

Rubber mallet for corner brace alignment (hammer will work)

(Optional) Bar clamp (at least 24-inch) for Side Panel assembly

Shovel(s) and 6-foot level for site prep. Wheelbarrow if moving soil. (Bobcat?)

Bring a tarp to lay over side of box while filling with soil to protect lumber

Bring extra (4) 2x4 pieces (18-24 inches) to block corners during Panel assembly

Order of construction:

1. Assemble and Cut lumber.

You should have 14 exact length 8-footers (cut them to exact length if they do not come

that way) for the Side Panels

14 48-inch length pieces for the End Panels

4- 23.75-inch lengths of 4 x 4 for the Corner Braces.

You will also need to cut the extra 2 x 4 into 4 23.5 inch lengths for Center Braces in

the middle of each of Side Panel and End Panel in the box. Good idea to make a 45-

degree bevel cut on one end of these 4 braces to face upward in the box, to reduce

chances of injury on 90-degree cut.

2. Assemble and Construct Side Panels

Take 7 of the 8-foot 2x4s and arrange them on a flat surface, either on a floor, or as I

have grown to appreciate, up on saw horses with an 8-foot piece of plywood making a

work table.

Sort through the 2x4s and choose the best surface to face out, choosing one relatively

knot-free board to place at the top. Take care to hide jagged or crappy looking edges

toward the inside and bottom where it wont show.

Once you have your seven boards in the order you want them, arrange them on top of (2)

4x4 Corner Braces placed 8 feet apart on your workbench (or floor). All 7 boards should

be flush to the edge and centered over the 4x4, leaving approx. 3/8 inch overlap on the

top and bottom of the 4x4. Use large carpenters square to check alignment along ends.

Use a small square (6 inch) to check 2x4 ends have clearance of 4x4 Getting this as

close as possible will result in good joinery at the corners.

Mark your hole drilling locations using staggered pattern, measuring in from the end of

each 2x4, inch and 2 inch respectively, taking care at top and bottom to cheat to

accommodate 3/8

th

inch clearances.

Once you have checked for square in both dimensions and for 3/8 inch clearances on

either end of the 4x4, drill and set a screw in top and bottom boards to hold the rest in

place while you pre-drill and insert the remaining screws. If you have trouble with

warping, using a bar clamp can make this task easier.

3. Assemble and Construct End Panels

Take 7 of the 48 inch 2x4s and arrange them on a flat surface, this time choosing your

best surface and facing it downward, again choosing a top board clear of knots.

Once you have 7 boards arranged as desired, check for square, pencil mark a centering

line for the 23.5 inch brace (measure 21 inches from either end to mark the edge of the

brace). Carefully drill and drive one screw top and bottom, fill in the rest. (This brace is

designed for purposes of prefabrication, not as structural support, and as such may be

removed after completion of box if desired.)

Assembly at Box site goes more quickly if staggered drill-hole pattern is done in

advance. Take care to measure in from each end of 2x4 in a 2 inch and 4 inch

pattern (see illustration).

4. Join Side and End Panels to Complete Box

This assembly can be done alone, but is much simpler to have a second helper to brace

materials.

Pre-set screws into pre-drilled End Panel holes approx. 1 inches deep.

On a relatively flat surface near where the Raised Bed will eventually reside, arrange one

Side Panel and End Panel at a 90-degree angle, using a pair of 2x4 blocks under the

corners to raise off the ground as needed. Use carpenters square to check, then drive

screws into 4x4, making sure there is no gap twixt 2x4 and 4x4 if necessary back screw

out and re-set to snug up this gap.

Align opposite Side Panel, attach in same manner. Finish by attaching remaining End

Panel.

With Box complete and in place, use 4 or 6-foot level to check if any additional leveling

is necessary.

5. Fill that Puppy with Soil.

Weve used 5 gallon buckets to haul soil by hand ugh. A wheelbarrow up a plank or

piece of plywood for a ramp can go quicker. Use a tarp to protect lumber from getting

trashed. Get the neighbor to come over with the Bobcat?

Fill to rim; soil will settle 2-3 inches on average.

Você também pode gostar

- Treasured Chest Build A Jewelry BoxDocumento9 páginasTreasured Chest Build A Jewelry BoxThanasis KyrgiazoglouAinda não há avaliações

- Hybrid Roubo - Nicholson WorkbenchDocumento22 páginasHybrid Roubo - Nicholson WorkbenchElisif DeFair100% (1)

- How To Make A Cornhole BoardDocumento4 páginasHow To Make A Cornhole BoardAndré VeigaAinda não há avaliações

- Plans Ladder ShelfDocumento6 páginasPlans Ladder ShelfMúsica viajera MXAinda não há avaliações

- How To Build A DIY Dog RampDocumento3 páginasHow To Build A DIY Dog RampRi SovannaphumiAinda não há avaliações

- Router Table Building With Cabinet StorageDocumento17 páginasRouter Table Building With Cabinet StorageLonebeavAinda não há avaliações

- Bench - Mendicino Bench PDFDocumento3 páginasBench - Mendicino Bench PDFmarianrkwAinda não há avaliações

- Japanese Woodworking Tools and TechniquesDocumento17 páginasJapanese Woodworking Tools and TechniquesRicardo Salcido67% (15)

- DIY Kitchen IslandDocumento17 páginasDIY Kitchen IslandJurica PrimoracAinda não há avaliações

- Gaming Computer DeskDocumento11 páginasGaming Computer DeskJorge OliveiraAinda não há avaliações

- Farmhouse X Corner DeskDocumento5 páginasFarmhouse X Corner Deskrichard humes100% (1)

- DIY Three-Bin Compost System: MaterialsDocumento2 páginasDIY Three-Bin Compost System: MaterialsTomásAinda não há avaliações

- WJ099 Picnic Table PDFDocumento0 páginaWJ099 Picnic Table PDFCarlos A. Mendel100% (1)

- Deck - Calistoga Spa SurroundDocumento4 páginasDeck - Calistoga Spa SurroundHelicon1Ainda não há avaliações

- DIY Kitchen Island: Tools ListDocumento14 páginasDIY Kitchen Island: Tools ListDanAinda não há avaliações

- Easy DIY Garden Shed Plans - 1Documento4 páginasEasy DIY Garden Shed Plans - 1Fred Mirtz100% (1)

- Bench - Langcrest - LoveseatDocumento5 páginasBench - Langcrest - LoveseatvdbrogerAinda não há avaliações

- Computer WorkstationDocumento8 páginasComputer Workstation- yAy3e -100% (1)

- Making High End Furniture From Plywood DIY ModernDocumento10 páginasMaking High End Furniture From Plywood DIY ModernVincent GandoisAinda não há avaliações

- Arbor - Making An Easy ArborDocumento5 páginasArbor - Making An Easy ArbordaniellourencoAinda não há avaliações

- DIY Tutorial Pallets Coffee Table 1001palletsDocumento7 páginasDIY Tutorial Pallets Coffee Table 1001palletsGabriel SueldoAinda não há avaliações

- A - 8 Pieces of 2×2 Lumber - 86" Long B - 40 Pieces of 1×3 Lumber - 24" Long C - 30 Pieces of 2×4 Lumber - 96 LongDocumento4 páginasA - 8 Pieces of 2×2 Lumber - 86" Long B - 40 Pieces of 1×3 Lumber - 24" Long C - 30 Pieces of 2×4 Lumber - 96 LongsmkpthoeAinda não há avaliações

- Build Your Own French Doors - Popular Woodworking MagazineDocumento34 páginasBuild Your Own French Doors - Popular Woodworking Magazinekostas1977Ainda não há avaliações

- Mid Century Modern Plywood Media ConsoleDocumento21 páginasMid Century Modern Plywood Media ConsoleLUCAS PALMIERIAinda não há avaliações

- Lake Tahoe Gazebo PDFDocumento5 páginasLake Tahoe Gazebo PDFHorace Prophetic DavisAinda não há avaliações

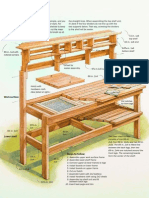

- Building A Potting Bench: Top Shelf UnitDocumento2 páginasBuilding A Potting Bench: Top Shelf UnitjteamAinda não há avaliações

- DIY Raised Garden Bed For Under $40Documento16 páginasDIY Raised Garden Bed For Under $40LonebeavAinda não há avaliações

- Concrete Bench ProcedureswoodsDocumento16 páginasConcrete Bench ProcedureswoodsKyjuan T. KingAinda não há avaliações

- Picnic Table That Converts To BenchesDocumento22 páginasPicnic Table That Converts To BenchesTibor LocAinda não há avaliações

- Bench PlanterDocumento25 páginasBench Planternf9cqrnpf4Ainda não há avaliações

- Word 2Documento11 páginasWord 2kimba worthAinda não há avaliações

- Altar InstructionsDocumento12 páginasAltar InstructionsSimonida Mona VulićAinda não há avaliações

- How To Build A CrateDocumento15 páginasHow To Build A CrateMuhammad LukmanAinda não há avaliações

- Mesa China CarpinteriaDocumento7 páginasMesa China CarpinteriaMCarrillo_1971Ainda não há avaliações

- Çalışma Tezgahı PlanıDocumento14 páginasÇalışma Tezgahı PlanıÖmür Eryüksel50% (2)

- Hidden Storage Coffee Table - RYOBI Nation Projects PDFDocumento14 páginasHidden Storage Coffee Table - RYOBI Nation Projects PDFbwatkins6100% (1)

- Champion Pigeon Loft Construction Made EasyNo EverandChampion Pigeon Loft Construction Made EasyAinda não há avaliações

- Double Decker PlayhouseDocumento9 páginasDouble Decker Playhousepierre van wykAinda não há avaliações

- Panel JigDocumento16 páginasPanel JigfasdfAinda não há avaliações

- Tools and Materials:: Rojects Online: Building A Six-Sided GazeboDocumento8 páginasTools and Materials:: Rojects Online: Building A Six-Sided GazeboMara_Traistaru_808Ainda não há avaliações

- Rotating Barrel ComposterDocumento3 páginasRotating Barrel Compostertraction9261Ainda não há avaliações

- Bike Shed PlansDocumento9 páginasBike Shed PlansZhijiang QiaoAinda não há avaliações

- Building ShelvesDocumento14 páginasBuilding ShelvesZoran MladenovicAinda não há avaliações

- Toy Box With EaselDocumento14 páginasToy Box With EaselAdnan HasanovicAinda não há avaliações

- Utility Cart PDFDocumento6 páginasUtility Cart PDFFe TusAinda não há avaliações

- Kids Art Table and ChairsDocumento16 páginasKids Art Table and ChairsOscar TNAinda não há avaliações

- Recipe Box: Project 15193EZDocumento5 páginasRecipe Box: Project 15193EZBSulli100% (1)

- Shelves PlansDocumento5 páginasShelves PlansShellyJackson0% (1)

- Ountry Bench: Materials List LumberDocumento8 páginasOuntry Bench: Materials List LumbervdbrogerAinda não há avaliações

- Andrew Harris Woodwork - CoffeeTableDocumento16 páginasAndrew Harris Woodwork - CoffeeTablemilofertasdigitalesAinda não há avaliações

- BgboxDocumento2 páginasBgboxmochadreamz200546700% (1)

- Kreg Workbench With DrawerDocumento12 páginasKreg Workbench With DrawerAdnan HasanovicAinda não há avaliações

- Craftsman Style Queen Sized HeadboardDocumento10 páginasCraftsman Style Queen Sized Headboardvidawo1012Ainda não há avaliações

- TV Wall ConsoleDocumento16 páginasTV Wall ConsoleAdnan HasanovicAinda não há avaliações

- Dog House Plans 3Documento5 páginasDog House Plans 3Devika PrithiAinda não há avaliações

- 2X4 Plywood Laced Post Shore DiagramsDocumento5 páginas2X4 Plywood Laced Post Shore DiagramsMuhdBukharyAinda não há avaliações

- How to Build a Counter Top with a Wood or Decorative Bevel EdgeNo EverandHow to Build a Counter Top with a Wood or Decorative Bevel EdgeAinda não há avaliações

- Family Handyman Ultimate 1 Day ProjectsNo EverandFamily Handyman Ultimate 1 Day ProjectsNota: 5 de 5 estrelas5/5 (1)

- Make Your Own Toolbox: A Woodworker’s Guide to Building Chests, Cases & CabinetsNo EverandMake Your Own Toolbox: A Woodworker’s Guide to Building Chests, Cases & CabinetsAinda não há avaliações

- Animals in Healthcare 14 FlyerDocumento1 páginaAnimals in Healthcare 14 Flyertbailey1111Ainda não há avaliações

- UMN 2014 Speak! FlierDocumento1 páginaUMN 2014 Speak! Fliertbailey1111Ainda não há avaliações

- CSPH5000 - HorseAsTeacher Flyer 2014Documento1 páginaCSPH5000 - HorseAsTeacher Flyer 2014tbailey1111Ainda não há avaliações

- Chicken Physical ExamDocumento1 páginaChicken Physical Examtbailey1111Ainda não há avaliações

- Background InfoDocumento3 páginasBackground Infotbailey1111Ainda não há avaliações

- Chicken AnatomyDocumento1 páginaChicken Anatomytbailey1111Ainda não há avaliações

- Pace Model For Aai 2014Documento6 páginasPace Model For Aai 2014tbailey1111Ainda não há avaliações

- 2011 ArticleDocumento3 páginas2011 Articletbailey1111Ainda não há avaliações

- Chicken NeedsDocumento1 páginaChicken Needstbailey1111Ainda não há avaliações

- MandalaSpring 2014 PagesDocumento5 páginasMandalaSpring 2014 Pagestbailey1111Ainda não há avaliações

- Pages From Ahtanews - Volume42issue1Documento2 páginasPages From Ahtanews - Volume42issue1tbailey1111Ainda não há avaliações

- AMZ PresenceDocumento6 páginasAMZ Presencemarginwalker77Ainda não há avaliações

- NE5521Documento9 páginasNE5521Carlos TibussiAinda não há avaliações

- DuPont Sontara Wipes Technical SpecsDocumento2 páginasDuPont Sontara Wipes Technical SpecsSkySupplyUSAAinda não há avaliações

- Database Design Concepts Introduction NotesDocumento42 páginasDatabase Design Concepts Introduction NotesmunatsiAinda não há avaliações

- Cs Acrovyn CatalogueDocumento83 páginasCs Acrovyn CatalogueBoboc AndreiAinda não há avaliações

- Catalyser: Magnetic Effects of Electric Current Faculty Sheet SolutionDocumento4 páginasCatalyser: Magnetic Effects of Electric Current Faculty Sheet SolutionShalika SinhaAinda não há avaliações

- Introduction To Igor Programming PDFDocumento33 páginasIntroduction To Igor Programming PDFpaulklyuyevAinda não há avaliações

- 2016 GME Steel ProductsDocumento16 páginas2016 GME Steel ProductsMarco Dos Santos NevesAinda não há avaliações

- 5950 Part 1-1990Documento120 páginas5950 Part 1-1990José Miguel100% (1)

- JSA Basket TransferDocumento3 páginasJSA Basket TransferCristina Rican100% (1)

- q64DA PDFDocumento1 páginaq64DA PDFSebastián LozadaAinda não há avaliações

- Recovery of Spent CatalystDocumento4 páginasRecovery of Spent CatalystUtsav PatelAinda não há avaliações

- Internal Arc IEC 61641 - EN - V07Documento24 páginasInternal Arc IEC 61641 - EN - V07arkupi100% (1)

- Hydrulic Hose and FittingDocumento66 páginasHydrulic Hose and FittingMamdouhAlhanafyAinda não há avaliações

- LT Loads&SwitchgearDocumento48 páginasLT Loads&SwitchgearsreekanthbammidiAinda não há avaliações

- 5 Automation Testing Challenges and Their SolutionDocumento3 páginas5 Automation Testing Challenges and Their SolutionBala MuruganAinda não há avaliações

- Features: Self Reset Auxiliary Flag Relay - Two ElementDocumento3 páginasFeatures: Self Reset Auxiliary Flag Relay - Two ElementbledmikifrAinda não há avaliações

- SAIC-Q-1043 Asphalt Core Density Testing InspectionDocumento3 páginasSAIC-Q-1043 Asphalt Core Density Testing InspectionAbdul HannanAinda não há avaliações

- Operation Manual Transas M-2Documento62 páginasOperation Manual Transas M-2Дмитрий ПеснякAinda não há avaliações

- Saskatchewan Drivers HandbookDocumento175 páginasSaskatchewan Drivers HandbookdrivershandbooksAinda não há avaliações

- Test Report (Revisi Fat)Documento5 páginasTest Report (Revisi Fat)Imamudin BuronanMertua TanpaSadar100% (1)

- SDHP CataloguesDocumento12 páginasSDHP CataloguesPuppala Laxmana PrasadAinda não há avaliações

- Energy Saving Basics - EsdsDocumento40 páginasEnergy Saving Basics - Esdsapi-238581599Ainda não há avaliações

- Low Cost Axial Vactrols: VTL5C3, 5C4Documento2 páginasLow Cost Axial Vactrols: VTL5C3, 5C4sillyAinda não há avaliações

- ASAP MethodologyDocumento14 páginasASAP MethodologyTiffany HughesAinda não há avaliações

- Automatic Room Light Controller With Visitor Counter-1Documento2 páginasAutomatic Room Light Controller With Visitor Counter-1Amitosh MishraAinda não há avaliações

- A Mini Unmanned Aerial Vehicle (Uav) : System Overview and Image AcquisitionDocumento7 páginasA Mini Unmanned Aerial Vehicle (Uav) : System Overview and Image AcquisitionhougieAinda não há avaliações

- Intro To Neutron ScatteringDocumento191 páginasIntro To Neutron ScatteringEleni MitsiAinda não há avaliações

- Atfd Design Calculation: Data Energy Balance Agitator Shell DesignDocumento1 páginaAtfd Design Calculation: Data Energy Balance Agitator Shell DesignManoj BAinda não há avaliações